Patents

Literature

76 results about "Piece table" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A Piece Table is a data structure typically used to represent a series of edits on a text document. An initial reference (or 'span') to the whole of the original file is created, with subsequent inserts and deletes being created as combinations of one, two, or three references to sections of either the original document or of the spans associated with earlier inserts.

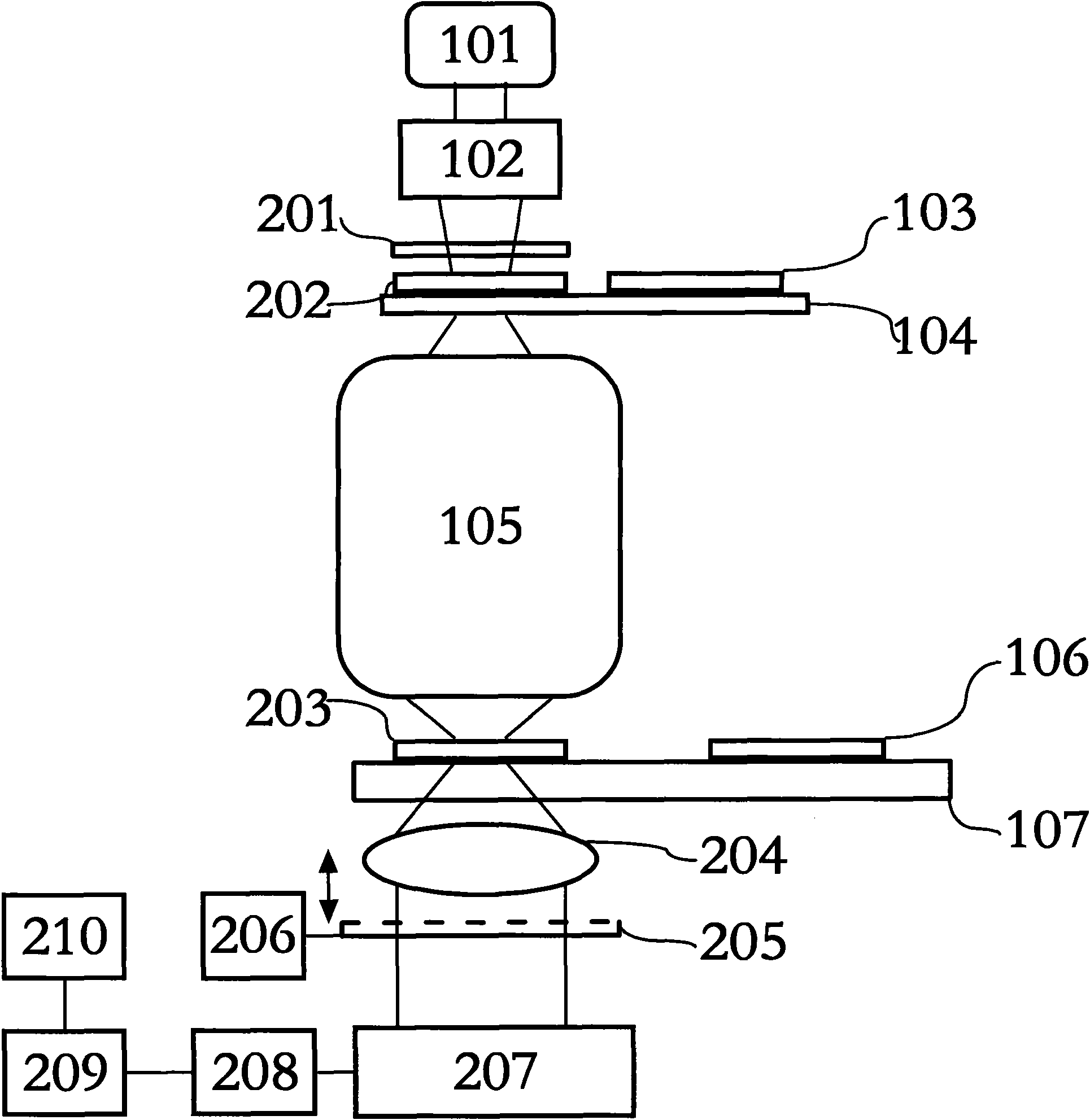

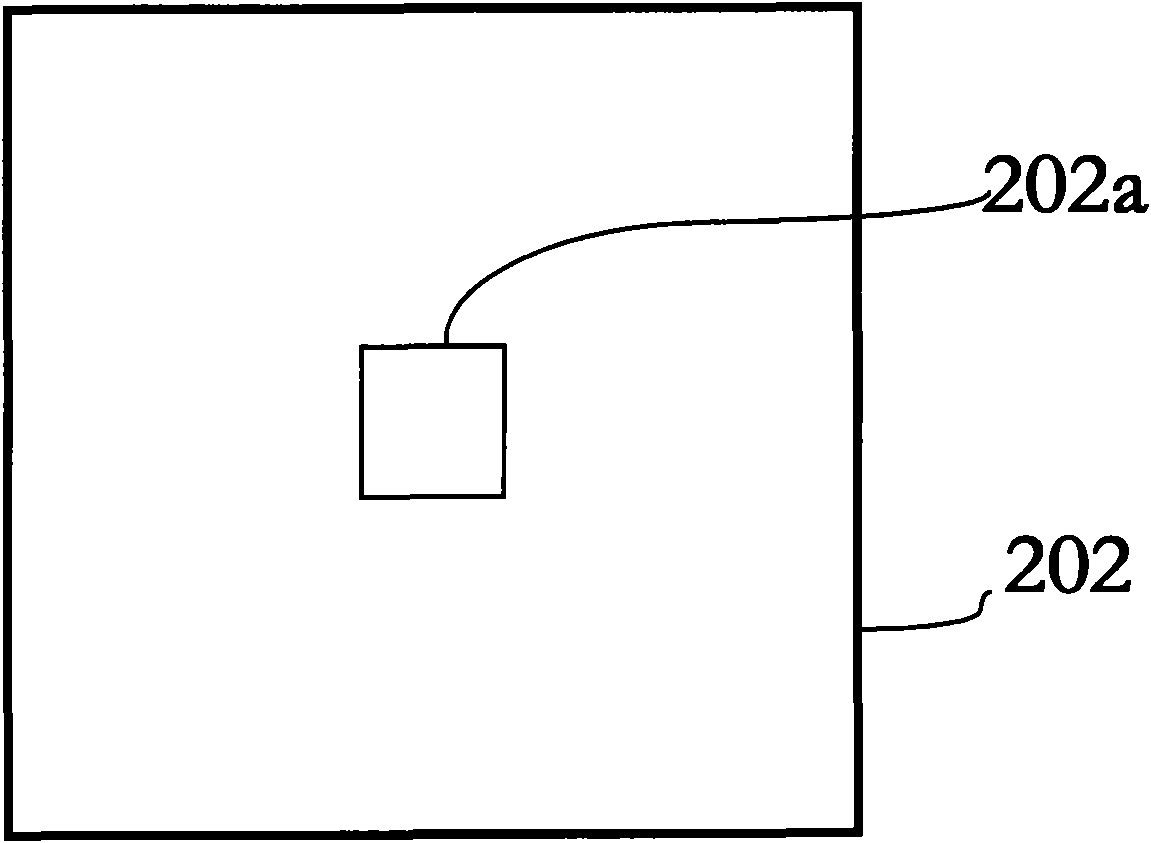

