Patents

Literature

128 results about "Sensitized cell" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

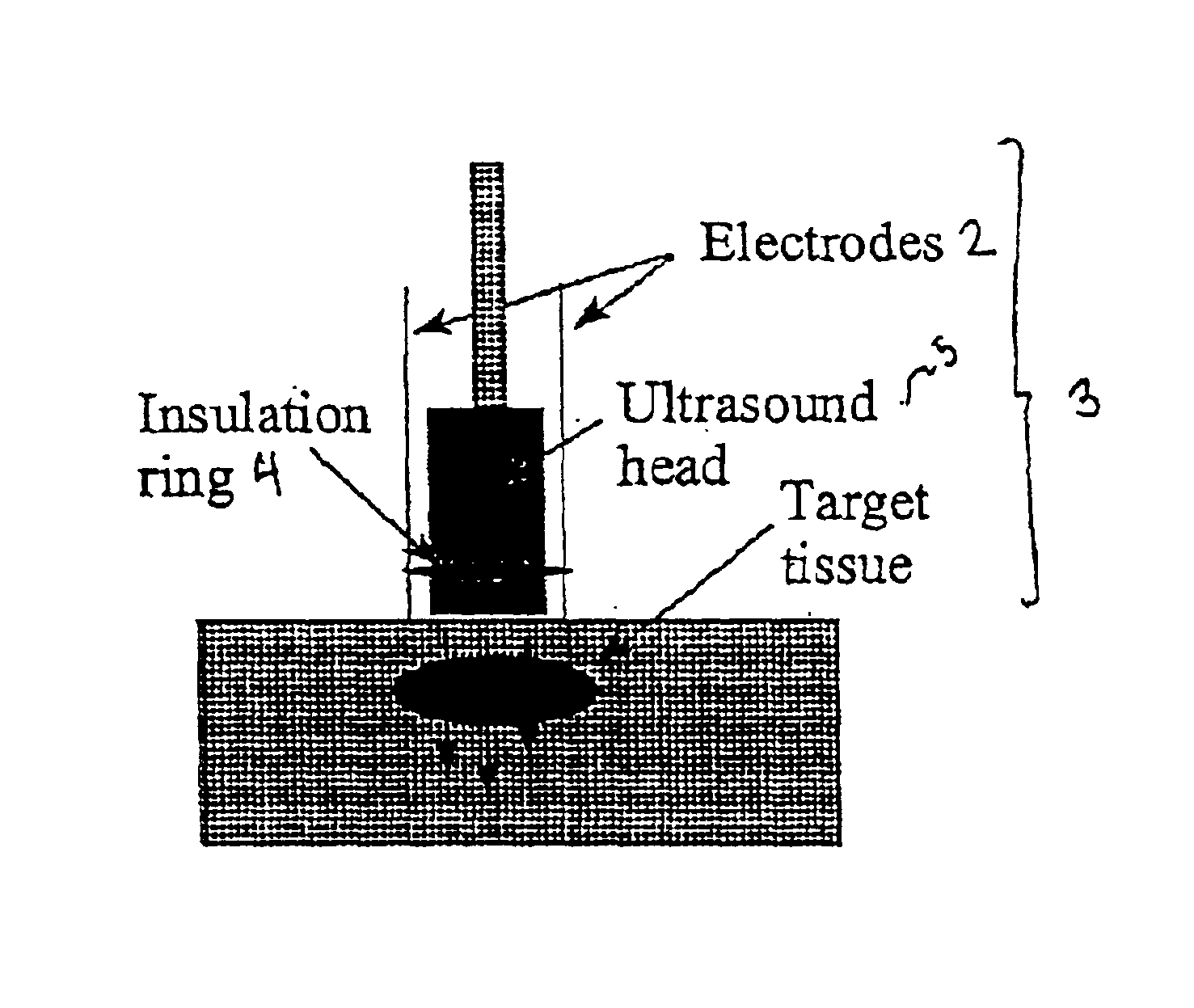

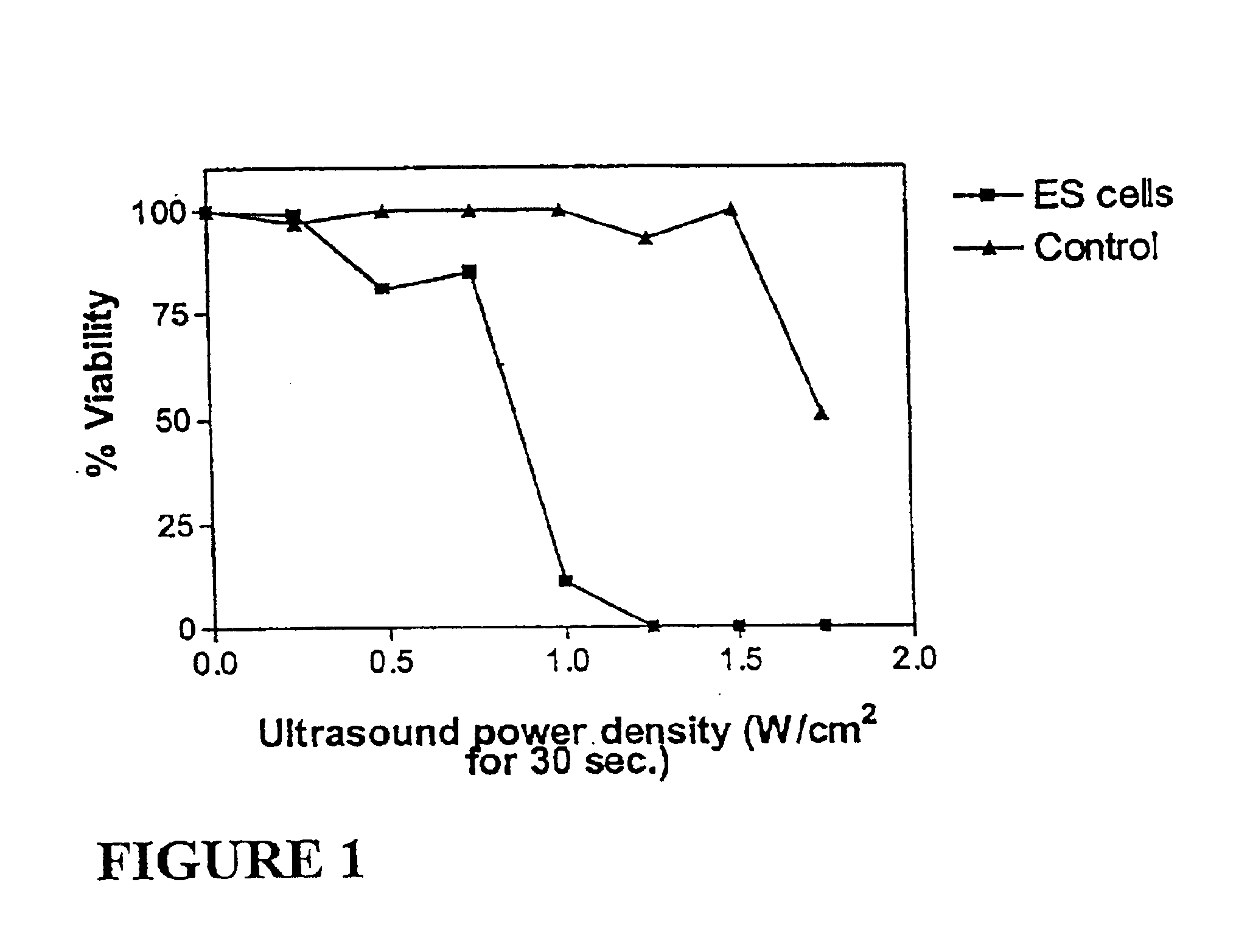

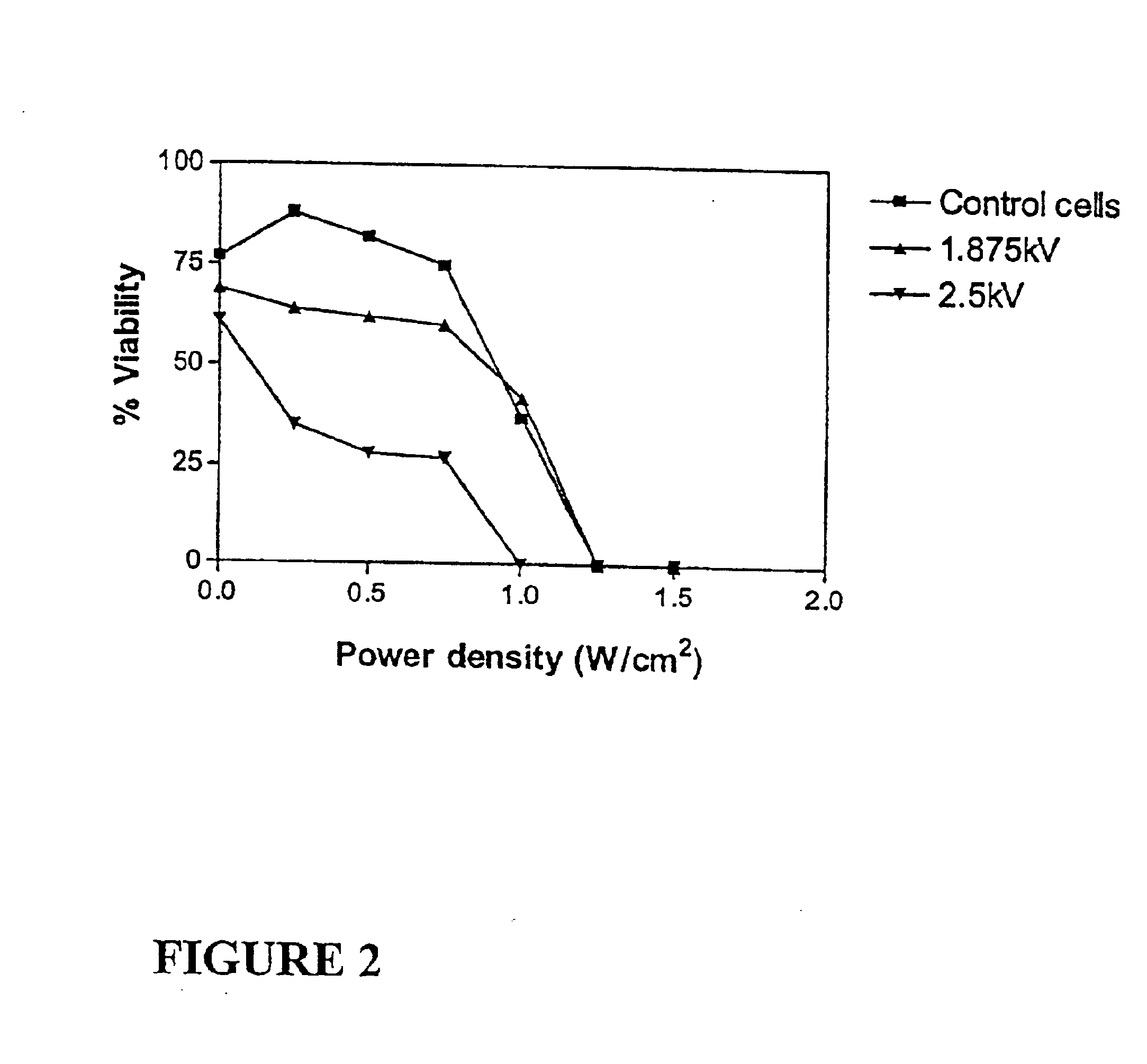

Ultrasound therapy for selective cell ablation

InactiveUS6821274B2Ultrasound therapyElectrical/wave energy microorganism treatmentSensitized cellApoptosis

The invention provides a method of sensitizing target cells to ultrasound energy using a stimulus such as an electric field. This "electrosensitisation" enables target cells to be disrupted by ultrasound at frequencies and energies of ultrasound which do not cause disruption of non-sensitized (i.e., non-target) cells. As a consequence, the method increases the selectivity of ultrasound therapy, providing a way to ablate undesired cells, such as diseased cells (e.g., tumor cells) while minimizing harm to neighboring cells. In another aspect, however, ultrasound can be used to sensitize cells while the electrical field is used to disrupt cells. The invention also provides an apparatus for performing the method and assays for identifying gene products and other molecules involved in apoptosis.

Owner:GENDEL

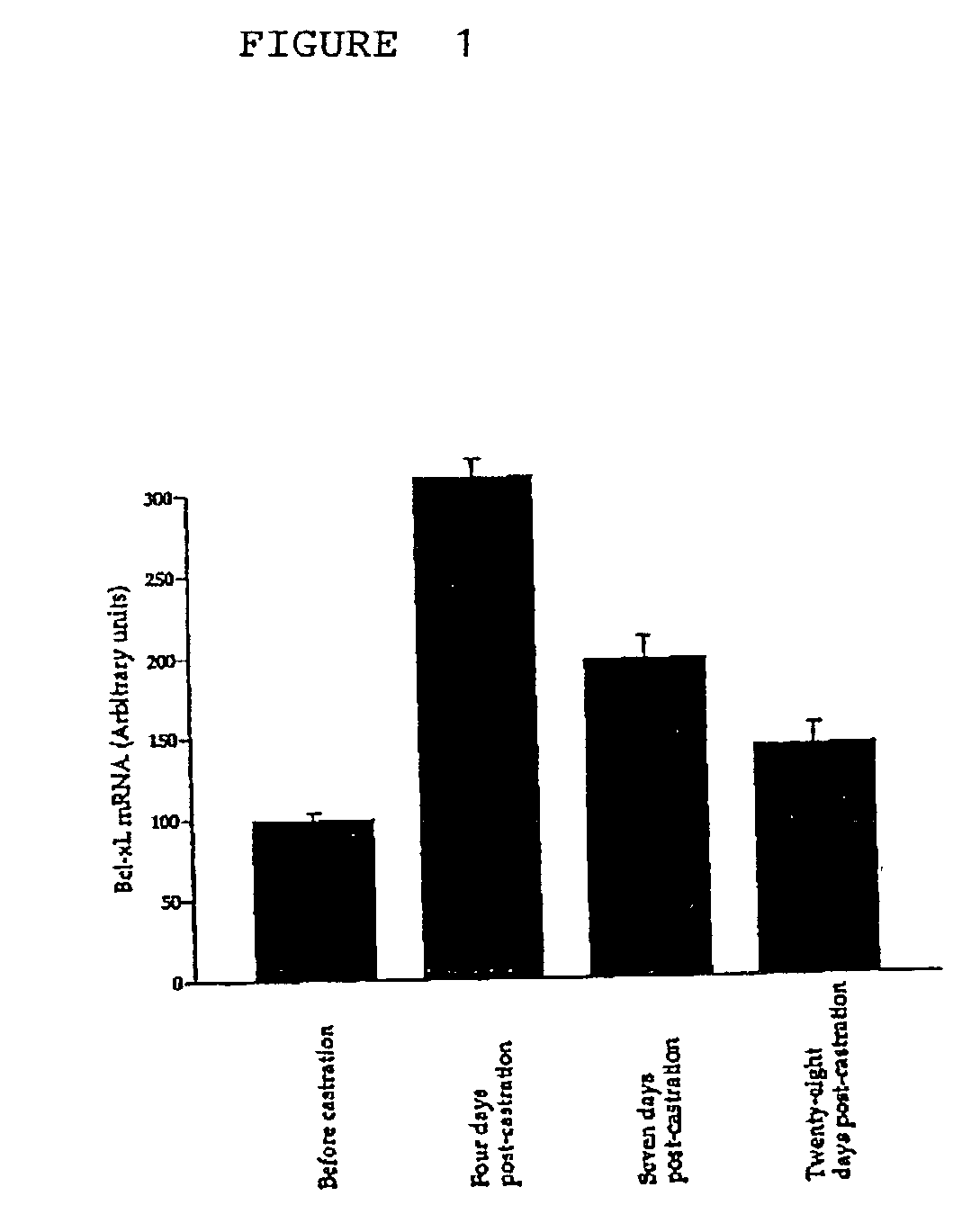

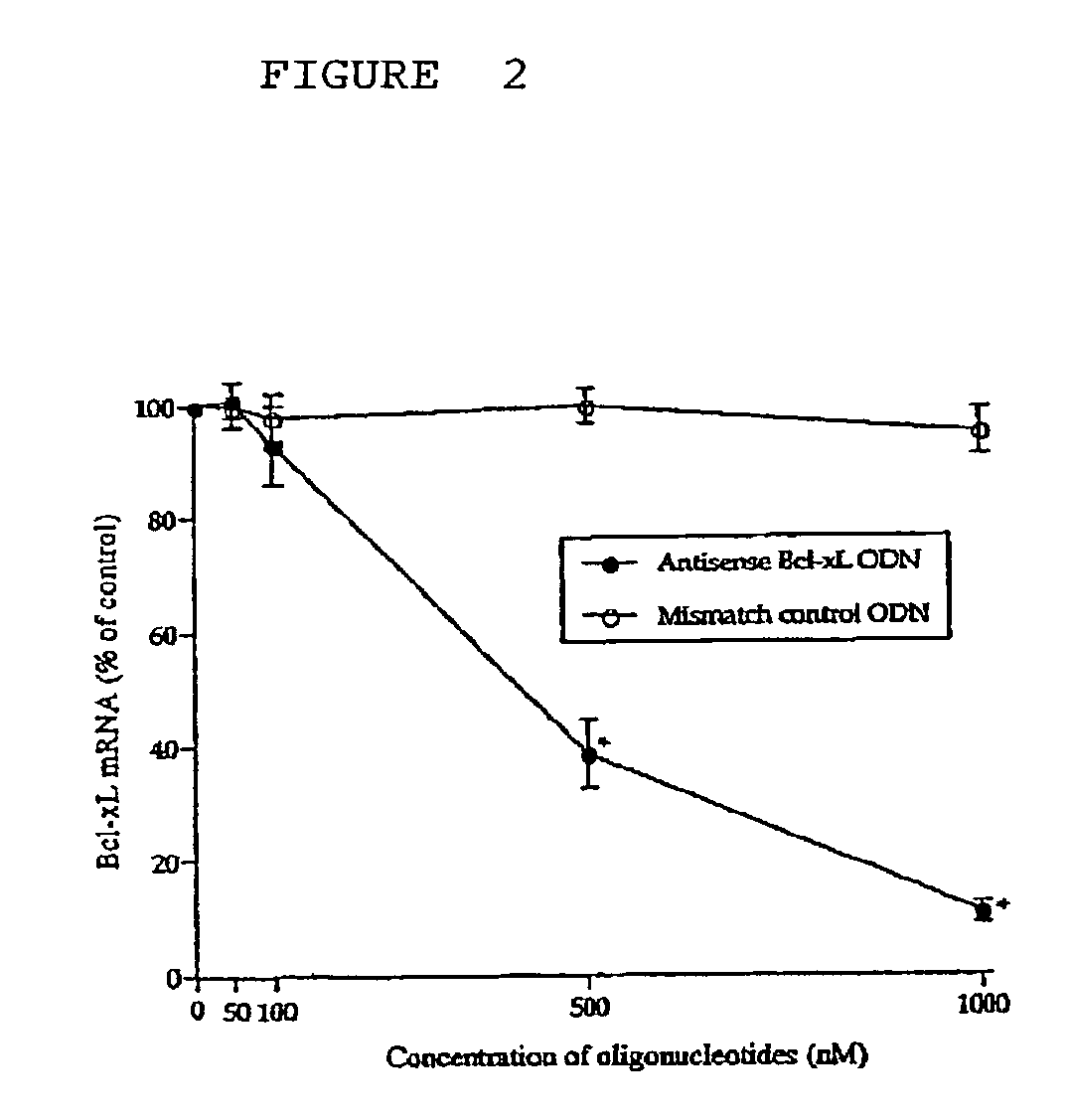

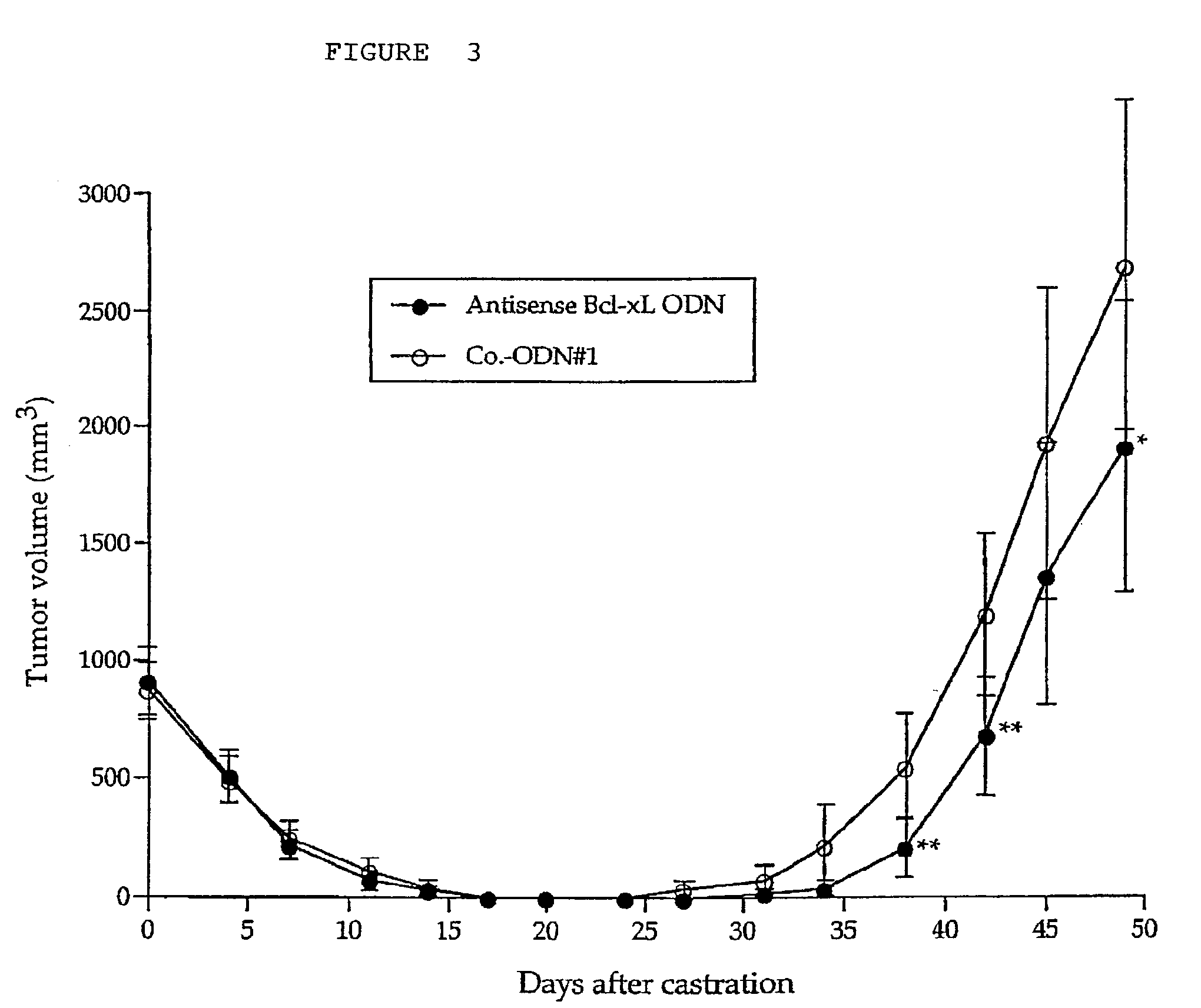

Antisense modulation of bcl-x expression

InactiveUS7148204B2Promote apoptosisReduce expressionBiocideHeavy metal active ingredientsDiseaseSensitized cell

Compositions and methods are provided for modulating the expression of bcl-x. Antisense compounds, particularly antisense oligonucleotides, targeted to nucleic acids encoding bcl-x are preferred. Methods of using these compounds for modulation of bcl-x expression and for treatment of diseases associated with expression of bcl-x are also provided. Methods of sensitizing cells to apoptotic stimuli are also provided.

