Rare earth copper and iron alloy and preparation method and application

A rare earth copper and iron alloy technology, applied in the field of rare earth copper iron alloy and its preparation, can solve the problems of low effect of improving the electrical conductivity of the alloy, complex types, reducing the competitiveness of enterprises, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

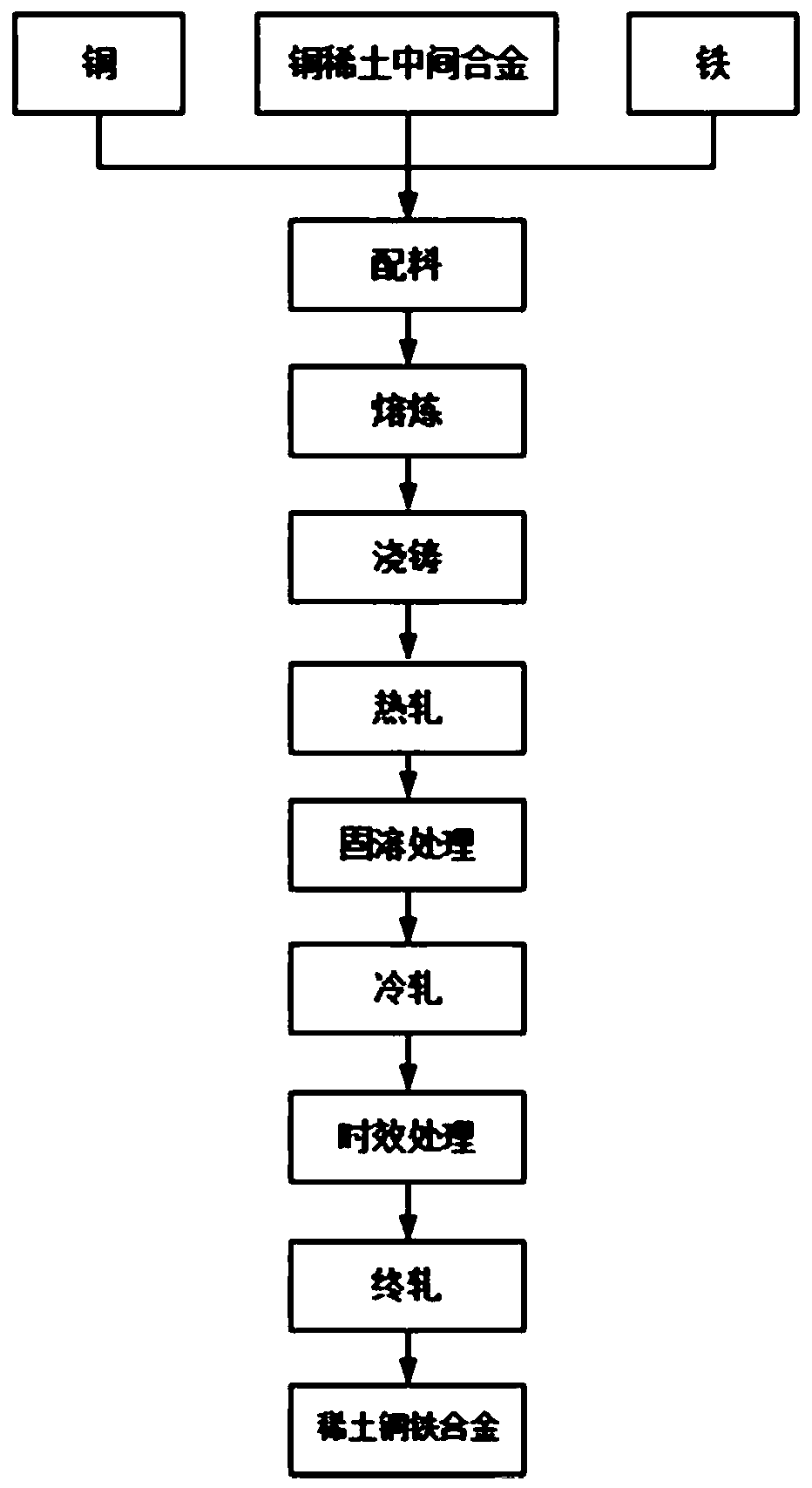

[0027] The present invention also provides a preparation method for the rare earth copper-iron alloy described in the above technical solution, comprising the following steps:

[0028] (1) Casting after smelting copper source, iron source and rare earth raw materials to obtain alloy ingot;

[0029] (2) Perform hot rolling, solution treatment, cold rolling, aging treatment and final rolling on the alloy ingot obtained in the step (1) in sequence to obtain the rare earth copper-iron alloy.

[0030] In the invention, copper source, iron source and rare earth raw materials are smelted and then cast to obtain alloy ingots. The present invention has no special limitation on the smelting equipment, and the smelting equipment well-known to those skilled in the art can be used. In the present invention, the smelting equipment is preferably a medium-frequency electromagnetic induction furnace.

[0031] In the present invention, the copper source is preferably electrolytic copper; the ...

Embodiment 1

[0058] In terms of mass percentage, the composition of the rare earth copper-iron alloy is 0.05% Ce, 14% Fe and 85.95% Cu.

[0059] The preparation method is as follows:

[0060] (1) Ingredients: 85% electrolytic copper, 14% pure iron and 1% copper rare earth master alloy (Cu-5wt%Ce) are configured into alloy components in mass percentage;

[0061] (2) Smelting: first mix electrolytic copper and pure iron and put them into an intermediate frequency electromagnetic induction furnace, and smelt according to the conventional Cu-Fe material smelting process. After melting, smelt for 20 minutes, then add copper rare earth master alloy, and smelt for 3 minutes. Cast into graphite molds at 1300°C, and obtain alloy ingots after peeling;

[0062] (3) Hot rolling: the alloy ingot is heated to a range of 900°C for homogenization treatment, kept for 3 hours, and then hot rolled at a temperature of 900°C with a total deformation of 50%.

[0063] (4) Solution treatment: put the hot-rolled...

Embodiment 2

[0068] In terms of mass percentage, the composition of the rare earth copper-iron alloy is 0.1% Ce, 14% Fe and 85.9% Cu.

[0069] In terms of mass percentage, the raw materials of the rare earth copper-iron alloy are 14% pure iron, 84% electrolytic copper and 2% copper rare earth master alloy (Cu-5wt%Ce).

[0070] The preparation method is the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com