Teaching practical training equipment by using flexible mixed order automatic production line as basis

An automated production line and basic technology, applied in the direction of teaching models, educational tools, instruments, etc., can solve the problems of not having mixed production conditions and single functions, and achieve the effect of diversification of training content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

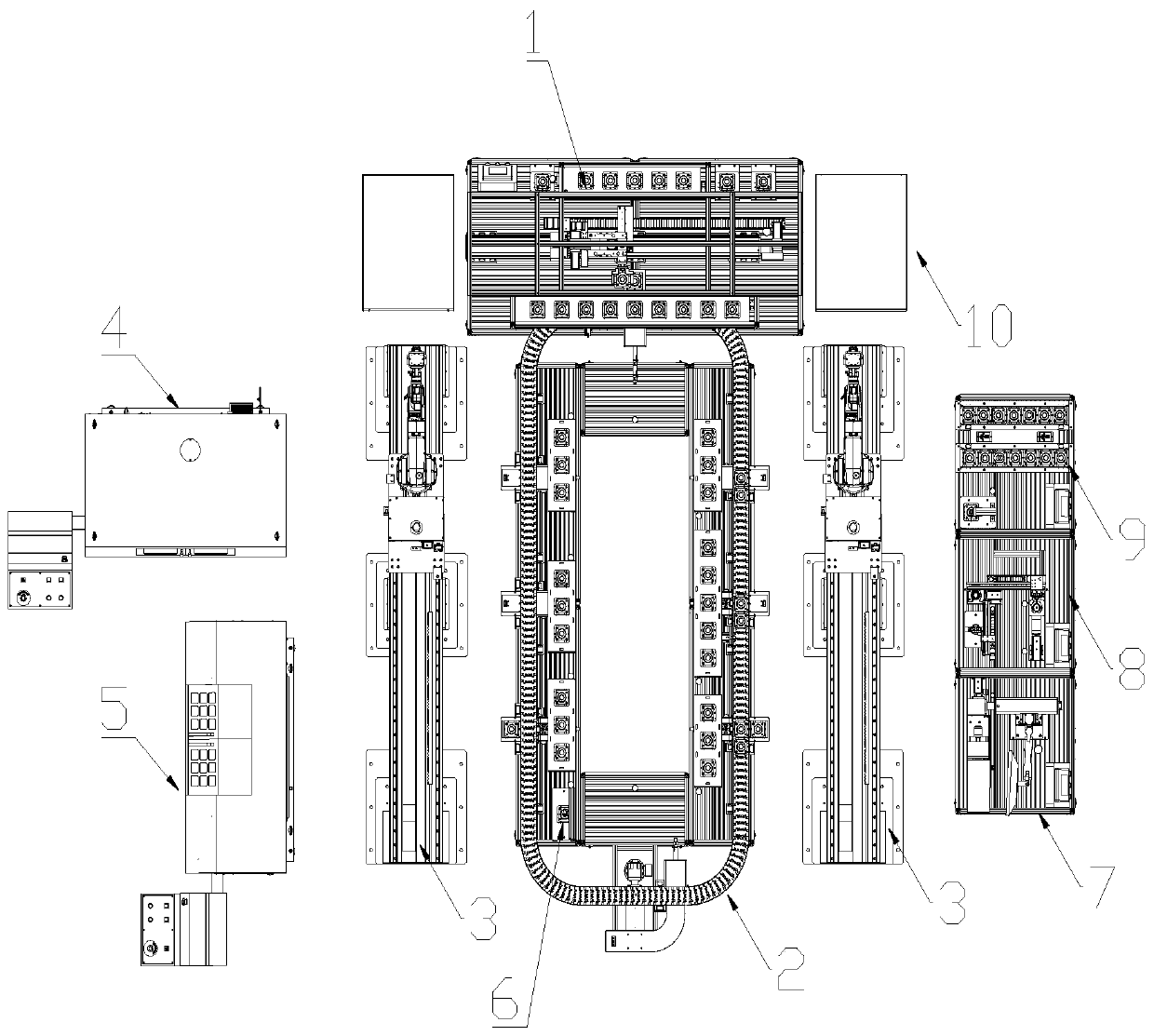

[0042] This embodiment provides a teaching and training equipment based on a flexible mixed-order automatic production line, which is used for integrated training on automatic production lines such as storage, transportation, processing, assembly, and testing of workpieces. The workpieces in this embodiment include cups body, sealing cover and cup cover, this equipment can process each blank workpiece into a cup body, sealing cover and cup cover, and then complete the assembly and testing of the cup body, sealing cover and cup cover, and put the finished product into storage.

