Fixture storage and switching system

A switching system and storage system technology, which is applied in the field of fixture storage switching system, can solve the problems of high docking precision requirements and rising costs, and achieve the effect of improving maintainability and flexible trajectory

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

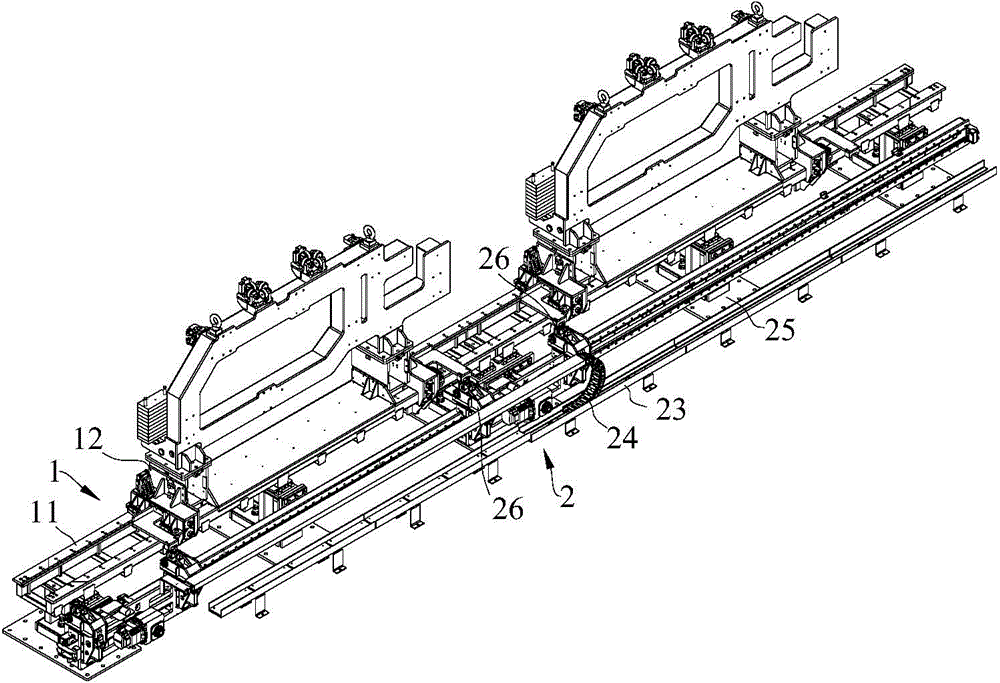

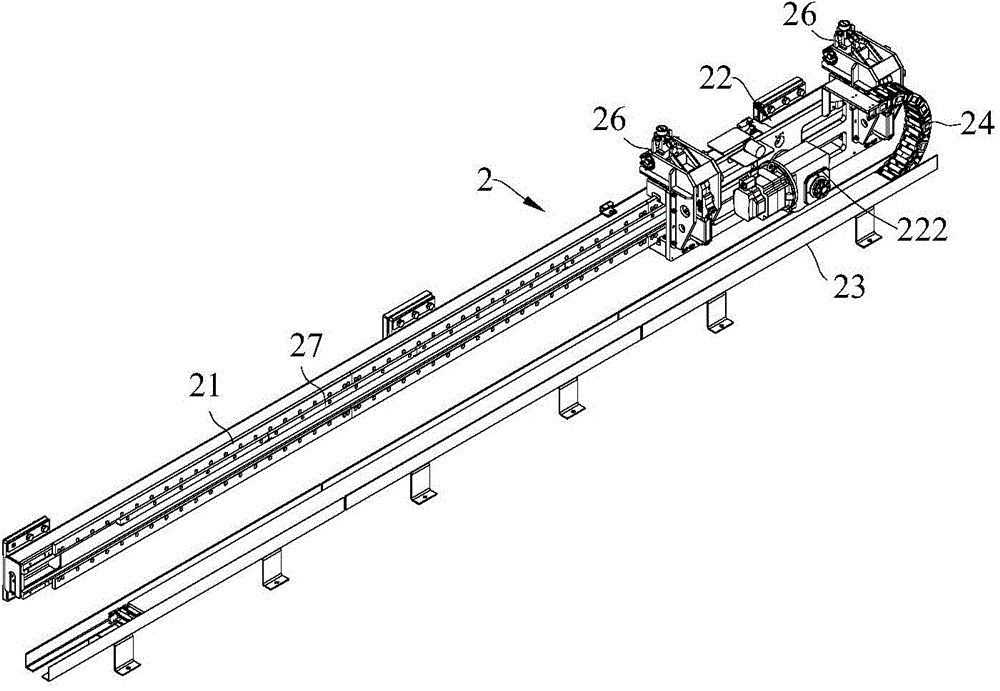

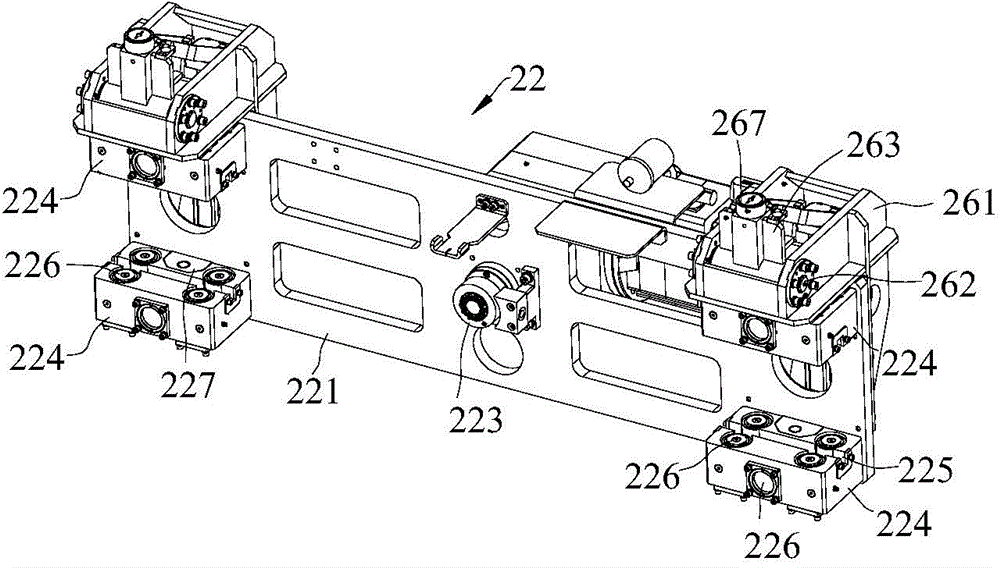

[0020] refer to Figure 1 to Figure 4 , which shows the specific structure of the preferred embodiment of the present invention. The structural characteristics of each element of the present invention will be described in detail below, and if there is a description of the direction (up, down, left, right, front and back), it is based on figure 1 The structure shown is a reference description, but the actual application direction of the present invention is not limited thereto.

[0021] The present invention provides a clamp storage switching system, comprising a clamp storage system 1 and a clamp drive system 2, the clamp storage system 1 includes a clamp movement track 11 and a clamp 12 located on the clamp movement track 11, the clamp drive The system 2 includes a driving track 21 which is independent from the clamp moving track 11 and arranged in parallel with the clamp moving track 11 and a driving trolley 22 which can run along the driving track 21, and a drag chain supp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com