Vanadium-containing hot rolled steel plate and preparation method thereof

A hot-rolled steel plate and slab technology, applied in the field of vanadium-containing hot-rolled steel plate and its preparation, can solve the problems of inconvenient steel plate welding, increased production organization, low-alloy steel performance, etc., to improve production efficiency, reduce alloy addition, Reduce the effect of mixing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Example 1 Production of continuous casting slab

[0037] Produce alloy steel with chemical composition weight percentage of C: 0.06%~0.10%, Si: ≤0.30%, Mn: 1.05%~1.25%, V: 0.04%~0.07%, P: ≤0.025%, S: ≤0.015% , Cast it into a continuous casting slab of 200mm×(900~1300)mm×11000mm by conventional continuous casting method. A total of 5 batches of continuous casting slabs were produced, with numbers 1, 2, 3, 4, and 5 respectively. The chemical composition of each batch is determined in Table 1.

[0038] Table 1 Determination results of chemical composition of continuous casting slab (%) (The balance is iron and inevitable impurities)

[0039] serial number

Embodiment 2

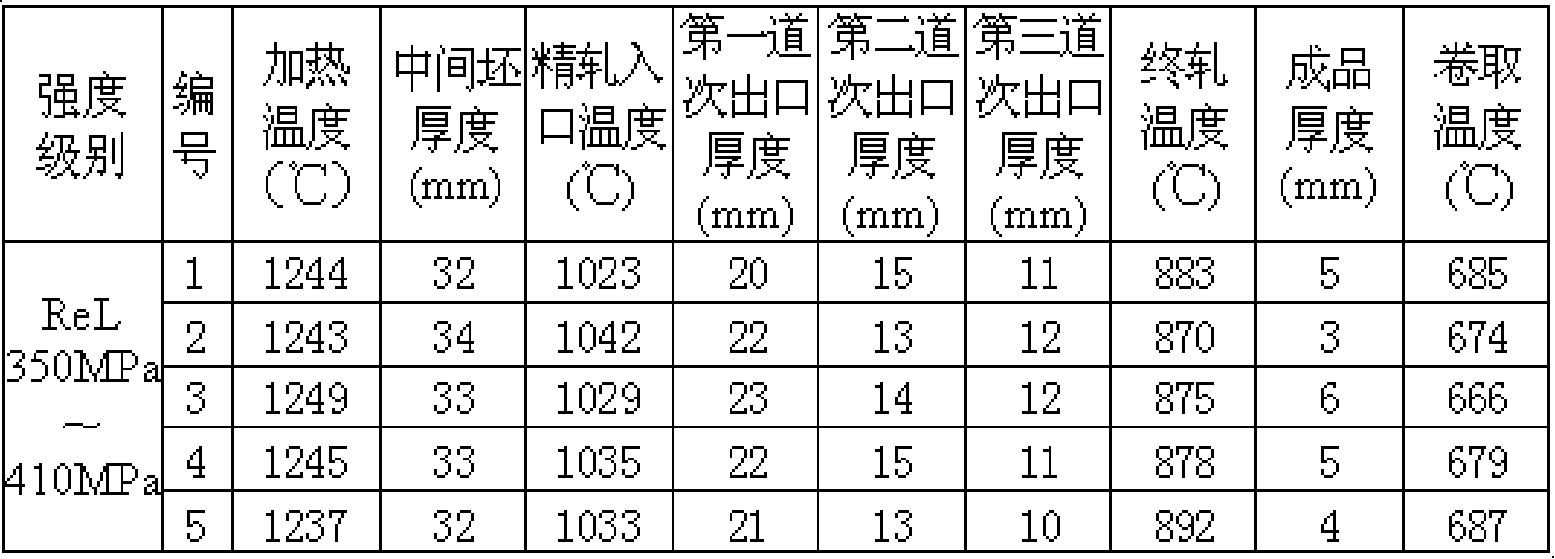

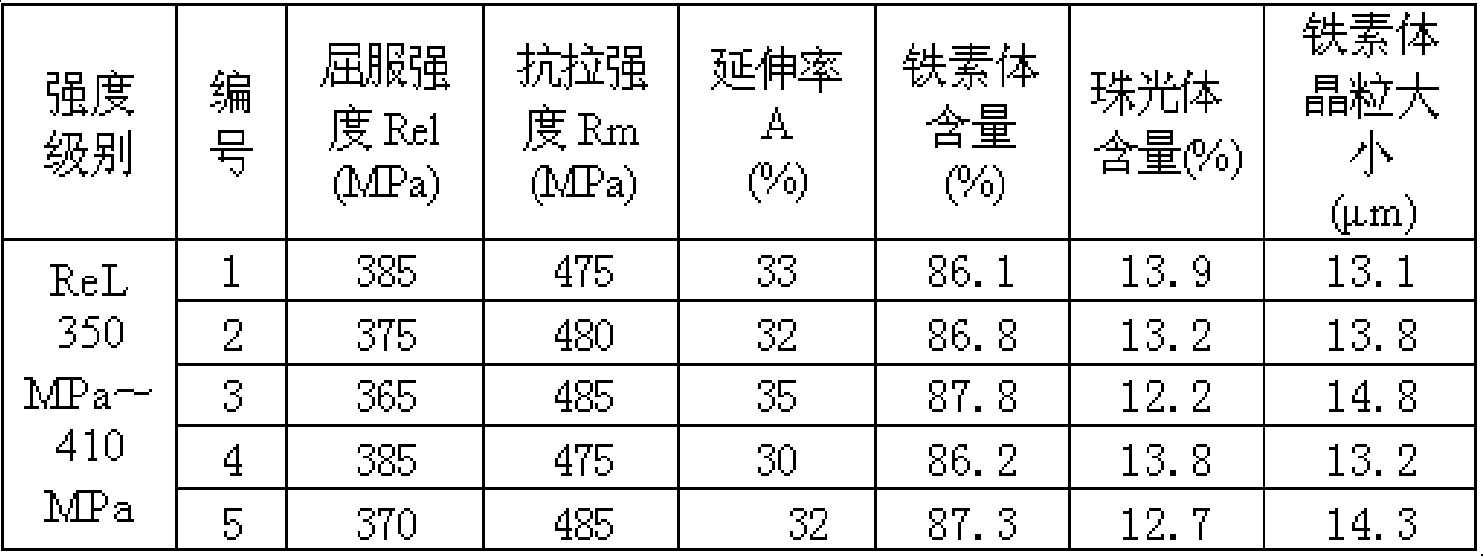

[0040] Example 2 Preparation of hot-rolled steel sheet with a yield strength ReL of 350MPa~410MPa

[0041] The continuous casting slab produced in Example 1 was heated to 1230°C to 1250°C for rough rolling. After the rough rolling, the thickness of the intermediate slab was 32mm to 34mm, and it was coiled in a coreless transfer hot coil box; the finishing rolling temperature was controlled at 1000℃~1040℃; the thickness of the first pass of finishing rolling is 20~23mm, the thickness of the second pass