A kind of seamless flux-cored welding wire for LNG storage tank high manganese low temperature steel and its preparation method

A technology of seamless flux-cored welding wire and low-temperature steel, applied in welding equipment, manufacturing tools, welding media, etc., can solve the problems of increased product cost, low workability, and high Ni content, so as to improve the loose loading ratio and prevent repeated The effect of moisture absorption and high impact toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

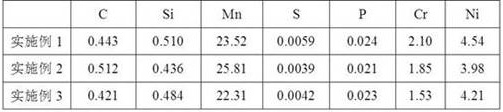

Embodiment 1

[0036] A seamless flux-cored welding wire for high-manganese low-temperature steel for LNG storage tanks, which contains raw materials and their proportions as follows: electrolytic manganese metal 67%, nickel powder 12%, silicon powder 0.9%, soda ash 0.6%, high-carbon ferrochrome 7%, sintered powder 8% (of which the proportion of each component is new potassium titanate 28%, alumina 22%, graphite 15%, magnesia 27%, the rest is binder), and the rest is iron powder; from the above raw materials Mixed composition, filling rate 37%, wire diameter 1.2mm.

Embodiment 2

[0038] A seamless flux-cored welding wire for high-manganese low-temperature steel for LNG storage tanks, which contains raw materials and their proportions as follows: electrolytic manganese metal 72%, nickel powder 10%, silicon powder 0.7%, soda ash 0.5%, high-carbon ferrochrome 4%, 6% sintered powder (including 28% new potassium titanate, 22% alumina, 15% graphite, 27% magnesia, and the rest is binder), and the rest is iron powder; from the above raw materials Mixed composition, filling rate 35%, wire diameter 1.2mm.

Embodiment 3

[0040]A seamless flux-cored welding wire for high-manganese low-temperature steel for LNG storage tanks, which contains raw materials and their proportions as follows: electrolytic manganese metal 74%, nickel powder 13%, silicon powder 0.5%, soda ash 0.8%, high-carbon ferrochrome 5%, sintered powder 5% (of which the proportion of each component is 28% of new potassium titanate, 22% of alumina, 15% of graphite, 27% of magnesia, and the rest is binder), and the rest is iron powder; from the above raw materials Mixed composition, filling rate 32%, wire diameter 1.2mm.

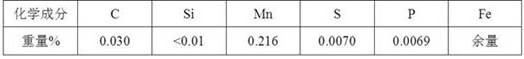

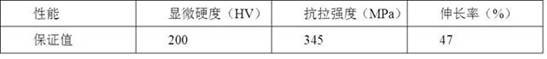

[0041] The preparation method of the seamless flux-cored welding wire for the high manganese steel of the LNG storage tank of the present invention is as follows: the sheath is made of SPHC steel strip, and the composition and properties are shown in Tables 1 and 2. The chemical composition and mechanical properties of the welding wire deposited metal are shown in Table 3 and Table 4.

[0042] Table 1 The chemica...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com