POY (polyester pre-oriented yarn) spinning method and device by using FDY (fully drawn yarn) spinning device

A spinning device and spinning technology, applied in the directions of melt spinning, textile and papermaking, filament/thread forming, etc. The wire system and the second wire guide system are not on the same vertical plane, etc., to achieve the effect of simple method, less investment in transformation, and fast transformation speed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Below in conjunction with accompanying drawing, specific embodiment of the present invention is described in detail,

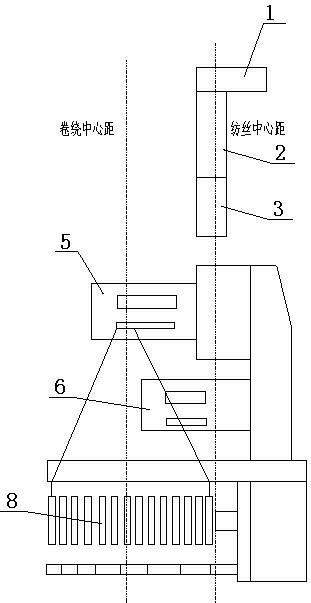

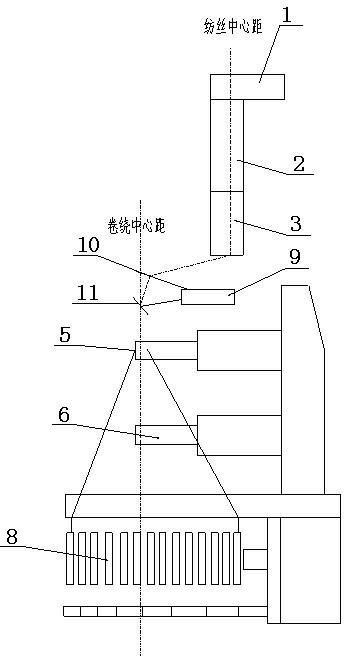

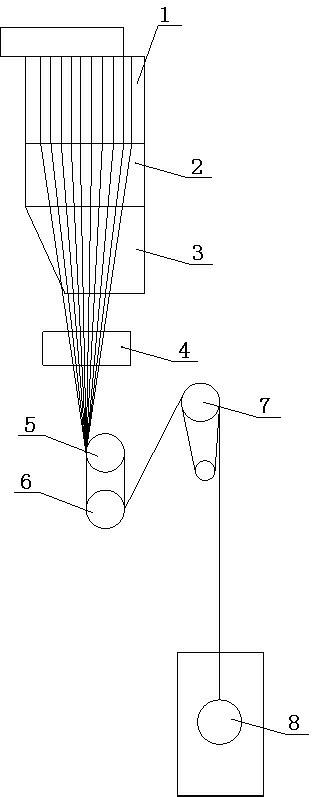

[0018] Such as figure 1 , image 3 The original FDY spinning device shown includes a box body 1 , a side blower window 2 , a tunnel 3 , a first heat roll 6 , a second godet roll 7 and a winder 8 . Such as figure 2 , Figure 4 As shown, the POY spinning device deactivates the oil tanker 4 of the original FDY spinning device, adds an oil nozzle 12 on the top of the tunnel 3 for oiling, and pre-networks the lower guide hook 10 and the comb-type yarn separator in front of the first hot roller 11 By setting the extension rod 9 to move outward, the spinning center line is moved outward; at the same time, the second hot roller 5 of the original FDY spinning device is deactivated, and the first hot roller 6 and the second godet roller 7 are kept, and the tow is once After passing through the first heating roller 6 and winding the second godet roller 7 4 to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com