Laminated structure of amorphous silicon solar battery and dye sensitization battery

A dye-sensitized battery, solar cell technology, applied in capacitor electrodes, capacitor electrolytes/absorbers, circuits, etc., can solve the problem of low photoelectric conversion efficiency of batteries, and achieve the effects of low price, improved conversion efficiency, and simple production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

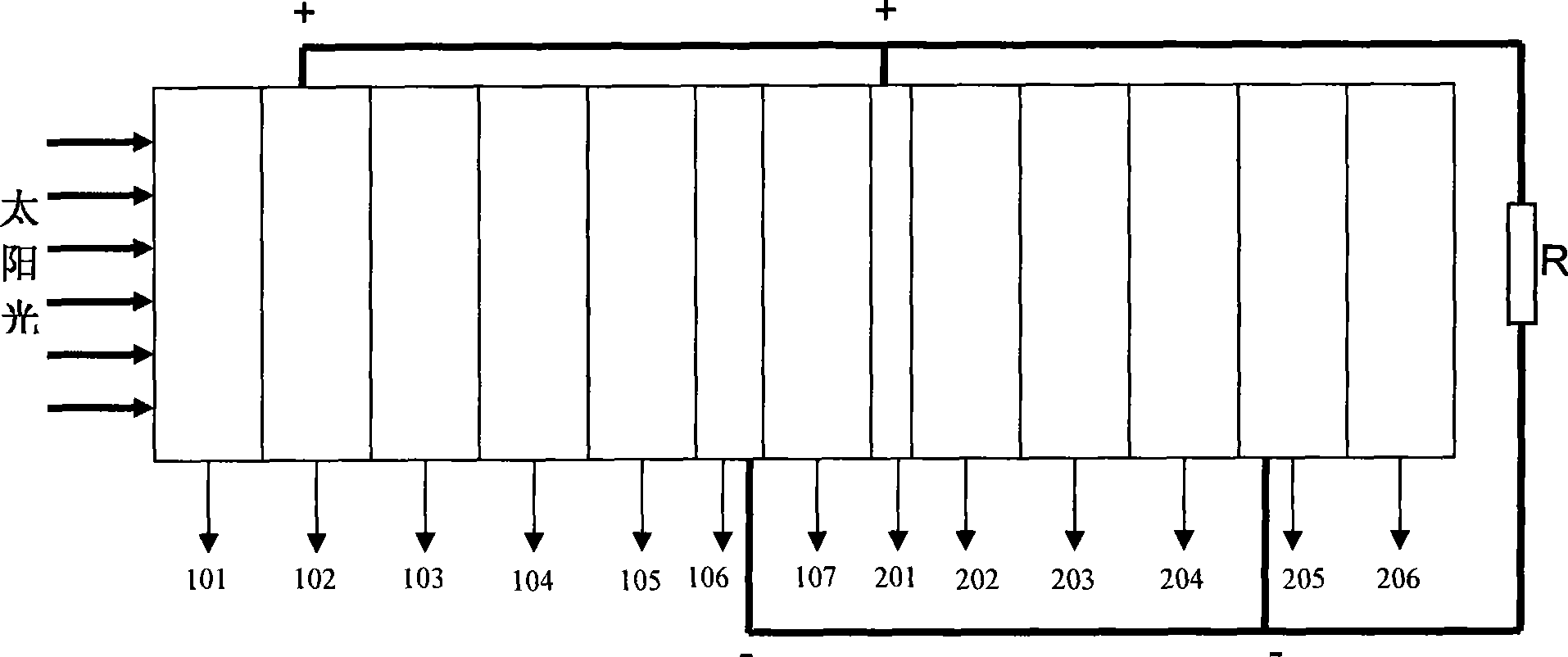

[0049] image 3 It is a schematic diagram of the structure of the amorphous silicon solar cell and the dye-sensitized laminated cell of the present invention, including the top amorphous silicon solar cell 1 that can absorb short-wave high-energy sunlight and the bottom dye-sensitized absorbing long-wave low-energy sunlight battery 2. Amorphous silicon solar cell 1 is composed of outermost transparent substrates 101 and 107, second outer transparent conductive oxide layers 102 and 106, and amorphous silicon semiconductor layers 103-105, including amorphous silicon semiconductor P layer 103, an amorphous silicon semiconductor I layer 104, and an amorphous silicon semiconductor N layer 105. The dye-sensitized cell 2 is composed of a counter electrode, a semiconductor sensitized photoanode located at the bottom, and an electrolyte 203 located between the two electrodes. The counter electrode is composed of a transparent conductive oxide layer 201 and a platinum catalyst layer 2...

