Perovskite solar cell composed of orderly-arranged small titanium dioxide balls and preparation method thereof

A technology of solar cells and titanium dioxide, applied in the direction of circuits, photovoltaic power generation, electrical components, etc., can solve problems such as pollution, large energy consumption and the environment, and achieve the effects of easy preparation, improved light utilization rate, and simple preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

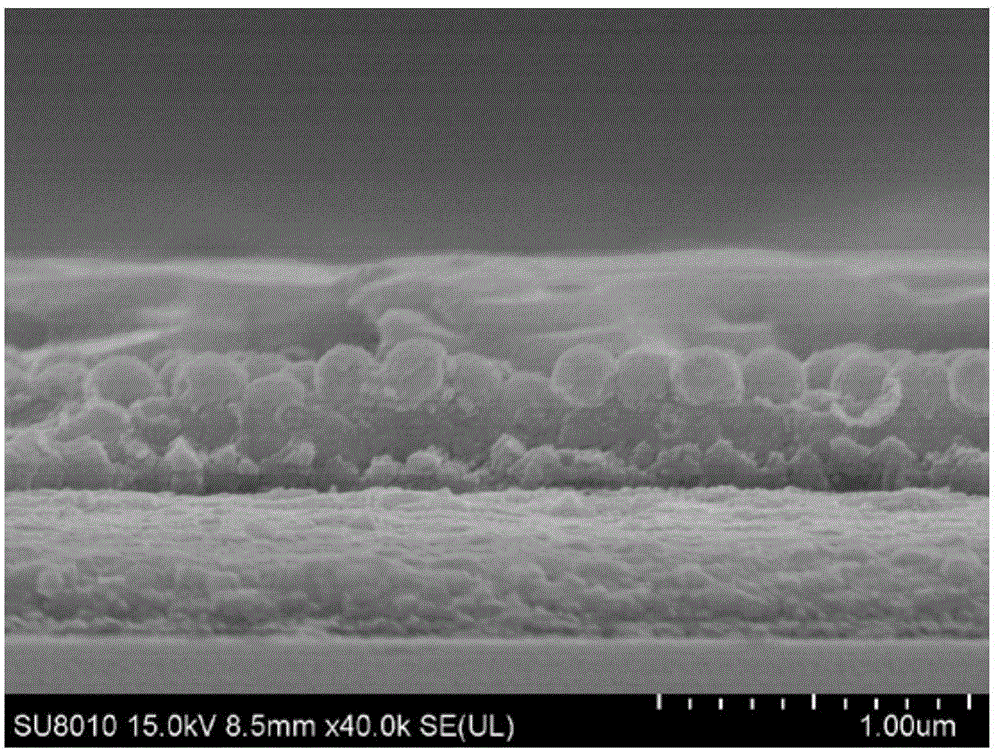

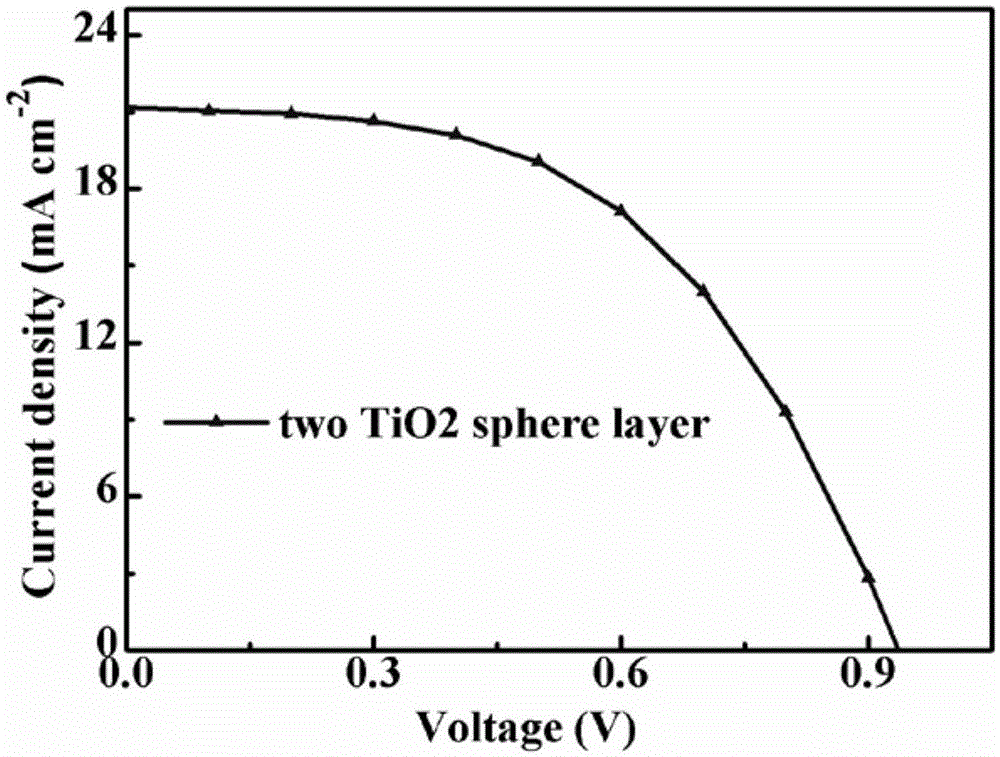

Embodiment 1

[0025] 200nm polystyrene colloidal beads are configured into a 5%wt aqueous solution, take out 5ml of polystyrene aqueous solution and add 5ml of ethanol to form a new matrix solution with a mixing ratio of 1:1, and finally add 0.1g of surfactant hexadecyl Trimethylammonium bromide, ultrasonically oscillate to obtain a mixed solution; use a pipette gun to take out 100ul of the mixed solution and drop it on a clean conductive glass surface, and spin-coat to prepare a uniform alternating bead layer; prepare the prepared mixture with a uniform colloid The substrate of the small ball layer is moved into the atomic layer deposition chamber to grow titanium dioxide, and the growth thickness is controlled to be 5nm thick; the substrate with grown titanium dioxide is taken out and calcined in an annealing furnace to remove the polystyrene part and control the heating rate The temperature is 1°C / min, and the temperature is raised to 550°C for calcination for 2h. Control the annealing f...

Embodiment 2