Owner:IONIS PHARMA INC

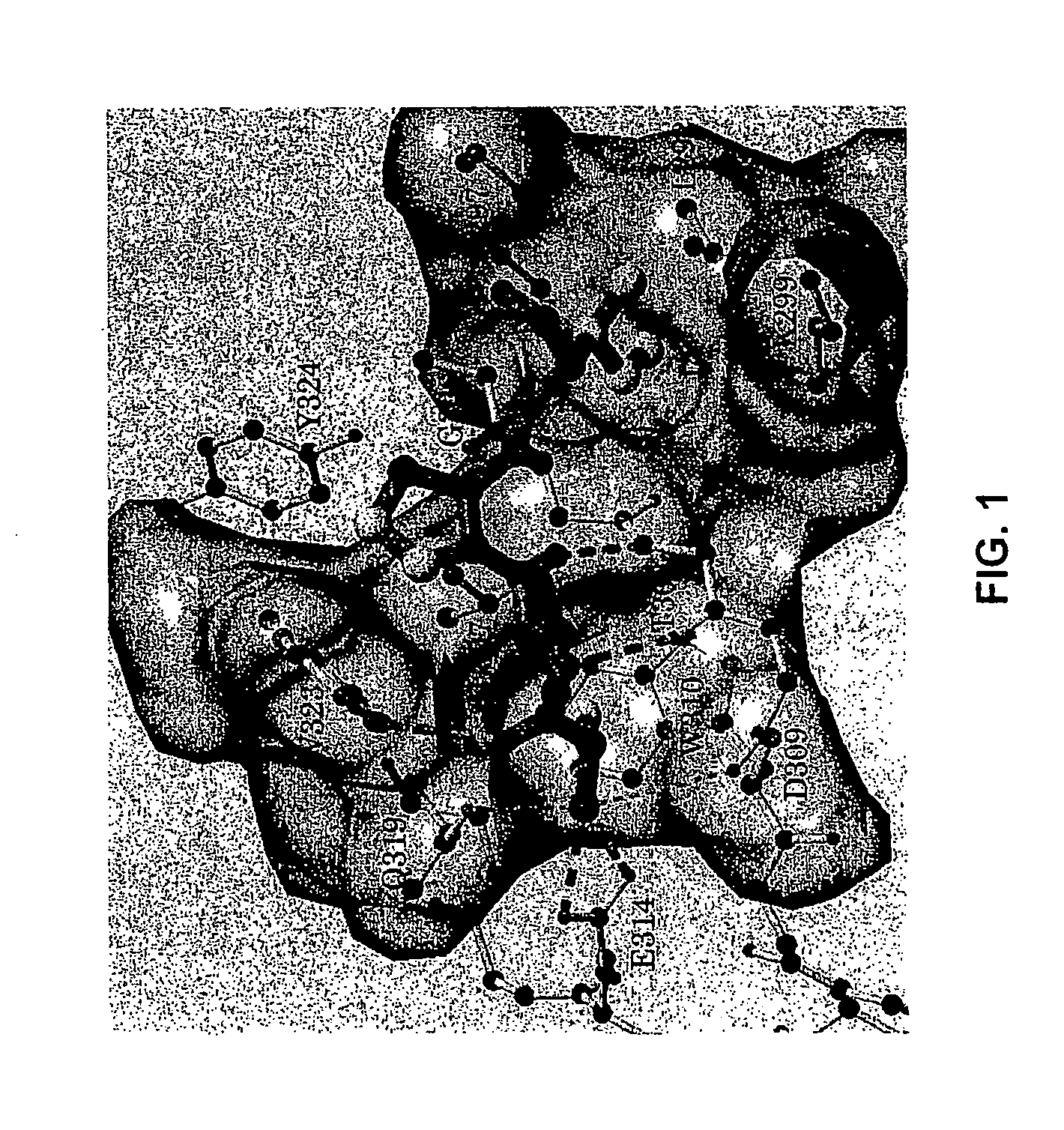

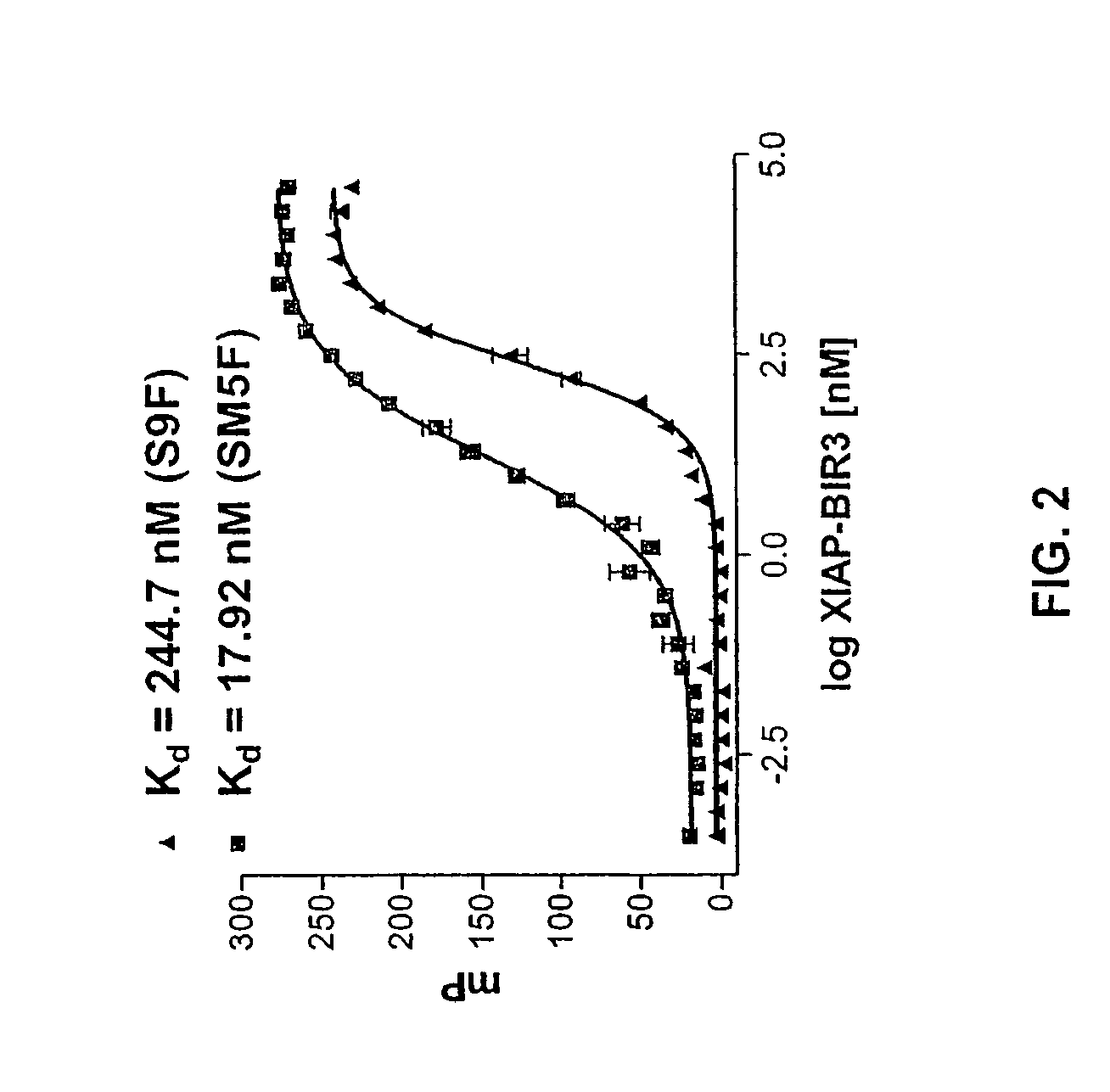

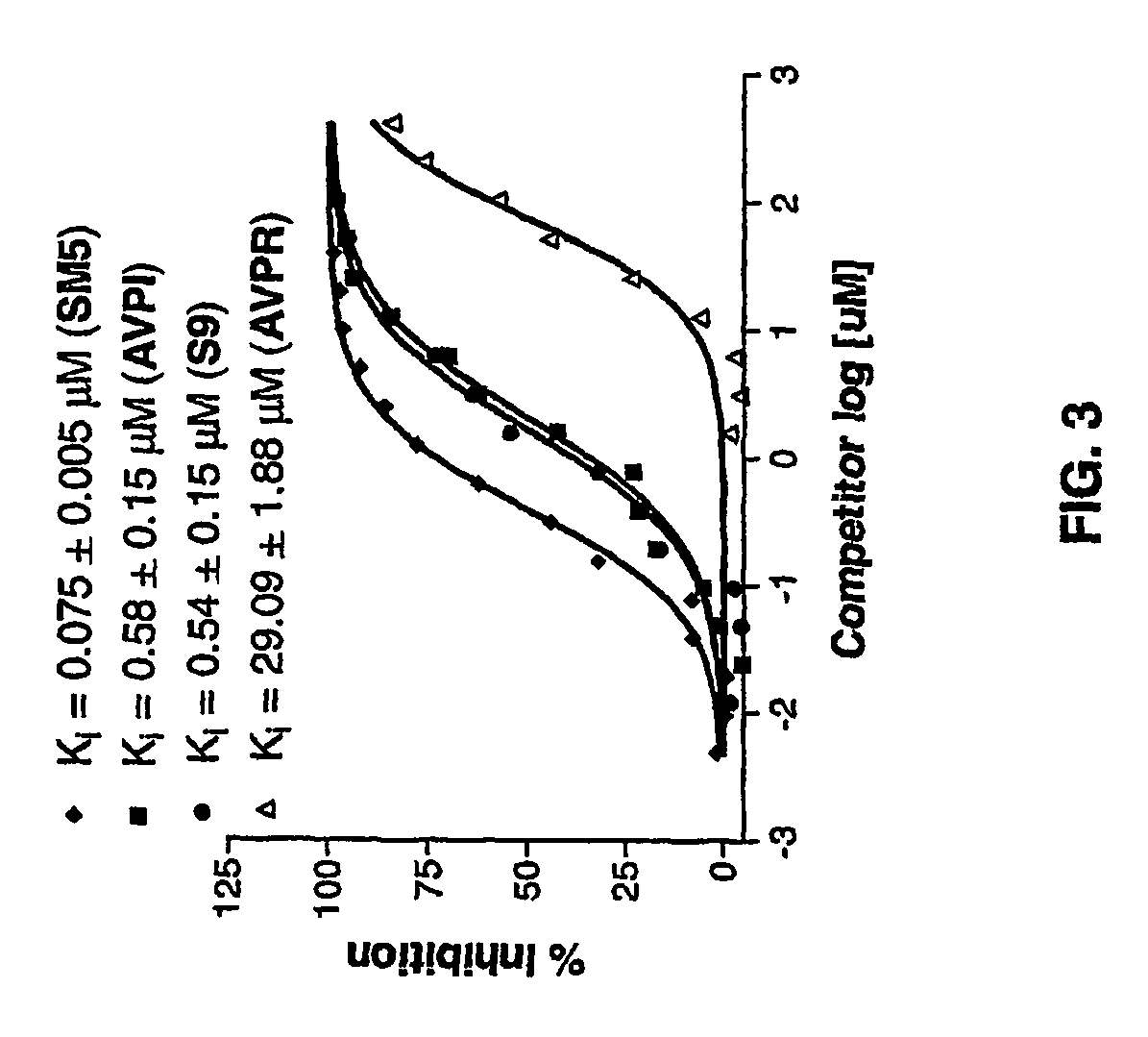

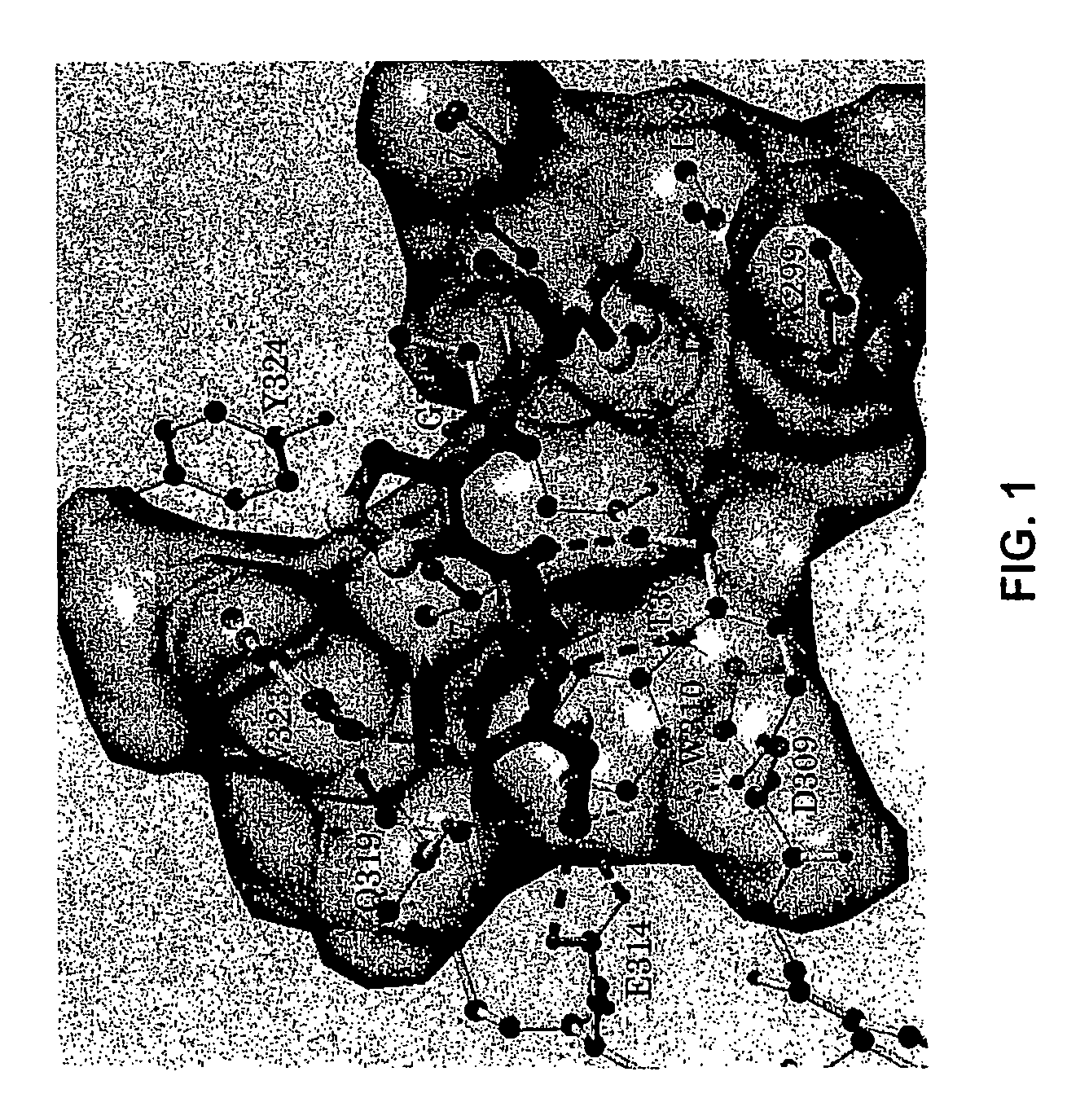

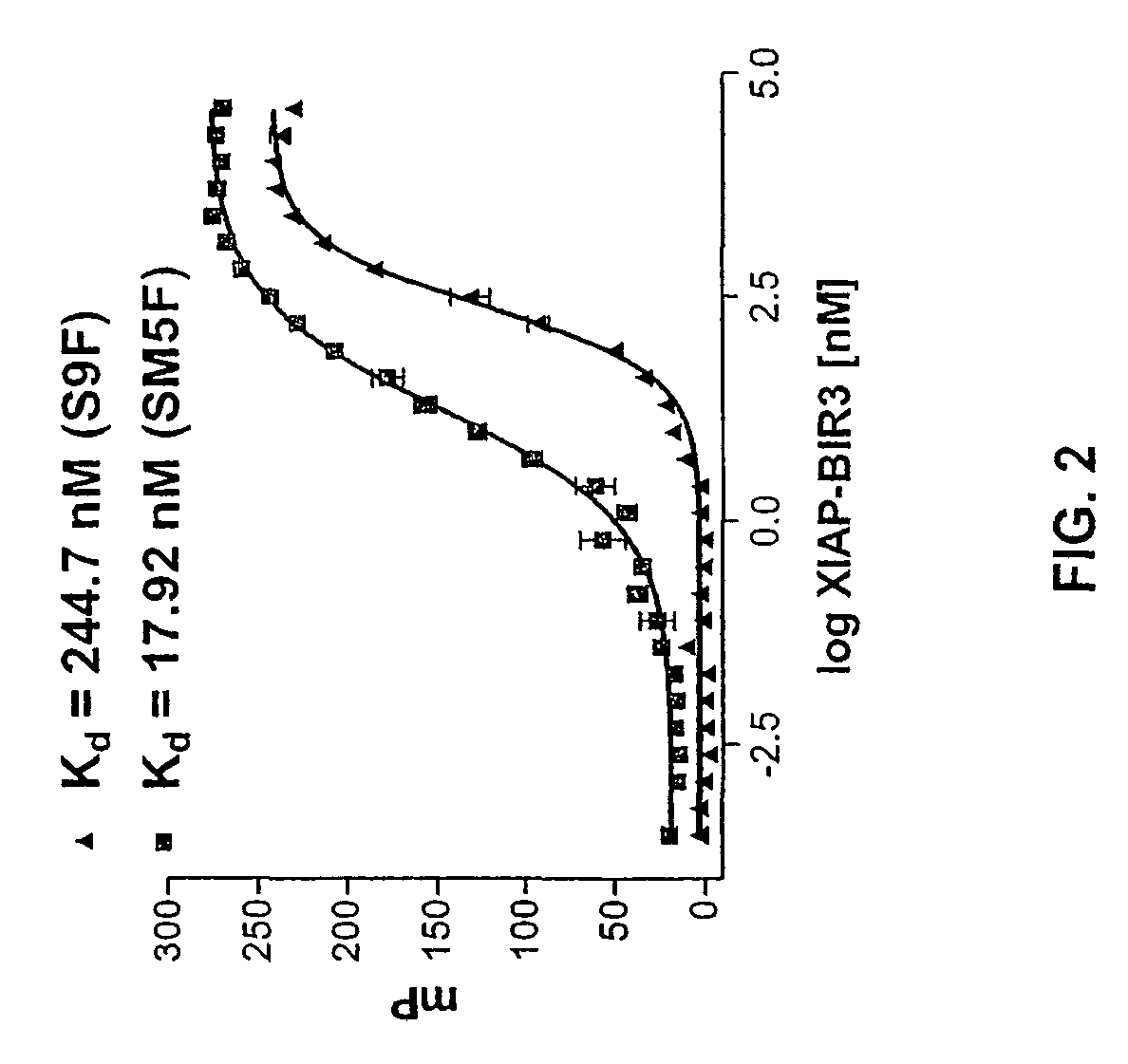

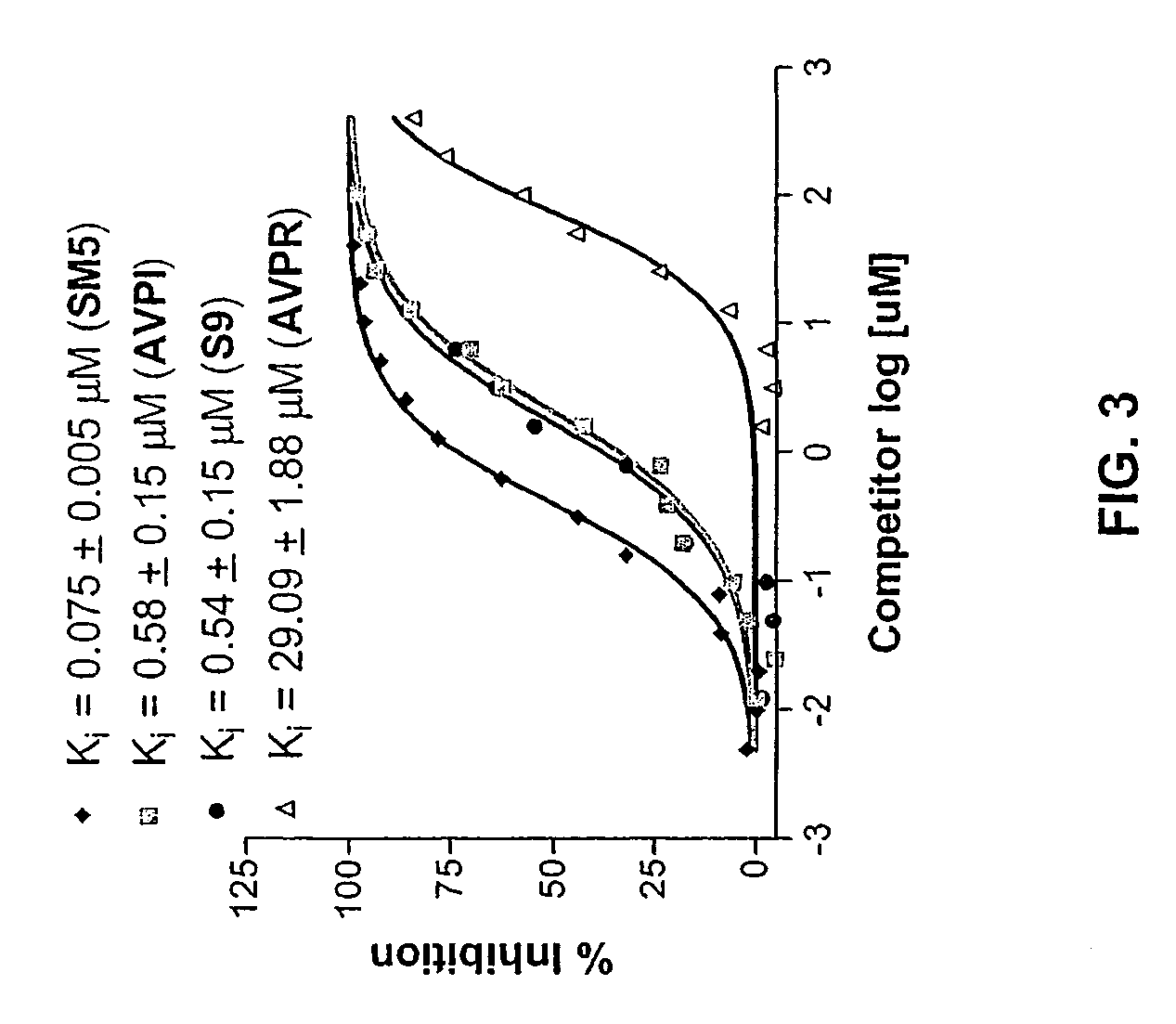

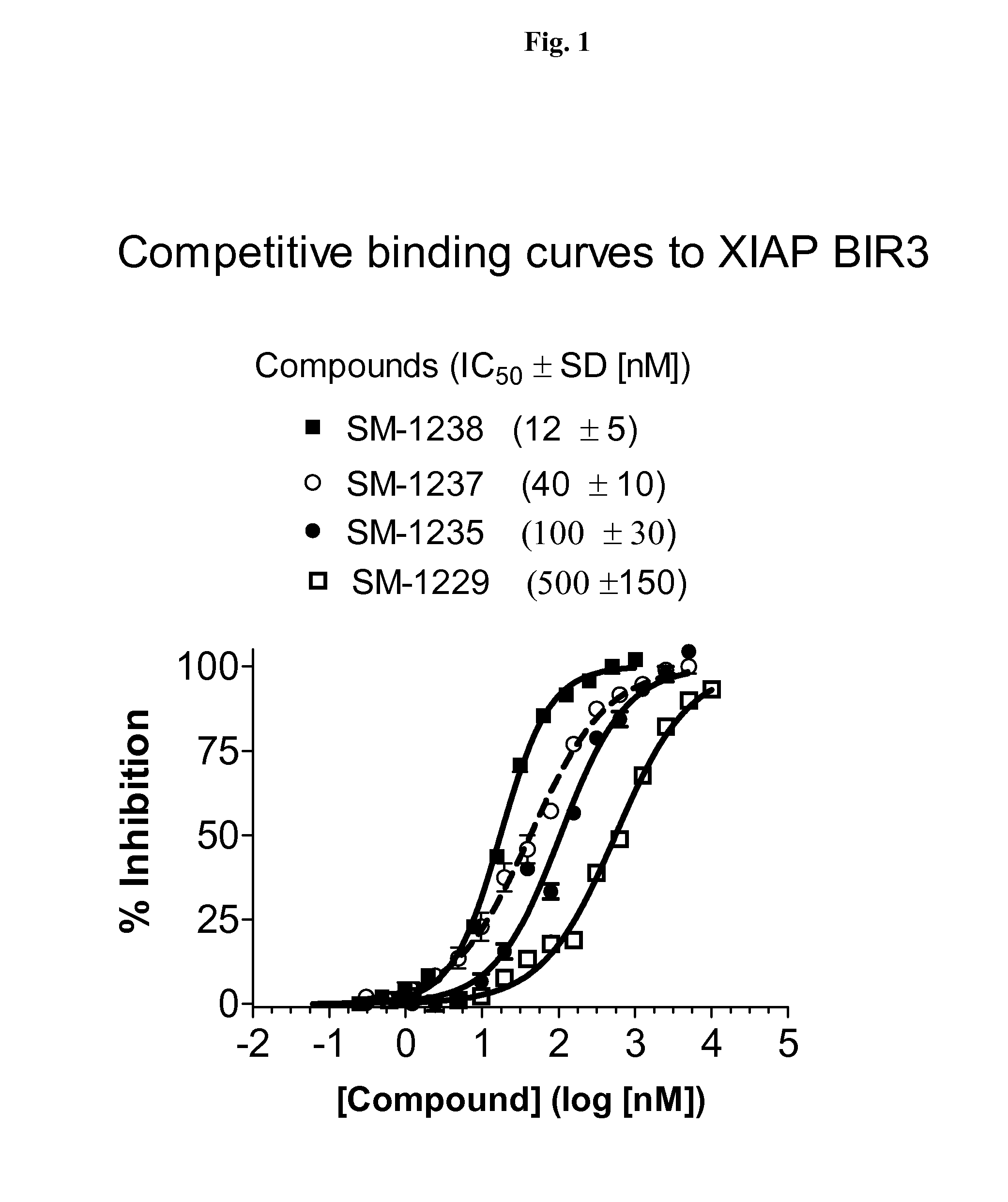

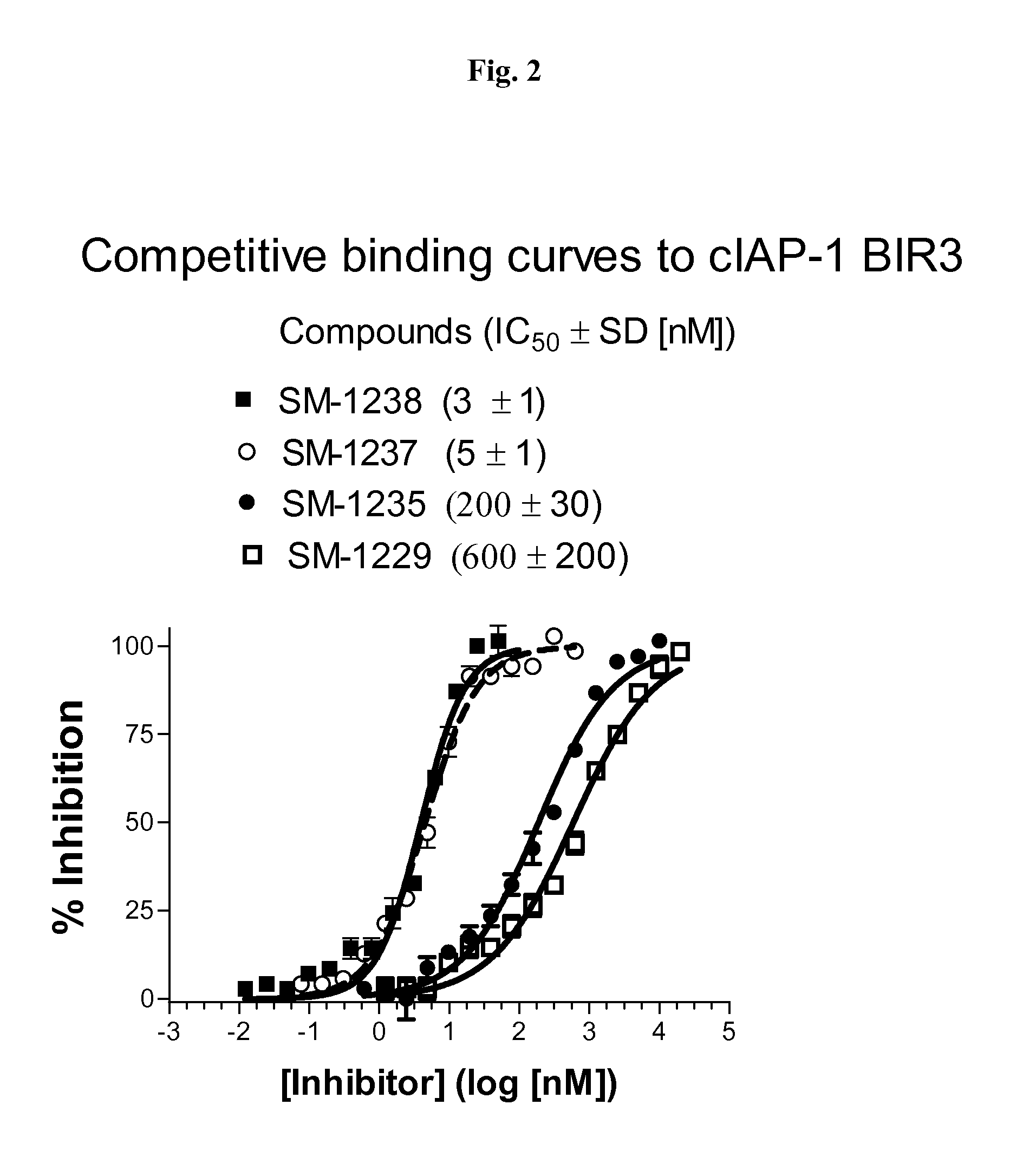

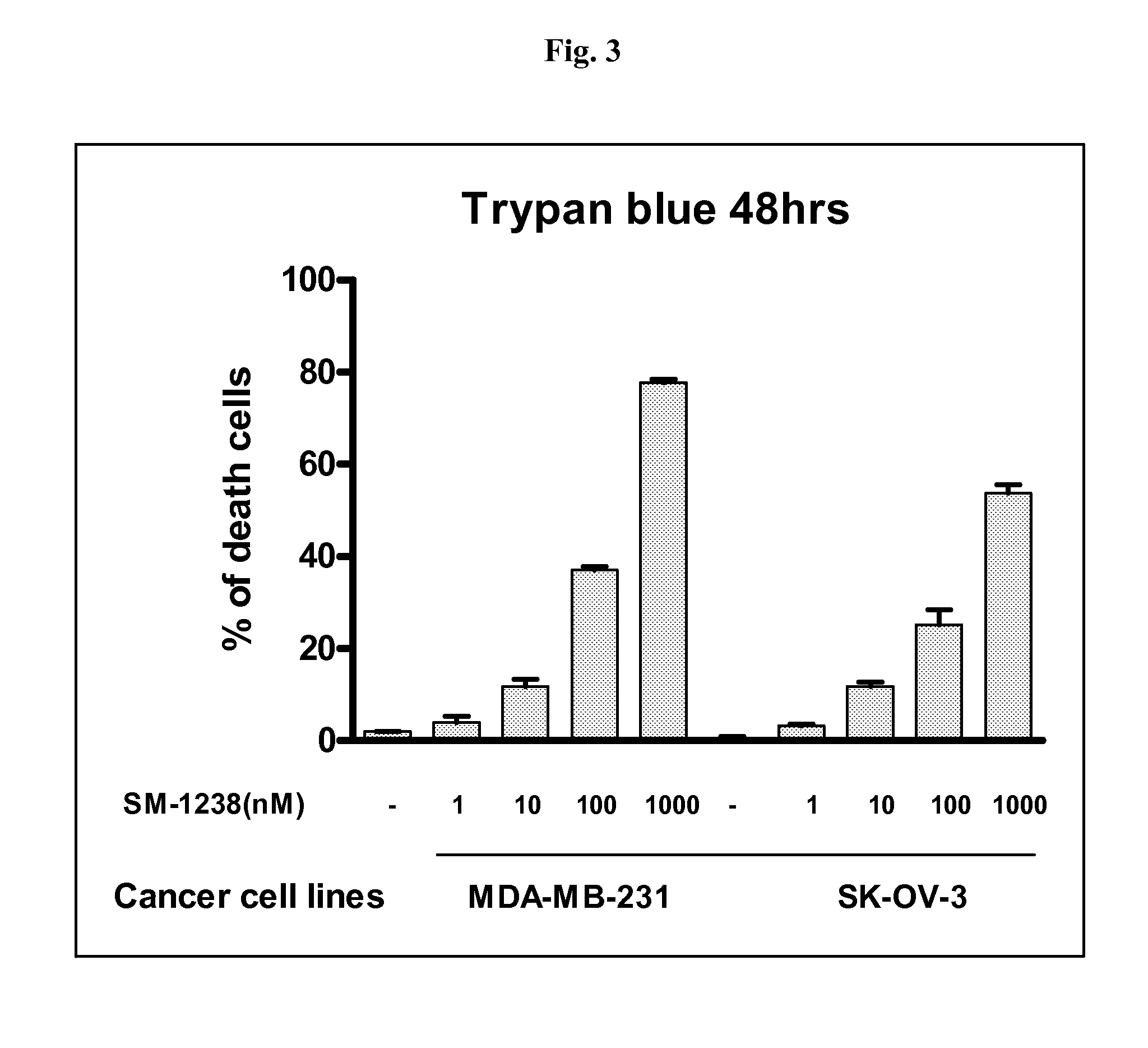

Bivalent SMAC mimetics and the uses thereof

ActiveUS20080089896A1Toxic reductionMore tolerableBiocideOrganic chemistrySmac mimeticsSensitized cell

The invention relates to bivalent mimetics of Smac which function as inhibitors of Inhibitor of Apoptosis Proteins. The invention also relates to the use of these mimetics for inducing apoptotic cell death and for sensitizing cells to inducers of apoptosis.

