Method for producing semi-processed cold-rolled non-oriented electrical steel

A technology for grain-oriented electrical steel and production methods, applied in metal rolling, elongation control and other directions, can solve the problems of poor magnetic properties and dimensional accuracy, difficult to meet mechanical and electrical products, and unusable by customers, and achieve weight reduction and low production costs. , the effect of reducing the size of the motor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

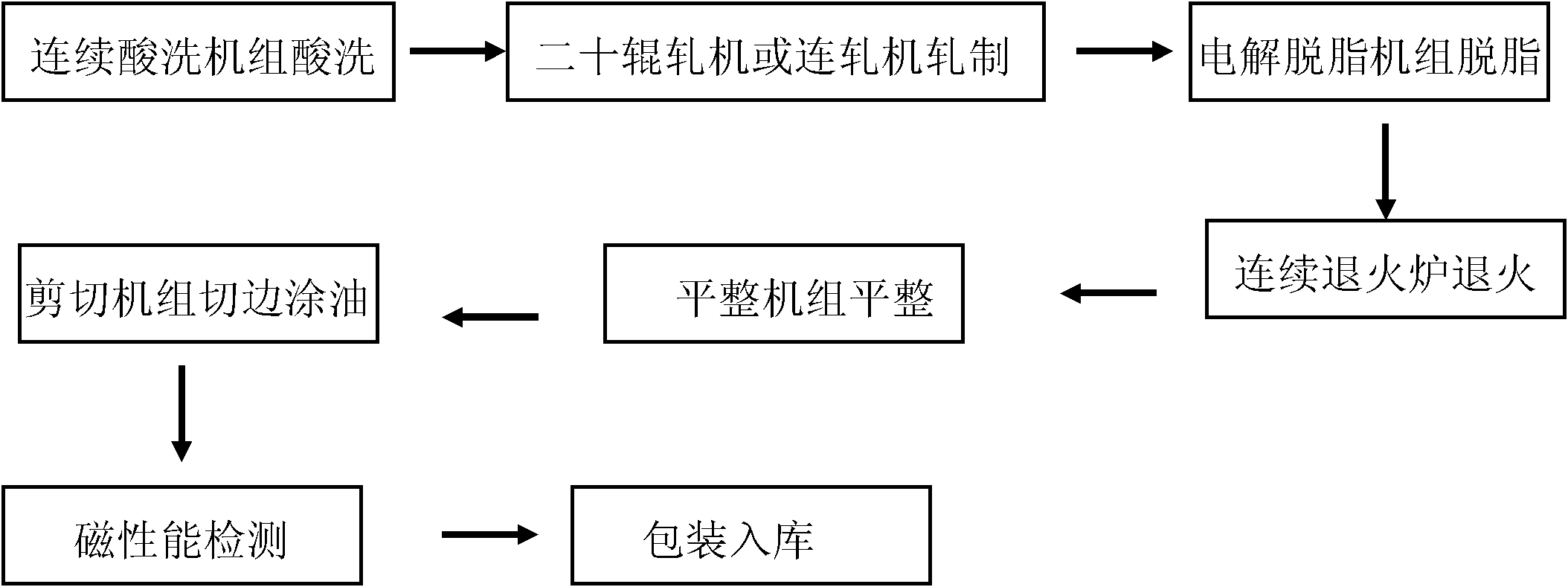

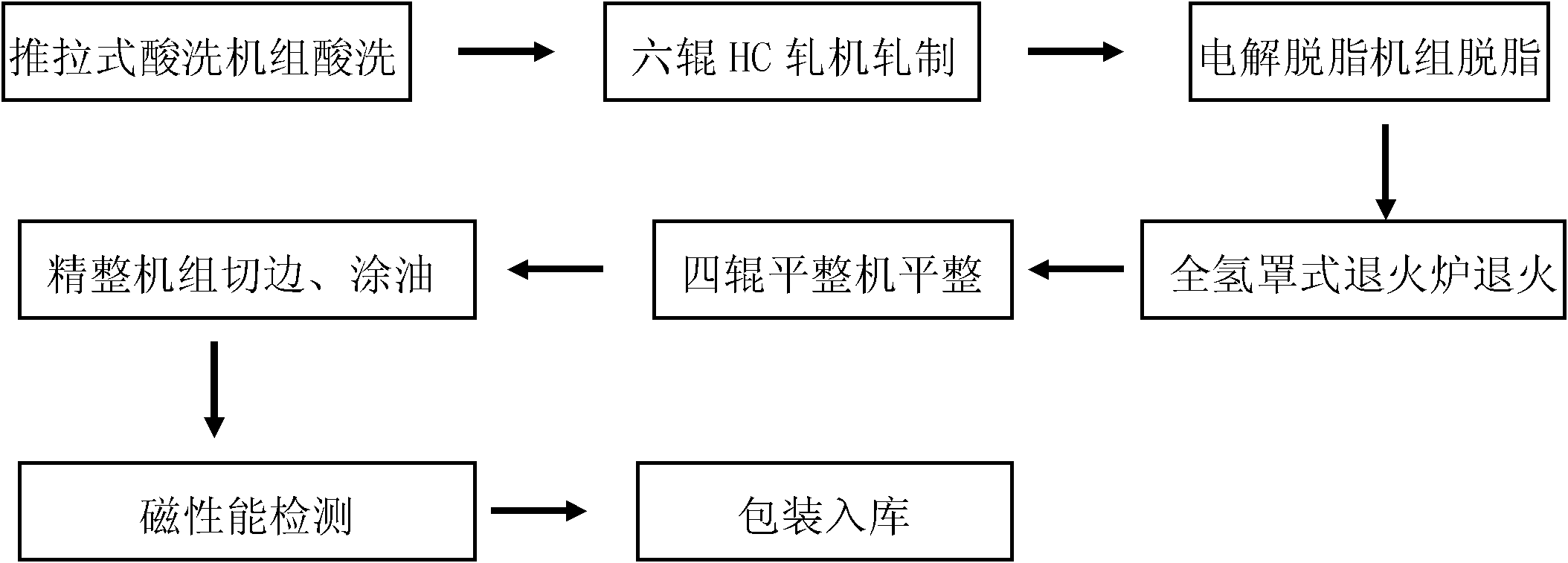

[0020] The production steps of semi-process cold-rolled non-oriented electrical steel are:

[0021] (1) Pickling: Pickle the non-oriented hot-rolled silicon steel strip with grade W600 using shallow groove turbulent flow push-pull pickling technology. The temperature of the first-stage acid bath is controlled at 80°C, and the last-stage acid bath The temperature of the solution is controlled at 60°C, and the concentration of the acid solution is controlled at 160g / L.

[0022] (2) Rolling: The steel strip after pickling is rolled to the set thickness by a six-high HC rolling mill, and the cold rolling deformation rate is ≥80%. In the final pass of rolling, a reasonable reserved amount is set to improve thickness control precision.

[0023] (3) Electrolytic degreasing:

[0024] The rolled steel strip is degreased by an electrolytic degreasing unit to remove grease and iron powder on the surface.

[0025] (4) Annealing:

[0026] The degreased steel strip is annealed in a full...

Embodiment 2

[0030] The production steps of semi-process cold-rolled non-oriented electrical steel are:

[0031] (1) Pickling: Pickle the non-oriented hot-rolled silicon steel strip with grade W800 using shallow groove turbulent flow push-pull pickling technology. The temperature of the first-stage acid bath is controlled at 90°C, and the last-stage acid bath The temperature of the solution is controlled at 70°C, and the concentration of the acid solution is controlled at 200g / L.

[0032] (2) Rolling: The steel strip after pickling is rolled to the set thickness by a six-high HC rolling mill, and the cold rolling deformation rate is ≥80%. In the final pass of rolling, a reasonable reserved amount is set to improve thickness control precision.