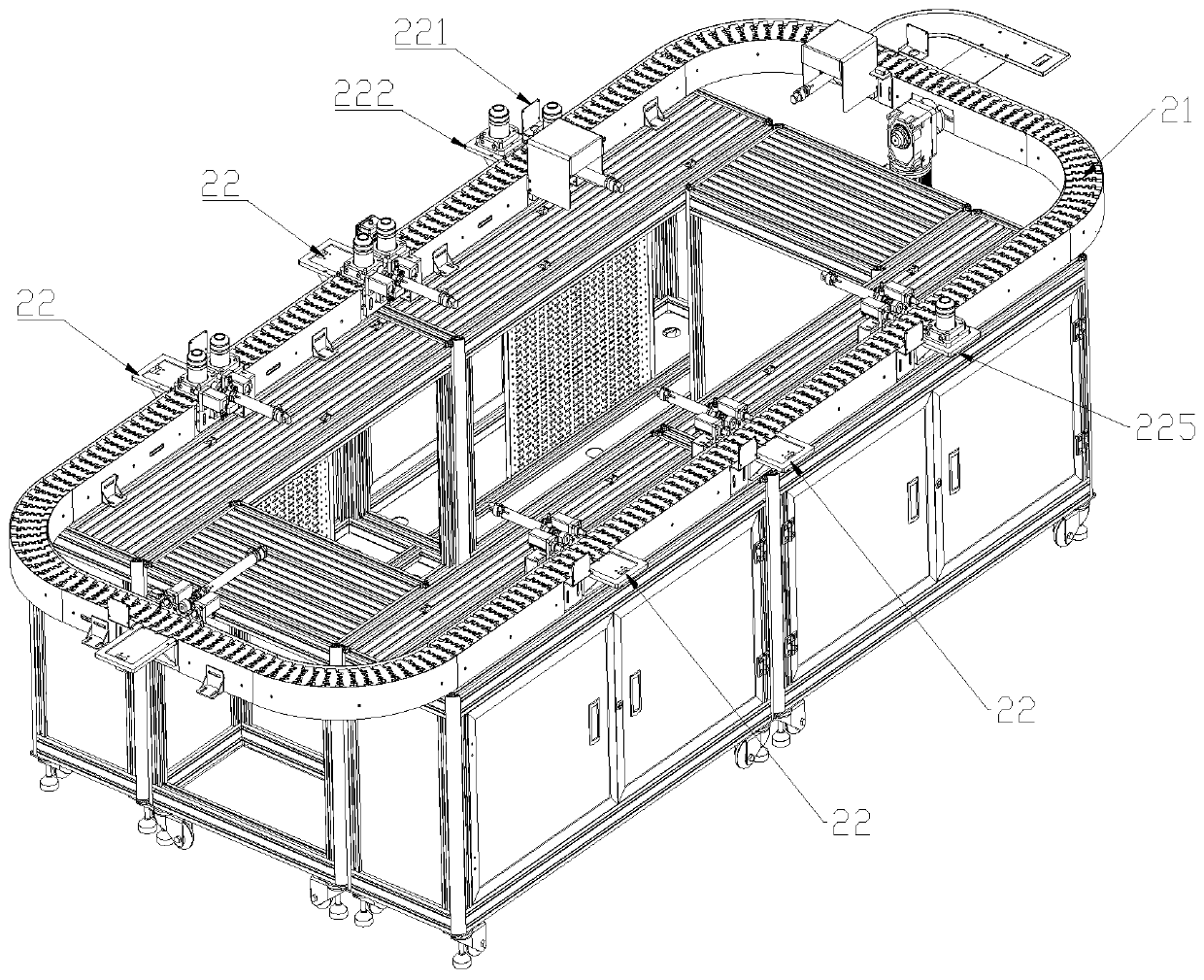

[0043] Such as figure 1 As shown, the equipment includes three-dimensional storage station 1, ring transfer station 2, robot station 3, machining center station 4, lathe processing station 5, visual inspection station 6, laser engraving station 7, assembly station 8, assembly inspection station 9 and the total control station 10 .

