Fireproof door glass pressing frame mounting hole drilling and forming device and drilling and forming method

A technology for forming equipment and installation holes, which is applied in the field of drilling and forming equipment for installation holes of fire door glass pressing frames and drilling and forming, which can solve the problems of limited space for glass pressing frames, error of hole distance, low production efficiency, etc., and achieve guaranteed The effect of overall molding quality, reduction of production cost and improvement of production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

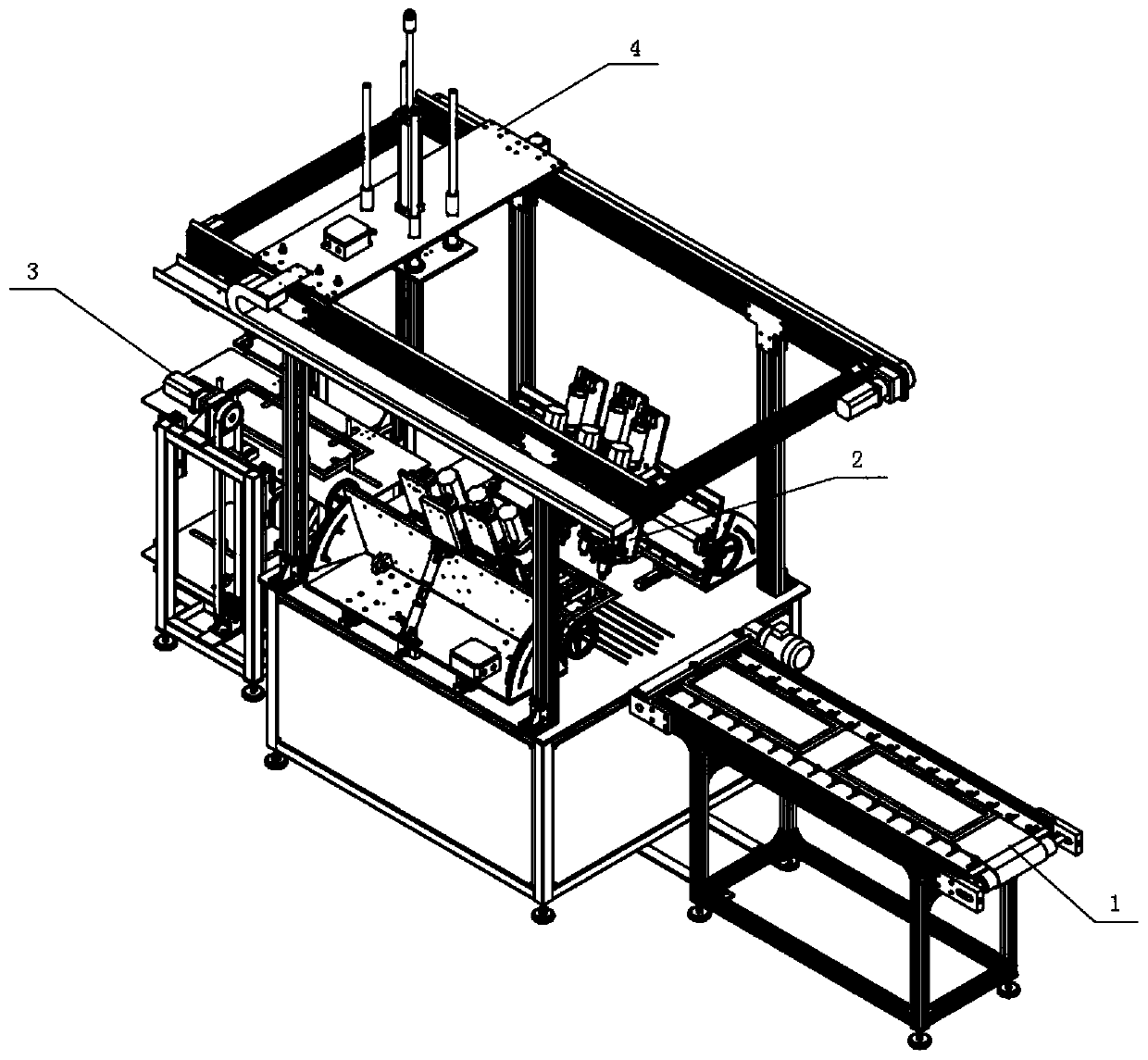

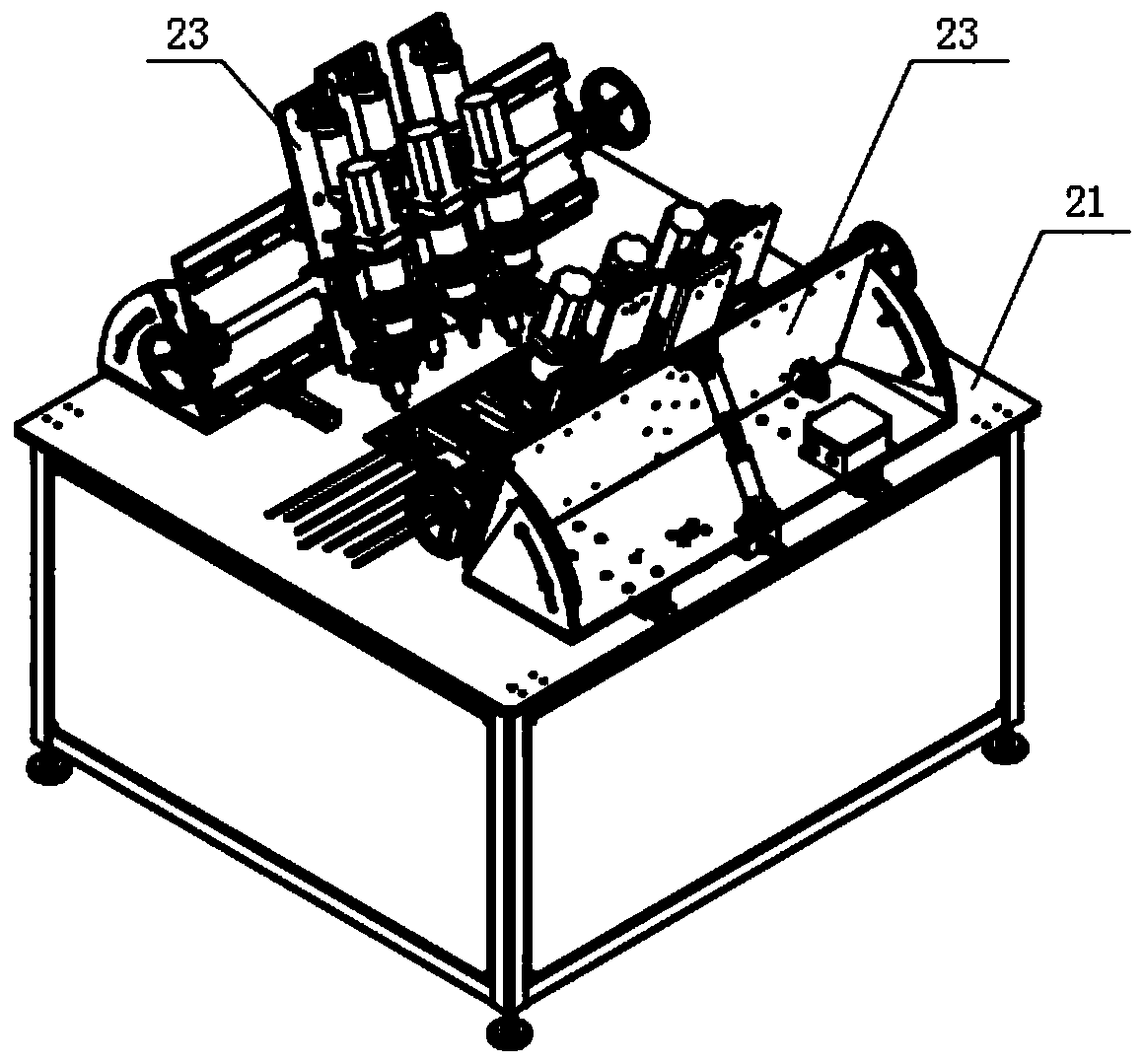

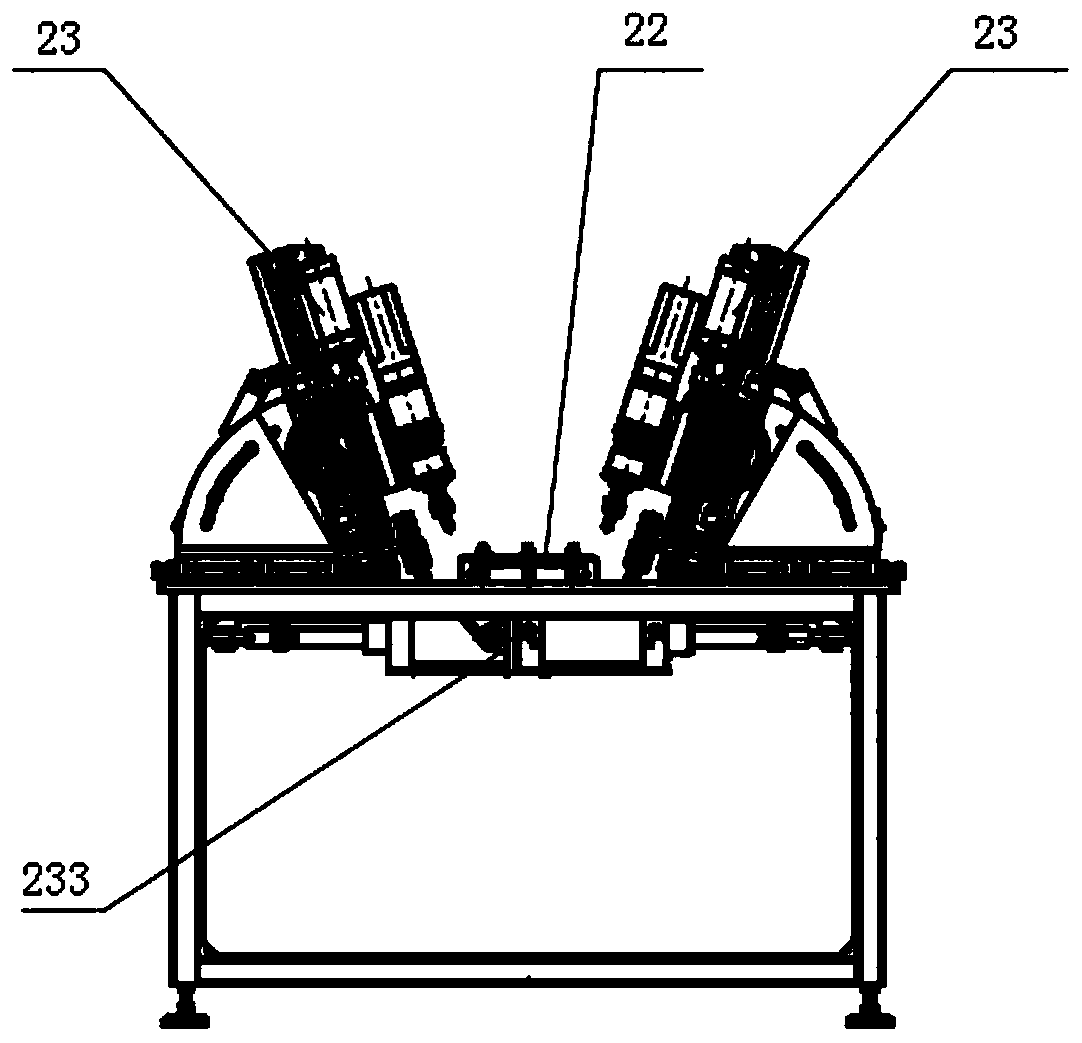

[0044] Such as Figure 1 to Figure 7 Shown is the first embodiment of the installation hole drilling and forming equipment for the fire door glass pressure frame of the present invention. Such as Figure 1 to Figure 3 As shown, a fire door glass press frame mounting hole drilling and forming equipment includes a feeding device 1, a drilling forming device 2 and a material storage device 3 arranged in sequence, and also includes a workpiece transfer device arranged above the drilling forming device 2 Device 4 and the electric control system that is used to control equipment; Drilling forming device 2 comprises workbench 21, positioning mechanism 22, is respectively located at the drill mechanism 23 of positioning mechanism 22 length direction both sides; Workpiece transfer device 4 comprises control frame 41 and The adsorption mechanism 42 is used to adsorb the glass press frame, and the control frame 41 controls the adsorption mechanism 42 to move along the length direction o...

Embodiment 2

[0057] This embodiment is similar to Embodiment 1, except that, in this embodiment, the adsorption mechanism 42 does not use electromagnets for adsorption, but vacuum adsorption.

Embodiment 3

[0059] This embodiment is similar to Embodiment 1, except that, in this embodiment, in the second adjustment mechanism 235 , what is used to adjust the sliding plate is not a hand wheel mechanism, but a motor or an air cylinder.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com