Engine docking test dolly for bench test and bench test system

A bench test and engine technology, applied in the direction of engine testing, machine/structural component testing, measuring devices, etc., can solve problems such as reduced production efficiency, adjustment, and the inability to simulate actual working conditions relatively accurately during thermal testing. Accurate testing and flexible production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings. It should be understood that the specific embodiments described here are only used to illustrate and explain the present invention, and are not intended to limit the present invention.

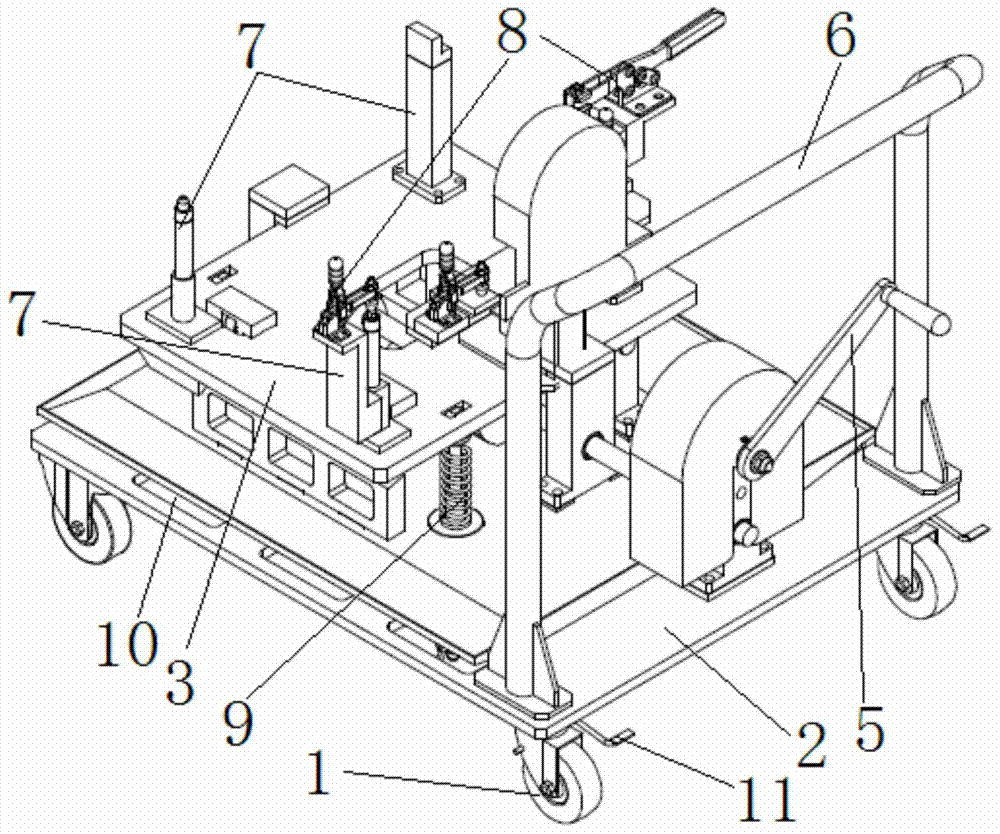

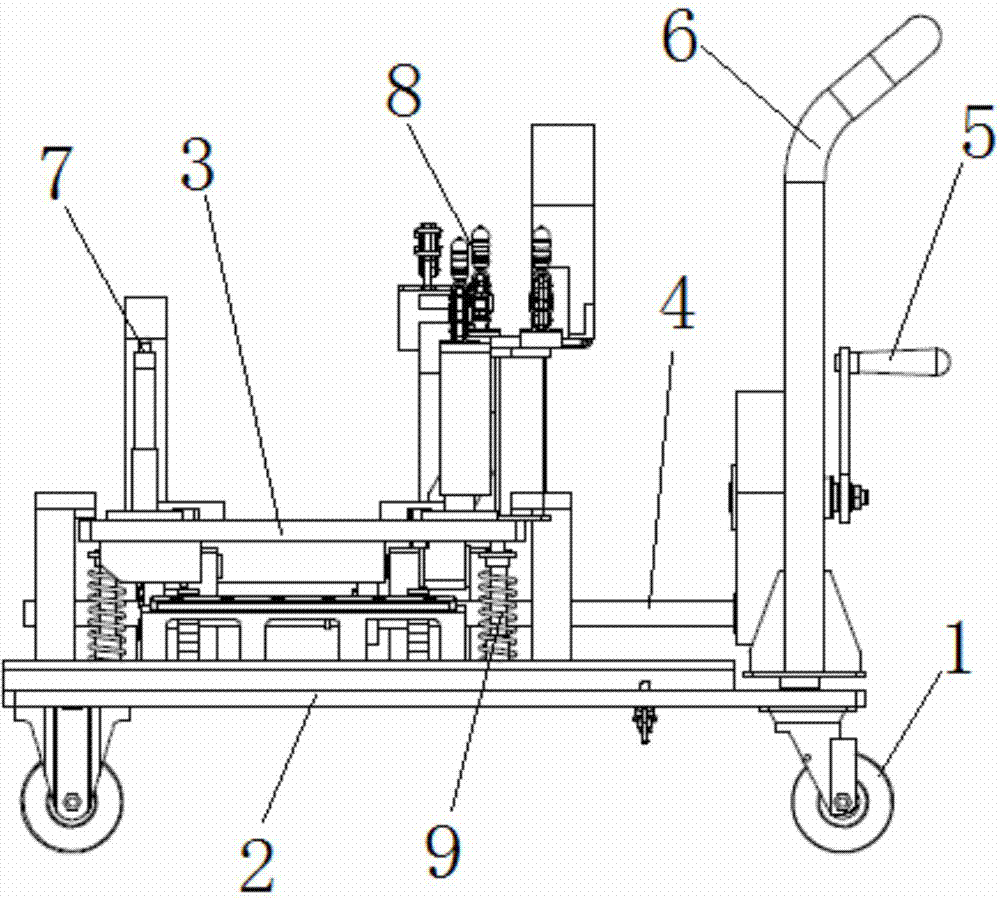

[0030] refer to figure 1 and figure 2 As shown, according to a specific embodiment of the present invention, an engine docking test trolley for a bench test includes a movable carrying platform 2 and a tray 3 for placing the engine, and the tray 3 is equipped with a The positioning and clamping mechanism of the positioning and clamping of the engine, and the tray 3 is pivotally mounted on the carrying platform 2, so that the engine placed on the tray 3 can be placed in different positions at different pivoting positions. the angle of inclination.

[0031] After the engine to be tested is placed on the pallet 3, the pallet 3 is pivoted to adjust the inclinati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com