[0033] (3) Electrolytic degreasing:

[0034] The rolled steel strip is degreased by an electrolytic degreasing unit to remove grease and iron powder on the surface.

[0035] (4) Annealing:

[0036] The degreased steel strip is annealed in a full...

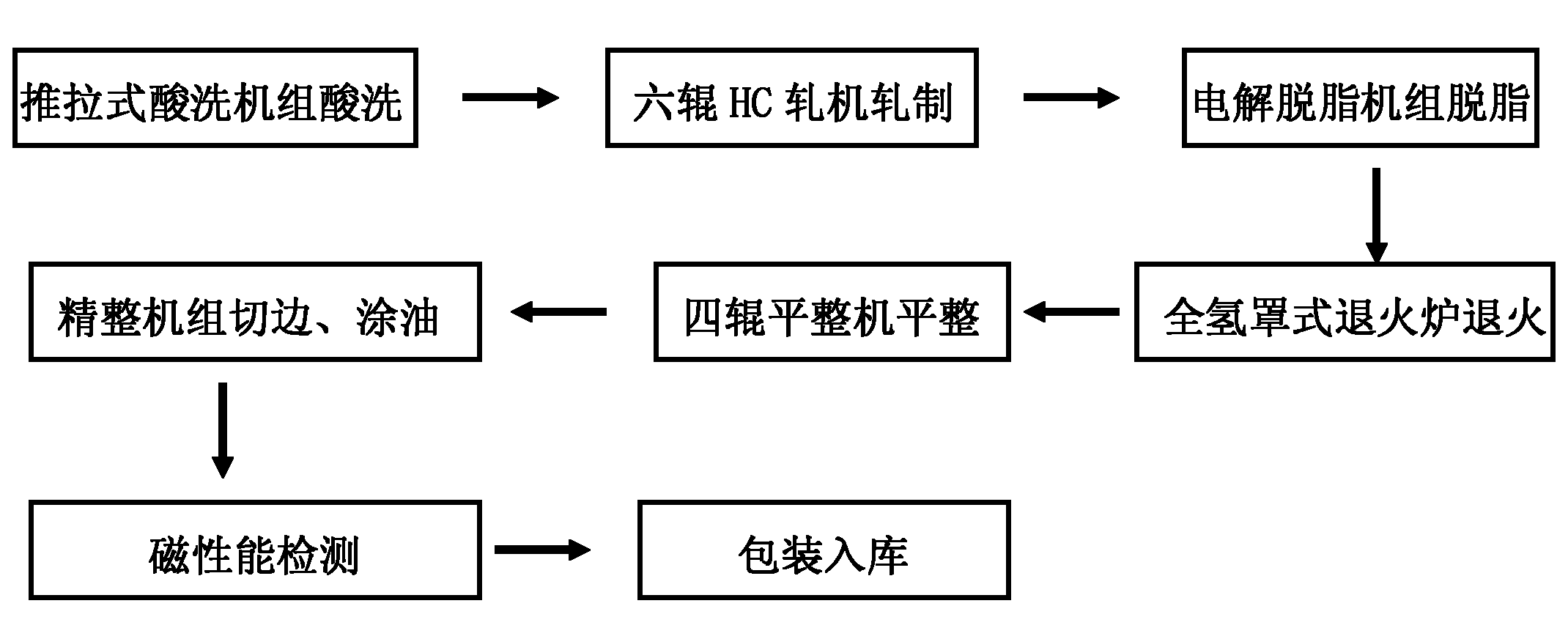

Embodiment 3

[0040] Production of semi-process cold-rolled non-oriented electrical steel, step (4) annealing:

[0041] The degreased steel strip is annealed in a full hydrogen bell annealing furnace, the heating time is controlled within 10 hours, recrystallization annealing is carried out at 780°C for more than 12 hours, and it is cooled slowly to 500°C and then cooled to 80°C with a cooling cover and released from the furnace ; Other steps are with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com