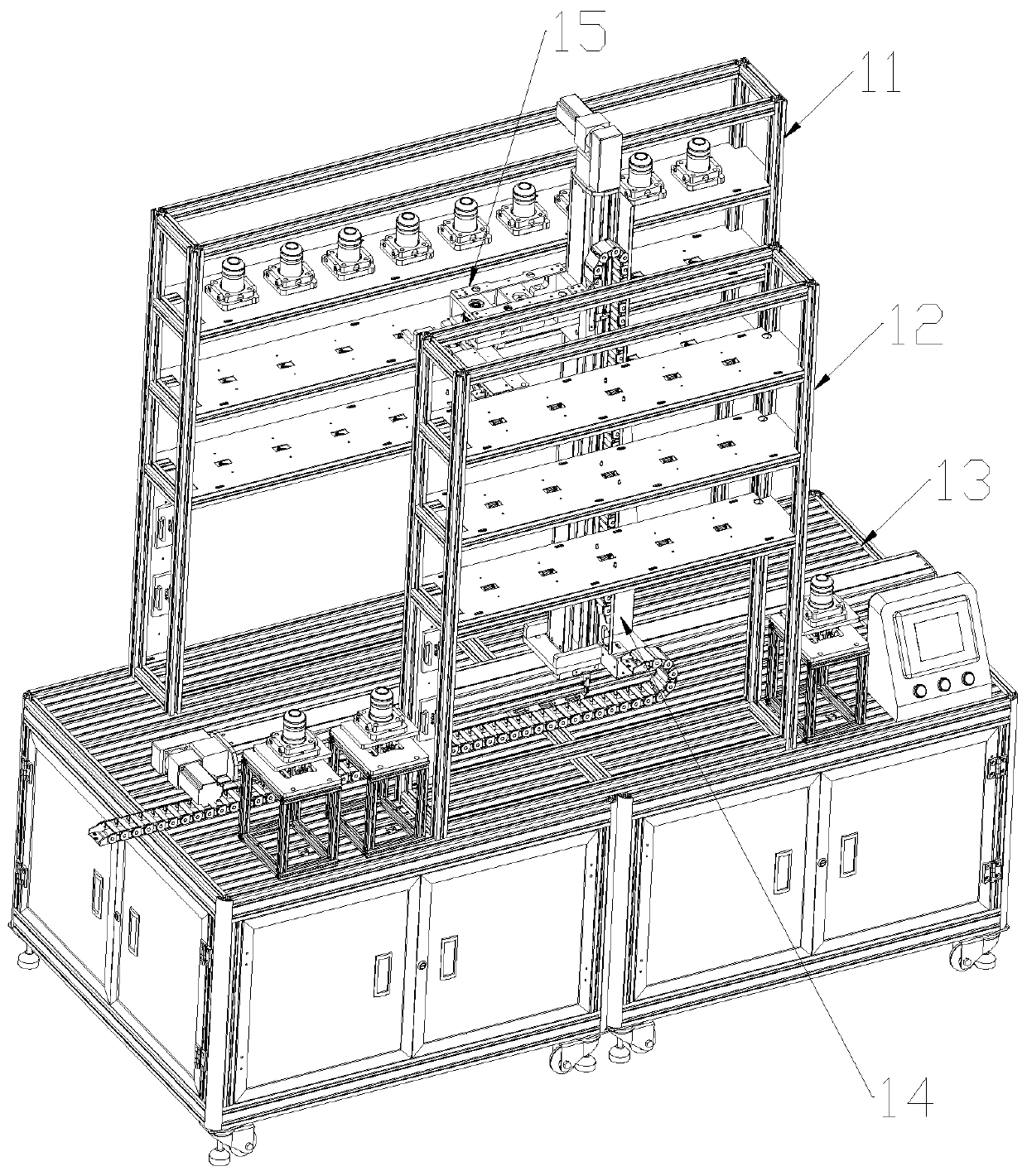

[0044] Such as figure 2 As shown, the three-dimensional storage stat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com