Workpiece locating device of multi-motorcycle-type welding production line of general motors

A welding production line, general automobile technology, applied in auxiliary devices, welding equipment, manufacturing tools, etc., can solve the problems of extending the cycle of new products into mass production, low degree of generalization of production equipment, affecting automobile production efficiency, etc. The effect of reducing capital investment, shortening the cycle of mass production, and enhancing general performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

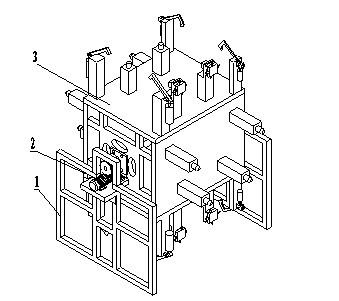

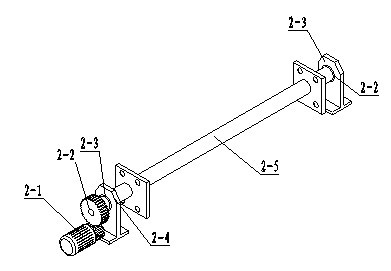

[0023] Referring to Fig. 1, the present invention comprises polyhedron workbench 3, driving mechanism 2 and frame 1, and described polyhedron workbench 3 is provided with four working surfaces at least, and it is fixedly assembled with driving mechanism 2, and described driving mechanism 2 is fixedly installed on frame 1 Above, the frame 1 includes two parts symmetrically arranged left and right, both of which are fixed on the horizontal working surface.

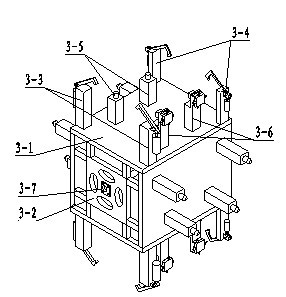

[0024] Referring to Fig. 3, the polyhedron workbench 3 of the present invention is a regular polyhedron structure, and its two end faces are mounting surfaces 3-2, and on each mounting surface 3-2, connecting plates 3-7 are fixedly assembled, and the polyhedron workbench 3 Each side is a working surface 3-1, and each working surface 3-1 is provided with a welding clamping mechanism and a positioning mechanism matched with workpieces of different models.

[0025] see image 3 , Figure 4 , the clamping mechanism of the pres...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com