Method for manufacturing directional silicon steel

A production method and technology of oriented silicon steel, which is applied in the field of iron and steel metallurgy, can solve the problems of increased production time and cost, reduced yield, and lengthened process, and achieve the effects of reduced high-temperature annealing time, reduced production time, and improved production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

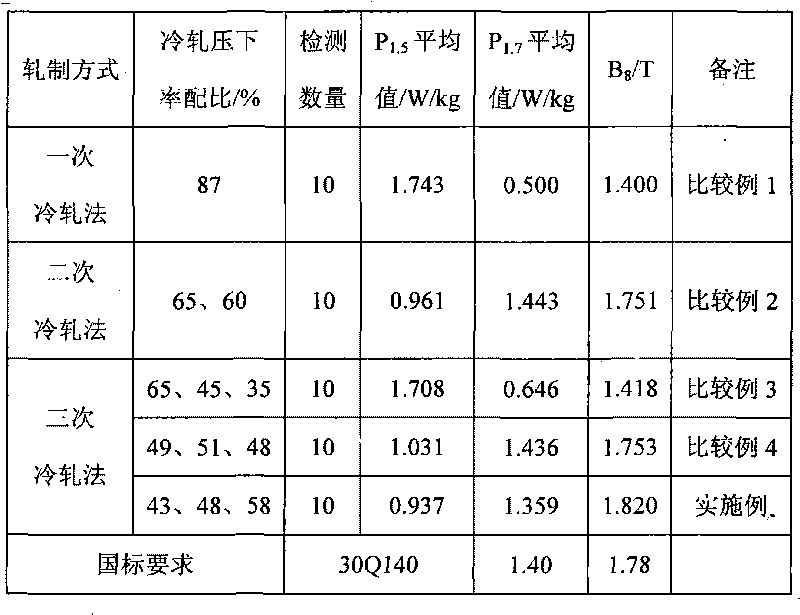

Examples

Embodiment Construction

[0024] The technological process of the present invention is: smelting→slab→heating→hot rolling→primary cold rolling→first intermediate annealing→second cold rolling→second intermediate annealing→third cold rolling→coating MgO→high temperature annealing.

[0025] The specific method is to perform vacuum melting according to the required composition of conventional oriented silicon steel, and cast into a slab. After cooling to room temperature, the surface of the slab is treated, and the treated slab is put into a heating furnace for high-temperature heating, and then heated after being discharged. Rolling and low-temperature coiling are characterized by three cold rolling, two intermediate annealing, one MgO coating production processes for rolling and treatment processes, the first intermediate annealing after one cold rolling; the first intermediate annealing eliminates processing Stress and partial decarburization. After the second cold rolling, the second intermediate annealin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com