Rapid clamping tool

A clamping and tooling technology, applied in the field of drum brake brake shoe processing, can solve the problems of large diameter, heavy weight and single variety of disc milling cutters

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

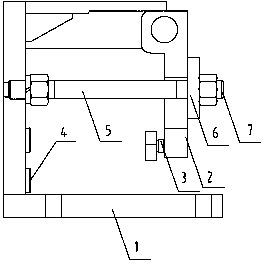

[0007] A quick clamping tool of the present invention includes a base assembly 1, a pressing plate assembly 2, a pressing column 3, a positioning block 4, an adjustable supporting column 5, a pin shaft 6 and a cotter pin 7. When working, turn the pressure plate assembly to the top, place the workpiece on the outside of the tooling, and the outer surface of the shoe and the outer surface of the roller shaft hole respectively face the left support block and baffle of the upper 1 base assembly, and push the shoe into , so that one end surface is in contact with the positioning block, and the adjustable support column determines whether it needs to be adjusted according to the actual situation. Turn the pressure plate assembly down and align it with the shoe reinforcement plate for compression, and the compression column determines whether it needs to be adjusted according to the actual situation. Both the outer circle of the shoe and the outer circle of the hole are arc surfaces, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com