Novel production method of c-orientation sapphire single crystal

A production method and technology for sapphire, applied in the directions of single crystal growth, single crystal growth, crystal growth, etc., can solve the problems of slow growth rate and small adjustable range, and achieve the effect of improving the utilization rate of materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

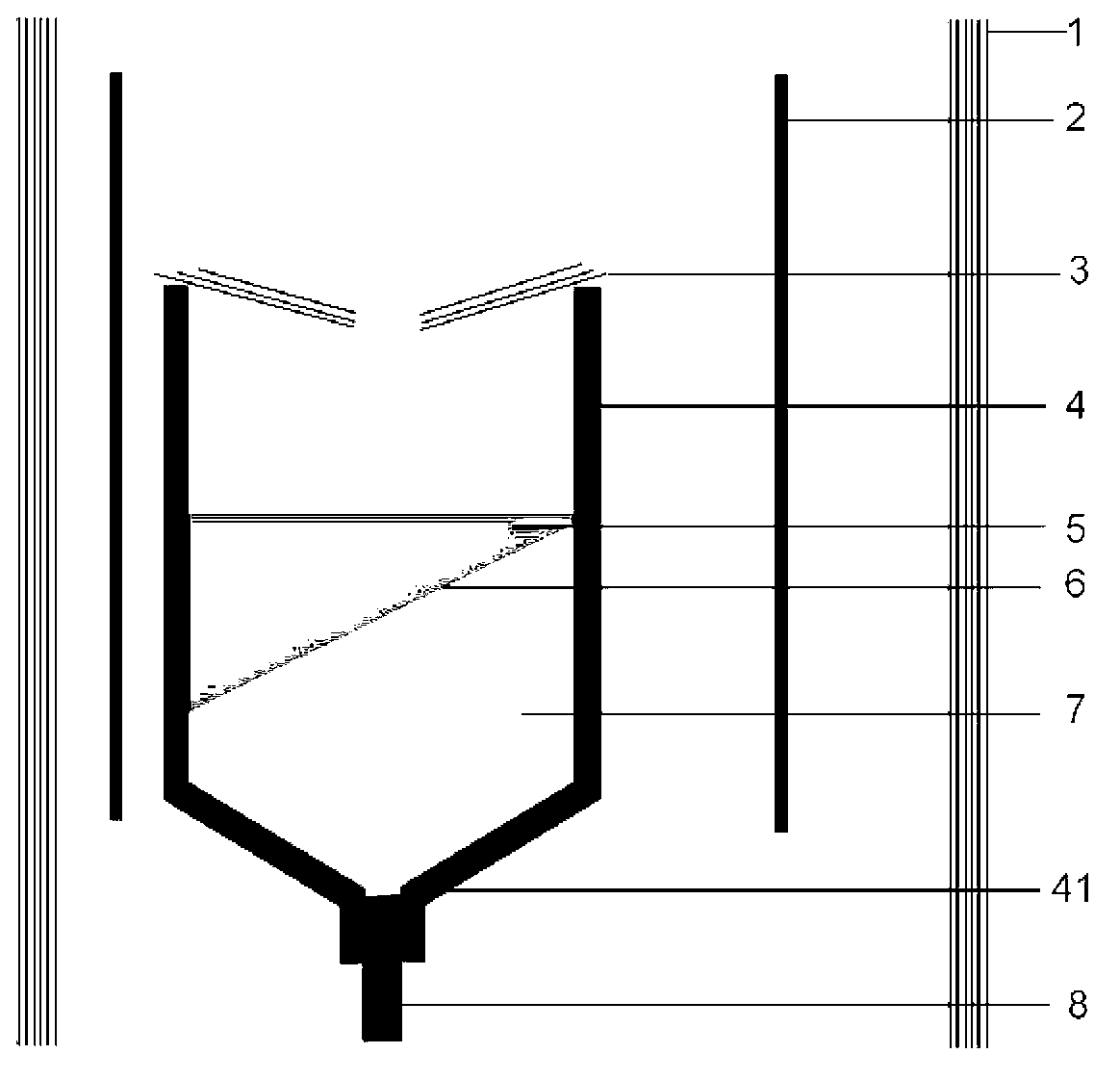

[0045] The thermal field shown in Figure 1 is used to grow c-oriented sapphire single crystal.

[0046] The three symmetry axes of the crucible, heater, and side reflector do not coincide to make the solid-liquid interface tilt, so that the solid-liquid interface is controlled as a plane at a certain angle with the c-plane. The process is as follows:

[0047] (1) Place the seed crystal: place the c-oriented seed crystal in the seed crystal groove of the crucible;

[0048] (2) Loading: Put 20-100kg of high-purity alumina raw material into the crucible, close the furnace cover, and start the cooling water circulation system;

[0049] (3) Vacuuming: Start the vacuum system and pump the furnace chamber pressure to 4Pa;

[0050] (4) Start the helium: start the helium cooling system, adjust the helium flow rate to 40-100slm, and prevent the seed crystal from completely melting during the materialization process;

[0051] (5) Heating material: Start the heating system to heat up un...

Embodiment 2

[0056] Attached figure 2 The thermal field shown carries out the growth of a c-oriented sapphire single crystal.