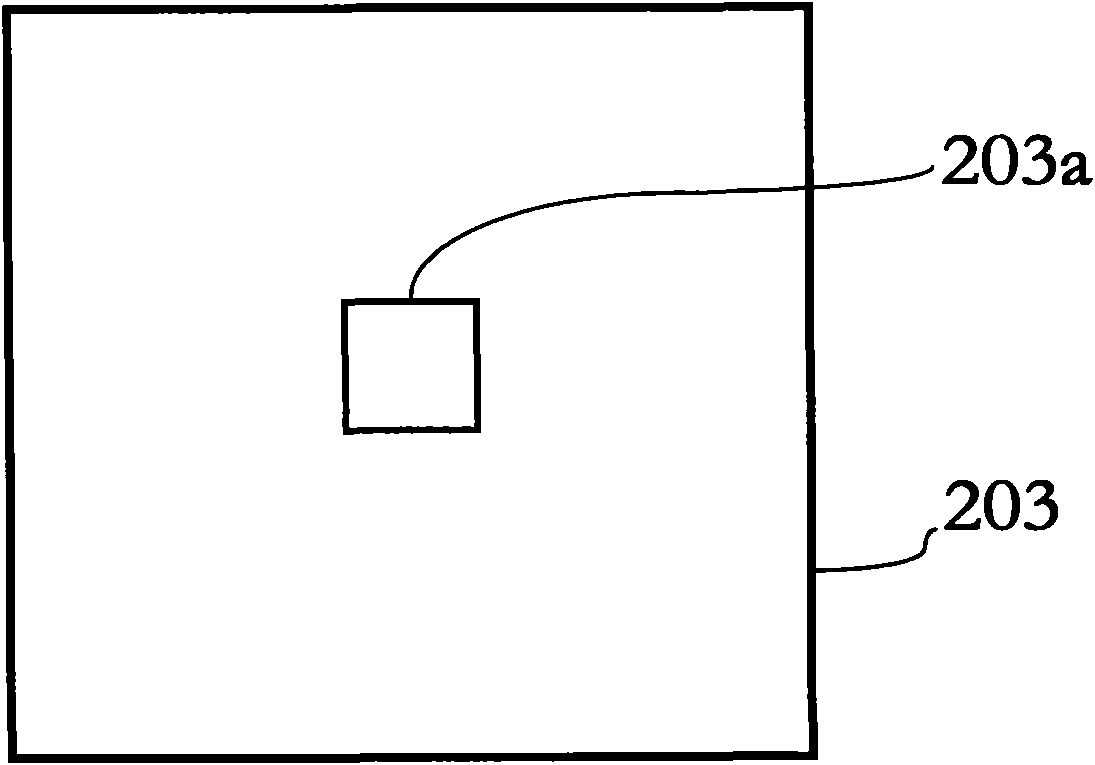

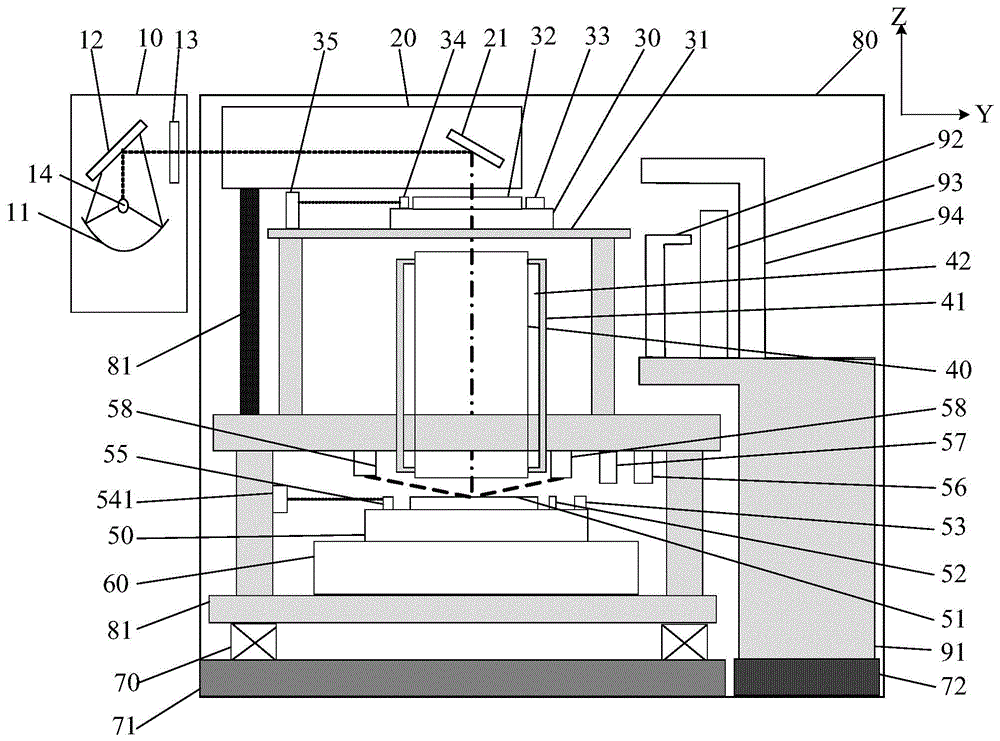

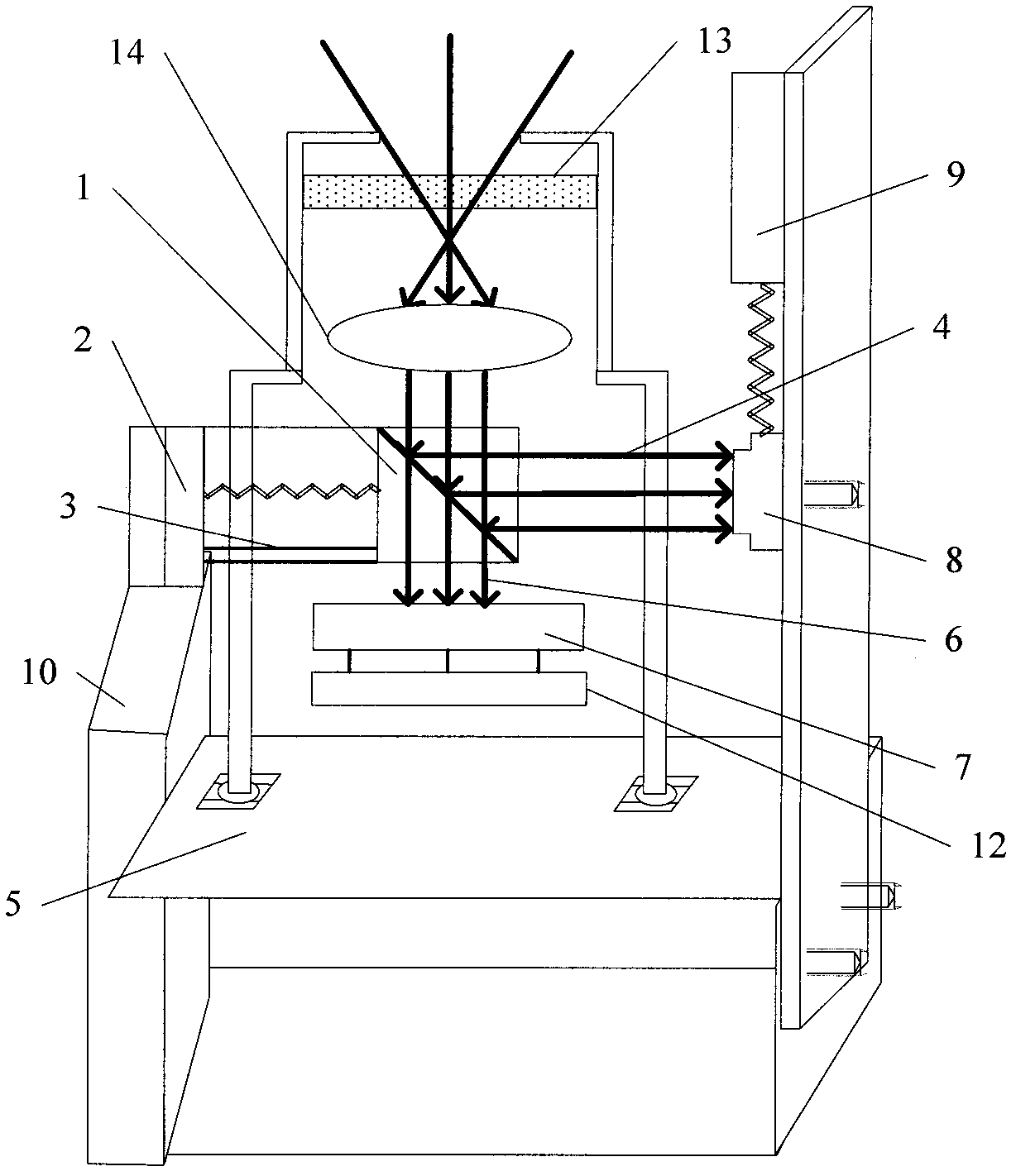

Photoetching machine projection objective wave aberration on-line detector and method

