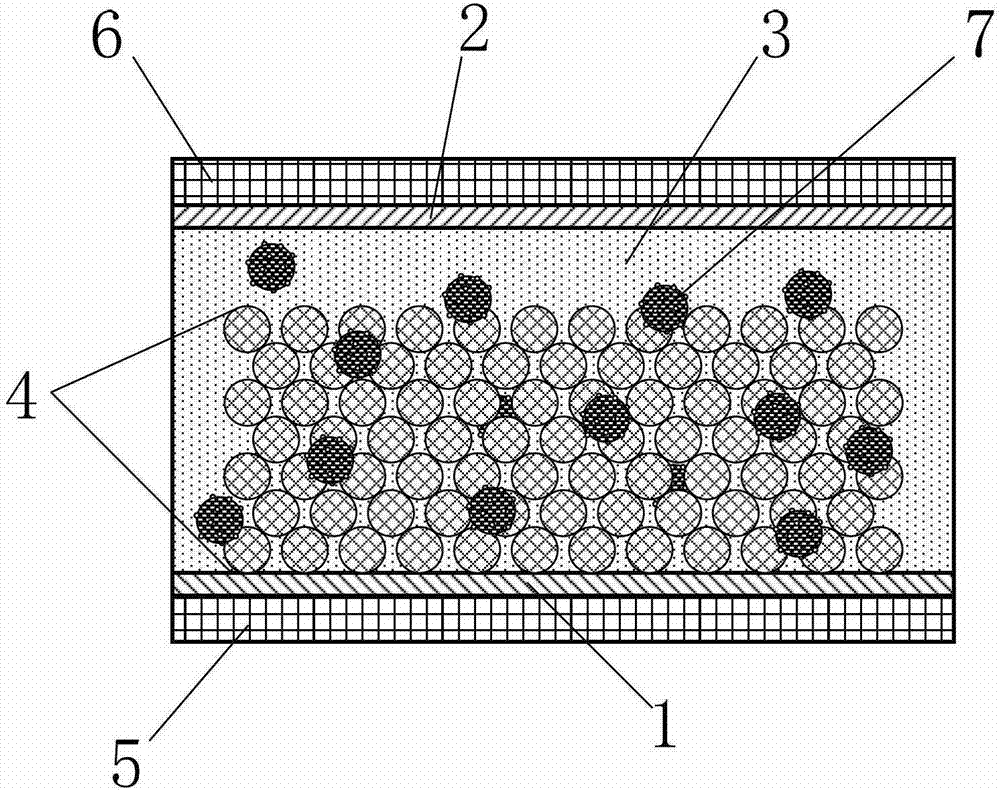

Dye-sensitized solar cell and method of making the same

A solar cell and dye-sensitized technology, which is applied in the field of dye-sensitized solar cells and their production, can solve the problems of low conversion efficiency dye-sensitized cells, etc., and achieve the goal of improving photoelectric conversion efficiency, enhancing life, and reducing transmission and total reflection Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