Owner:RGT UNIV OF MICHIGAN

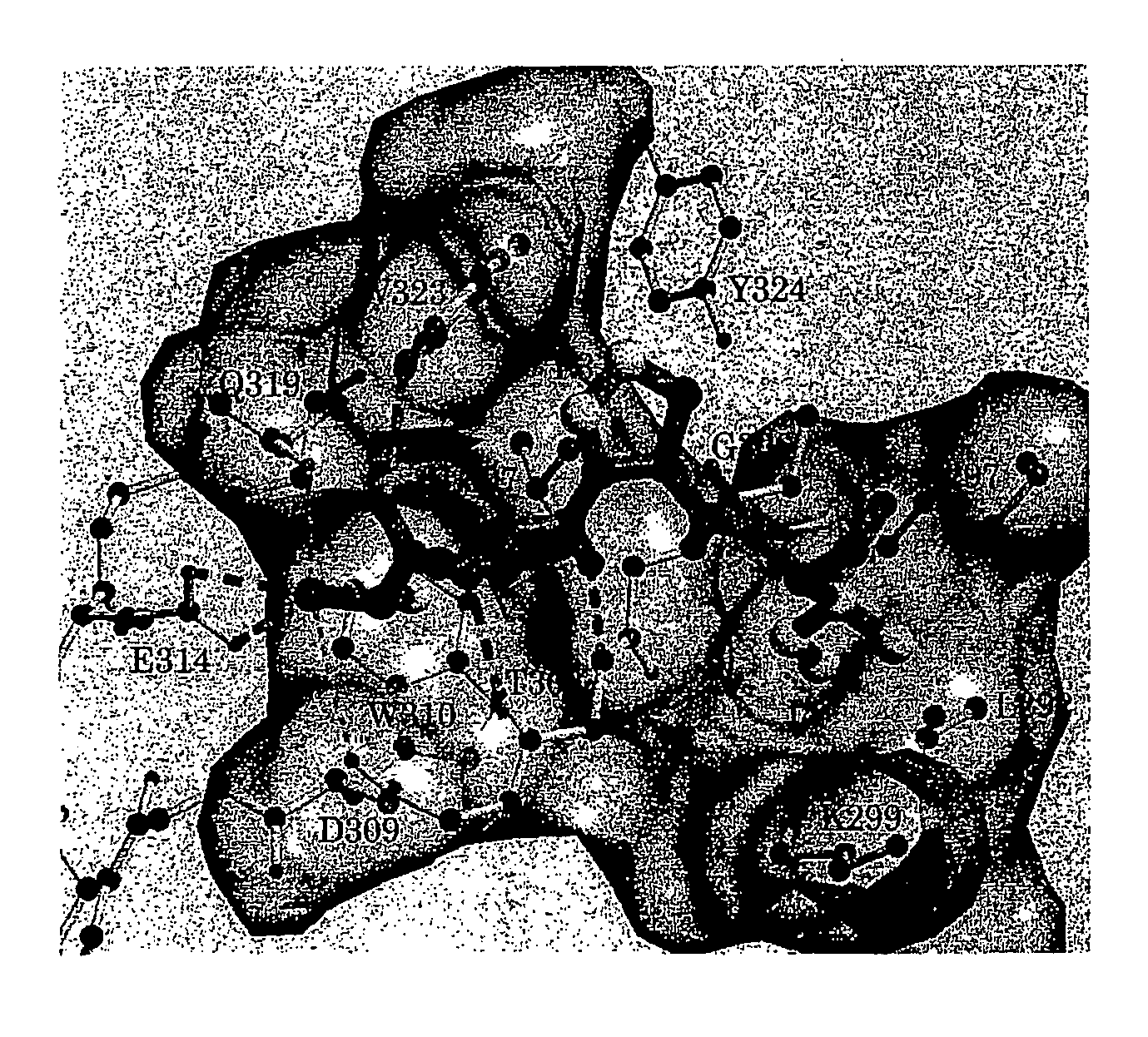

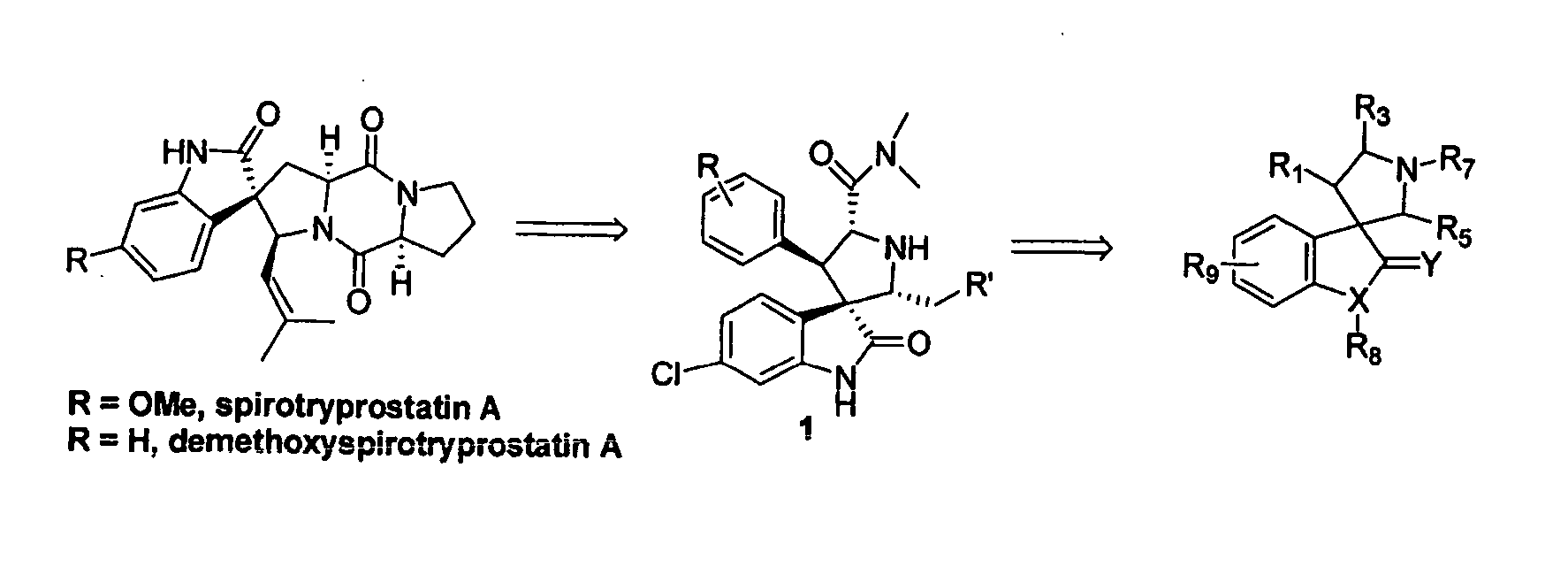

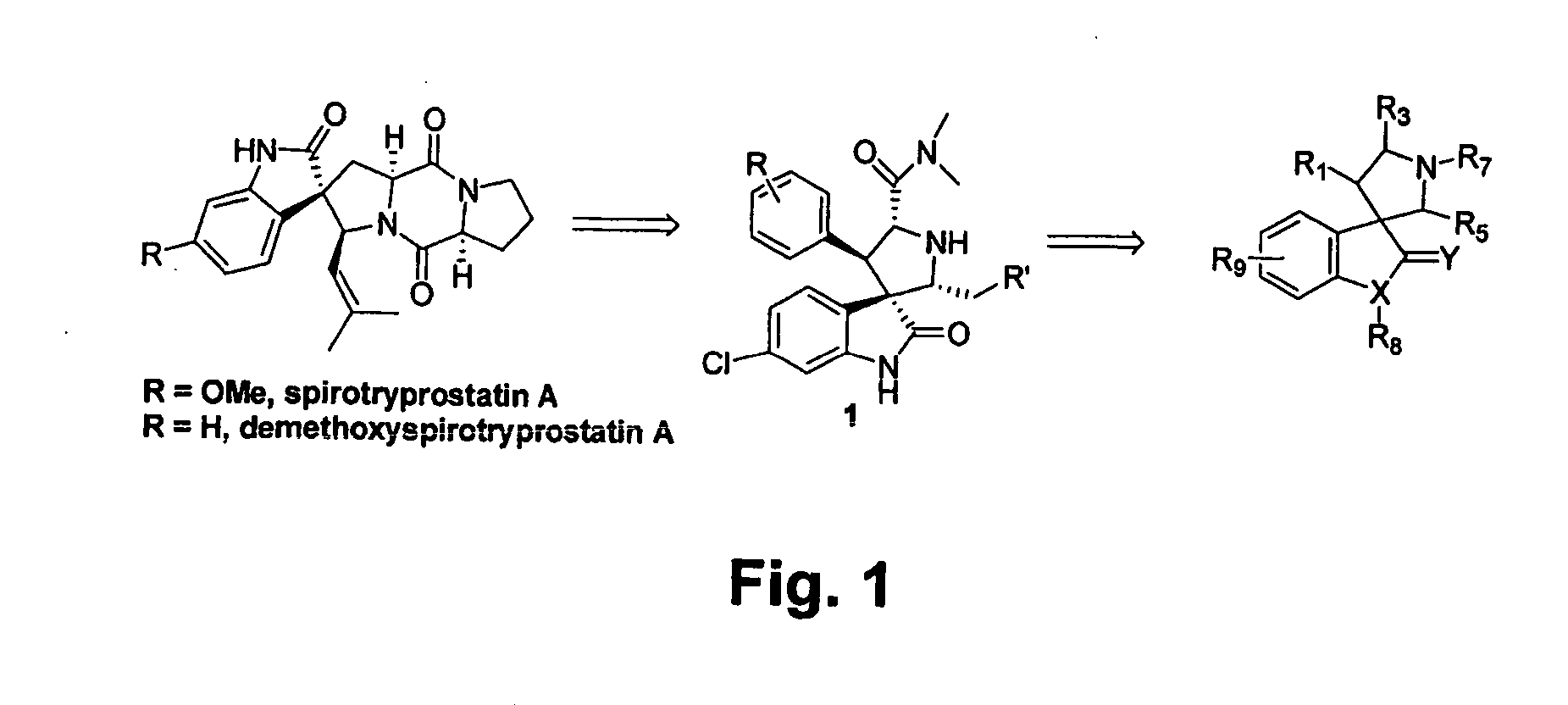

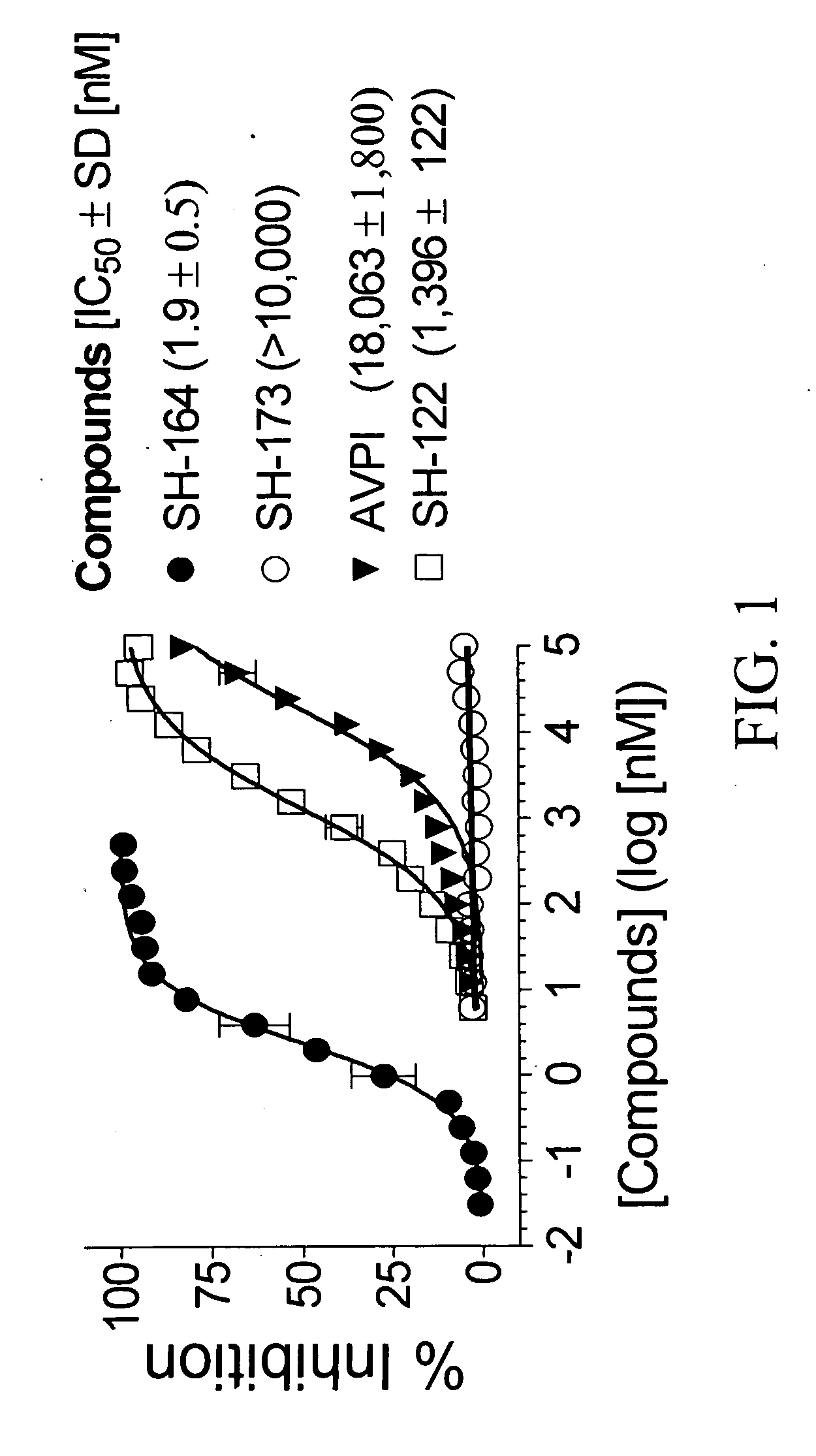

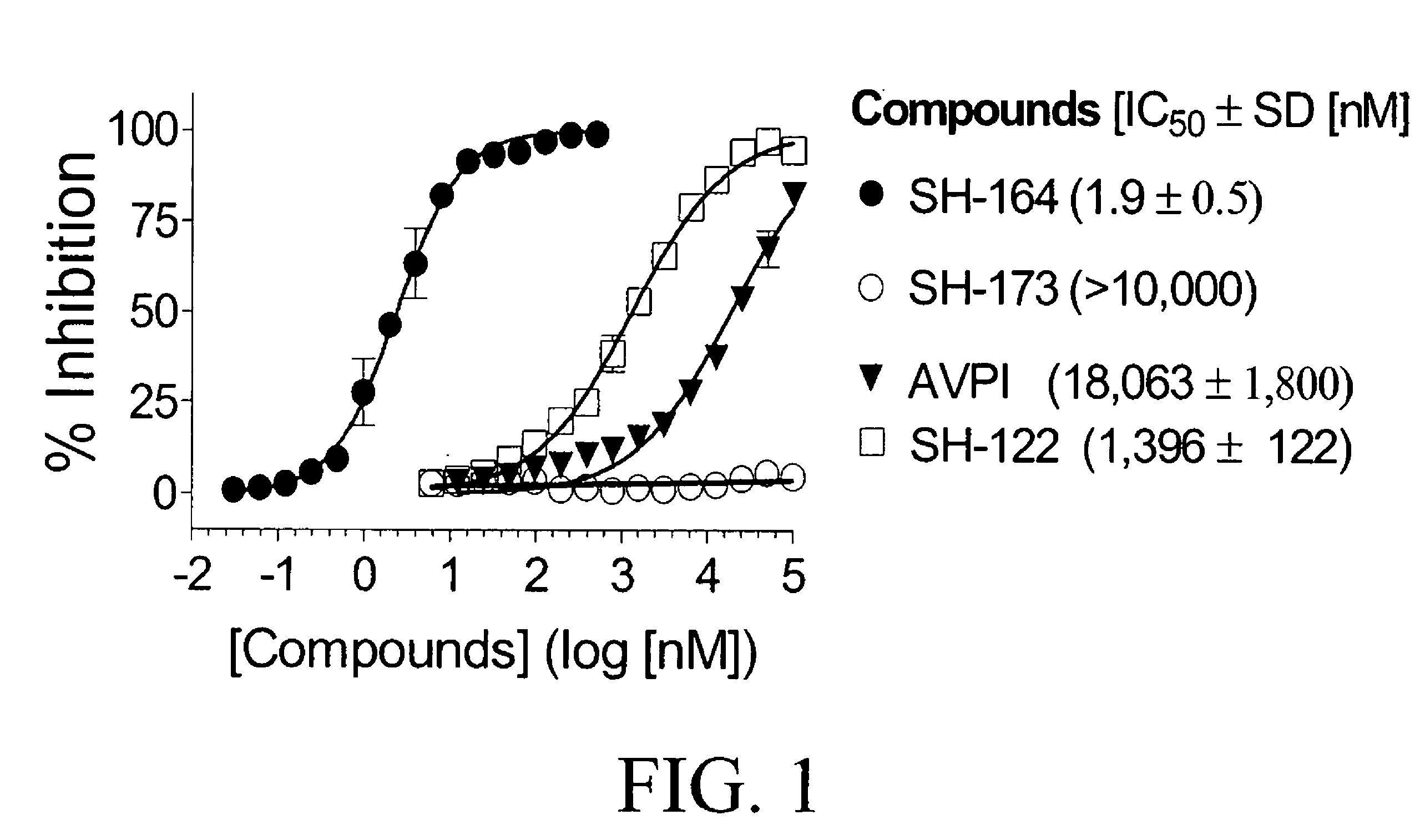

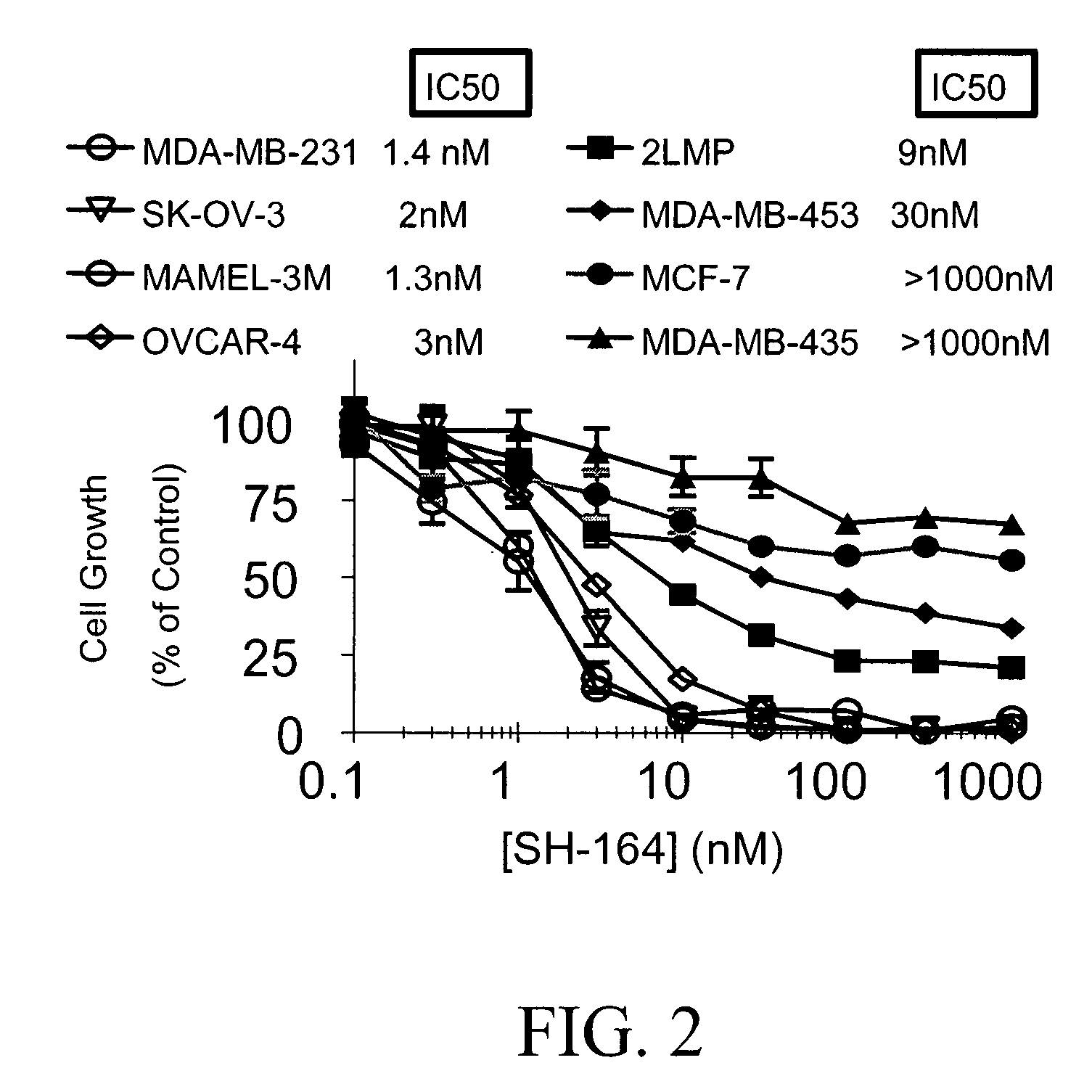

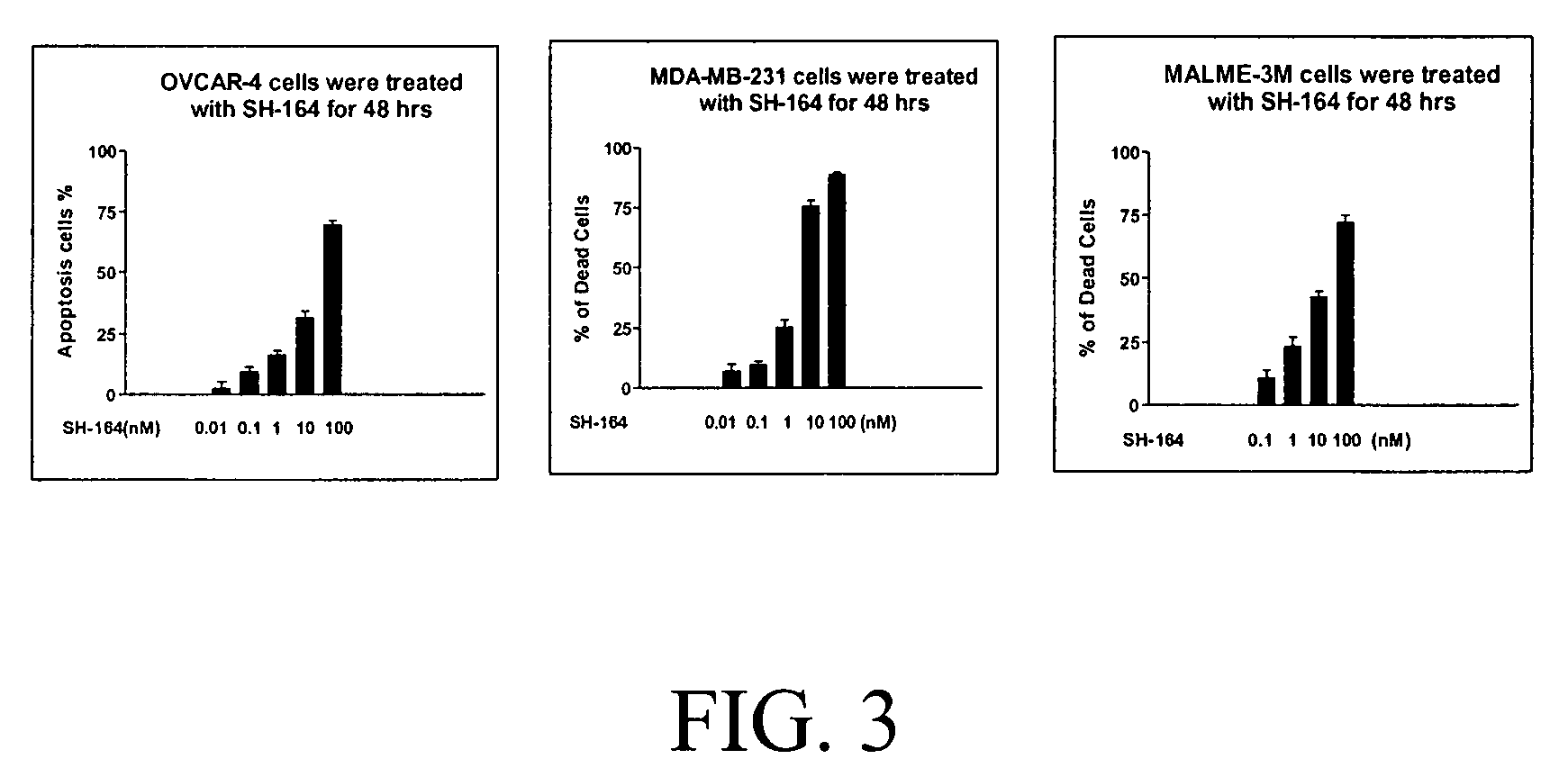

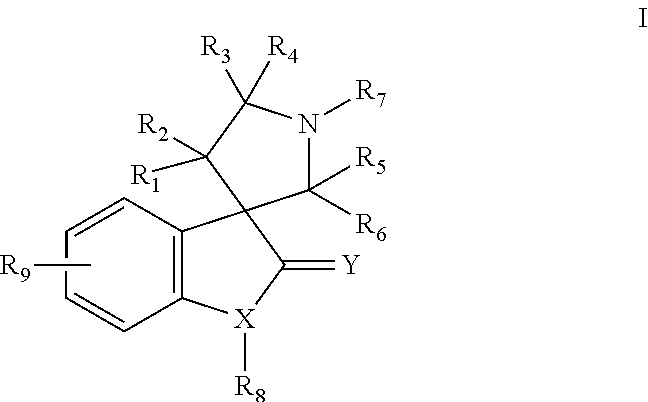

Small molecule inhibitors of MDM2 and the uses thereof

InactiveUS7759383B2Extended half-lifeIncrease the function(s) of p53BiocideOrganic chemistrySensitized cellMdm2 Protein

Owner:RGT UNIV OF MICHIGAN

Indole inhibitors of MDM2 and the uses thereof

InactiveUS7737174B2Growth inhibitionExtended half-lifeBiocideOrganic chemistrySensitized cellMdm2 Protein

Owner:RGT UNIV OF MICHIGAN

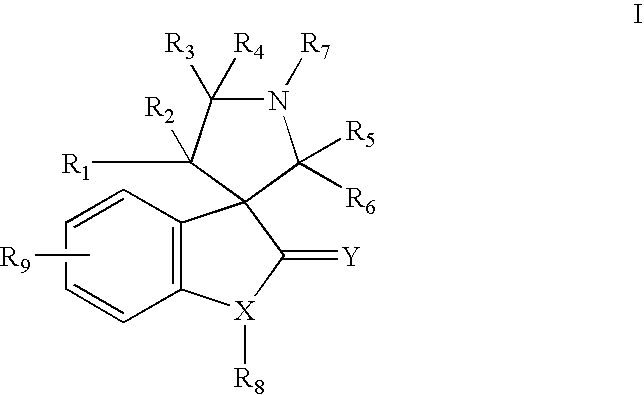

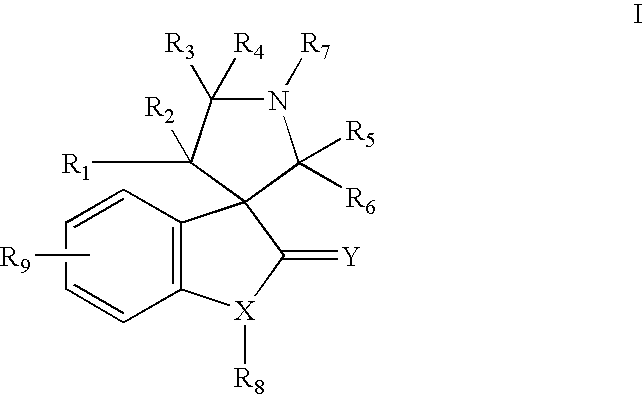

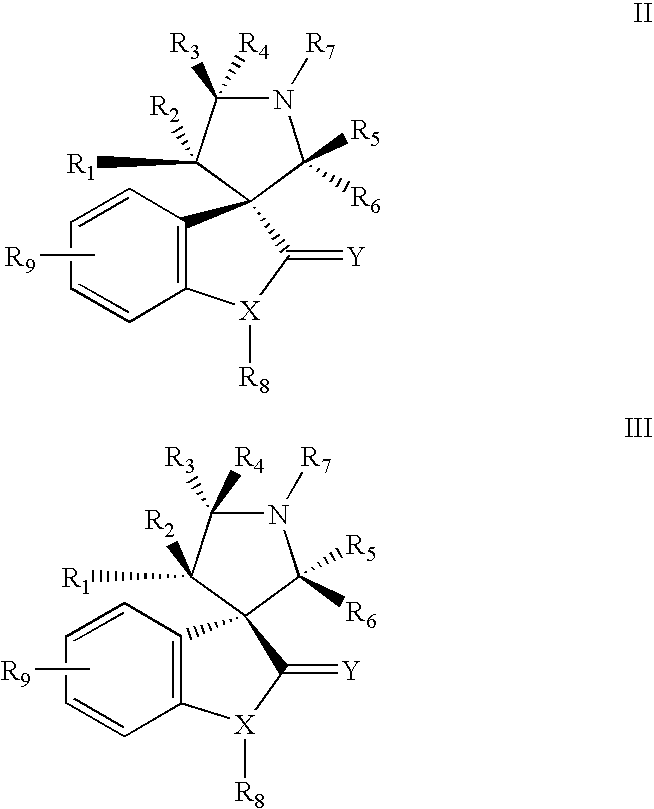

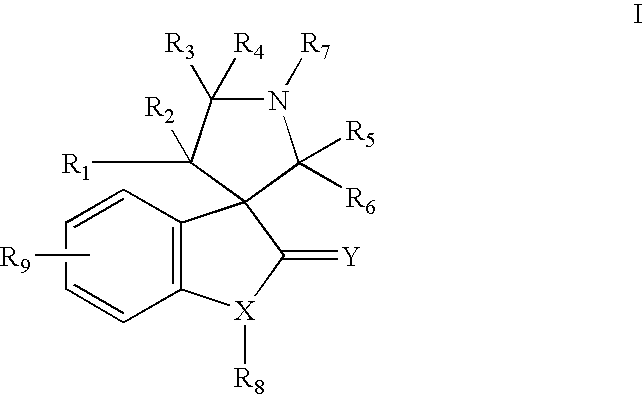

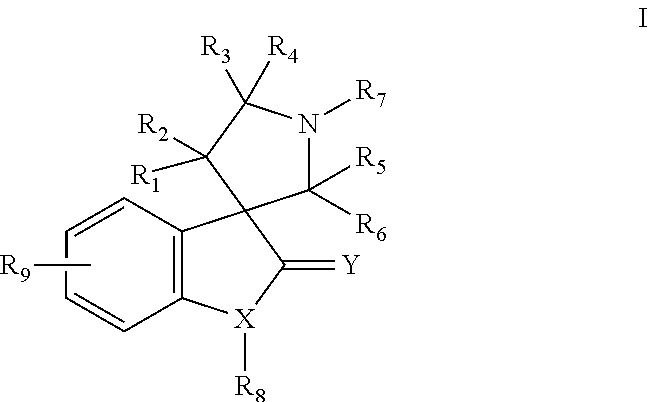

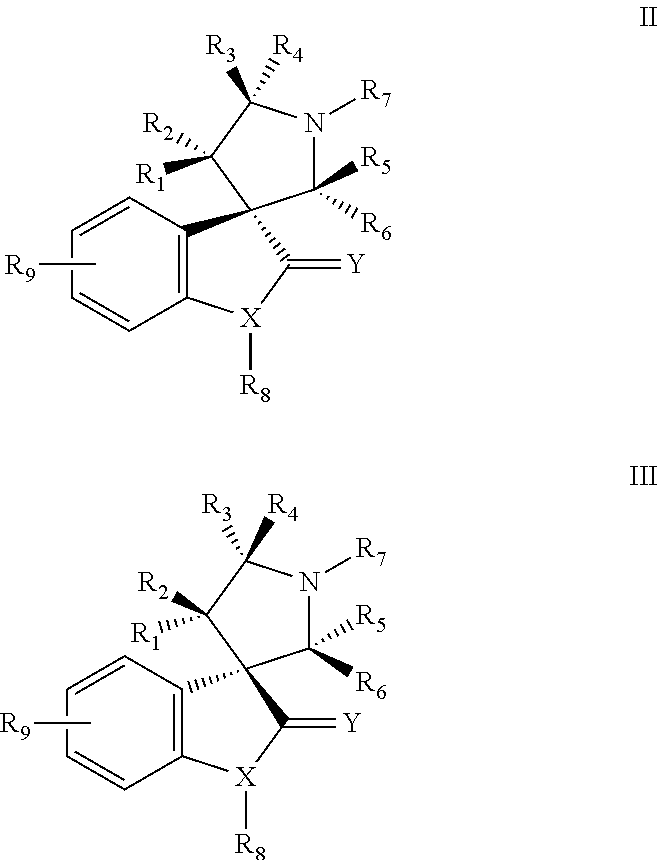

Conformationally Constrained Smac Mimetics and the Uses Thereof

ActiveUS20080269140A1High expressionToxic reductionDipeptide ingredientsTripeptide ingredientsSmac mimeticsSensitized cell

The invention relates to conformationally constrained mimetics of Smac which function as inhibitors of Inhibitor of Apoptosis Proteins. The invention also relates to the use of these mimetics for inducing apoptotic cell death and for sensitizing cells to inducers of apoptosis.

Owner:RGT UNIV OF MICHIGAN

Adoptive immunotherapy using macrophages sensitized with heat shock protein-epitope complexes

InactiveUS6156302AEnhancing host 's immunocompetenceHigh activityBiocideOrganic active ingredientsDiseaseInterleukin 6

