Flexible production line suitable for automobile side body production

A production line and flexible technology, applied in vehicle parts, auxiliary devices, conveyors, etc., can solve the problems of low degree of flexibility and low output, and achieve the effect of speeding up production takt, convenient use and small footprint

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

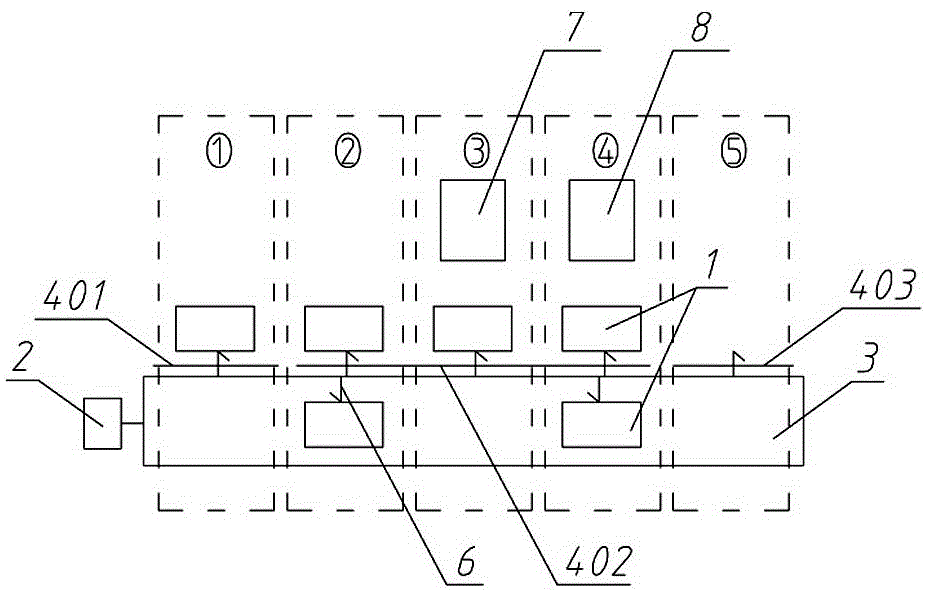

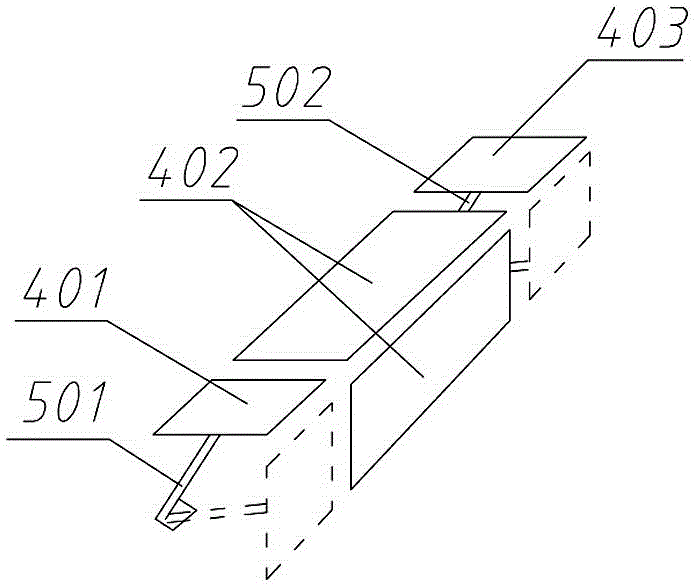

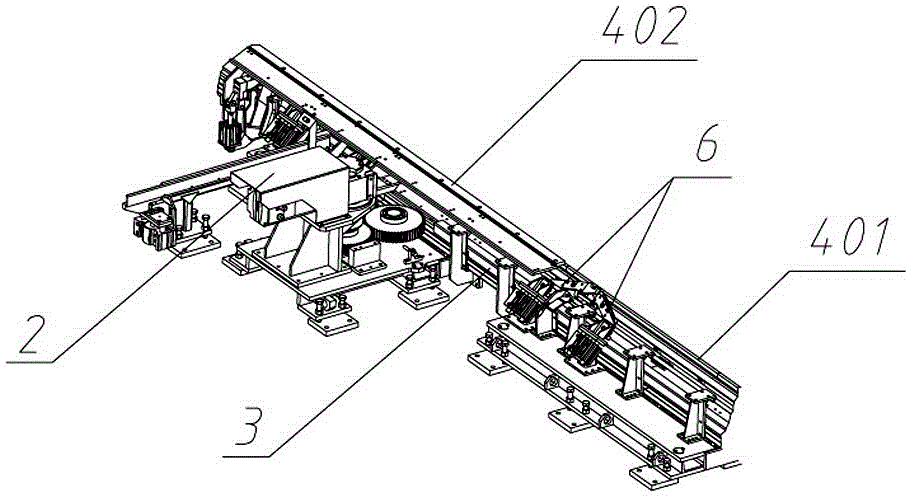

[0019] Such as Figure 1-3 As shown, the flexible production line suitable for the production of automobile side panels according to the present invention includes an on-line station ①, a preparation station ②, a positioning and clamping main welding station ③, and a quick-cut repair welding station from left to right. ④ and the conveying line of the off-line station ⑤, the conveying line is a reversible reciprocating conveying production line, which includes a conveying line body and six four-model switching conveying trolleys 1 . Such as image 3 As shown, the conveying line body includes a reciprocating conveying rod 3 driven by a forward and reverse motor 2. Specifically, the forward and reverse motor 2 meshes with the left side of the quadrangular prism-shaped reciprocating conveying rod 3 through gears. Driven by the drive, the reciprocating conveying rod 3 can move forward or backward. The top and / or the right side of the reciprocating conveying rod 3 are provided wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com