Workpiece feeding rack limiting device for intelligent robot rolled hemming system

A technology of robot intelligence and rolling hemming, which is applied in the direction of positioning device, feeding device, storage device, etc., can solve the problems of rolling equipment damage, occupying a lot of land, and large economy, so as to achieve the effect of flexible production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

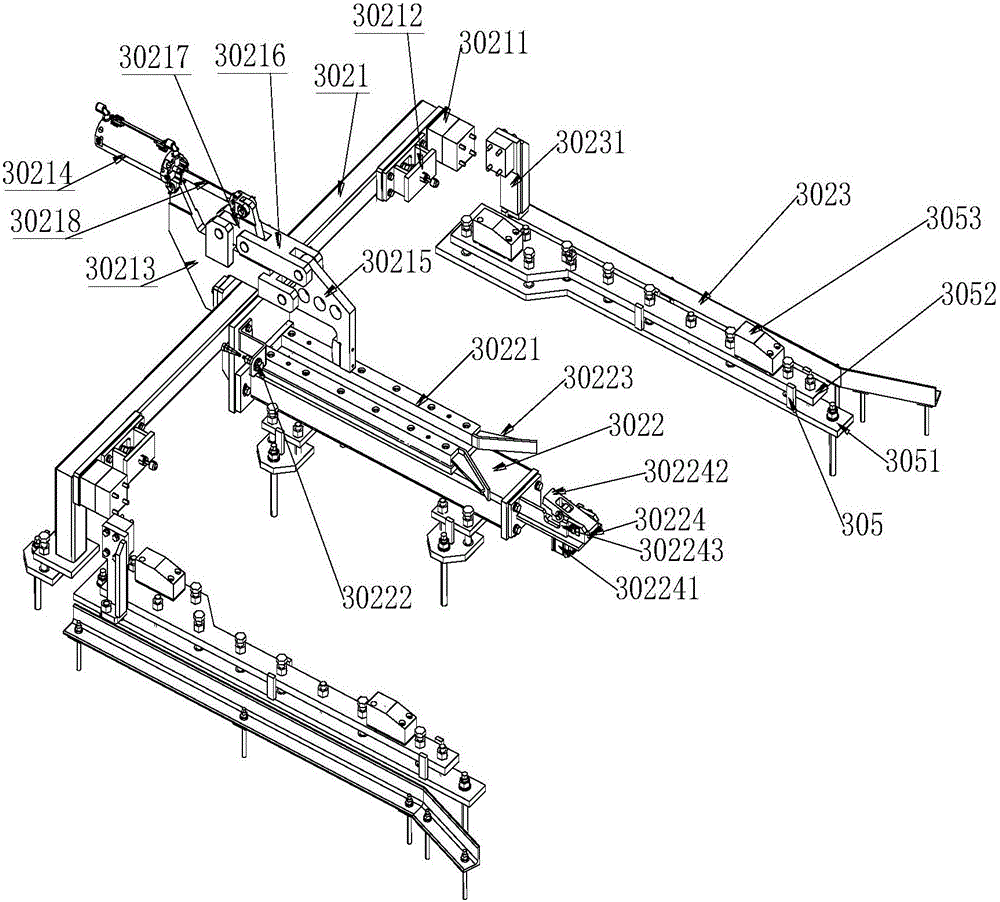

[0014] The present invention and the technical solutions in the embodiments of the present invention will be clearly and completely described below in conjunction with the accompanying drawings.

[0015] Such as figure 1 As shown in the figure, a limit device for an upper frame of a robotic intelligent rolling hemming system includes an X-direction limit frame 3021, which is a rod and is fixed and installed on the ground through anchor bolts. The two ends of one side of the limit frame 3021 along the X direction are respectively provided with an X-direction pressure block 30211 of the loading table and an X-direction side proximity switch 30212 of the loading table for detecting the position of the loading table;

[0016] The X-direction limit frame 3021 is equipped with an X-direction limit cylinder mounting plate 30213 in the middle of the X-negative direction side, and is arranged along the X-direction. The X-direction limit cylinder 30214 of the upper piece table, one end...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com