The present invention relates to methods and compositions for enhancing immunological responses and for the prevention and treatment of infectious diseases or primary and metastatic neoplastic diseases based on the administration of macrophages and / or other antigen presenting cells (APC) sensitized with heat shock proteins non-covalently bound to peptide complexes and / or antigenic components. APC are incubated in the presence of hsp-peptide complexes and / or antigenic components in vitro. The sensitized cells are reinfused into the patient with or without treatment with cytokines including but not limited to interferon- alpha , interferon- alpha , interleukin-2, interleukin-4, interleukin-6 and tumor neurosis factor.

Owner:FORDHAM UNIVERSITY

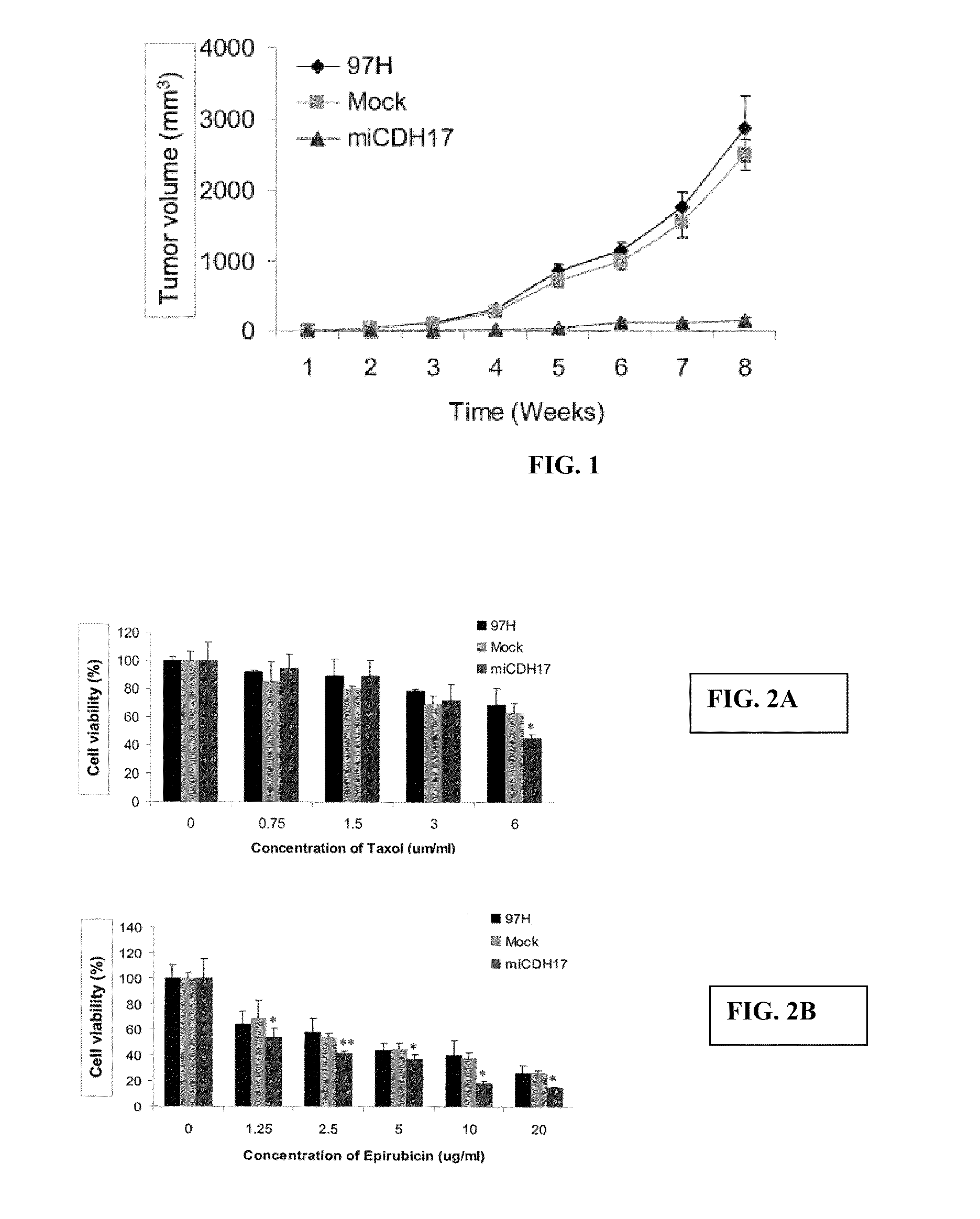

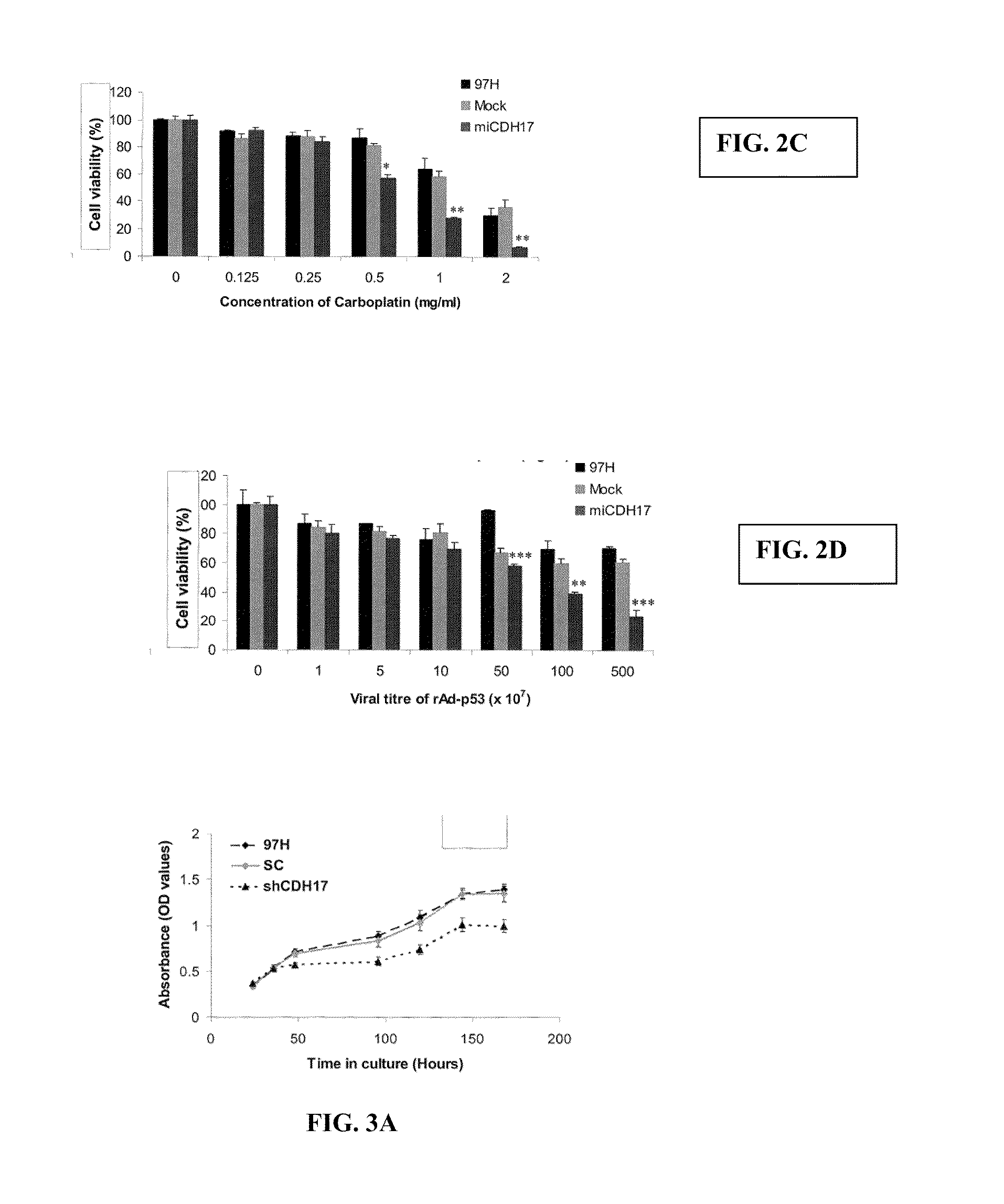

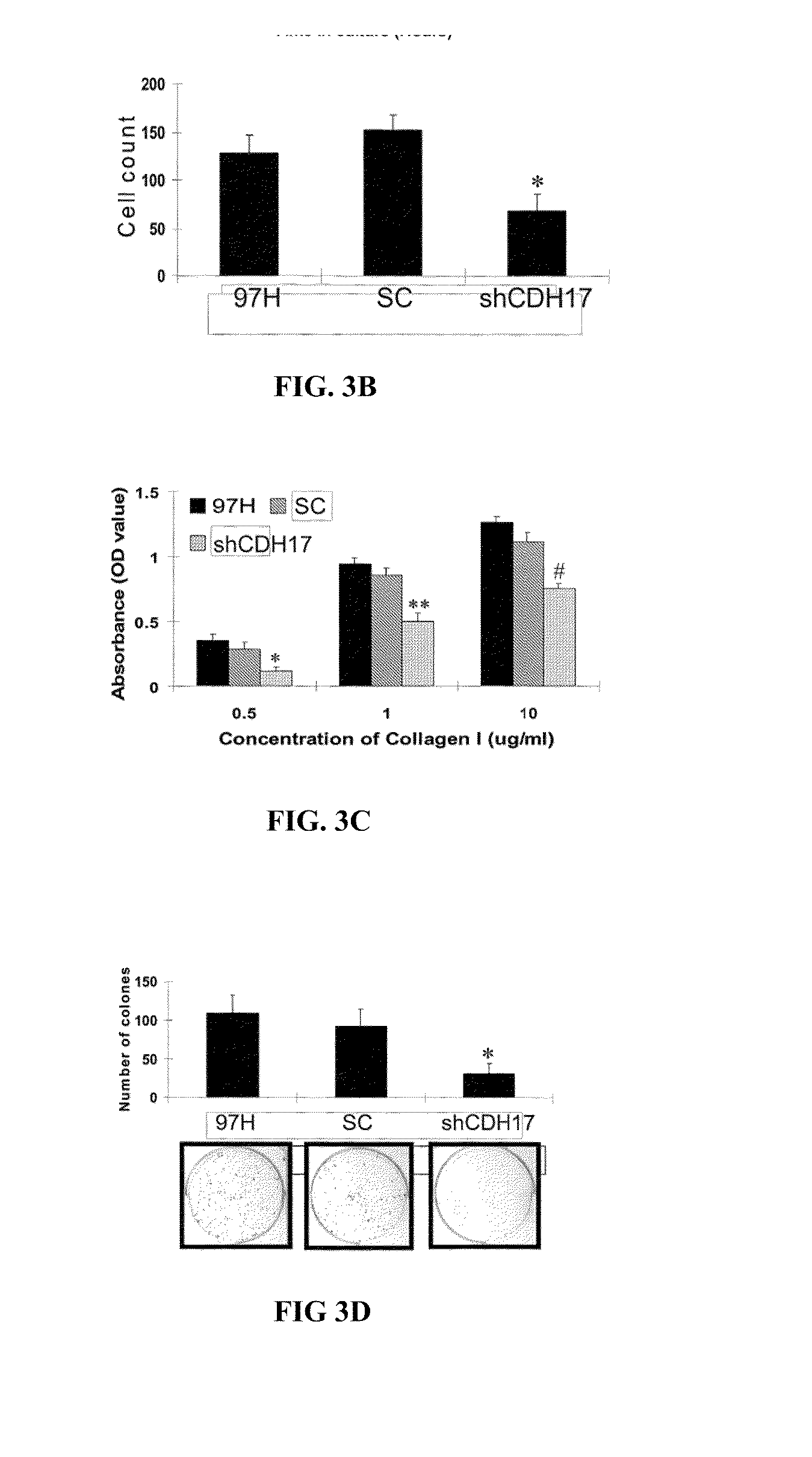

Cadherin-17 as diagnostic marker and therapeutic target for liver cancer

ActiveUS20100092978A1Inhibit expressionInhibit progressSugar derivativesMicrobiological testing/measurementCancer preventionBacteriuria

Compositions and methods for diagnosing, treating and / or preventing cancers characterized by CDH17 overexpression based on the detection of CDH17 or the use of CDH17 as a target for therapeutic intervention or prophylactic intervention are provided. Methods for diagnosing and / or monitoring liver cancers using the expressing of CDH17 involve detecting and / or quantitating the CDH17 protein or encoding nucleic acids (DNA or RNA) in a biological sample such as urine from the subject. Methods for treating liver cancers using CDH17 as a target and of sensitizing cells with aberrant expression of CDH17 have also been developed. The methods include suppression or knockdown of the expression of CDH17 by administering an effective amount of a CDH17 inhibitor.

