Electrode pair of dyestuff sensitized Nano crystal thin film of solar cell

A technology of solar cells and sensitized nanocrystals, which is applied in the field of solar cells, can solve problems such as reducing photoelectric conversion efficiency, being susceptible to corrosion, and affecting the expansion of cell scale, so as to improve photoelectric conversion efficiency, reduce ohmic loss, and good stability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Use fluorine-doped conductive glass (FTO) (Heilongjiang Hake New Energy Co., Ltd., sheet resistance 30Ωcm -2 ) as the substrate. On the cleaned FTO glass, use the plating solution as shown in Table 1 to uniformly plate a layer of nickel-phosphorus alloy under the conditions of pH 4-7, temperature 75-85°C and plating time 15-20min, and then at 300°C After heat treatment for 1 hour, the conductive substrate with nickel-phosphorus alloy layer of the present invention is obtained. Table 1 is the bath composition.

[0030] NiSO 4 ·6H 2 O NaPO 2 ·H 2 O H 3 BO 3 C 3 h 6 o 3 (lactic acid)

(gL -1 ) (gL -1 ) (gL -1 ) (mL L -1 )

20-30 20-30 10-20 15-25

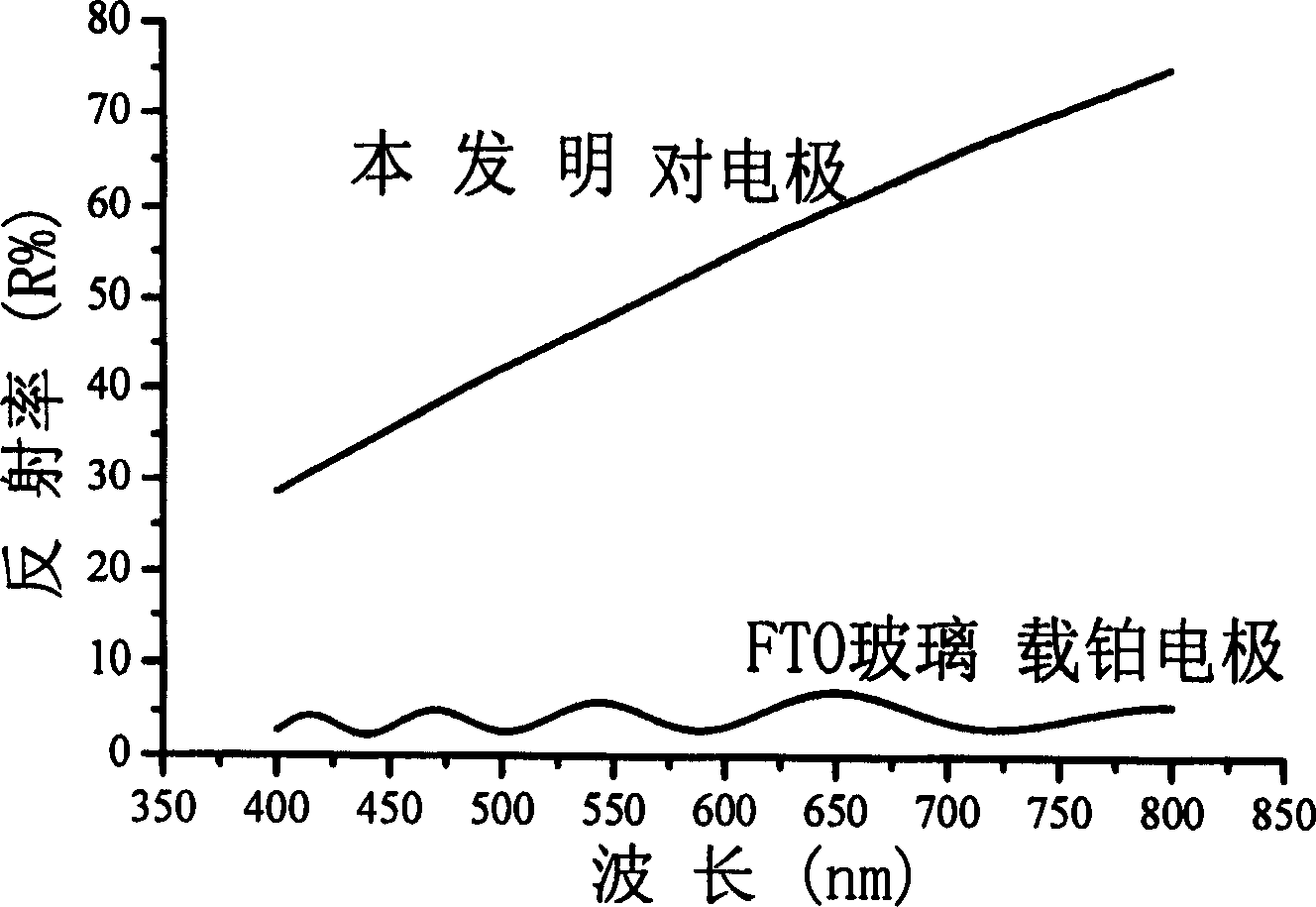

[0031] use D 41-4 Type four-probe measuring instrument (state-operated Jianzhong Machine Factory) measures the sheet resistance of the present invention with the conductive substrate of nickel-phosphorus alloy layer, and the result is 0.5 Ω cm -2 , showin...

