Method and device for detecting product surface defects

A defect detection and product technology, applied in the detection field, can solve problems such as poor flexibility, high cost, and low degree of flexibility, and achieve the effects of flexible production, improved work efficiency, and reduced device and human costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

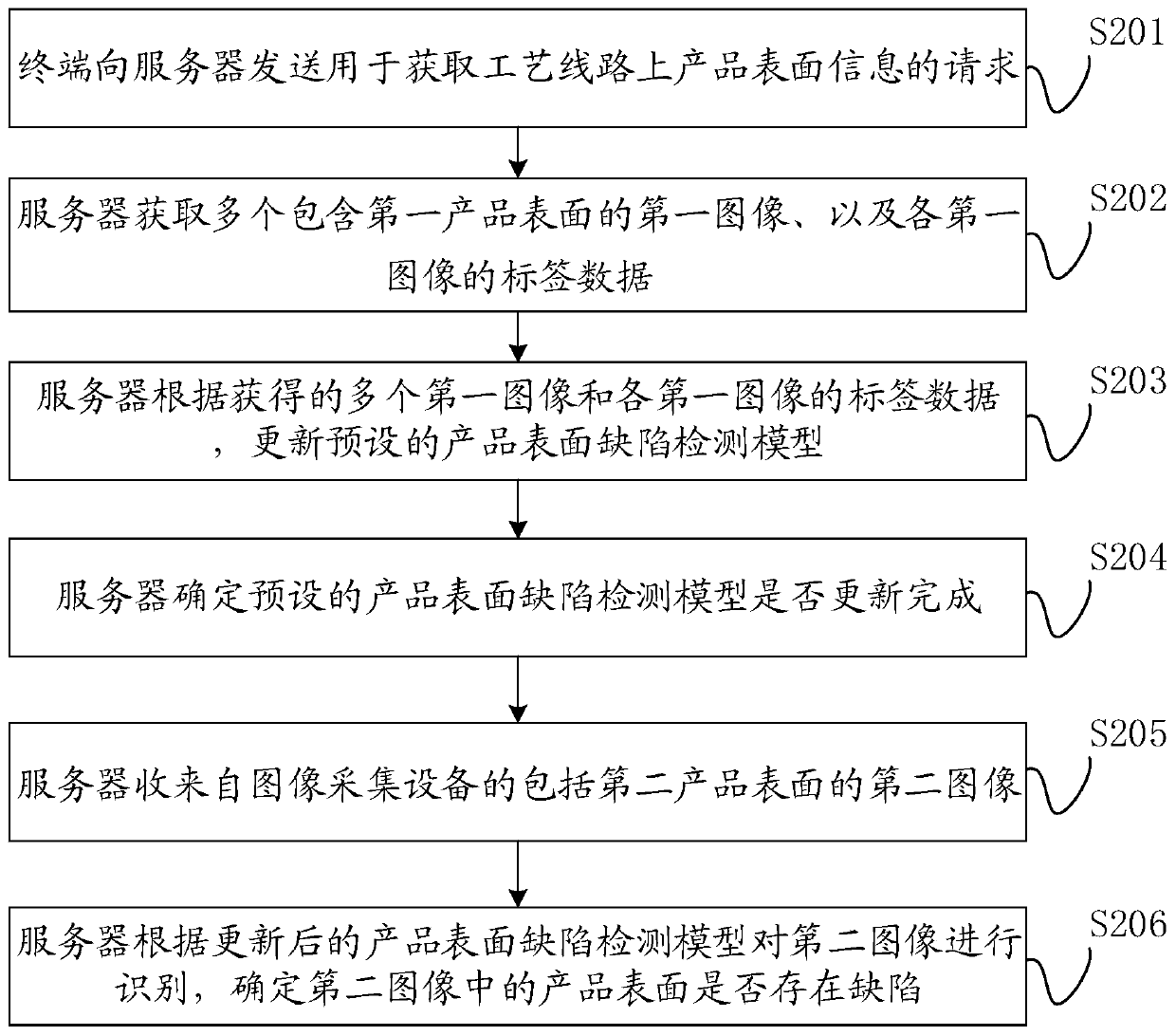

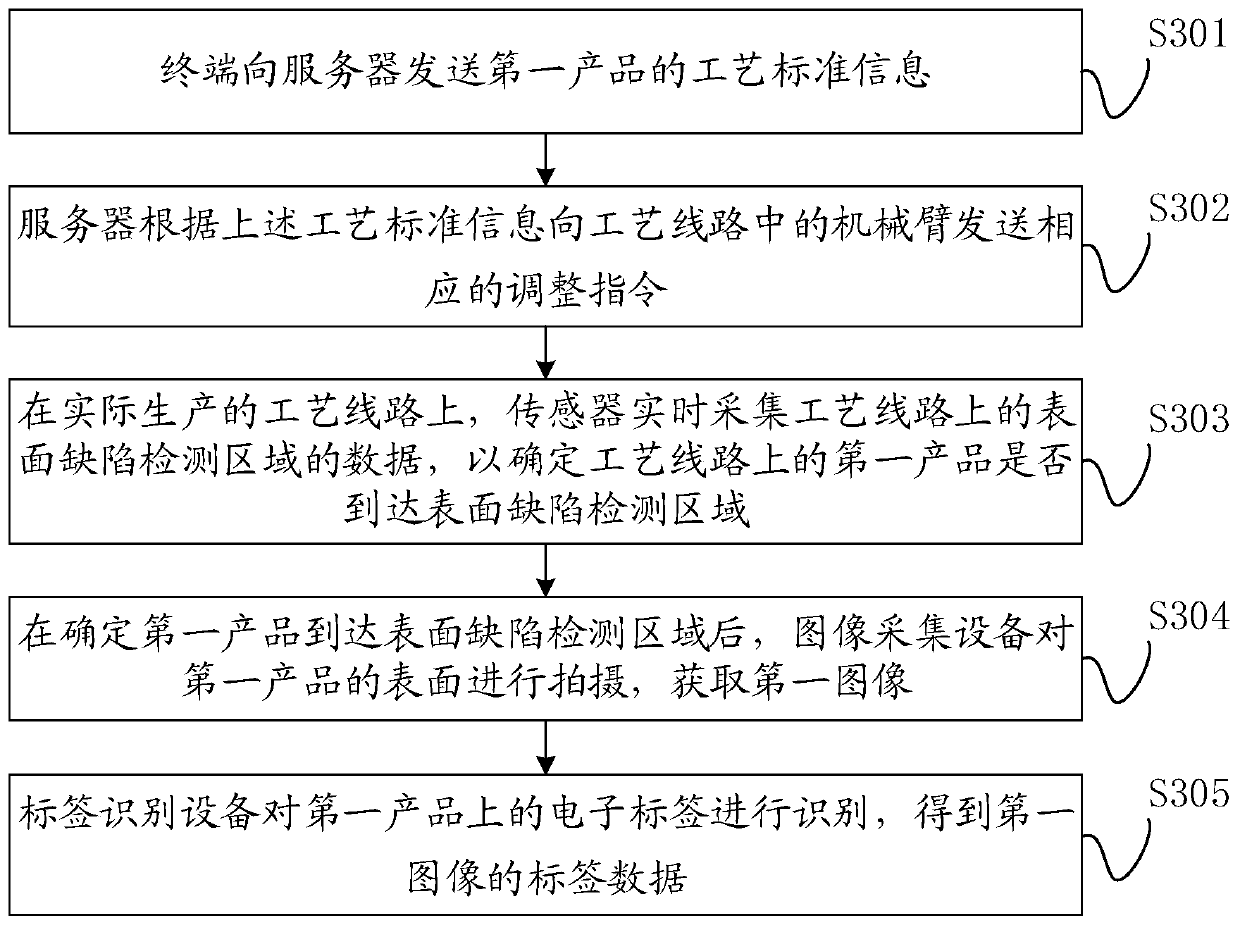

[0021] In order to explain the overall concept of the present application more clearly, the following detailed description will be given by way of examples in combination with the accompanying drawings.