Embodiment 2

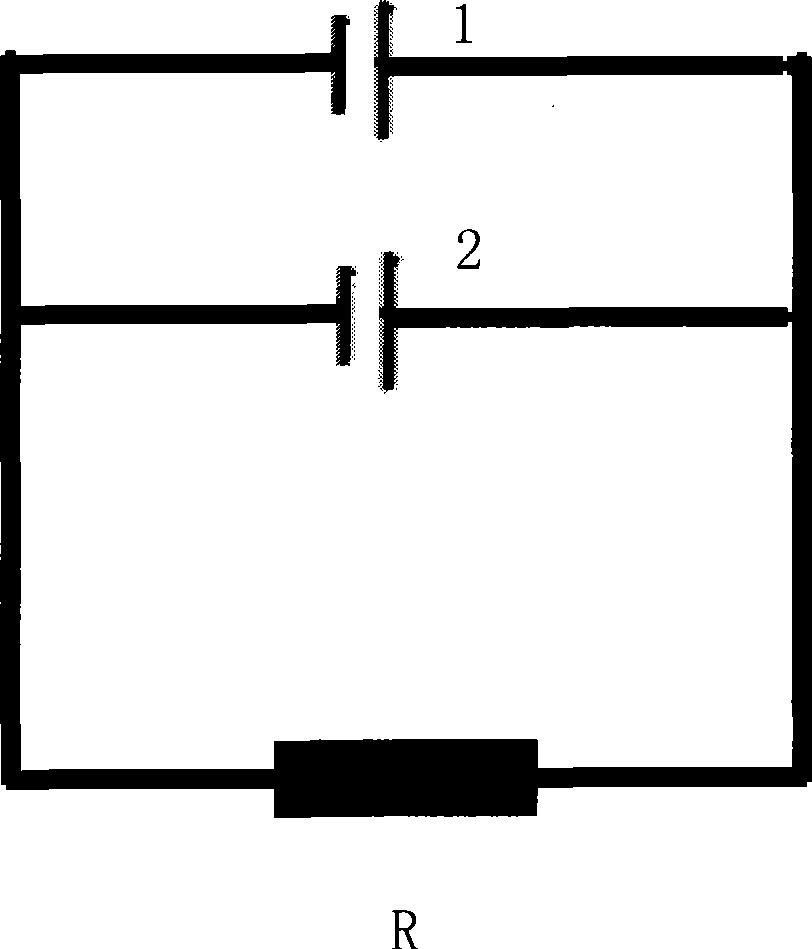

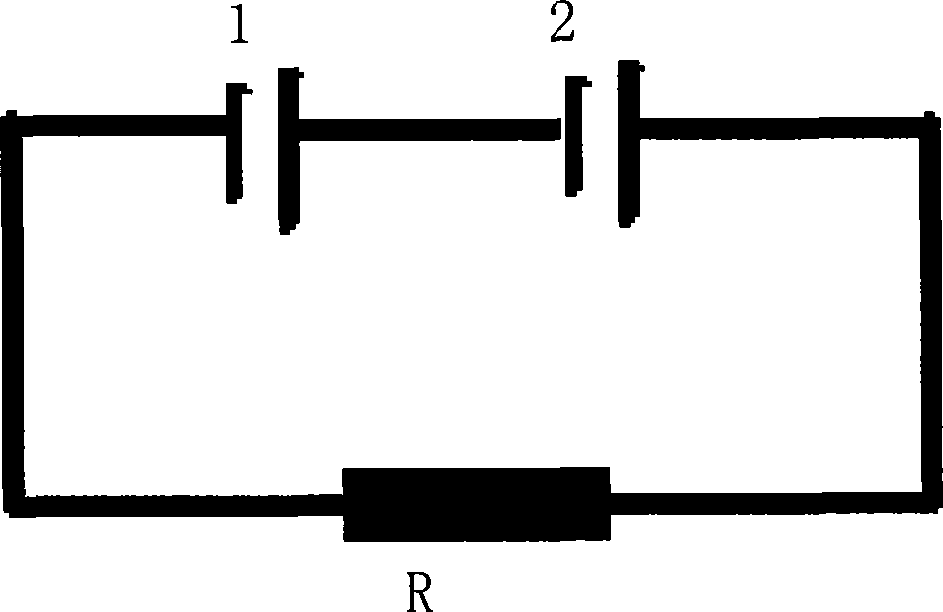

[0053] The basic structure includes an amorphous silicon solar cell 1 on the top and a dye-sensitized solar cell 2 on the bottom. Change the adsorption amount of the dye in the dye-sensitized cell, so that the short-circuit current of the dye-sensitized cell and the amorphous silicon solar cell are basically similar, and the current matching is realized, such as Figure 4 As shown, the amorphous silicon solar cell and the dye-sensitized cell are connected in series, that is, the transparent conductive oxide layer 102 of the amorphous silicon solar cell is used as the positive external circuit, and the transparent conductive oxide layer 106 of the amorphous silicon solar cell is (negative electrode) connected to the transparent conductive oxide layer 201 (positive electrode) of the dye-sensitized cell, figure 2 yes Figure 4 From the equivalent circuit diagram, it can be seen that the two batteries are connected in series, and the transparent conductive oxide layer 205 of the...

Embodiment 3

[0056] The basic structure includes an amorphous silicon solar cell 1 on the top and a dye-sensitized solar cell 2 on the bottom. Change the dye adsorption amount of the dye-sensitized cell to achieve current matching between the two cells, and connect the amorphous silicon solar cell and the dye-sensitized cell in series, that is, the negative electrode of the amorphous silicon solar cell is connected to the negative electrode of the dye-sensitized cell. Positive pole, the positive pole external circuit of the amorphous silicon solar cell, and the negative pole external circuit of the dye-sensitized battery. Wherein, there is no transparent conductive glass barrier (107 in embodiment 1) between the N layer 105 of the P-I-N layer of the amorphous silicon solar cell and the catalyst layer 202 of the dye-sensitized cell, but is directly connected through a layer of buffer layer 3, such as Figure 5 and Figure 6 As shown, a platinum catalyst layer 202 is attached to the buffer ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com