Low-temperature-resistant and easy-to-weld ultra-low-carbon steel thick plate and preparation method thereof

An ultra-low carbon steel and easy-to-weld technology, which is applied in the field of ultra-low carbon steel and its preparation, can solve the problems of unsatisfactory pipeline transportation steel pipe requirements, unsatisfactory mechanical properties of steel, and poor resistance to large deformation, so as to achieve energy saving and consumption reduction Cost, good economic benefit, good effect of crack arrest toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

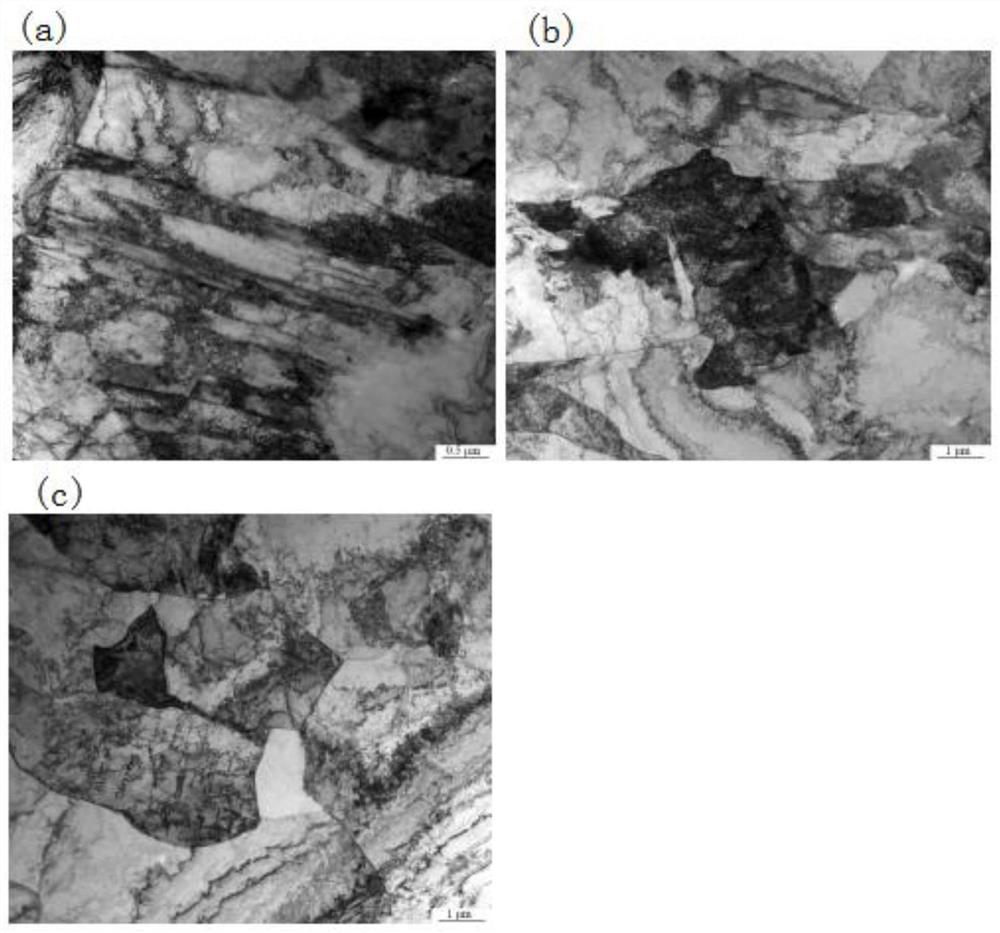

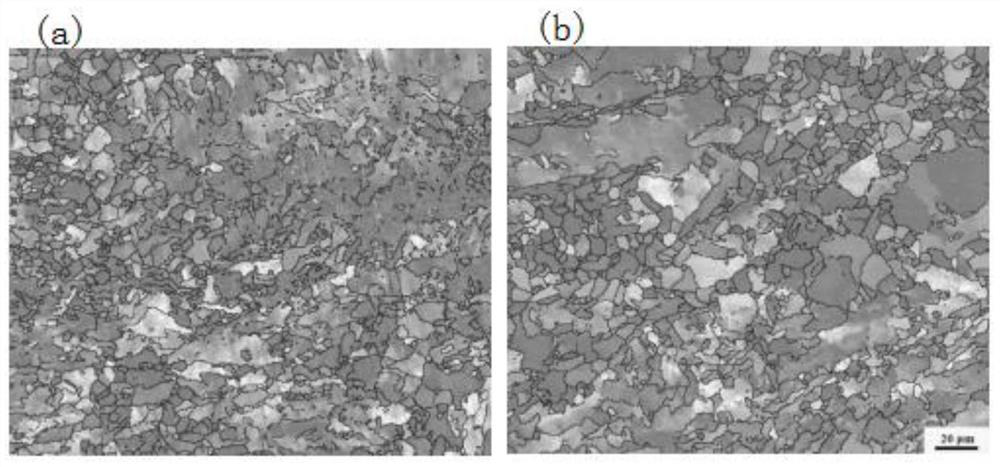

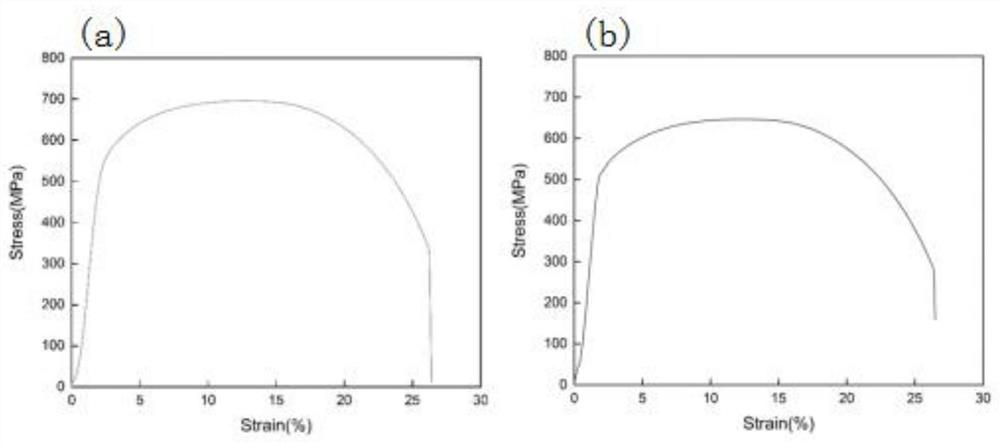

[0046] In order to further clarify the technical problems, technical solutions and technical effects to be solved by the present invention, the following will be described in detail with reference to the accompanying drawings and the embodiments. The embodiments are only to help understand the present invention and should not be regarded as a specific limitation of the present invention.

[0047] Aiming at the problems of the prior art, the present invention provides an ultra-low carbon steel thick plate that is resistant to low temperature and easy to weld and a preparation method thereof. As shown in Table 2, steels with matching strength and toughness, low temperature resistance and easy welding were obtained, as shown in Table 3.

[0048] Table 1 lists the mass percentages of the main alloy elements in the examples and comparative examples of this technical solution. The contents of other elements in the examples and comparative examples are the same, wherein Ca is 0.0025wt...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com