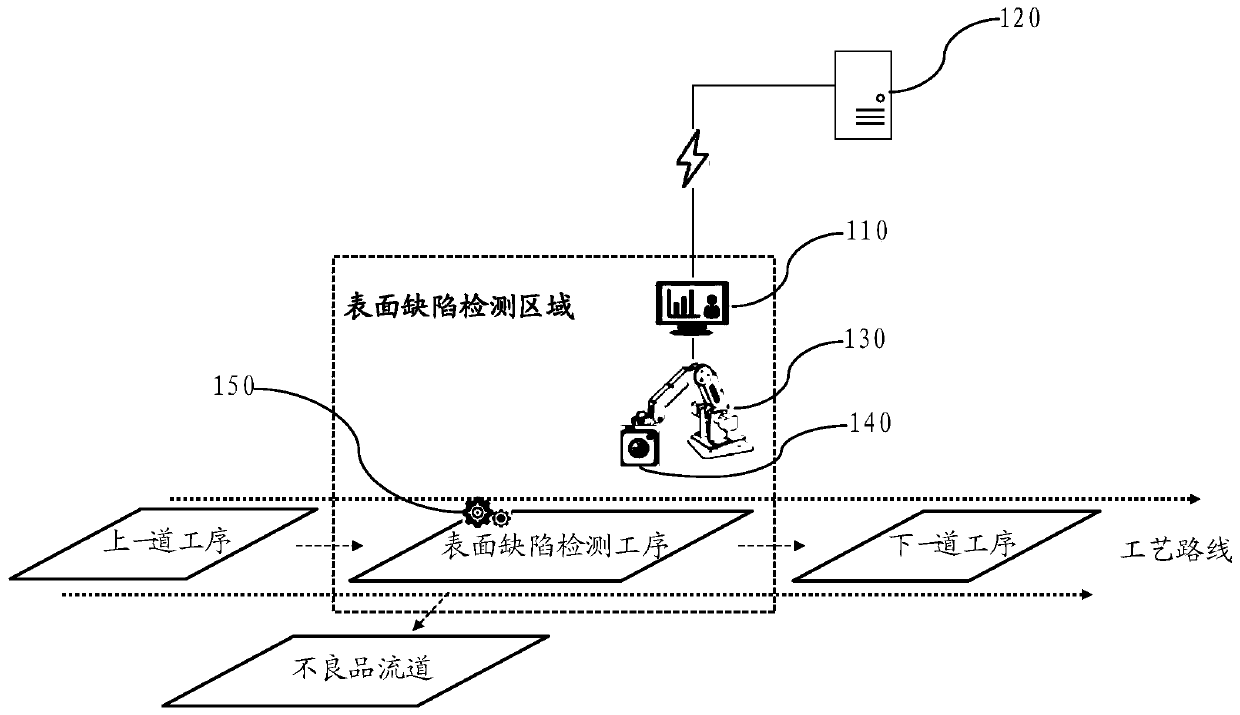

[0022] figure 1 An application scene diagram of a product surface defect detection method provided in the embodiment of this application. Such as figure 1 As shown, the production process line includes many processes, such as the surface defect detection process. In the surface defect detection area of the process line, a robot arm 130 and an image acquisition device 140 fixedly connected to the robot arm 130 are provided.

[0023] On the process line, the terminal 110 sends a product surface defect detection request to the server 120, and when the product to be inspected for surface defect detection arrives at the surface defect detection area from the previous process, the server 120 sends a corresponding response to the mechanical arm 130 and the image acquisition devic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com