Owner:THE UNIVERSITY OF HONG KONG

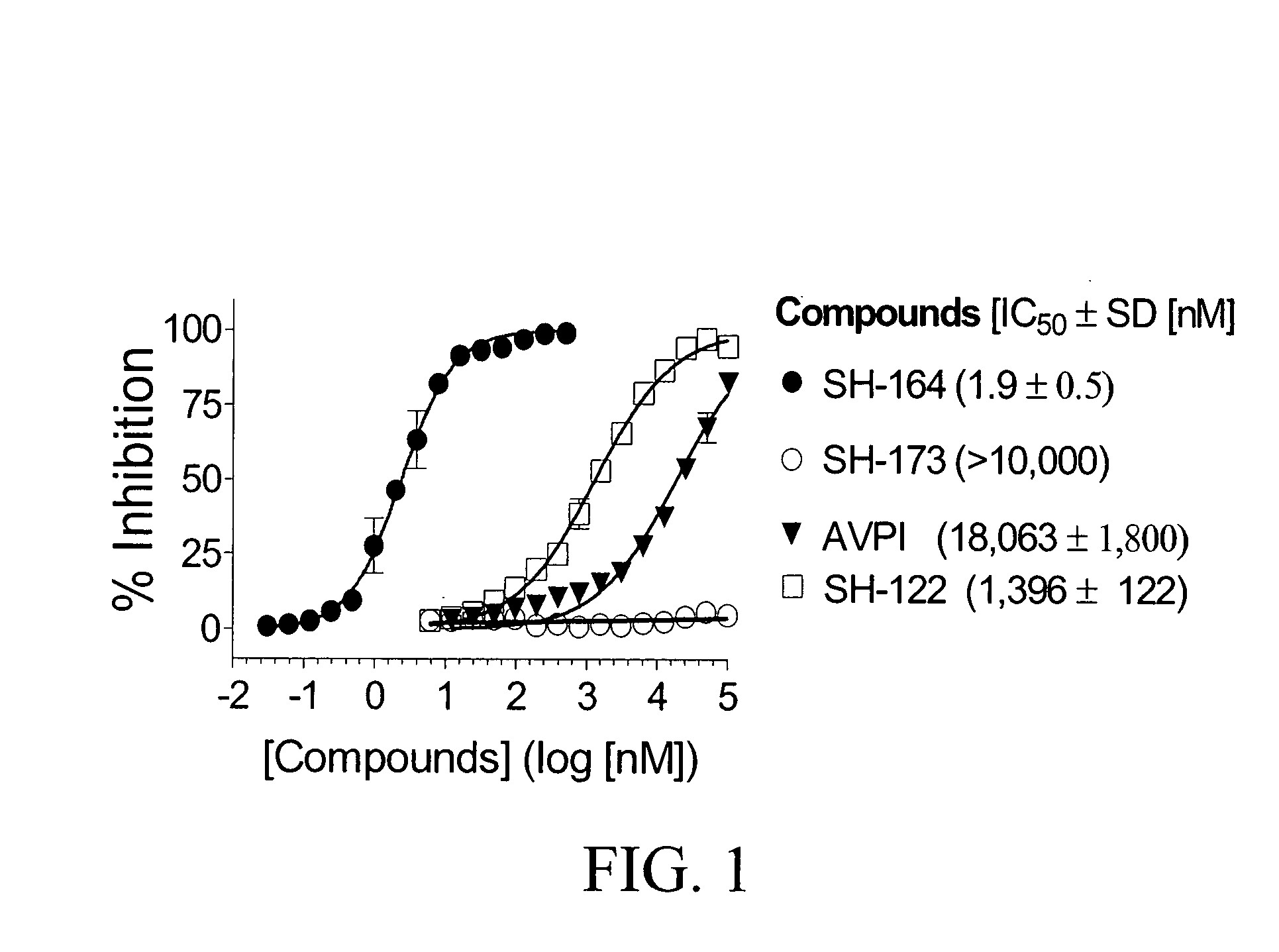

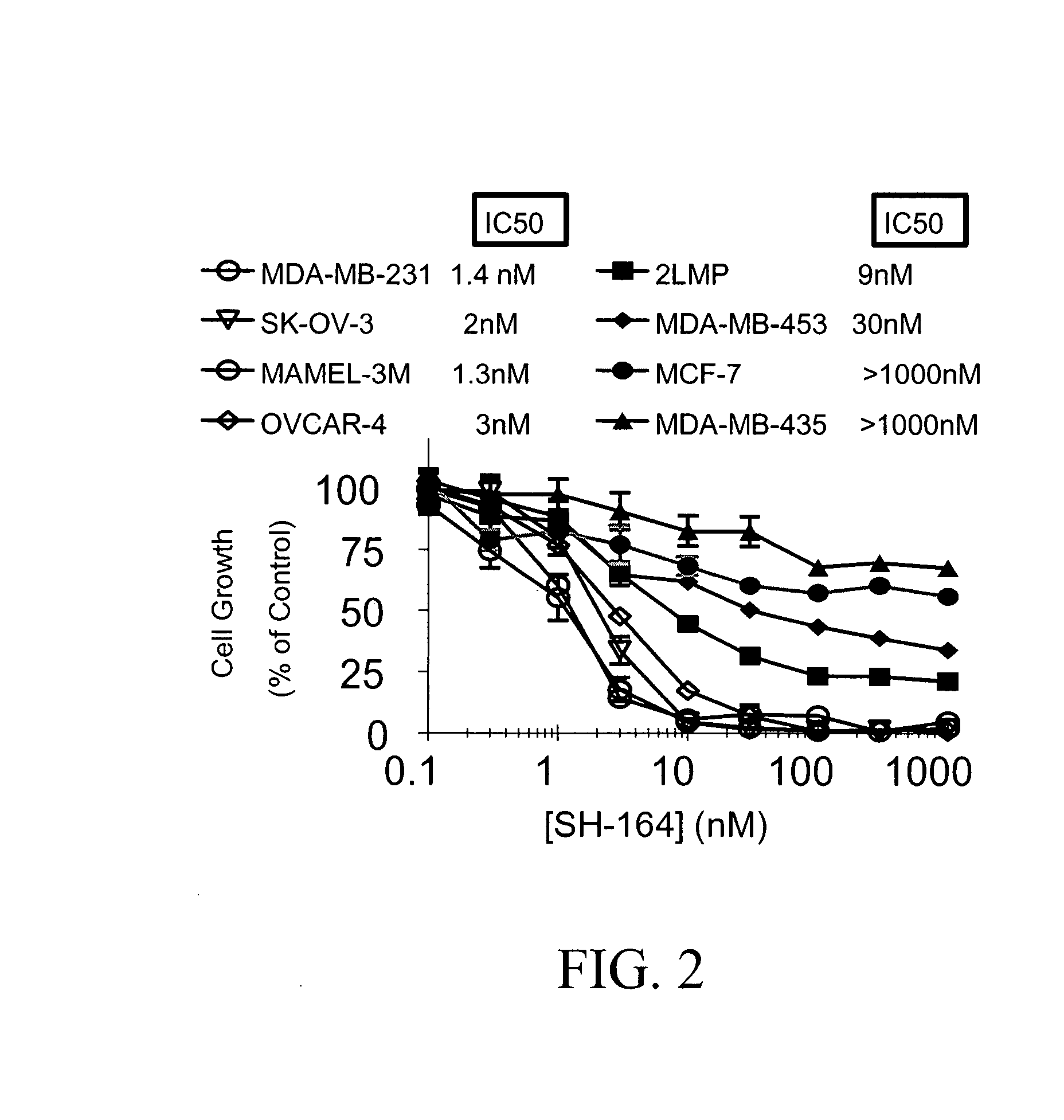

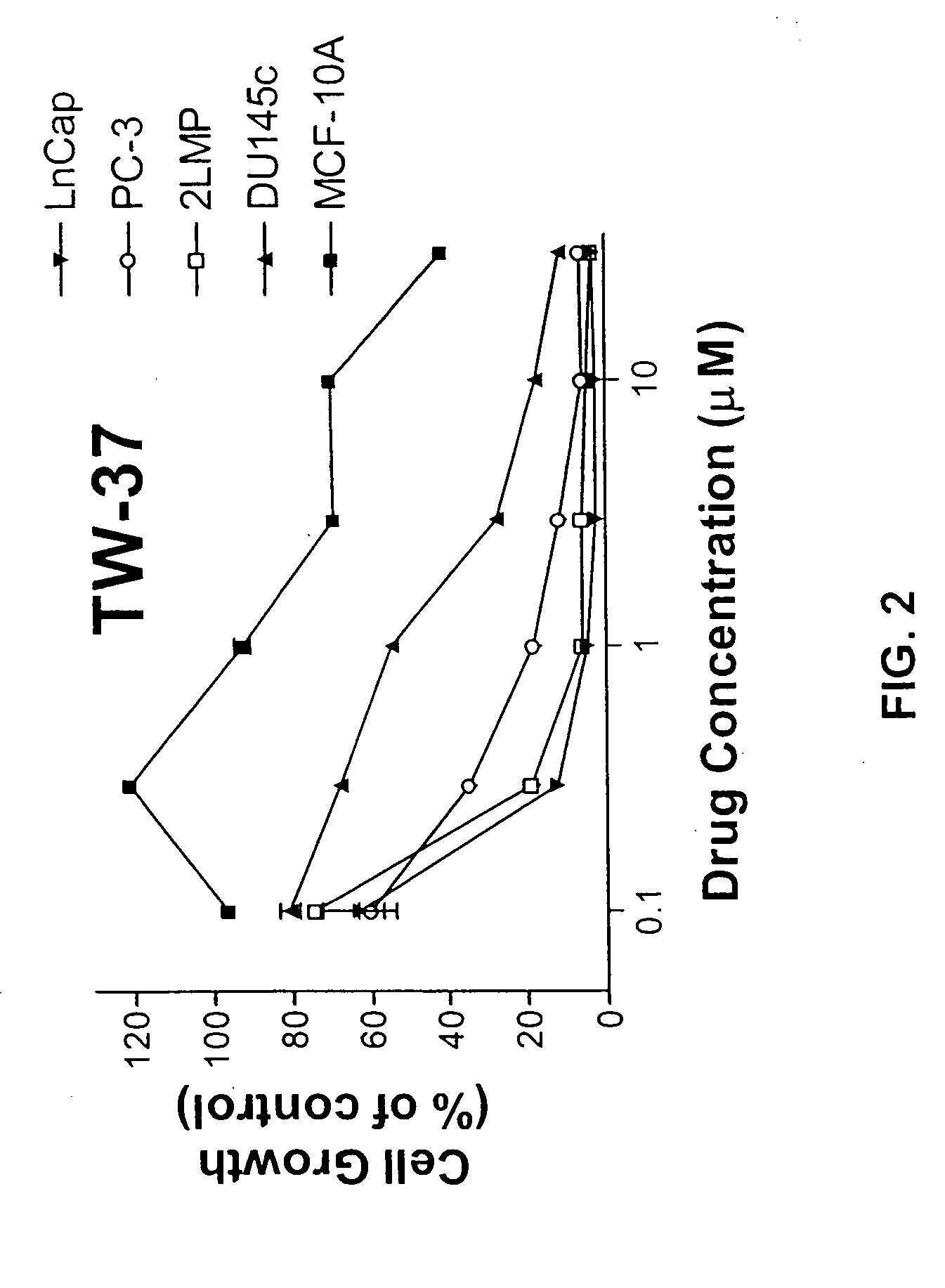

Small molecule inhibitors of anti-apoptotic BCL-2 family members and the uses thereof

ActiveUS20060084647A1Great clinical benefitGreat tumor responseUrea derivatives preparationBiocideSensitized cellBcl-2 Genes

The invention relates to small molecules which function as inhibitors of anti-apoptotic Bcl-2 family member proteins (e.g., Bcl-2 and Bcl-xL). The invention also relates to the use of these compounds for inducing apoptotic cell death and sensitizing cells to the induction of apoptotic cell death.

Owner:RGT UNIV OF MICHIGAN

Small molecule inhibitors of MDM2 and the uses thereof

InactiveUS20060211757A1Growth inhibitionExtended half-lifeBiocideOrganic chemistrySensitized cellMdm2 Protein

Owner:RGT UNIV OF MICHIGAN

Bivalent smac mimetics and the uses thereof

ActiveUS20090123480A1Toxic reductionMore tolerableBiocideOrganic chemistrySmac mimeticsSensitized cell

The invention relates to bivalent mimetics of Smac which function as inhibitors of Inhibitor of Apoptosis Proteins. The invention also relates to the use of these mimetics for inducing apoptotic cell death and for sensitizing cells to inducers of apoptosis.

Owner:RGT UNIV OF MICHIGAN

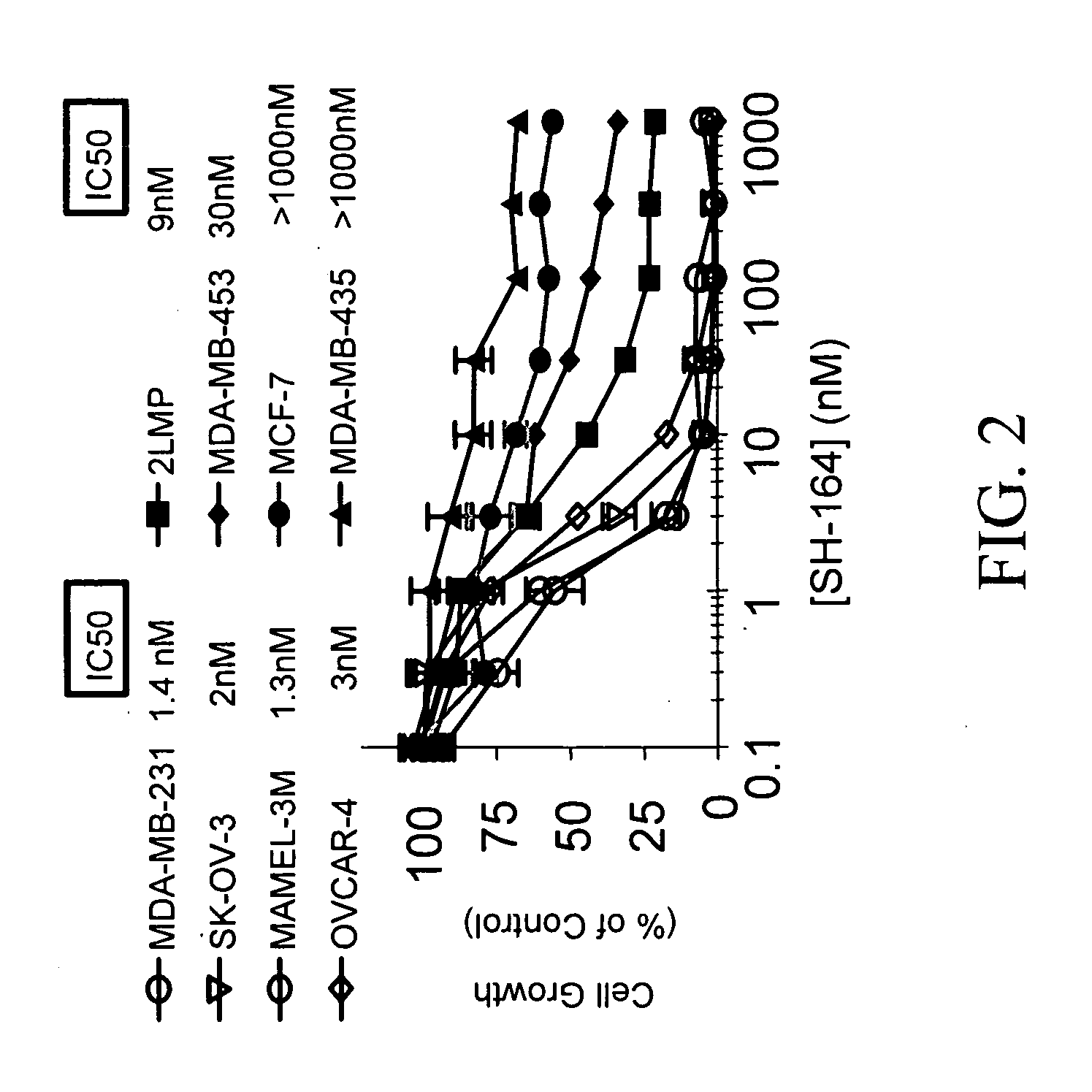

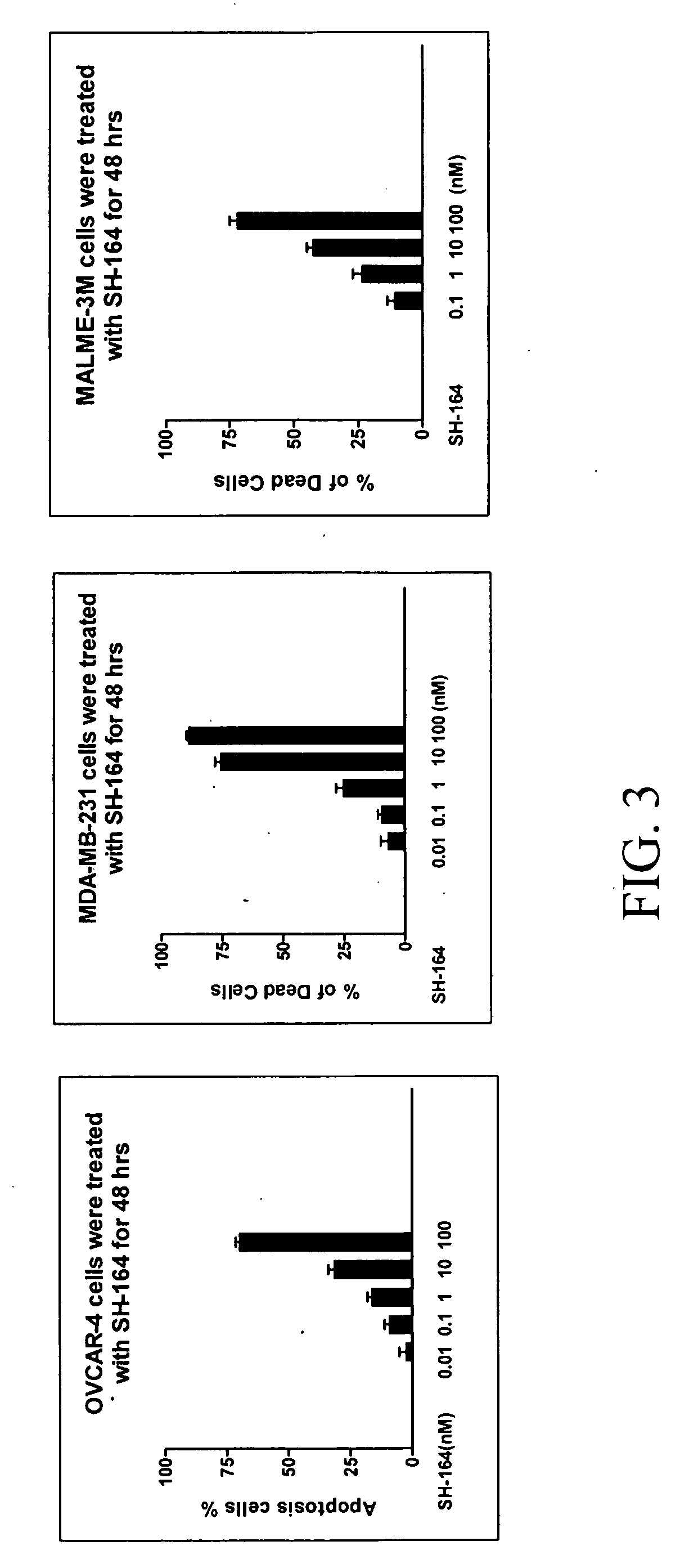

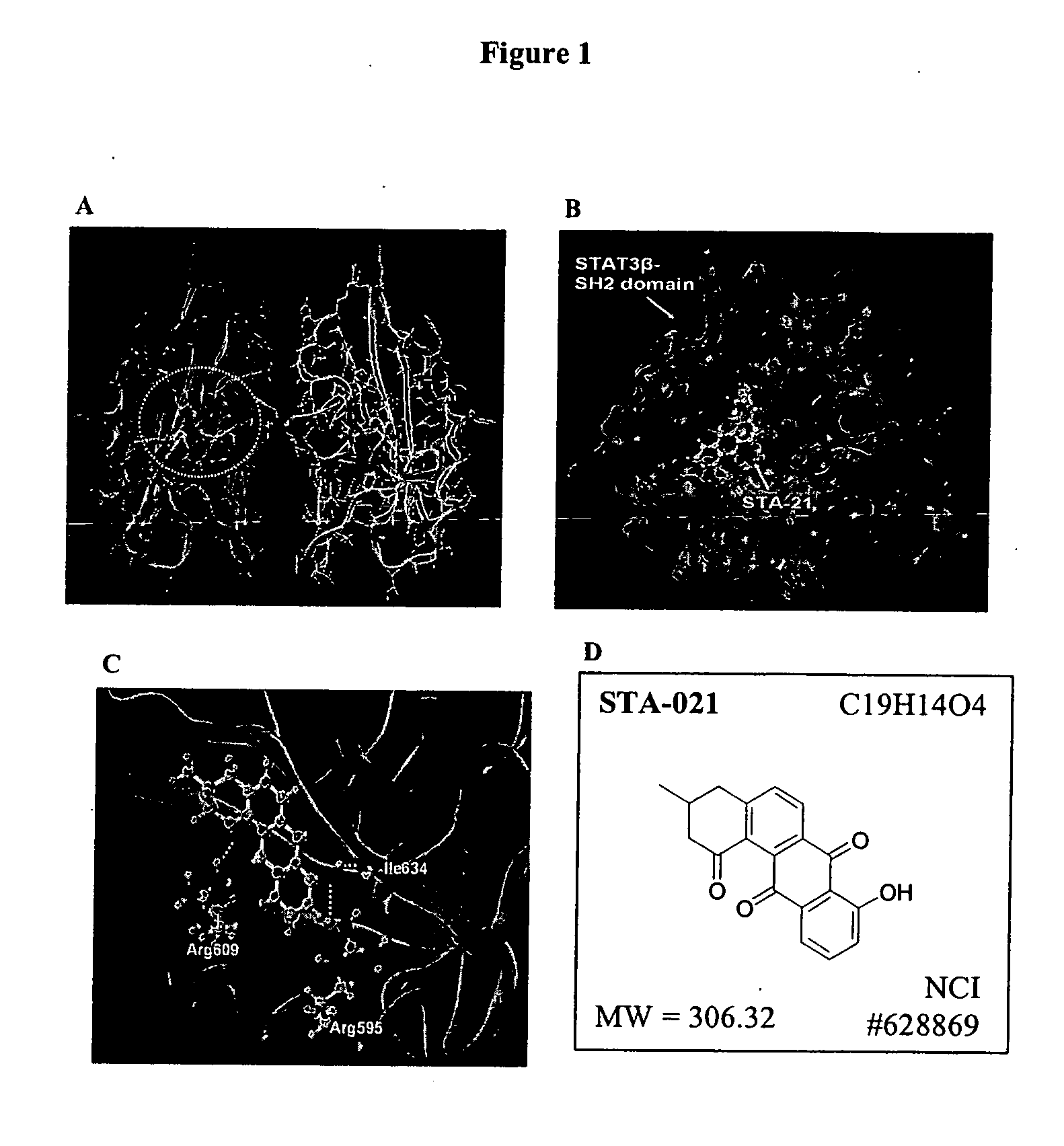

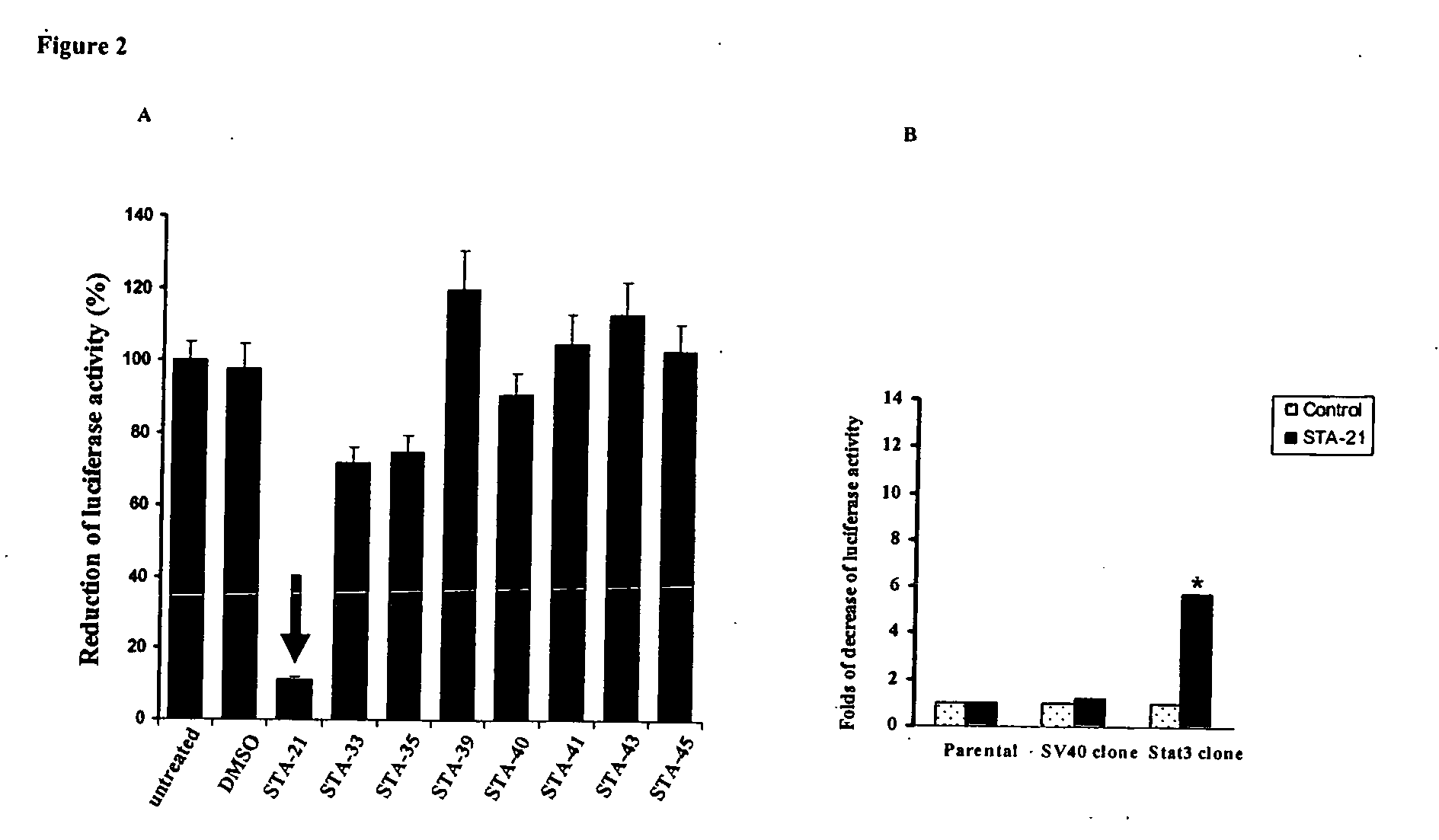

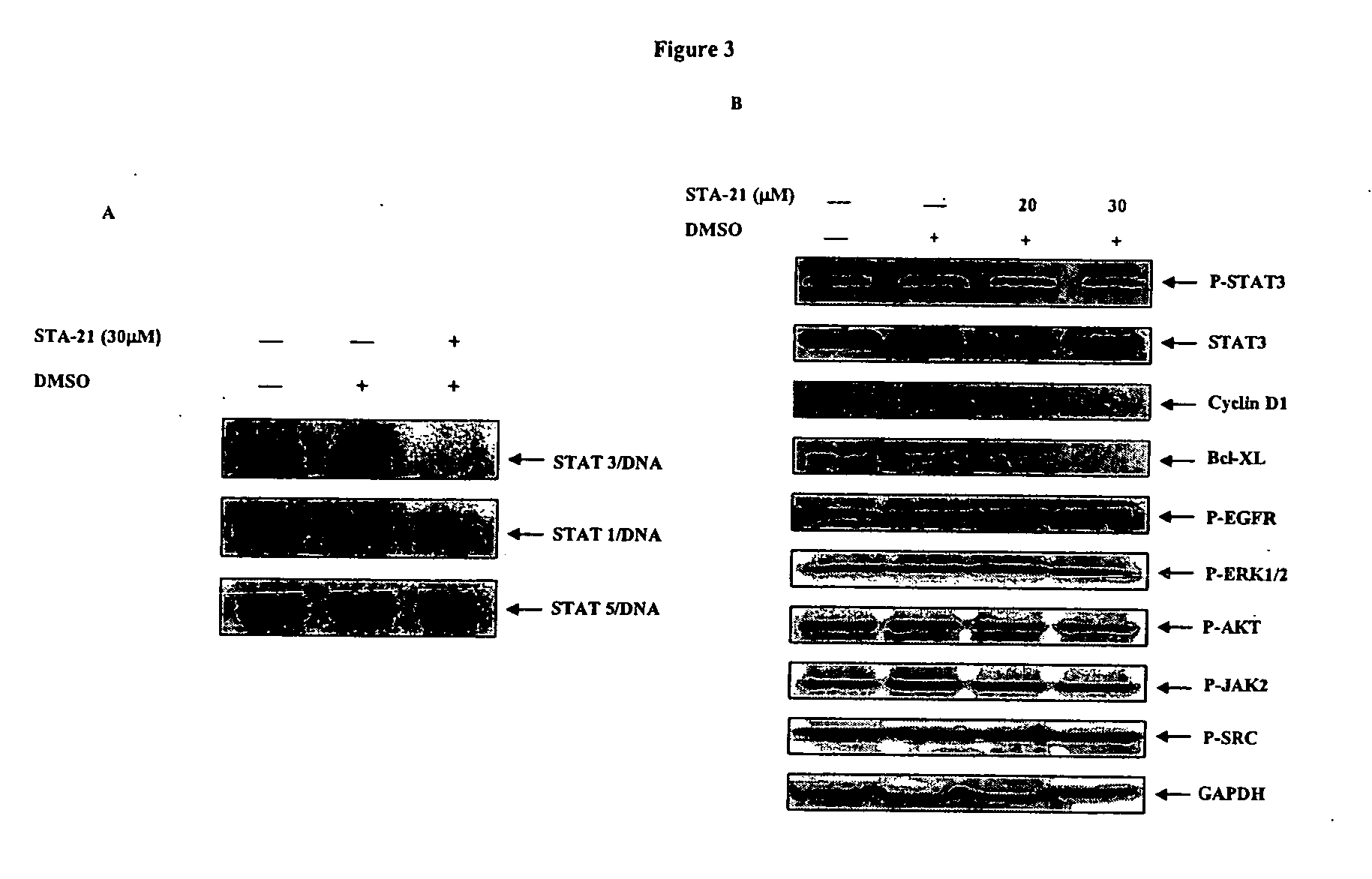

Small molecule inhibitors of STAT3 and the uses thereof

InactiveUS20060247318A1Great clinical benefitGreat tumor responseBiocideKetone active ingredientsSensitized cellStat3 inhibitor

Owner:RGT UNIV OF MICHIGAN

Conformationally Constrained Smac Mimetics And The Uses Thereof

InactiveUS20080132485A1Toxic reductionMore tolerableBiocideOrganic chemistrySmac mimeticsSensitized cell

The invention relates to conformationally constrained mimetics of Smac which function as inhibitors of Inhibitor of Apoptosis Proteins. The invention also relates to the use of these mimetics for inducing apoptotic cell death and for sensitizing cells to inducers of apoptosis.

