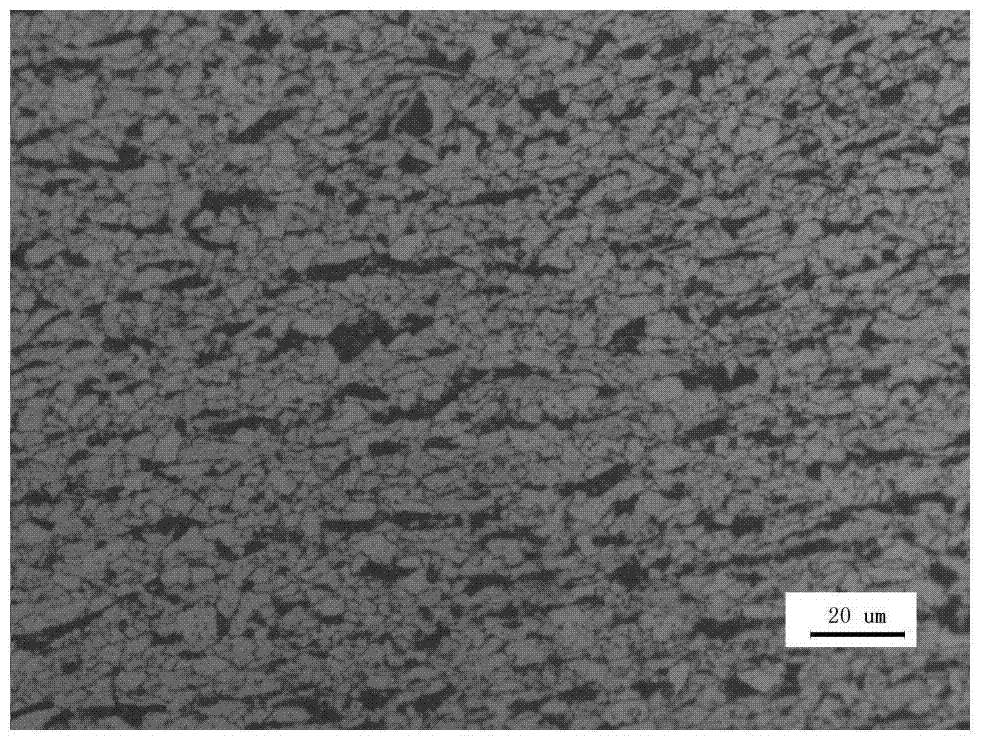

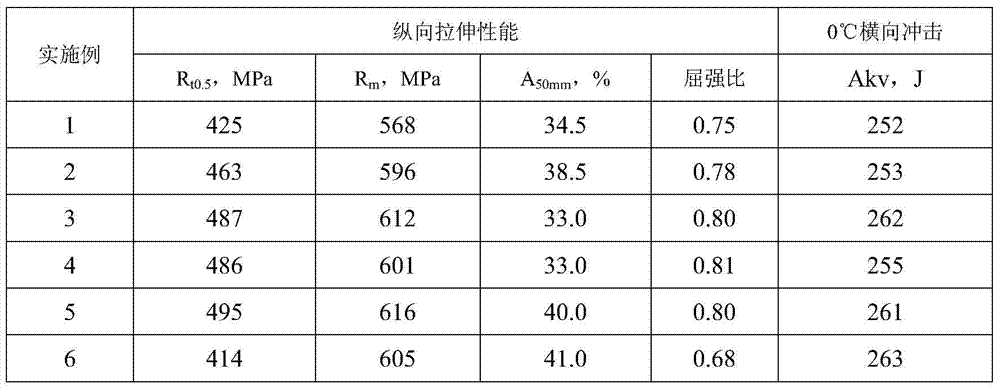

J55 grade steel for resistance welding casing with low yield strength ratio and its manufacturing method

A low yield ratio, resistance welding technology, applied in J55 grade ERW oil casing steel and its manufacturing field, can solve the problems of weldability, impact toughness and formability, low tensile strength, high yield strength, etc., to achieve yield No significant increase in strength, high tensile strength, and low yield strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] Its chemical composition (weight, %) ratio is as follows: C: 0.090% ~ 0.128%, Si: 0.10% ~ 0.35%, Mn: 1.02% ~ 1.25%, P: ≤0.015%, S: ≤0.008%, Nb: 0.01% to 0.03%, Ti: 0.010% to 0.030%, Cr: 0.30% to 0.40%, Als: 0.02% to 0.06%, N: ≤0.008%, and the rest are Fe and unavoidable elements.

[0040] Its characteristics are:

[0041] 1) Smelting and continuous casting process: molten iron pretreatment, converter smelting - through top blowing or top-bottom composite blowing, refining outside the furnace - LF furnace light desulfurization treatment, and calcium treatment to control the shape of inclusions and improve the ductility of steel, Toughness and cold bending performance, continuous casting of slabs to make continuous casting slabs - continuous casting adopts electromagnetic stirring or dynamic light reduction to improve the quality of continuous casting slabs.

[0042] 2) Rolling process: the continuous casting slab is heated to 1160-1200°C by the heating furnace, and then...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com