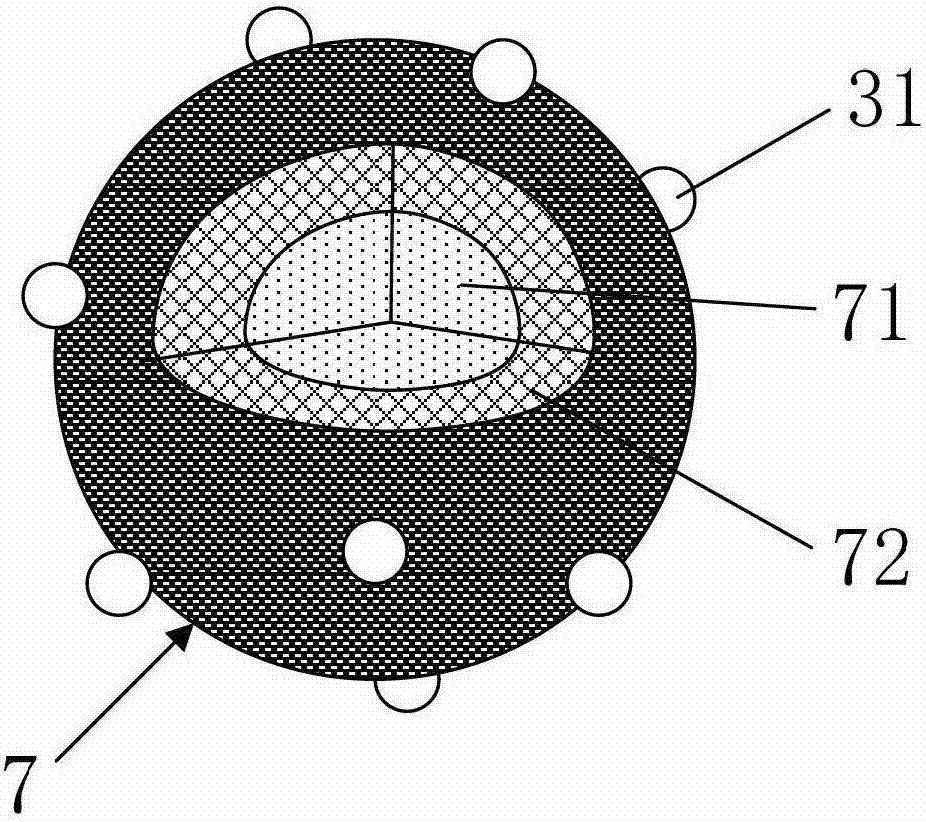

[0044] Wherein, the preparation method of the core-shell structure nanoparticle sol in step S10 includes the following steps:

[0045] S10ˊ, the oxidation-reduction reaction of the oxidant and the reducing agent solution containing the metal element solution occurs, and the mixture is stirred at a fixed speed and frequency under a constant temperature condition, and after a full reaction, it is naturally cooled to room temperature while maintaining a stirring state to obtain a metal nanoparticle sol;

[0046] S20ˊ, PVP particles dissolve in water to form PVP molecular sol;

[0047] S30', mixing the aforementioned metal nanoparticle sol and PVP molecular sol, and then continuously stirring for more than ten hours under normal temperature conditions to obtain a core-shell structured nanoparticle sol with a metal core embedded in the PVP organic shell.

[0048] List a few specific examples as follows:

Embodiment 1

[0050] In Example 1, a core-shell structured nanoparticle (Au / PVP) with gold as the core and PVP wrapped in an outer layer was selected, and a dye-sensitized battery containing Au / PVP was prepared by a titration spin coating method. The Au / PVP preparation method is mainly divided into three steps: 1. Preparation of gold sol; 2. Preparation of PVP aqueous solution; 3. Mixing reaction of 1 and 2 to obtain Au / TiO 2 . The preparation method of gold nanoparticles adopts the redox reaction between chloroauric acid solution and sodium citrate solution. In this example, 200mL of 10-4mol / L chloroauric acid solution and 2mL of 4*10-2mol / L sodium citrate solution are used. , Stirring at a constant temperature of 100 degrees Celsius at a frequency of 500 revolutions per minute, fully reacting for 15-20 minutes and then cooling to room temperature while maintaining agitation to obtain a gold nanoparticle sol with an average diameter of about 15-100nm; the molecular weight is 10000-30000 PVP...

Embodiment 2

[0053] In the second embodiment, a core-shell structured nanoparticle (Au / PVP) with gold as the core and PVP wrapped in an outer layer is selected, and a dye-sensitized battery containing Au / PVP is prepared by an ultraviolet curing method. The Au / PVP preparation method is mainly divided into three steps: 1. Preparation of gold sol; 2. Preparation of PVP aqueous solution; 3. Mixing reaction of 1 and 2 to obtain Au / TiO 2 . The preparation method of gold nanoparticles adopts the redox reaction between chloroauric acid solution and sodium citrate solution. In this example, 200mL of 10-4mol / L chloroauric acid solution and 2mL of 4*10-2mol / L sodium citrate solution are used. , Stirring at a constant temperature of 100 degrees Celsius at a frequency of 500 revolutions per minute, fully reacting for 15-20 minutes and then cooling to room temperature while maintaining agitation to obtain a gold nanoparticle sol with an average diameter of about 15-100nm; the molecular weight is 10000-30...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com