Owner:RGT UNIV OF MICHIGAN

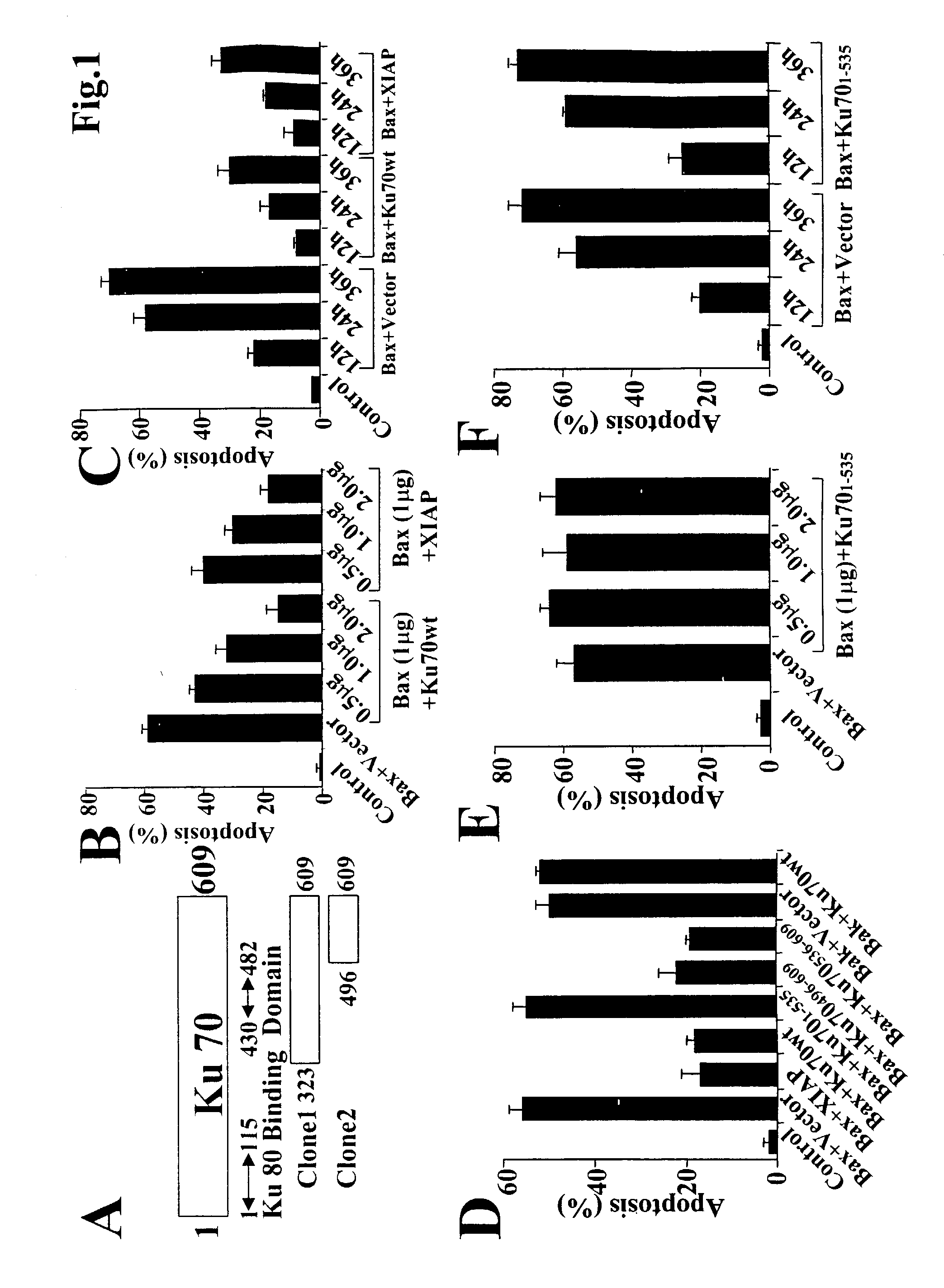

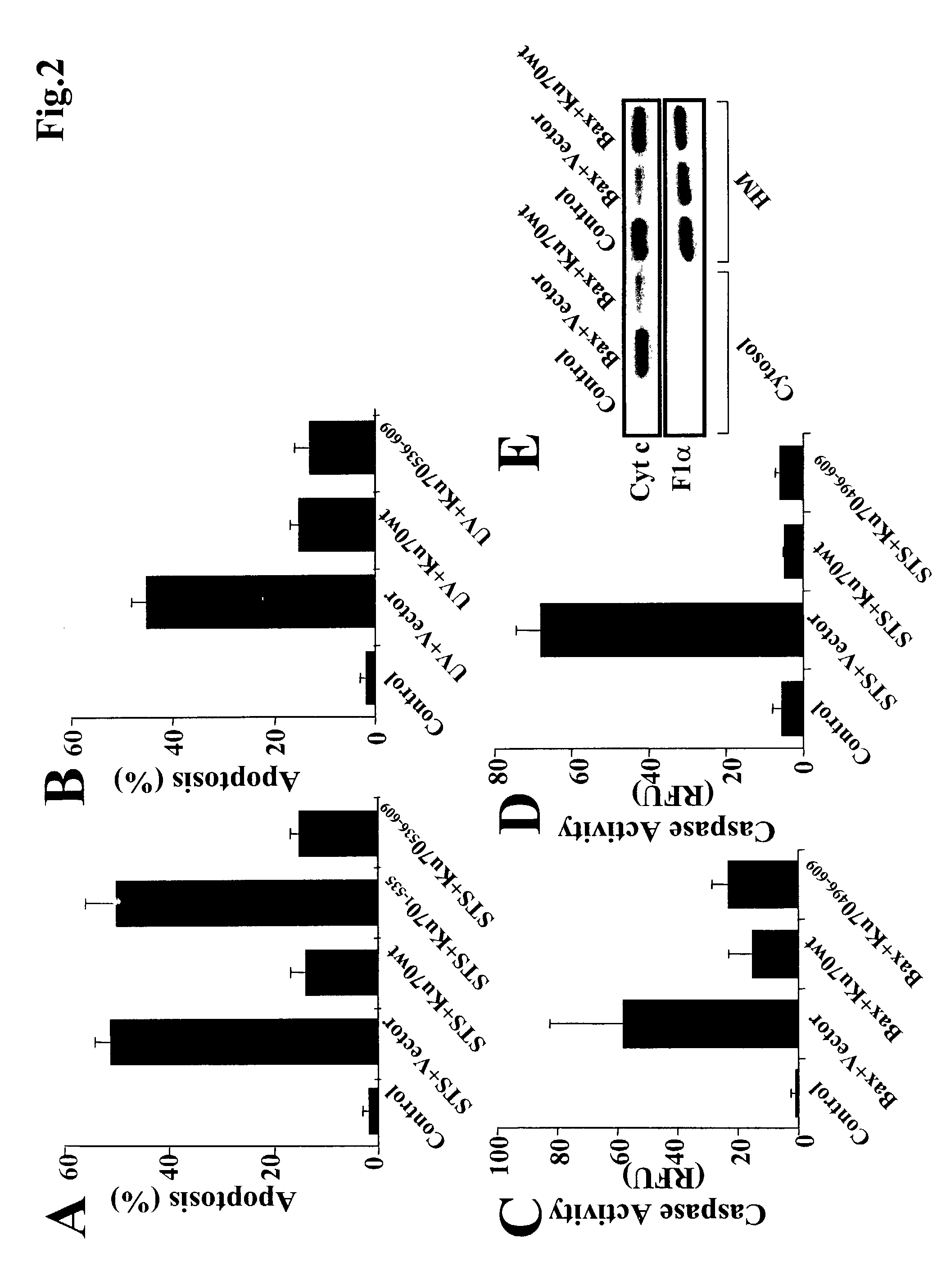

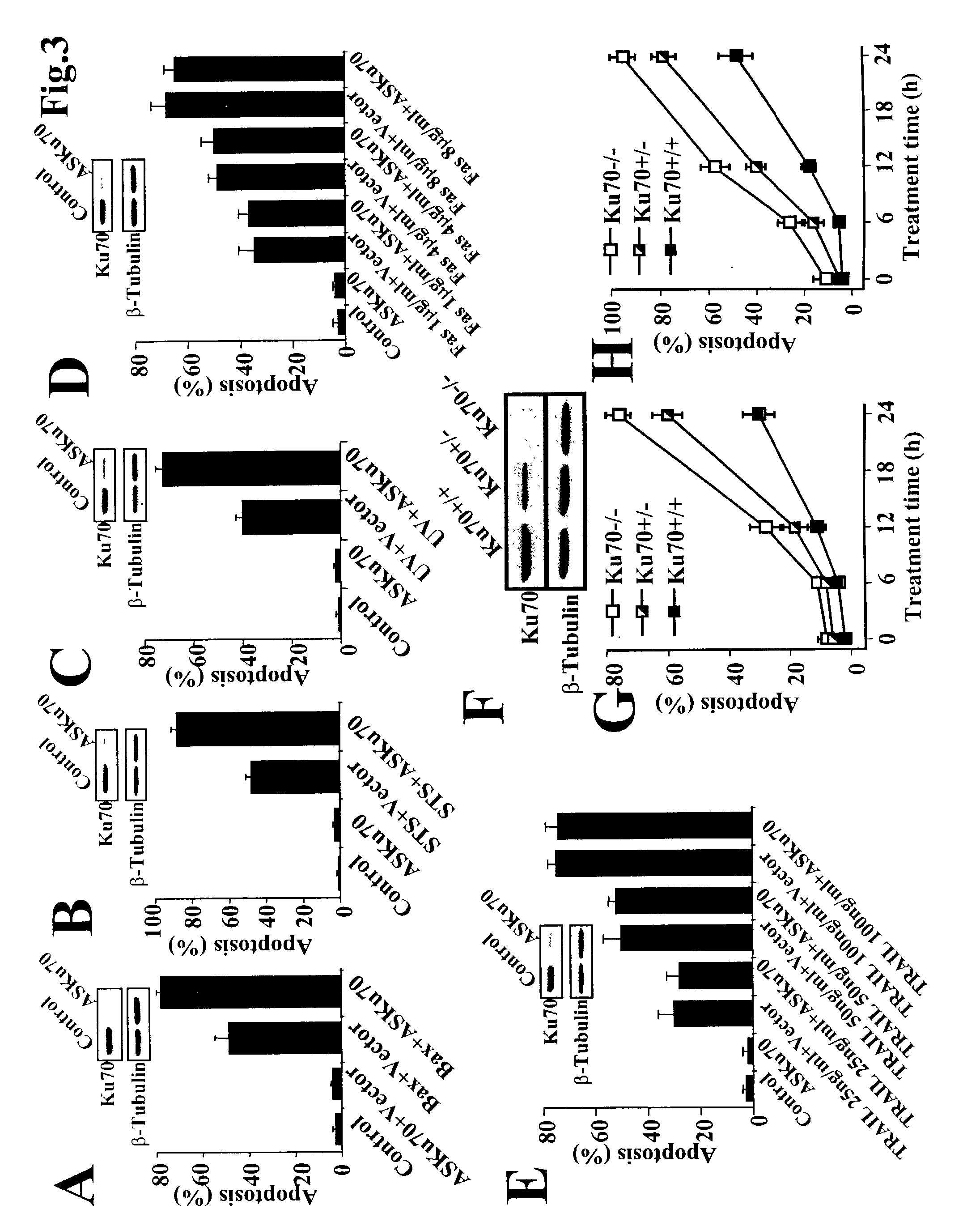

Method of modulating or examining Ku70 levels in cells

A method of predicting whether cells would respond to therapies which are mediated through Bax-regulated apoptosis is disclosed. In one embodiment, the method comprises the step of: (a) examining the intensity of the expression of the Bax protein or mRNA in a cell relative to a control, and (b) based on that intensity level, predicting whether cells will respond to therapies which are mediated through Bax-regulated apoptosis, wherein a high Bax level indicates that one may lower Ku70 levels and increase sensitivity to apoptosis. In another embodiment, the invention is a method of sensitizing cells to cancer therapy, comprising the step of reducing the cell's native Ku70 protein level. In another embodiment the invention is method of treating cell death-related diseases comprising the step of increasing cellular Ku70 protein level.

Owner:VERSITI BLOOD RES INST FOUND INC

New small molecule inhibitors of mdm2 and the uses thereof

InactiveUS20080125430A1Growth inhibitionExtended half-lifeBiocideOrganic chemistrySensitized cellMdm2 Protein

Owner:RGT UNIV OF MICHIGAN

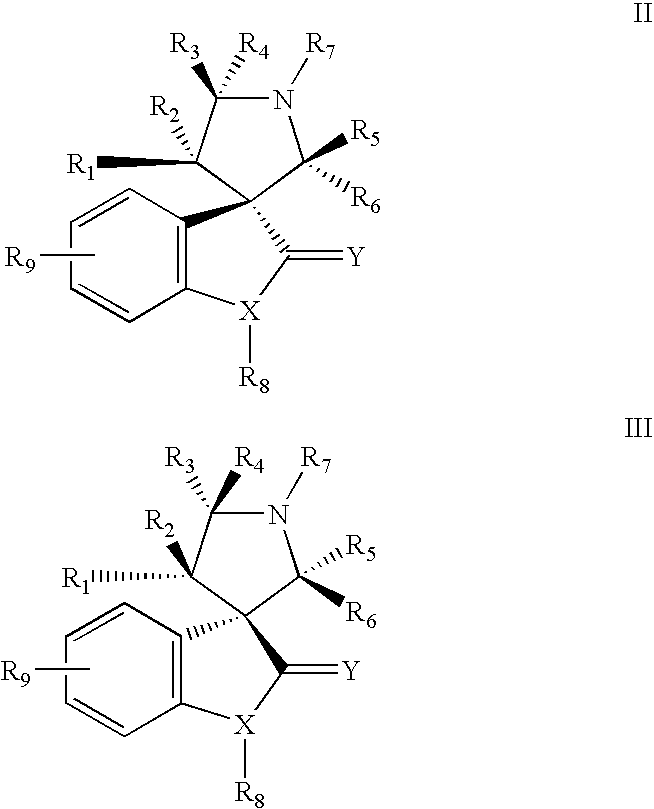

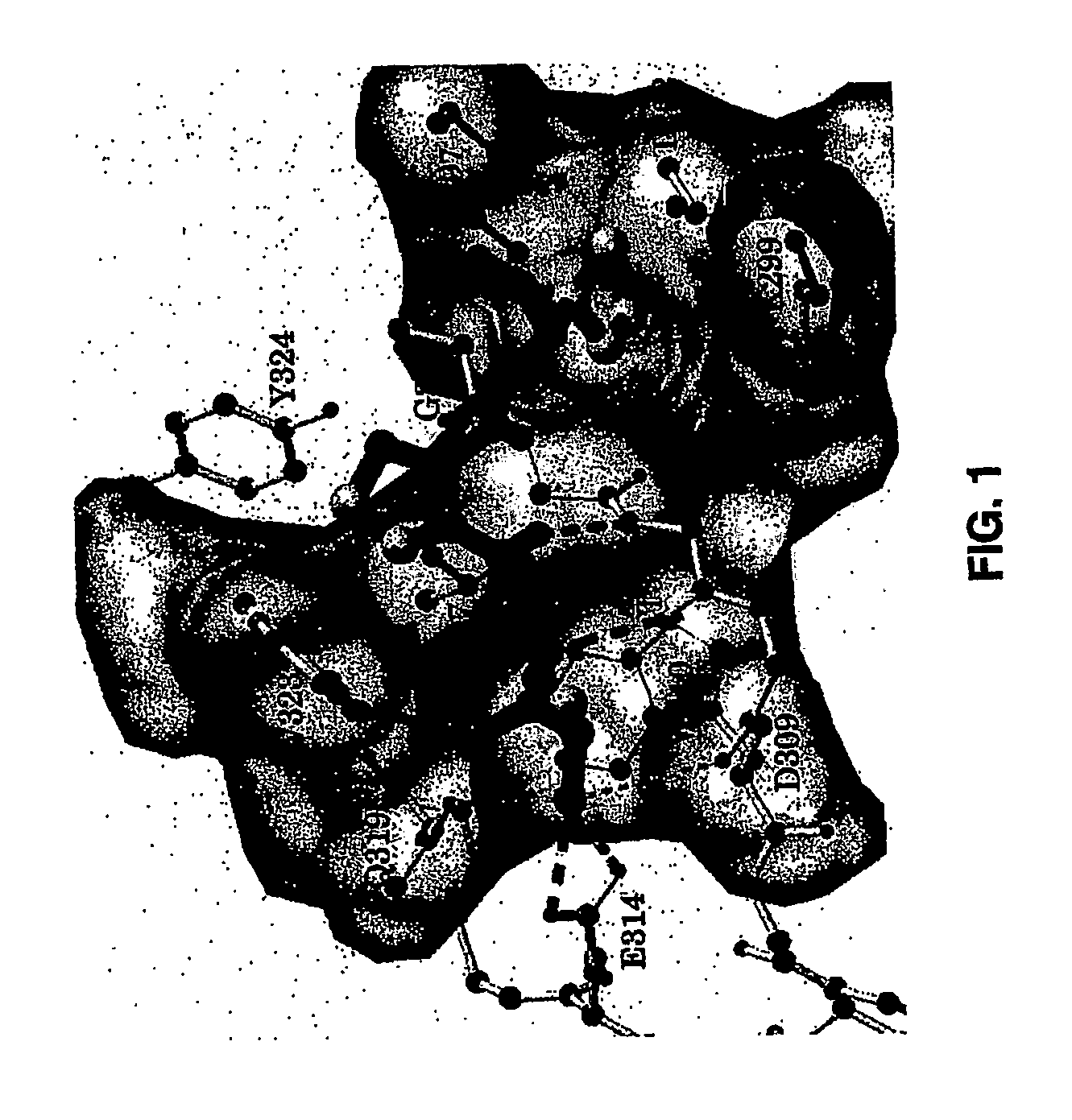

Conformationally constrained Smac mimetics and the uses thereof

InactiveUS7674787B2Toxic reductionMore tolerableBiocideOrganic chemistrySmac mimeticsSensitized cell

The invention relates to conformationally constrained mimetics of Smac which function as inhibitors of Inhibitor of Apoptosis Proteins. The invention also relates to the use of these mimetics for inducing apoptotic cell death and for sensitizing cells to inducers of apoptosis.

Owner:RGT UNIV OF MICHIGAN

Conformationally constrained Smac mimetics and the uses thereof

ActiveUS7932382B2Toxic reductionMore tolerableAntineoplastic agentsHeterocyclic compound active ingredientsSmac mimeticsSensitized cell

The invention relates to conformationally constrained mimetics of Smac which function as inhibitors of Inhibitor of Apoptosis Proteins. The invention also relates to the use of these mimetics for inducing apoptotic cell death and for sensitizing cells to inducers of apoptosis.

Owner:RGT UNIV OF MICHIGAN

Bivalent Smac mimetics and the uses thereof

Owner:RGT UNIV OF MICHIGAN

Small molecule inhibitors of MDM2 and the uses thereof

InactiveUS8222288B2Growth inhibitionExtended half-lifeBiocideOrganic chemistrySensitized cellCell growth

Owner:RGT UNIV OF MICHIGAN

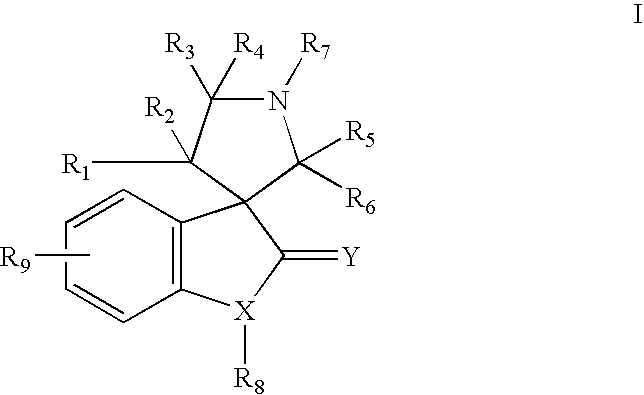

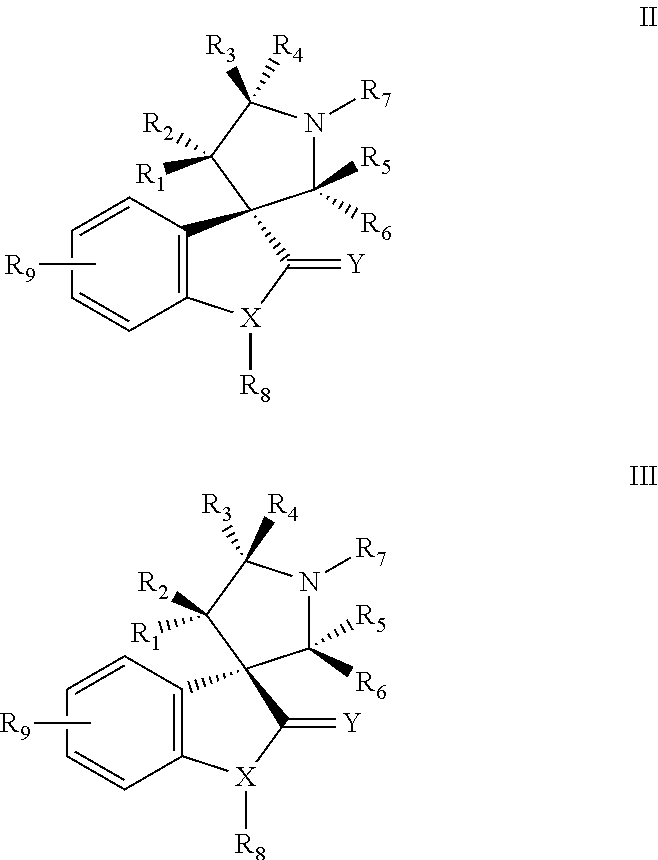

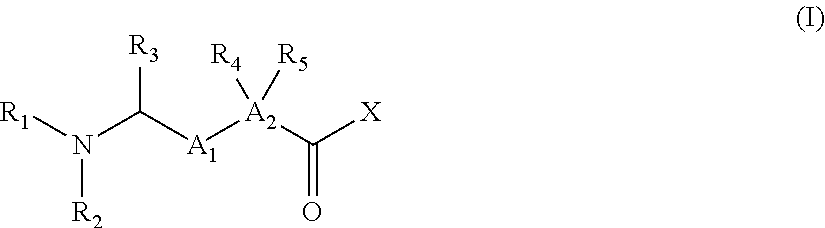

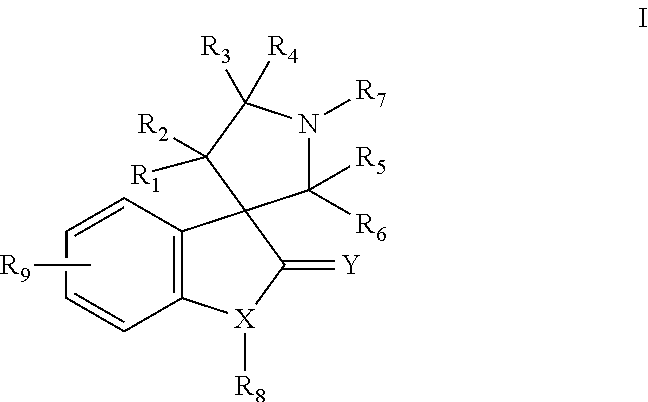

Iap binding compounds

The present invention relates to compounds of formula (I), or pharmaceutically acceptable salts, solvates or prodrugs thereof, that bind to Inhibitor of Apoptosis Proteins (IAPs). The compounds of the invention may be used as diagnostic and therapeutic agents in the treatment of proliferative diseases, such as cancer, for promoting apoptosis in proliferating cells, and for sensitizing cells to inducers of apoptosis. The present invention furthermore provides a polymeric compound of formulas (VI) or (VII), comprising either at least two monomeric units of compounds of formula (I), or at least one monomeric unit of a compound of formula (I) and an entity E. The present invention further relates to pharmaceutical compositions comprising said compounds of formulas (I), (VI), and (VII) and the use of said compounds in medicine.

