Amorphous soft magnet core and manufacturing method thereof

A soft magnetic core and magnetic core technology, applied in the manufacture of inductors/transformers/magnets, magnetic materials, magnetic objects, etc., can solve the problems that the iron core is difficult to meet the requirements, the excitation current is small, and the function of the amorphous iron core is single.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

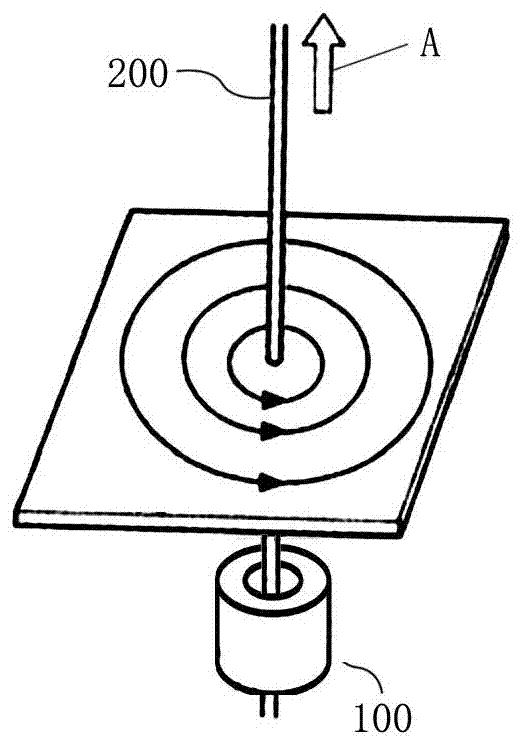

[0058] Change the alloy composition to Co 58 Fe 5 Ni 10 Si 11 B 16 The cobalt-based amorphous thin strip is wound into an annular iron core with an inner diameter of 20 mm and an outer diameter of 31 mm, and placed in a tubular heat treatment furnace for heat treatment. The heat treatment temperature is in the range of 350-550 ° C, and the heat treatment time is about 0.5 h~6h, during heat treatment according to Figure 1A As shown, a static magnetic field of 800A / m is applied longitudinally along the amorphous thin strip, and the static hysteresis loop and magnetic performance parameters of the ring iron core are tested by the impact method.

[0059] Figure 4 It is the central area diagram of the hysteresis loop of the amorphous soft magnetic core at a temperature of 380°C in a hydrogen protective atmosphere for 0.5h, 2h, 4h and 6h respectively. It can be seen that Fe 5 co 58 Ni 10 Si 11 B 16 After the amorphous soft magnetic core undergoes a series of longitudinal ...

example 2

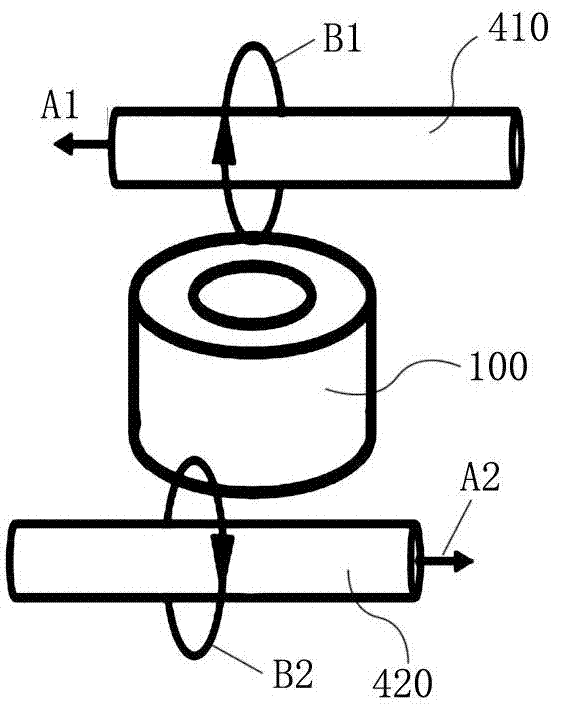

[0061] Change the alloy composition to Fe 65 co15 Si 5 B 15 The iron-based amorphous thin strip is wound into an annular iron core with an inner diameter of 20mm and an outer diameter of 31mm, and placed in such as Figure 1C The heat treatment is carried out under the double-biased annular magnetic field environment shown, the annealing temperature is 380 ° C, and the holding time is set to 5, 20, 40, 60 and 120 minutes respectively. The static hysteresis loop and the ring iron core are tested by the impact method Magnetic performance parameters. Such as Figure 6A As shown, the hysteresis loops of the iron core obtained under the condition of no magnetic field in the heat treatment process are symmetrically distributed, but after the double-biased circular magnetic field treatment, the core exchange bias characteristic is significant, Figure 6B Further, in the double-biased annular magnetic field environment, the heat treatment holding time gradually increases, and the ...

example 3

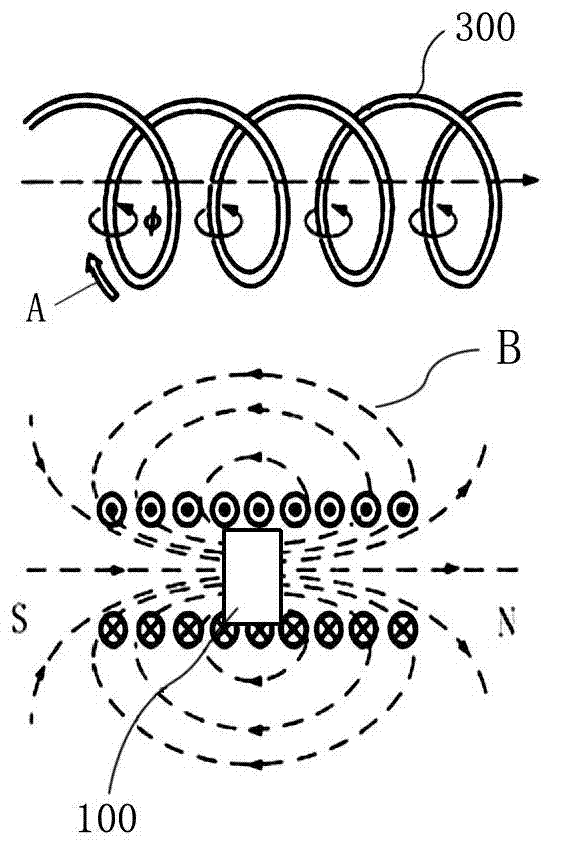

[0063] Cobalt-based amorphous iron core Fe 5 co 58 Ni 10 Si 11 B 16 After heat treatment in the magnetic field, the hysteresis loop is measured by the impact current detection method as follows: Figure 7 As shown in (a), the hysteresis loop of the annealed cobalt-based soft magnetic core is completely shifted to the right of the origin, that is, it presents a positive bias feature, and it is very obvious. The magnetic field annealed cobalt-based magnetic core according to figure 2 In the way shown, a coil with a certain number of turns is wound on the ring core, and then connected to the pulse power supply. With the output of the reverse pulse current, a pulse magnetic field opposite to the direction of the magnetic field applied during annealing is induced inside the core. Through Adjust the size of the reverse pulse current to control the magnitude of the reverse pulse magnetic field. After each reverse magnetic impact, remove the magnetic core and measure the change...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com