is 13~15mm, the thickness of the third pass is 10~12mm, and the thickness of the finished product is 3~7mm; The final rolling temperature range is 870℃~900℃; after rolling, laminar cooling is cooled from 870℃~900℃ to the coiling temperature range of 660℃~700℃ at an average cooling rate of 8.5~20.0℃ / s, and then sent after cooling. The finishing line performs leveling and sub-rolling. The rolling process parameters and finished product properties are shown in Table 2 and Table 3.

[00...

Embodiment 3

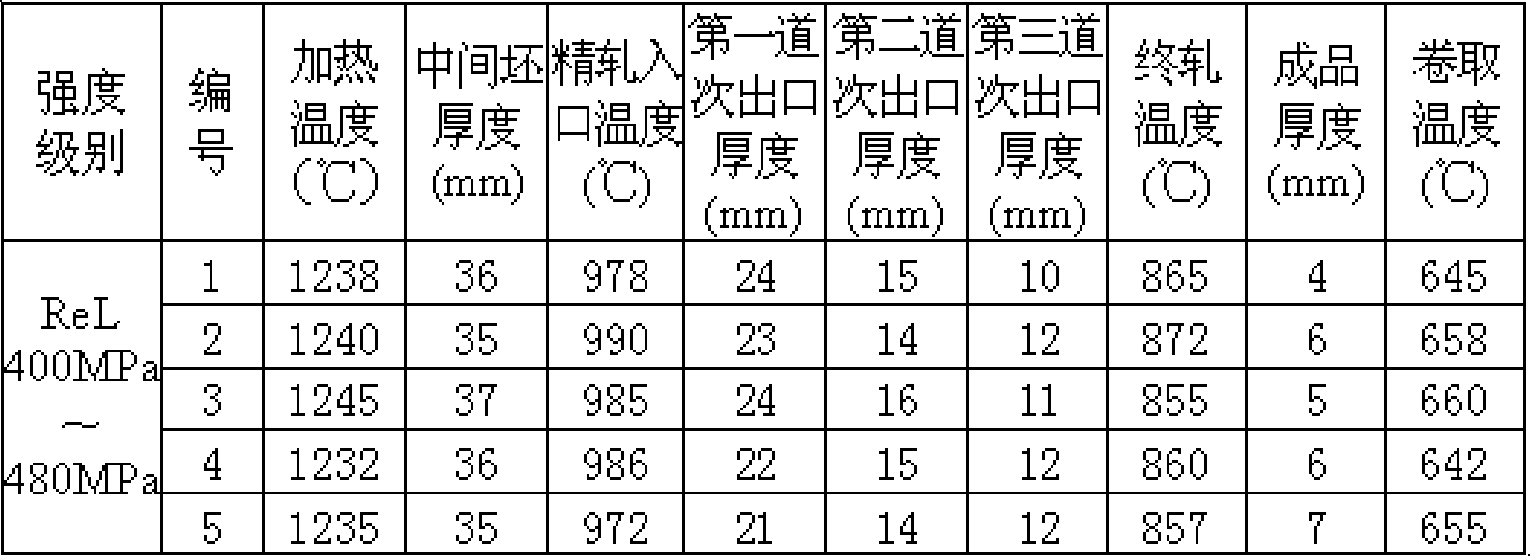

[0046] Example 3 Preparation of hot-rolled steel sheet with a yield strength ReL of 400MPa~480MPa

[0047] The continuous casting slab produced in Example 1 was heated to 1230°C to 1250°C for rough rolling. After the rough rolling, the thickness of the intermediate slab was 35mm to 37mm, and it was coiled in a coreless transfer hot coil box; the finishing rolling temperature was controlled at 970℃~1000℃; the thickness of the first pass of finishing rolling is 21~24mm, the thickness of the second pass is 14~16mm, the thickness of the third pass is 10~12mm, and the thickness of the finished product is 3~7mm; The final rolling temperature range is 850℃~880℃; after rolling, laminar cooling is cooled from 850℃~880℃ to the coiling temperature range of 630℃~660℃ at an average cooling rate of 8.5~20.0℃ / s, and then sent after cooling. The finishing line performs leveling and sub-rolling. The rolling process parameters and finished product properties are shown in Table 4 and Table 5.

[0048]...

PUM

| Property | Measurement | Unit |

|---|---|---|

| grain size | aaaaa | aaaaa |

| grain size | aaaaa | aaaaa |

| grain size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com