Owner:NUEVOLUTION AS

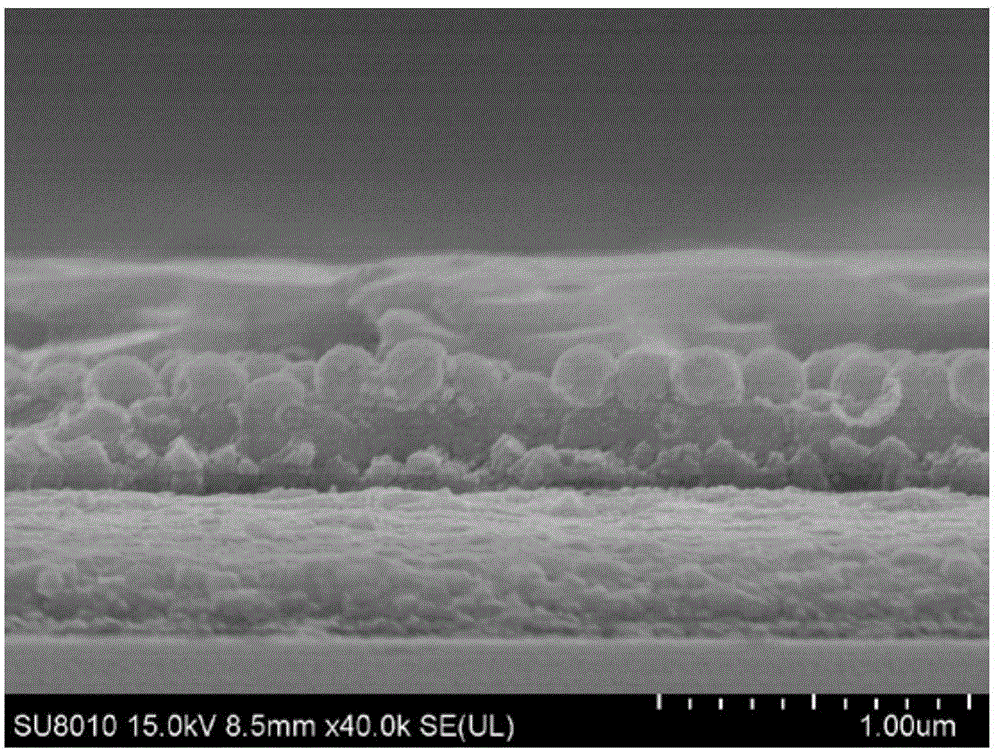

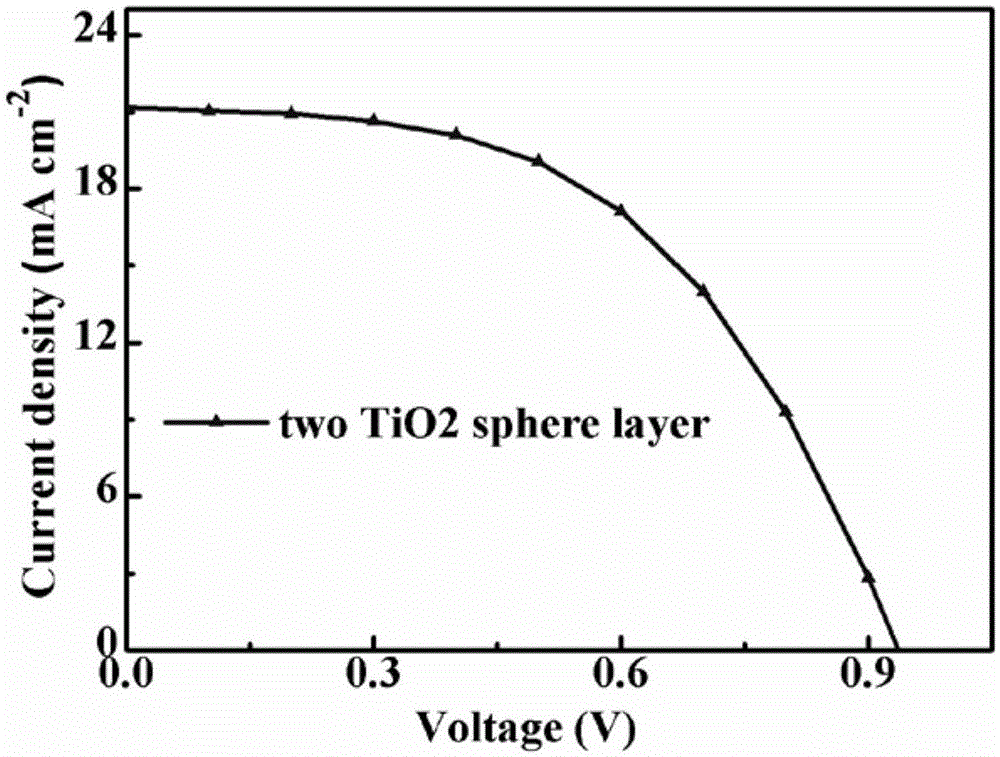

Perovskite solar cell composed of orderly-arranged small titanium dioxide balls and preparation method thereof

ActiveCN105118919AImprove performanceSimple structureSolid-state devicesSemiconductor/solid-state device manufacturingSensitized cellPhotonics

The invention discloses a perovskite solar cell composed of orderly-arranged small titanium dioxide balls and a preparation method thereof. Regularly-arranged small titanium dioxide balls are used as a carrier of the solar cell, and a perovskite material is used as a light absorber. The small titanium dioxide balls are distributed in a single layer or in multiple layers. The solar cell is prepared through atomic layer deposition. The small titanium dioxide balls form a titanium dioxide frame, and are used as a perovskite carrier and a light utilization layer at the same time. The advantages of different photonic crystals of the small titanium dioxide balls of different sizes are utilized, and the thickness of titanium dioxide is precisely controlled by an atomic layer deposition technology to enable synergy between light utilization and electron transport to be achieved. The utilization rate of light and the electron transport performance are improved, and the performance of the cell is greatly improved. The titanium dioxide structure of the invention can be applied to dye-sensitized cells, quantum dot cells, perovskite cells and other novel solar cells.

Owner:SUZHOU UNIV

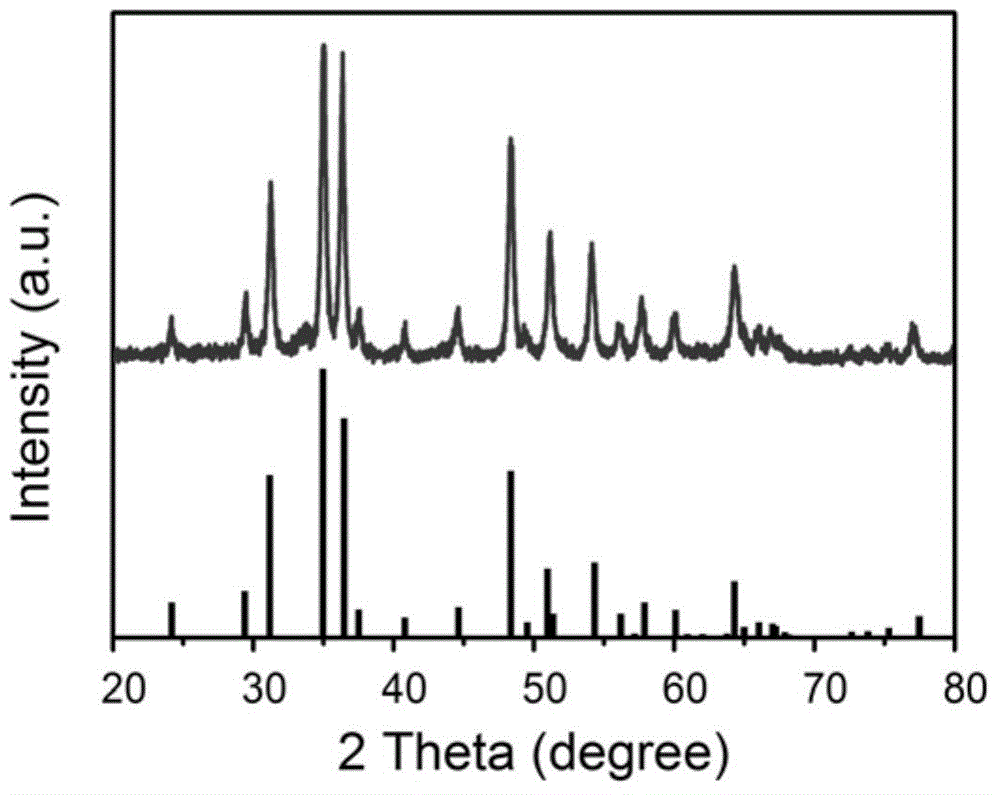

Nano titanium dioxide coated carbon nanotube reinforced carbon nanofiber and preparation method thereof

InactiveCN102634873AOne-dimensional continuityLarge specific surface areaArtificial filament chemical after-treatmentArtifical filament manufactureFiberSensitized cell

The invention discloses a nano titanium dioxide coated carbon nanotube reinforced carbon nanofiber which is characterized in that the surface layer is uniformly coated with anatase titanium dioxide particles with diameters of 1-100nm, the inside contains single-wall or multi-wall carbon nanotubes with diameters of 0.9-100nm, and the diameter of the carbon nanofiber is 30-700nm. The nano titanium dioxide coated carbon nanotube reinforced carbon nanofiber is prepared from the following components in percentage by mass: 0.05-25% of nano titanium dioxide, 0.05-30% of carbon nanotube and 45-99.9% of carbon fiber. With the features one-dimension continuity, high specific area and the like, the fiber has higher solution absorptivity and incident light diffuse reflection effect, has the characteristics of higher softness, higher conductivity and stronger workability than the titanium dioxide nanowire and nanofiber, and can effectively enhance the photoelectric conversion rate of the solar dye-sensitized cells.

Owner:JIANGNAN UNIV

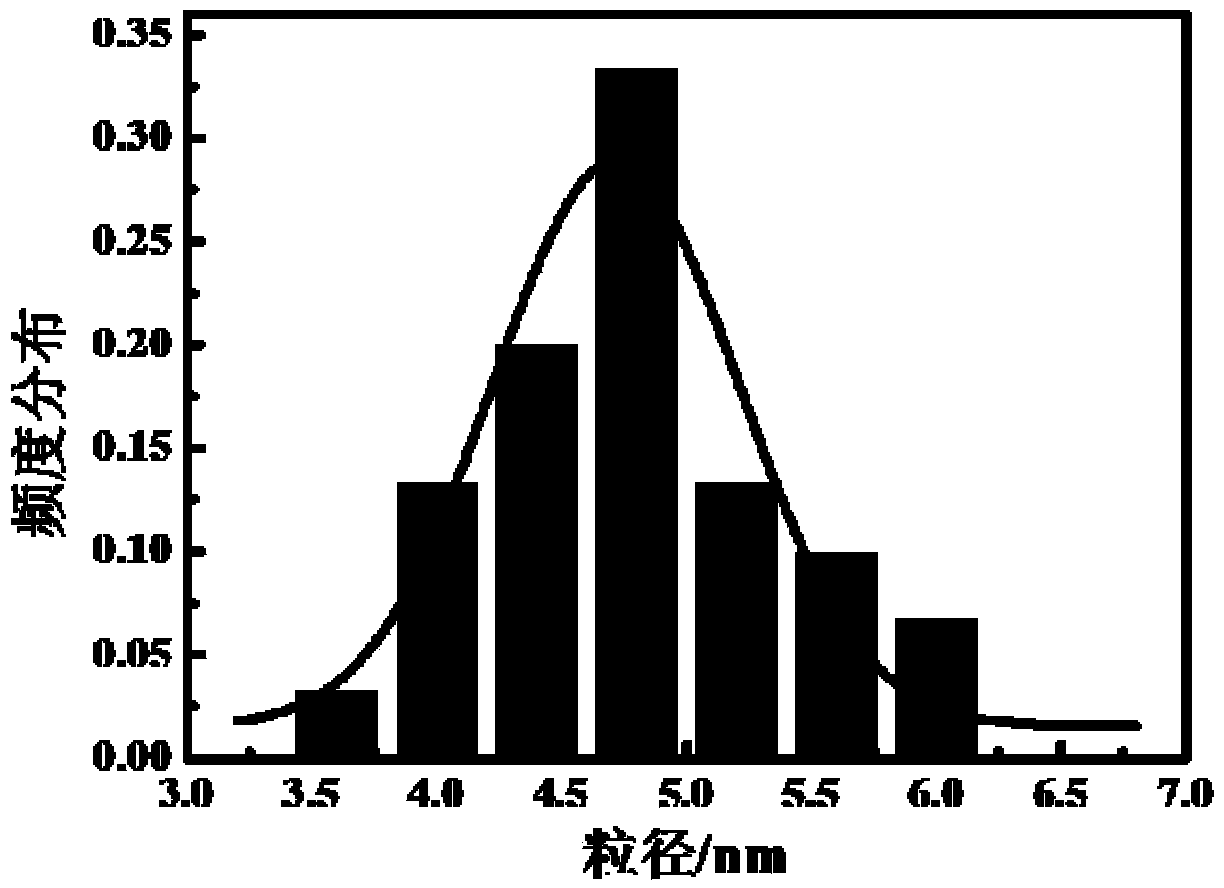

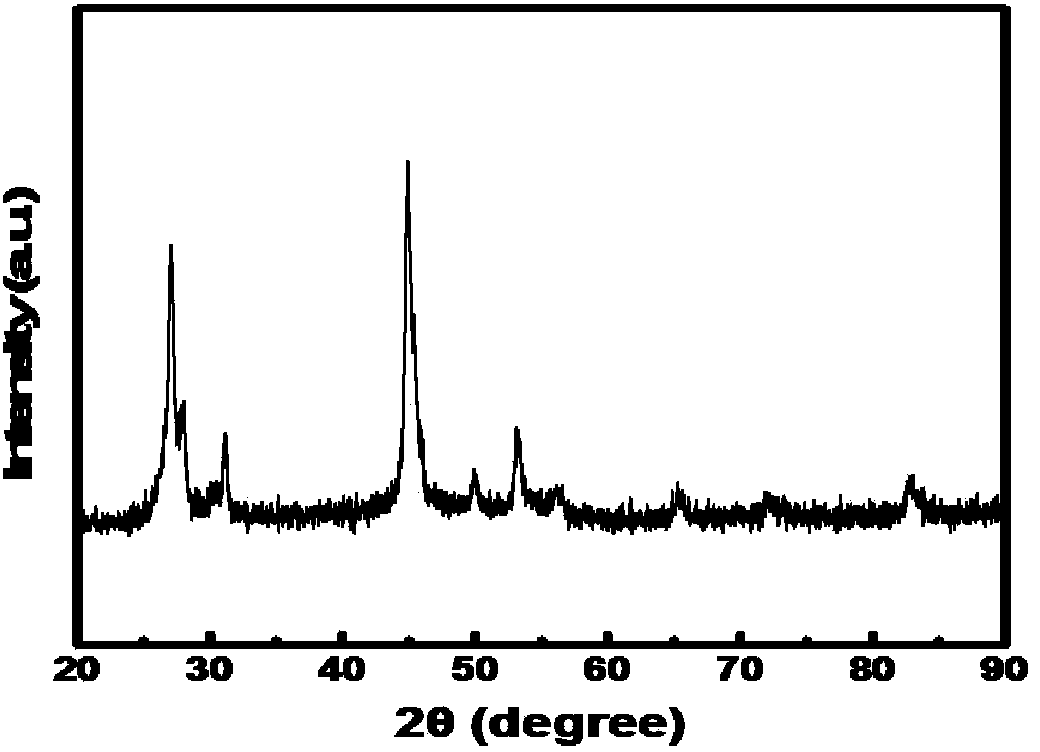

Copper selenide fluorescent quantum dot and preparation method and application thereof

InactiveCN103803511ASimple methodMild conditionsLight-sensitive devicesLuminescent compositionsQuantum yieldSensitized cell

The invention relates to a copper selenide fluorescent quantum dot and a preparation method and application thereof. The copper selenide fluorescent quantum dot is characterized in that the quantum dot is one of Cu2Se, CuSe and Cu(2-x)Se or a combination thereof; the particle size of the quantum dot is 2-10nm, the quantum yield is 10-60%, and the half-peak width of the photoluminescence spectrum is 30-150nm. The preparation method comprises the following steps: with an aqueous solution with copper salt dissolved in as an aqueous phase and an organic solvent with a long-chain ligand dissolved in as an oil phase, stirring in an inertia protective gas, and heating in an oil bath to form a precursor solution; pouring an aqueous solution of sodium hydrogen selenide into the hot precursor solution, and heating for reaction; sampling at different time to obtain organic-phase quantum dot solutions with different emission fluorescence; precipitating the upper-layer organic-phase quantum dot solution; centrifuging and dispersing, and repeating to remove unreacted raw materials to obtain the copper selenide fluorescent quantum dot. The quantum dot does not contain heavy metal elements such as cadmium and the like to realize low toxicity, has the advantages of high quantum yield, uniform particle size, relatively narrow fluorescence emission spectrum and adjustable light color along with excitation wavelength, and can be used for preparing quantum dot solar sensitized cells and LED (light-emitting diode) devices.

Owner:NANJING TECH UNIV

Small molecule inhibitors of mdm2 and the uses thereof

InactiveUS20100317661A1Extended half-lifeIncrease the function(s) of p53BiocideOrganic chemistrySensitized cellMdm2 Protein

Owner:RGT UNIV OF MICHIGAN

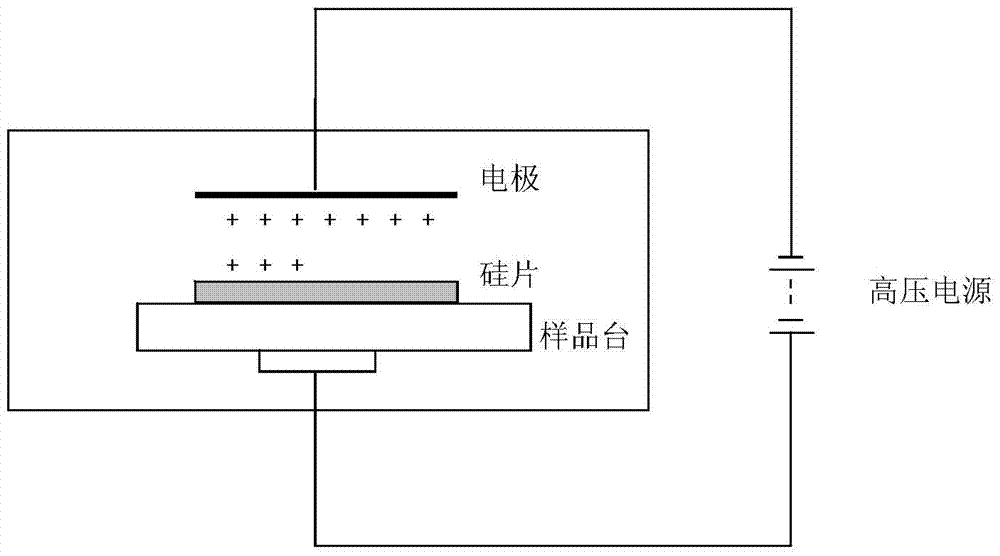

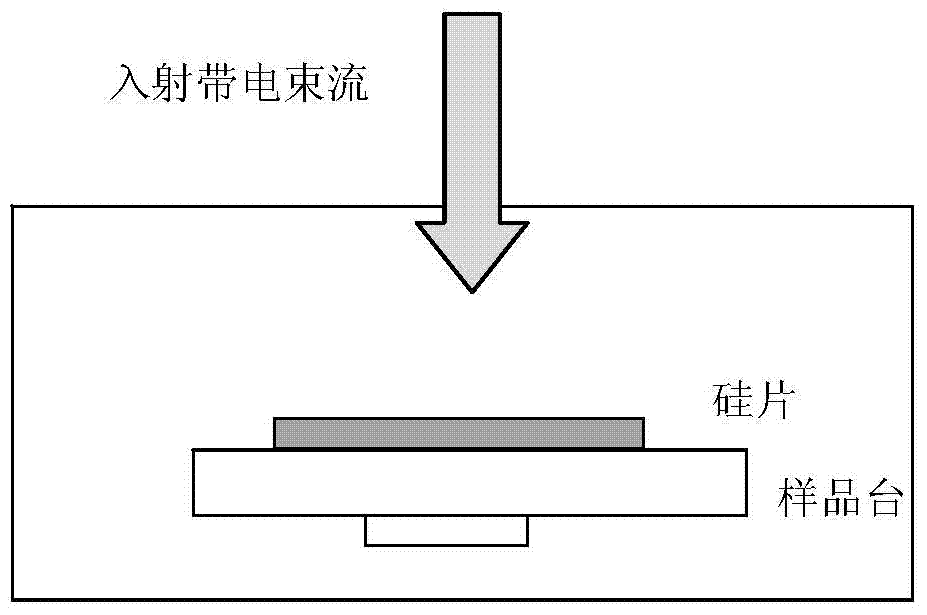

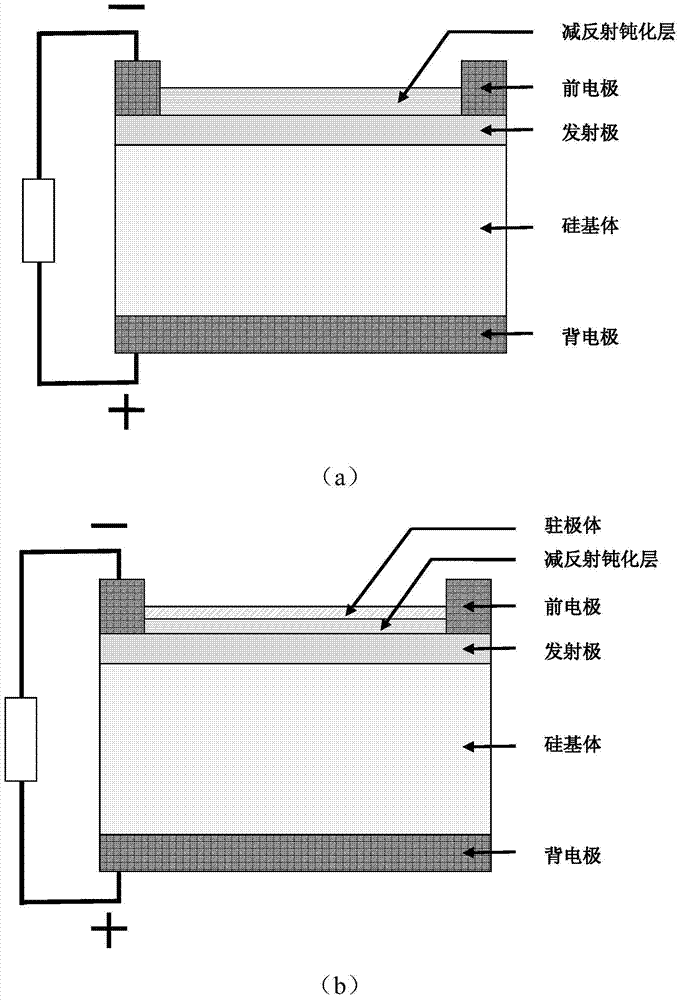

Electret-structure-introduced efficient solar cell and preparing method thereof

ActiveCN103681889AIncrease the open circuit voltageSmall temperature coefficientFinal product manufacturePhotovoltaic energy generationSensitized cellIndium

The invention relates to an electret-structure-introduced efficient solar cell and a preparing method thereof. The electret-structure-introduced efficient solar cell and the preparing method thereof are characterized in that an electret thin layer is introduced into a traditional solar cell structure to improve the monochromatic incident photon-to-electron conversion efficiency of the solar cell. The introduced electret structure can be obtained through any one of the four modes of 1) performing electret treatment on a surface passivation antireflection film of the solar cell to enable the solar cell to have an electret function; 2) or separately depositing an electret thin layer on the surface of the solar cell; 3) or introducing encapsulating materials with electret properties into component encapsulation; 4) or inducing an electret thin layer in a cell or a component through treatment of electret means after the preparation of the solar cell or the component is completed. The electret-structure-introduced efficient solar cell and the preparing method thereof are not only applicable to crystalline silicon cells, but also applicable to solar cells of other types such as amorphous silicon thin film cells, cadmium telluride cells, gallium arsenide cells, copper indium gallium diselenide cells, dye-sensitized cells and organic cells.

Owner:ZHONGWEI NEW ENERGY CHENGDU CO LTD

Heteroaryl-substituted bicyclic smac mimetics and the uses thereof

ActiveUS20110046189A1High expressionMore tolerableBiocideOrganic chemistrySmac mimeticsSensitized cell

The invention relates to heteroaryl-substituted bicyclic mimetics of Smac which function as inhibitors of Inhibitor of Apoptosis Proteins. The invention also relates to the use of these mimetics for inducing apoptotic cell death and for sensitizing cells to inducers of apoptosis.