[0028] 350nm polystyrene colloidal beads are configured into 5%wt aqueous solution, take out 10ml of polystyrene aqueous solution and add 5ml of ethanol to form a new matrix solution with a mixing ratio of 2:1, and finally add 0.15g of surfactant hexadecyl Trimethylammonium bromide, ultrasonically oscillated to obtain a mixed solution; use a pipette gun to take out 150ul of the mixed solution and drop it on a clean conductive glass surface, and spin-coat to prepare a uniform alternating bead layer; the prepared uniform colloid The substrate of the small ball layer is moved into the atomic layer deposition chamber for the growth of titanium dioxide, and the growth thickness is controlled to be 10nm thick; the substrate of the grown titanium dioxide is taken out and calcined in an annealing furnace to remove the polystyrene part and control the heating rate The temperature is 1°C / min, and the temperature is raised to 550°C for calcination for 2h. Control the annealing furnace to...

Embodiment 3

[0030]500nm polystyrene colloidal beads are configured into a 5%wt aqueous solution, take out 15ml of polystyrene aqueous solution and add 5ml of ethanol to form a new matrix solution with a mixing ratio of 3:1, and finally add 0.2g of surfactant hexadecyl Trimethylammonium bromide, ultrasonically oscillated to obtain a mixed solution; use a pipette gun to take out 200ul of the mixed solution and drop it on a clean conductive glass surface, and spin-coat to prepare a uniform alternating bead layer; The substrate of the small ball layer is moved into the atomic layer deposition chamber for the growth of titanium dioxide, and the growth thickness is controlled to be 15nm thick; the substrate of the grown titanium dioxide is taken out and calcined in an annealing furnace to remove the polystyrene part and control the heating rate The temperature is 1°C / min, and the temperature is raised to 550°C for calcination for 2h. Control the annealing furnace to uniformly cool down to room ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com