Device and method for rapidly manufacturing large-area dye-sensitized solar cell

A solar cell and dye-sensitized technology, which is applied in the field of rapid preparation of large-area dye-sensitized solar cells, can solve the problems of magnetron sputtering coating density and unevenness, and achieve the effect of simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] 1. Cleaning of conductive glass: Use distilled water, absolute ethanol, and acetone to ultrasonically clean the cut conductive glass for 30 minutes in sequence, and dry it for later use.

[0036]2. Platinum grid electrode: drip chloroplatinic acid solution with a syringe at 5 μl / s on the side of the cleaned FTO (100mm×120mm) conductive glass, put it in a muffle furnace and heat it at 400°C for 30min, take it out for use Anhydrous ethanol clear.

[0037] 3. TiO 2 Preparation of slurry: The slurry was mixed with P25, absolute ethanol, OP emulsifier, acetylacetone, and PEG2000 in a ratio of 20:1:1:4, stirred on a magnetic stirrer for 1 hour, and left to stand for 10 minutes for later use.

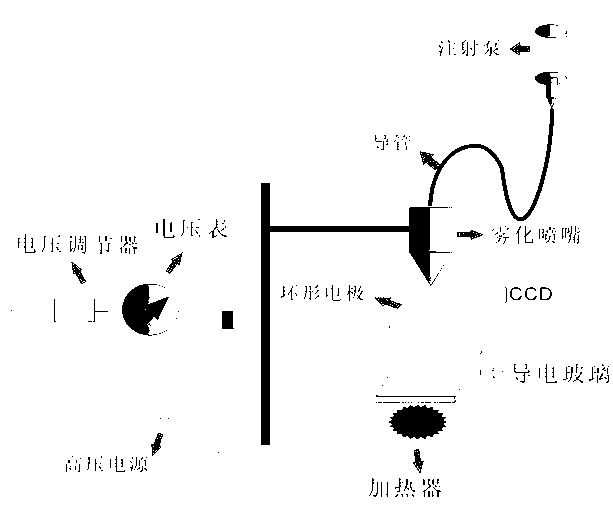

[0038] 4. Electrostatic spraying of TiO2 film: TiO2 2 The slurry is sucked into a 10ml syringe and installed on the syringe pump. Set the flow rate to 0.5ml / min. Turn on the CCD industrial camera and adjust the high-voltage DC stabilized current power supply. When the jet mode change...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com