Owner:RGT UNIV OF MICHIGAN

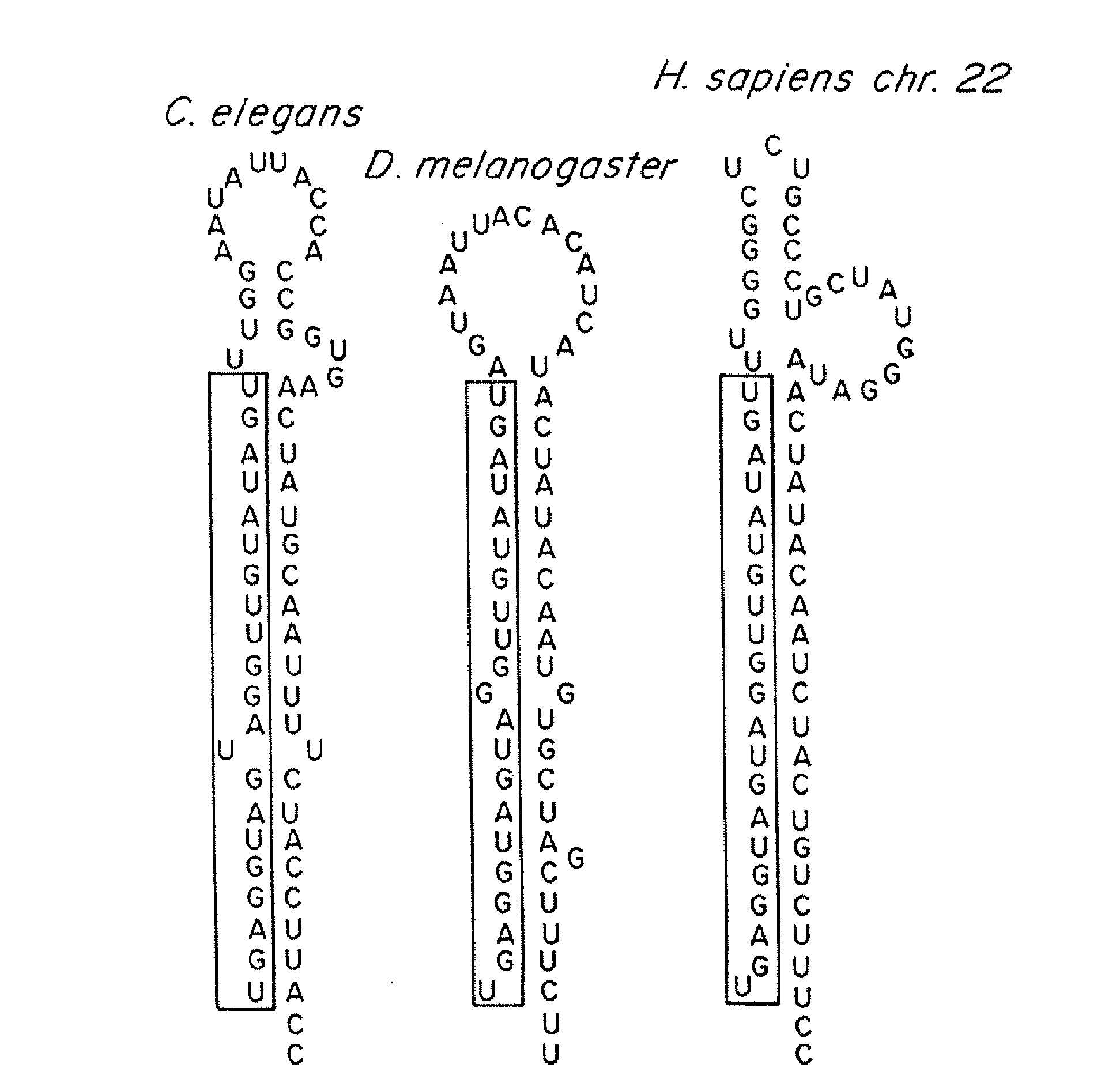

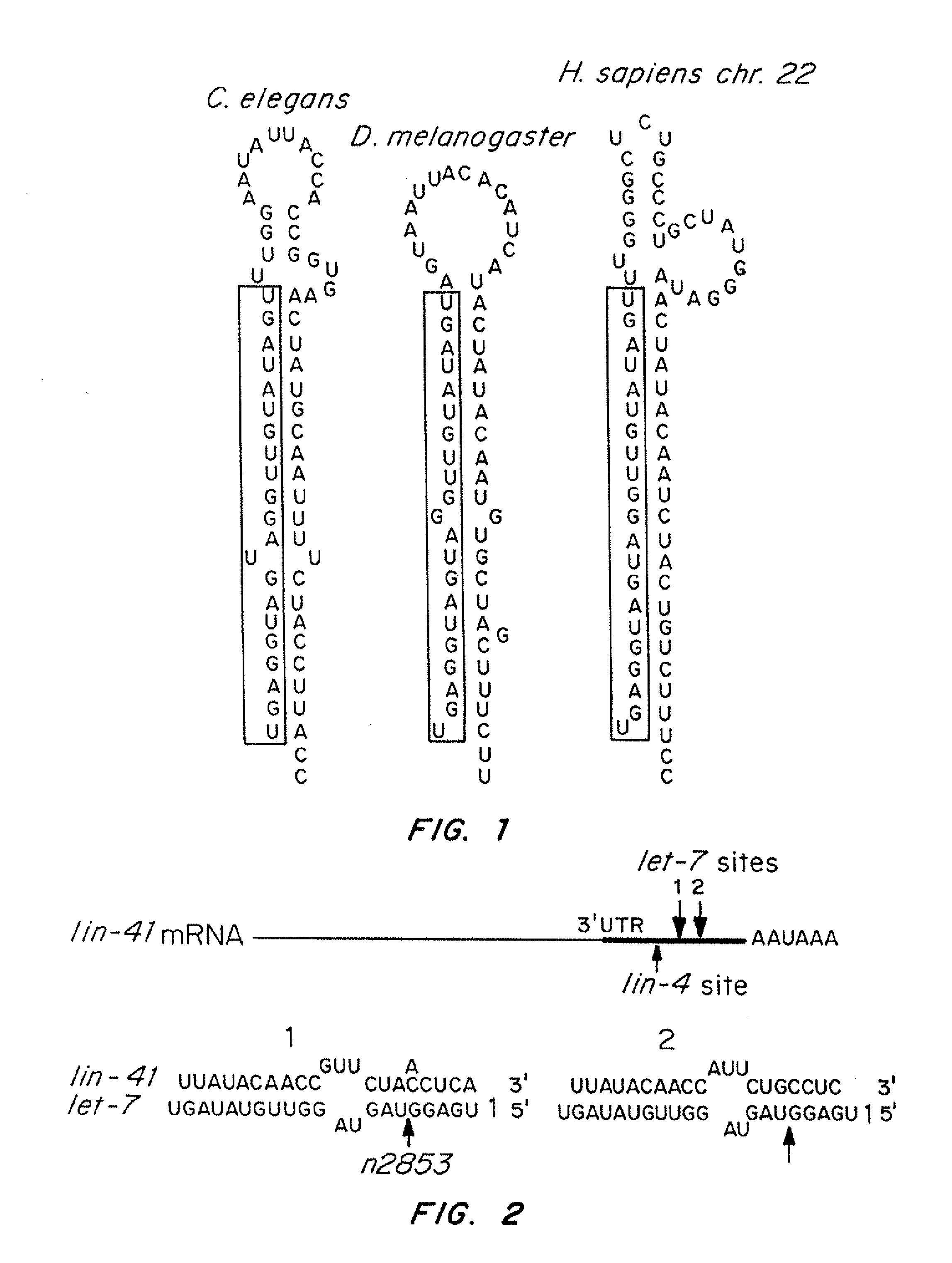

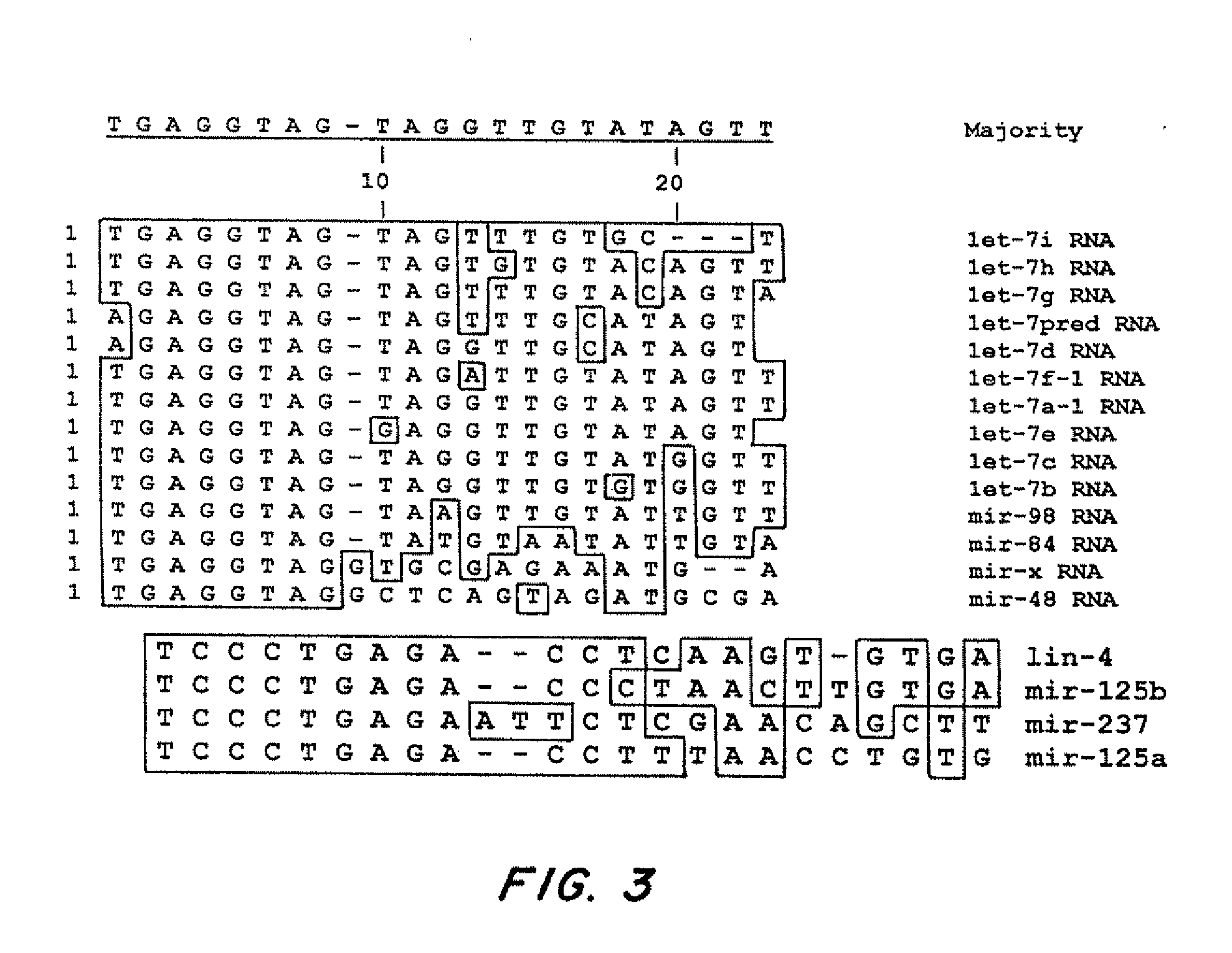

Regulation of oncogenes by micrornas

ActiveUS20080119436A1Small sizeImprove manifestationNervous disorderPeptide/protein ingredientsSensitized cellDna encoding

Naturally occurring miRNAs that regulate human oncogenes and methods of use thereof are described. Suitable nucleic acids for use in the methods and compositions described herein include, but are not limited to, pri-miRNA, pre-miRNA, mature miRNA or fragments of variants thereof that retain the biological activity of the mature miRNA and DNA encoding a pri-miRNA, pre-miRNA, mature miRNA, fragments or variants thereof, or regulatory elements of the miRNA. The compositions are administered to a subject prior to administration of a cytotoxic therapy in an amount effective to sensitize cells or tissues to be treated to the effects of the cytotoxic therapy.

Owner:YALE UNIV

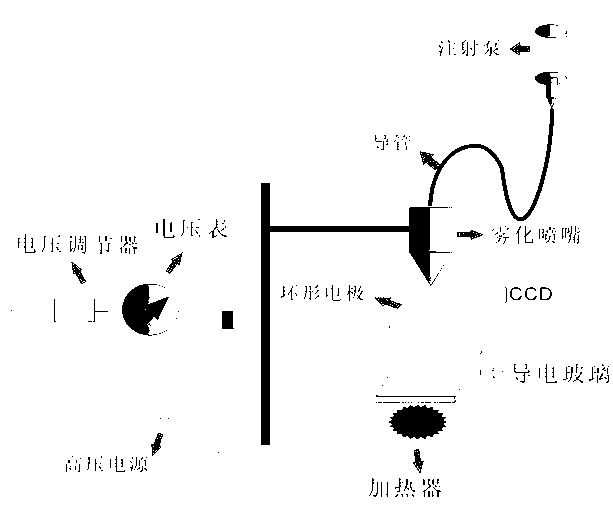

Device and method for rapidly manufacturing large-area dye-sensitized solar cell

ActiveCN102956356AAccurate sprayingNo manual operationLight-sensitive devicesFinal product manufactureScreen printingSensitized cell

The invention provides a device and a method for rapidly manufacturing a large-area dye-sensitized solar cell and relates to optimization of a dye-sensitized solar cell manufacturing process in the field of new energy. One key problem to be solved in dye-sensitized cell research is as follows: industrial production and large-scale application are seriously restricted due to the fact that the photoelectric conversion efficiency and the cell stability are obviously different due to different manufacturing methods. The invention provides a method for manufacturing a dye-sensitized thin-film cell by utilizing a spray deposition method based on the electrostatic atomization principle, namely directly stacking, assembling and forming thin-film cell modules on various substrate materials by utilizing an electrostatic spraying technology and combining a method of automatically controlling simulated printing by a computer, and obtaining high-quality large-area dye-sensitized thin-film cell by virtue of optimizing related process parameters. The device and the method can be used for overcoming the defects of grid line breakage, short circuit, wavy reticulate patterns and the like caused by a process of manufacturing an electrode film by virtue of a silk screen printing method, and the defect of too compact and uneven magneto-controlled sputter coating.

Owner:徐州新路智能科技有限公司

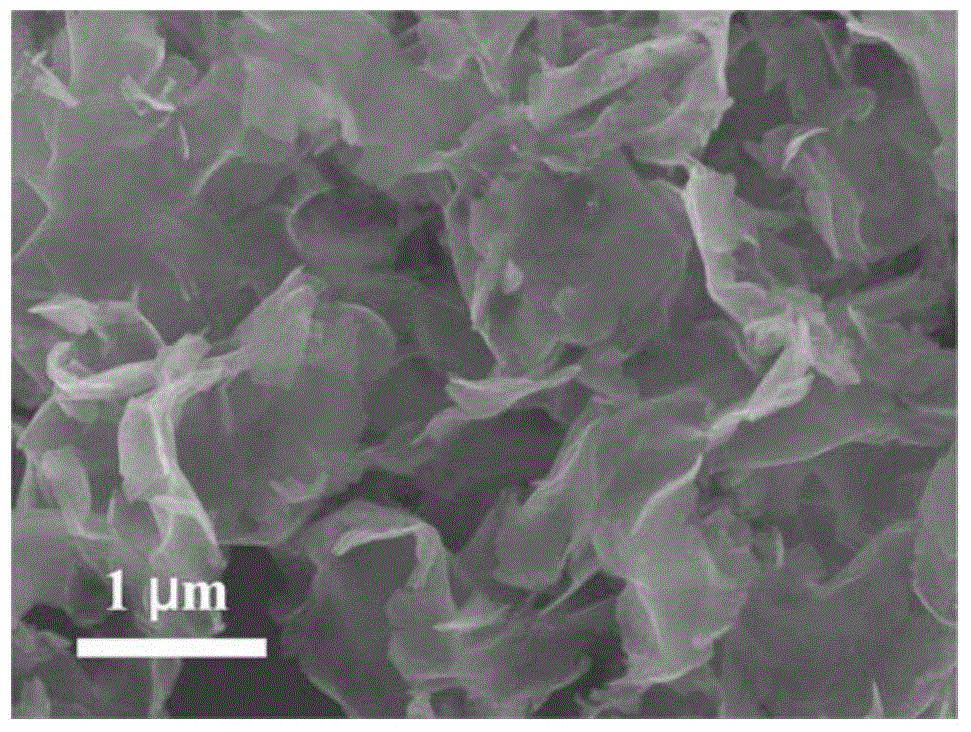

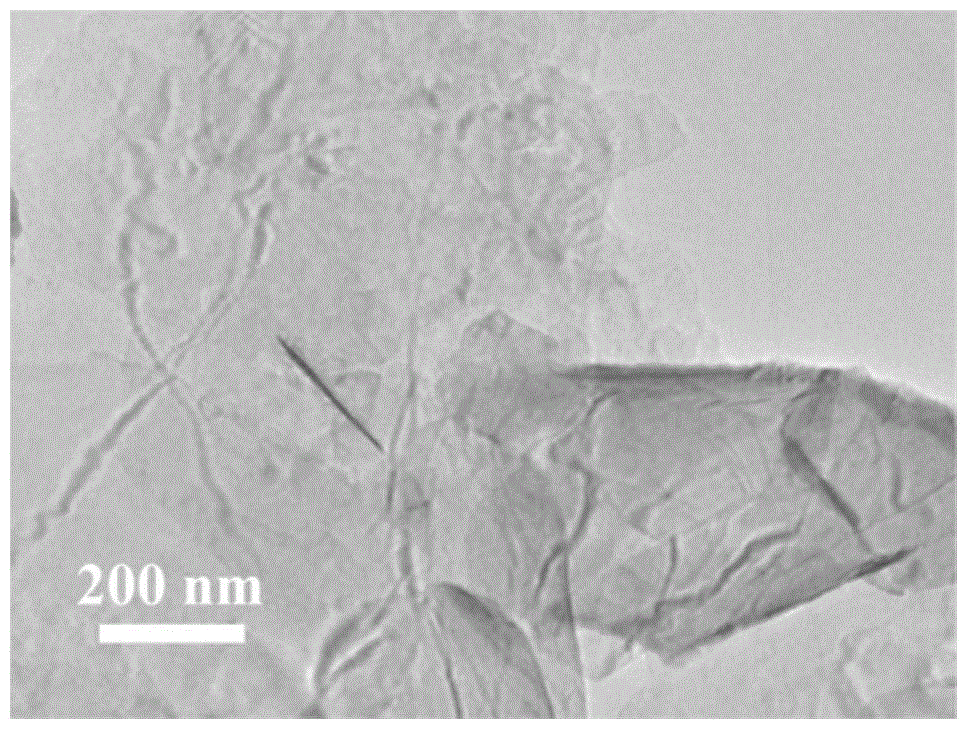

Two-dimensional ultrathin ferric diselenide nano material as well as preparation method and application thereof

ActiveCN104477857AEasy to operateMaterial nanotechnologyLight-sensitive devicesSensitized cellSolvent

The invention relates to a two-dimensional ultrathin ferric diselenide nano material as well as a preparation method and an application thereof. The nano material is 0.5-5 microns in size and 3-7nm thick; the nano material is prepared by the following steps: mixing Se powder with a solvent, adding a certain amount of thiol and stirring for 1-5min in the atmosphere of inert gas so as to obtain a high-activity Se precursor; dissolving an inorganic solvent of iron to an oleylamine solvent, injecting the Se precursor at a certain temperature, and reacting for a certain duration in the atmosphere to the inert gas so as to obtain the ultrathin ferric diselenide nano material, wherein the ultrathin ferric diselenide nano material can be used for preparing the counter electrode of a dye-sensitized cell. Compared with the prior art, the ferric diselenide prepared by the invention is controllable in morphology, and is simple to operate, good in repeatability, low in cost and prone to large-scale production.

Owner:SHANGHAI JIAO TONG UNIV

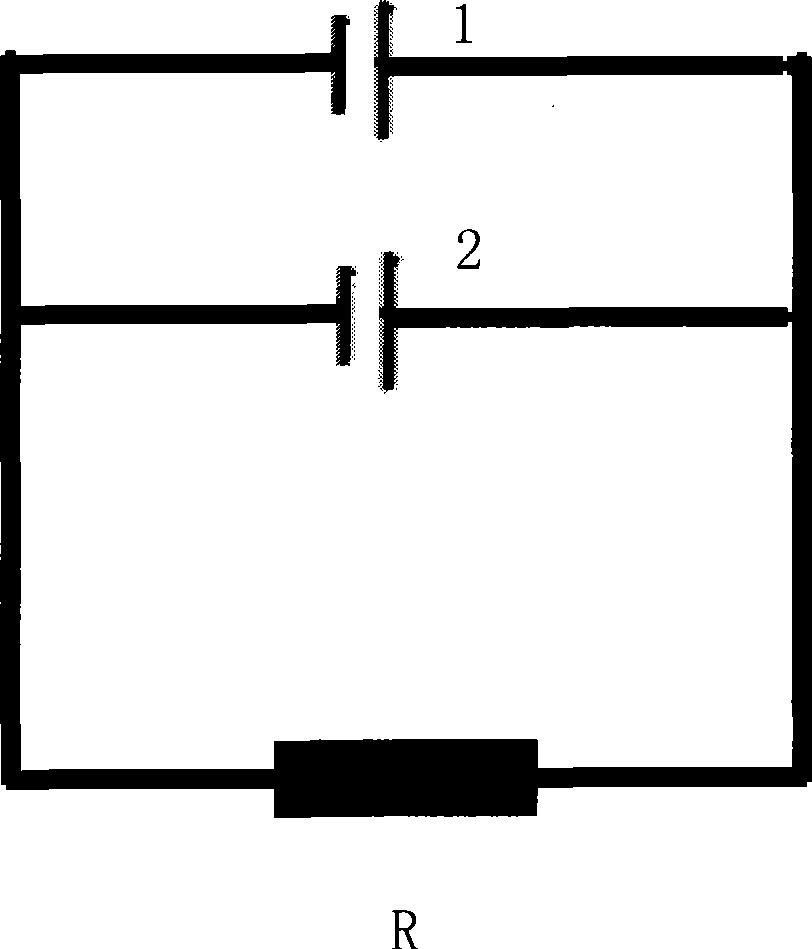

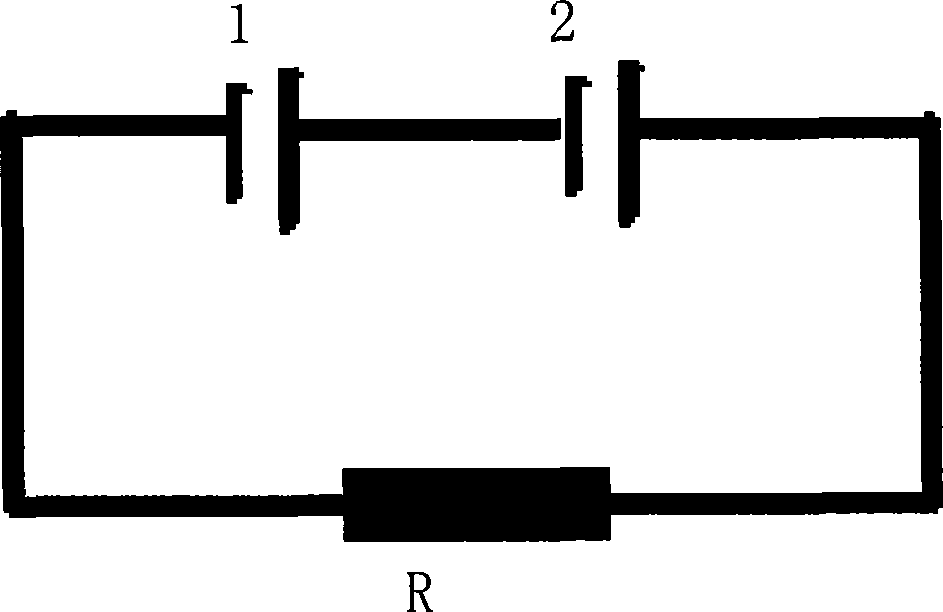

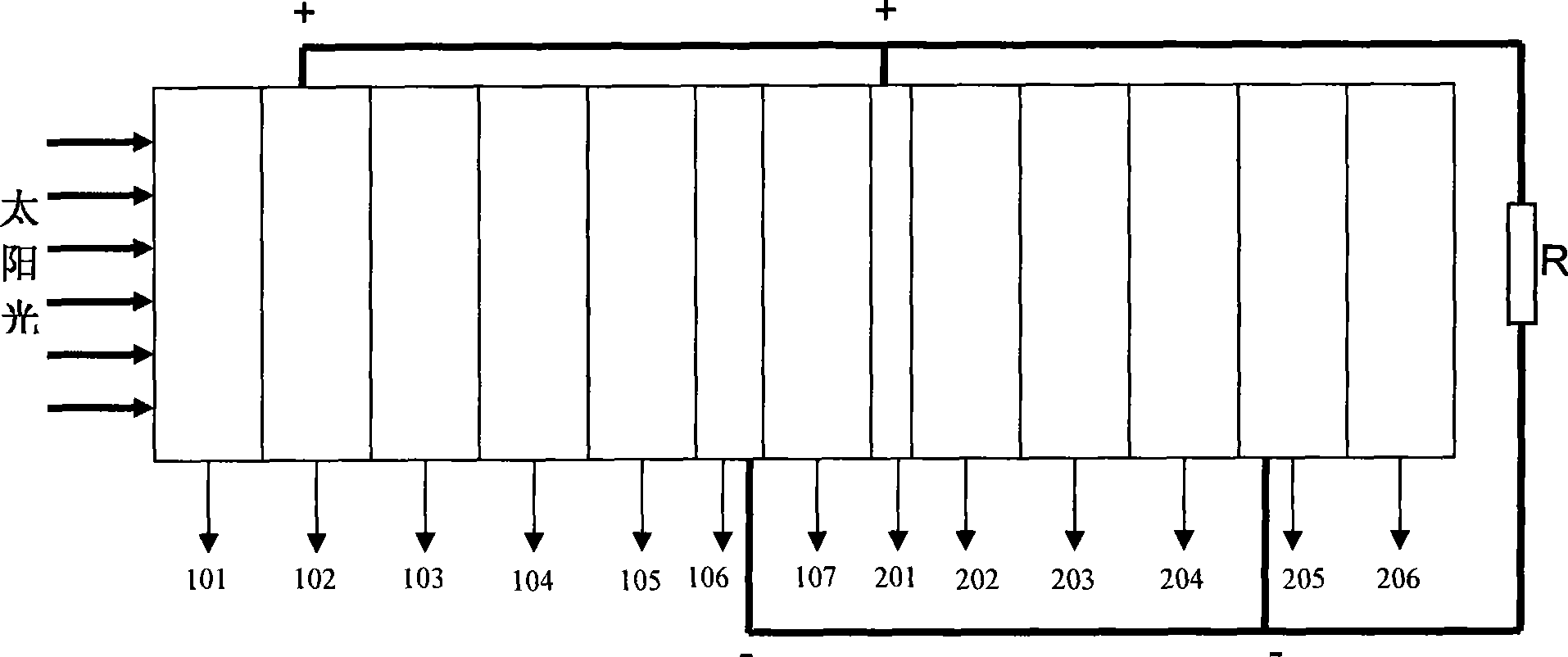

Laminated structure of amorphous silicon solar battery and dye sensitization battery

InactiveCN101510470AAchieve absorptionSimple preparation processLight-sensitive devicesFinal product manufactureSensitized cellLight energy

The invention relates to an amorphous silicon solar cell and dyestuff sensitized cell laminated structure which comprises an amorphous silicon solar cell positioned at the top and used for absorbing high-energy sunlight with biased shortwave, and a dyestuff sensitized cell positioned at the bottom and used for absorbing low-energy sunlight with biased long-wave, wherein, the amorphous silicon solar cell and the dyestuff sensitized cell are connected in series or in parallel; the amorphous silicon solar cell and dyestuff sensitized cell laminated structure can achieve the following effects: the dyestuff sensitized cell can be used for adsorbing close infrared light; the designed laminated cell is characterized by simple manufacturing technique and low price; the problem that the conventional solar cell has low photoelectric transformation efficiency and narrow solar energy absorbing spectrum can be solved; and the structure can increase the utilization rate of sunlight to the greatest extent, improve transformation efficiency and reduce light energy loss.

Owner:上海拓引数码技术有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com