Non-oriented electrical steel used for stereoscopic transformer with rolled iron core and production method thereof

A technology of grain-oriented electrical steel and three-dimensional wound iron core, applied in the field of steelmaking, can solve problems such as the adverse effects of the promotion of three-dimensional wound iron core transformers, and achieve the effects of reducing iron loss, improving recrystallization texture, and improving magnetic induction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

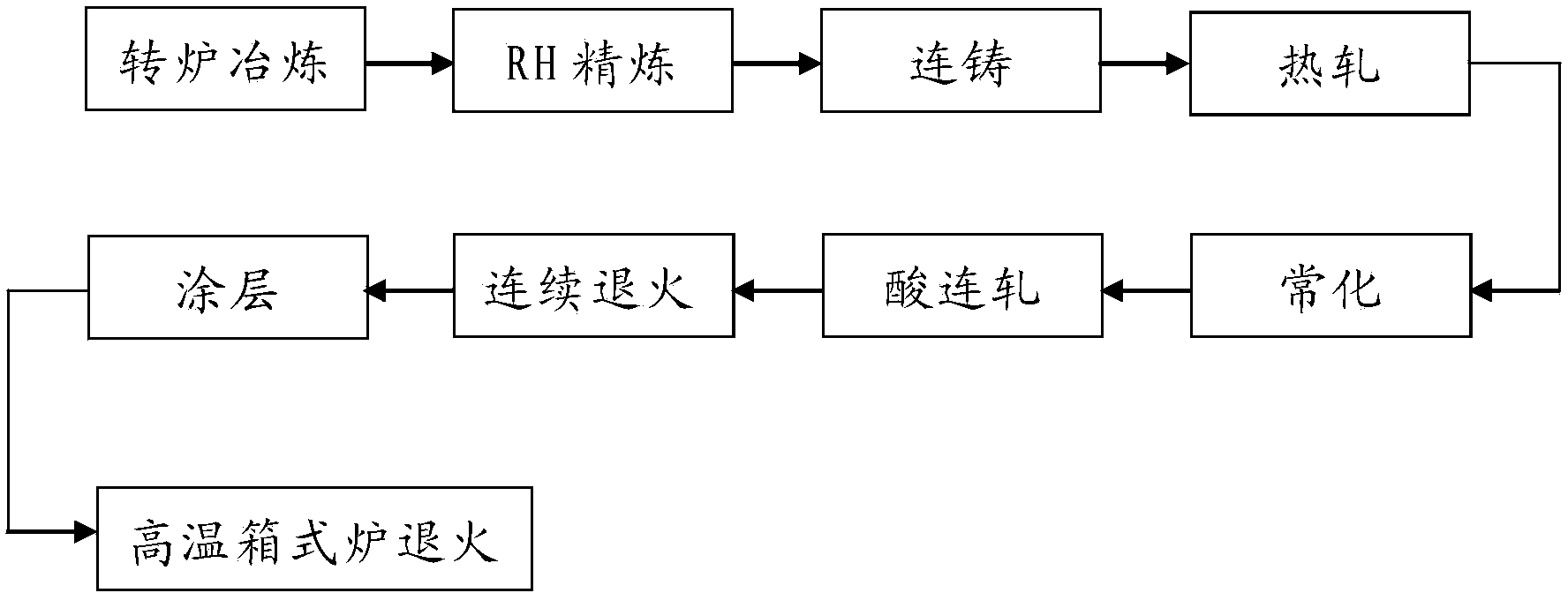

Method used

Image

Examples

Embodiment 1

[0045] Use molten iron with a titanium content of 0.15%, and the temperature of the molten iron is 1320°C for desulfurization treatment. The S of the molten iron is 0.0030%, and 1 ton of low-sulfur scrap steel is added. The composition of the end point of the converter is 0.04% for C, 0.0040% for S, and 0.023% for P. , O activity 500ppm, tapping temperature 1650 ℃. RH refining adopts decarburization mode. First, low-carbon ferrosilicon is used to adjust silicon, then aluminum particles are used to adjust aluminum, and finally micro-carbon ferromanganese is adjusted to manganese. The end temperature of RH refining is 1580 ° C, and the entire refining cycle is 45 minutes. The continuous casting adopts full-protection casting, uses carbon-free silicon steel heat preservation agent, uses automatic control of mold liquid level, and uses special mold slag for silicon steel; adopts electromagnetic stirring, the target casting speed is 1.10m / min, and the secondary cooling water adopts ...

Embodiment 2

[0049] Use molten iron with a titanium content of 0.14%, the temperature of the molten iron is 1340°C, and carry out desulfurization treatment. The S of the molten iron is 0.0024%, and 1.2 tons of low-sulfur scrap steel is added. The composition of the end point of the converter is 0.045% for C, 0.0042% for S, and 0.025% for P. , O activity 550ppm, tapping temperature 1630 ℃. RH refining adopts decarburization mode. First, low-carbon ferrosilicon is used to adjust silicon, then aluminum particles are used to adjust aluminum, and finally micro-carbon ferromanganese is adjusted to manganese. The end temperature of RH refining is 1570 ° C, and the entire refining cycle is 40 minutes. The continuous casting adopts full-protection casting, uses carbon-free silicon steel heat preservation agent, uses automatic control of mold liquid level, and uses special mold slag for silicon steel; adopts electromagnetic stirring, the target casting speed is 1.0m / min, and the secondary cooling wat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com