[0057] The three symmetry axes of the crucible, heater, and side reflective screen do not coincide to make the solid-liquid interface tilt, and a frustum-shaped reflective screen is placed on the top of the crucible to reduce the radial temperature gradient of the crystal and the melt, so that the solid-liquid interface is One plane, the heater is in the shape of a truncated cone with a small opening at the upper end and a larger opening at the lower end to increase the axial temperature gradient, so that the solid-liquid interface is controlled as a plane at a certain angle with the c-plane. The process is as follows:

[0058] (1) Place the seed crystal: place the c-oriented seed crystal in the seed crystal groove of the crucible;

[0059] (2) Loading: Put 20-100kg of high-purity alumina raw material into the crucible, close the furnace cover, and start the coo...

Embodiment 3

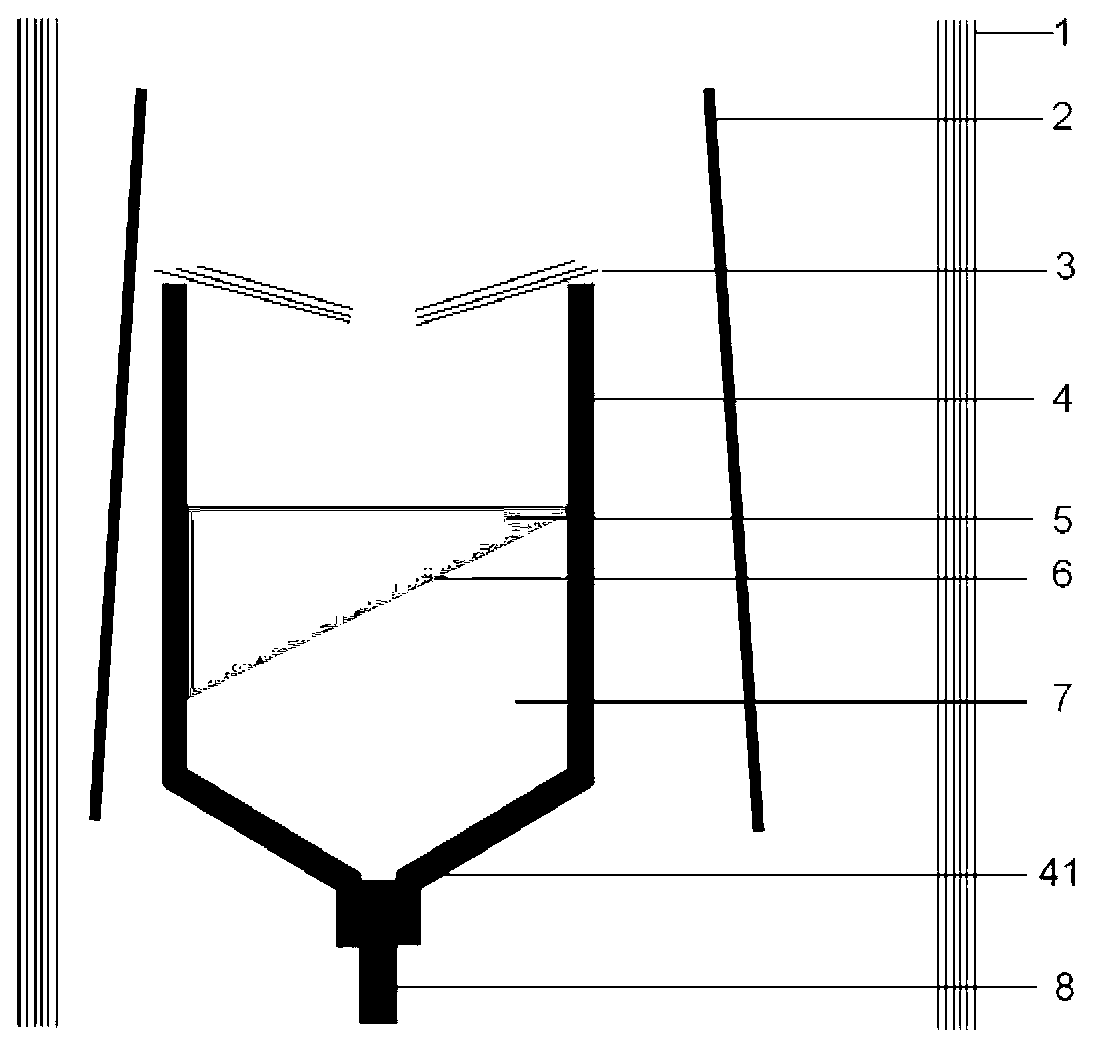

[0067] Attached image 3 The thermal field shown carries out the growth of a c-oriented sapphire single crystal.

[0068] The three symmetry axes of the crucible, heater, and side reflective screen do not coincide to make the solid-liquid interface tilt, and a frustum-shaped reflective screen is placed on the top of the crucible to reduce the radial temperature gradient of the crystal and the melt, so that the solid-liquid interface is One plane, make the side reflective screen in the shape of a truncated cone with a small opening at the upper end and a larger opening at the lower end to increase the axial temperature gradient, thereby controlling the solid-liquid interface to be a plane at a certain angle with the c-plane. The process is as follows:

[0069] (1) Place the seed crystal: place the c-oriented seed crystal in the seed crystal groove of the crucible;

[0070] (2) Loading: Put 20-100kg of high-purity alumina raw material into the crucible, close the furnace cover,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com