Embodiment 2

[0034] Use fluorine-doped conductive glass (FTO) (Heilongjiang Hake New Energy Co., Ltd., sheet resistance 30Ωcm -2 ) as the substrate. On the cleaned FTO glass, use the plating solution composed in Table 2 at pH 2-6, temperature 60-85°C and plating time 1-2 hours, current density 1A / square decimeter, duty ratio 1 / 10 A layer of nickel-phosphorus alloy is uniformly plated under the conditions, and then heat-treated at 300° C. for 1 hour to obtain the conductive substrate with the nickel-phosphorus alloy layer of the present invention. Table 2 is the composition of the chemical-electrochemical composite plating solution.

[0035] NiSO 4 ·6H 2 O NaPO 2 ·H 2 O H 3 BO 3

[0036] use D 41-4 Type four-probe measuring instrument (state-operated Jianzhong Machinery Factory) measures the sheet resistance of the present invention with the conductive substrate of the nickel-phosphorus alloy layer, and the result is 0.2 Ω cm -2 , showing that the method of the pres...

Embodiment 3

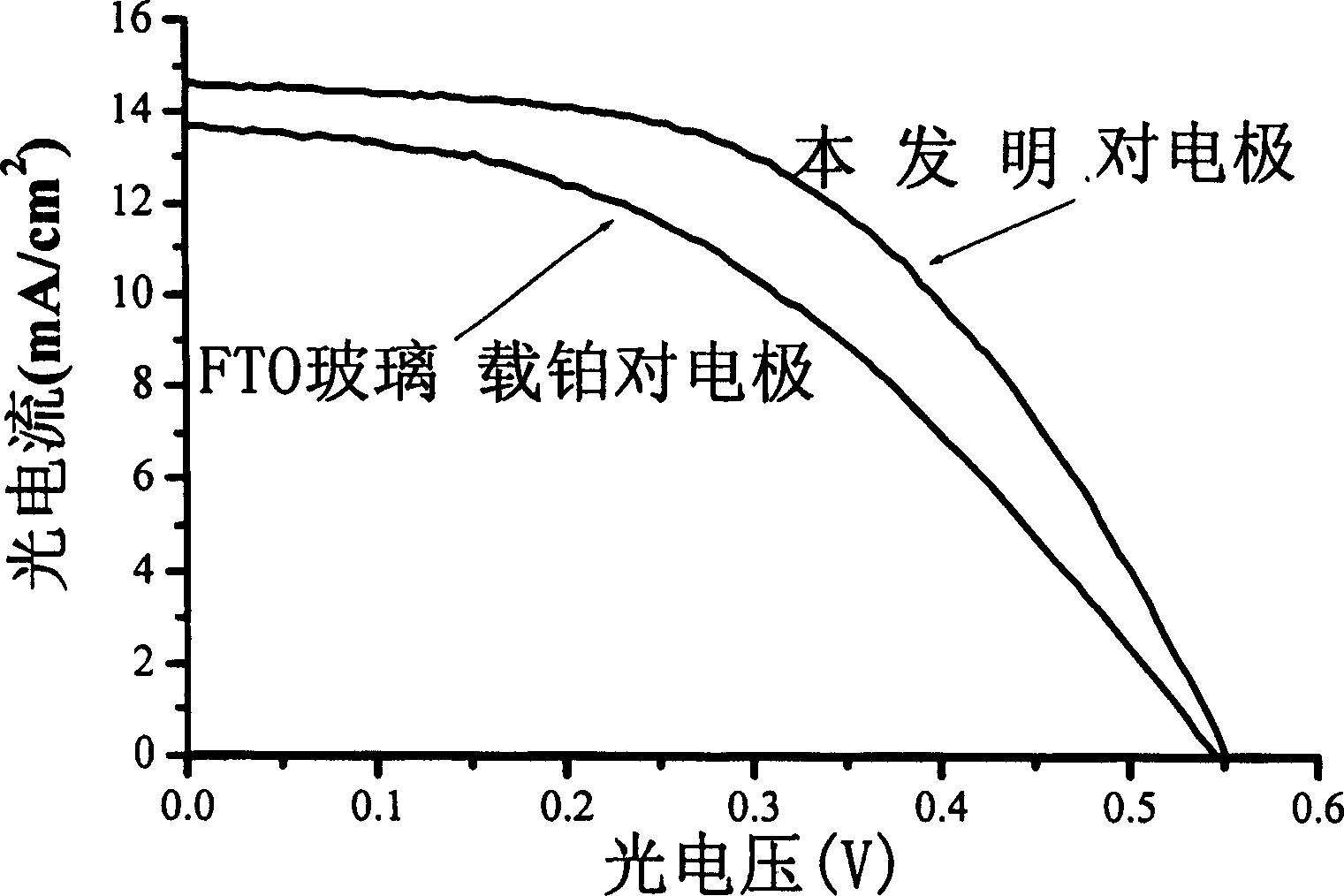

[0038] H 2 PtCl 6 Isopropanol solution was spin-coated on the conductive substrate with nickel-phosphorus alloy layer of the present invention obtained in Example 1, dried and then heat-treated at 300° C. for 15 minutes, and cooled to obtain the novel counter electrode of the present invention. Using different concentrations of H 2 PtCl 6 Virahol solution obtains the novel counter electrode of the present invention of different loaded platinum amounts, then measures its R respectively ct and platinum loading. The results are shown in Table 3, and Table 3 shows the catalytic activity of the counter electrodes of the present invention with different platinum loadings.

[0039] Platinum load (μg / cm 2 )

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| reflectance | aaaaa | aaaaa |

| reflectance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com