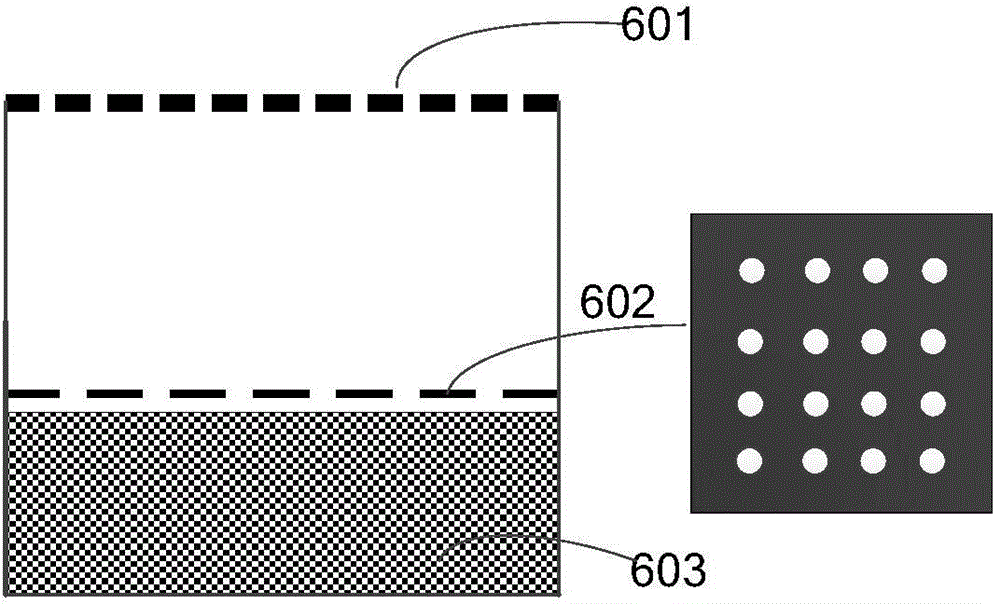

ActiveCN101840164AMake up timeMake up for the lack of low contrast of interference fringesPhotomechanical exposure apparatusMicrolithography exposure apparatusWave aberrationMeasurement precision

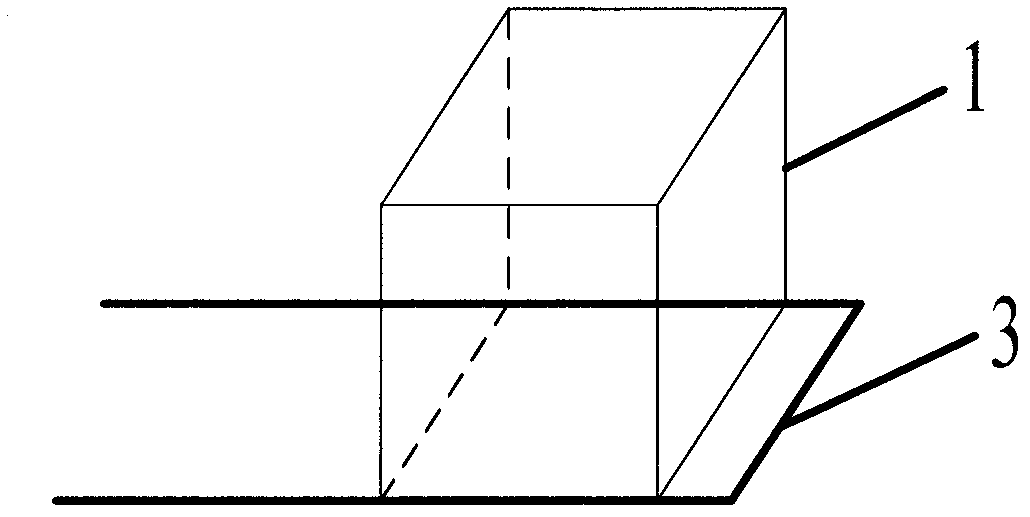

The invention discloses a photoetching machine projection objective wave aberration on-line detector and a method. A diffuser is integrated on an object space mask plate which is arranged on the object plane of a projection objective, fixed, supported and driven by an object space work piece table in the photoetching machine; an image space mask plate is arranged on the image plane of the projection objective, supported and driven by an image plane work piece table. A collimator objective is arranged after the image surface of the projection objective; and the focal plane of the object space of the collimator objective is coincided with the image plane of the projection objective. Shearing mechanism is arranged between the projection objective and a photoelectric detector. The invention can realize the continuous tunableness of the shear ratio and increases the measuring sensitivity and measuring accuracy; secondly, a square hole is used for expanding the light source, thus increasing the utilization factor of the light intensity of the exposure light source, the measuring speed and measuring accuracy; and finally, the system error self-calibration technology can rapidly obtain the wave aberration of the projection objective with high precision.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

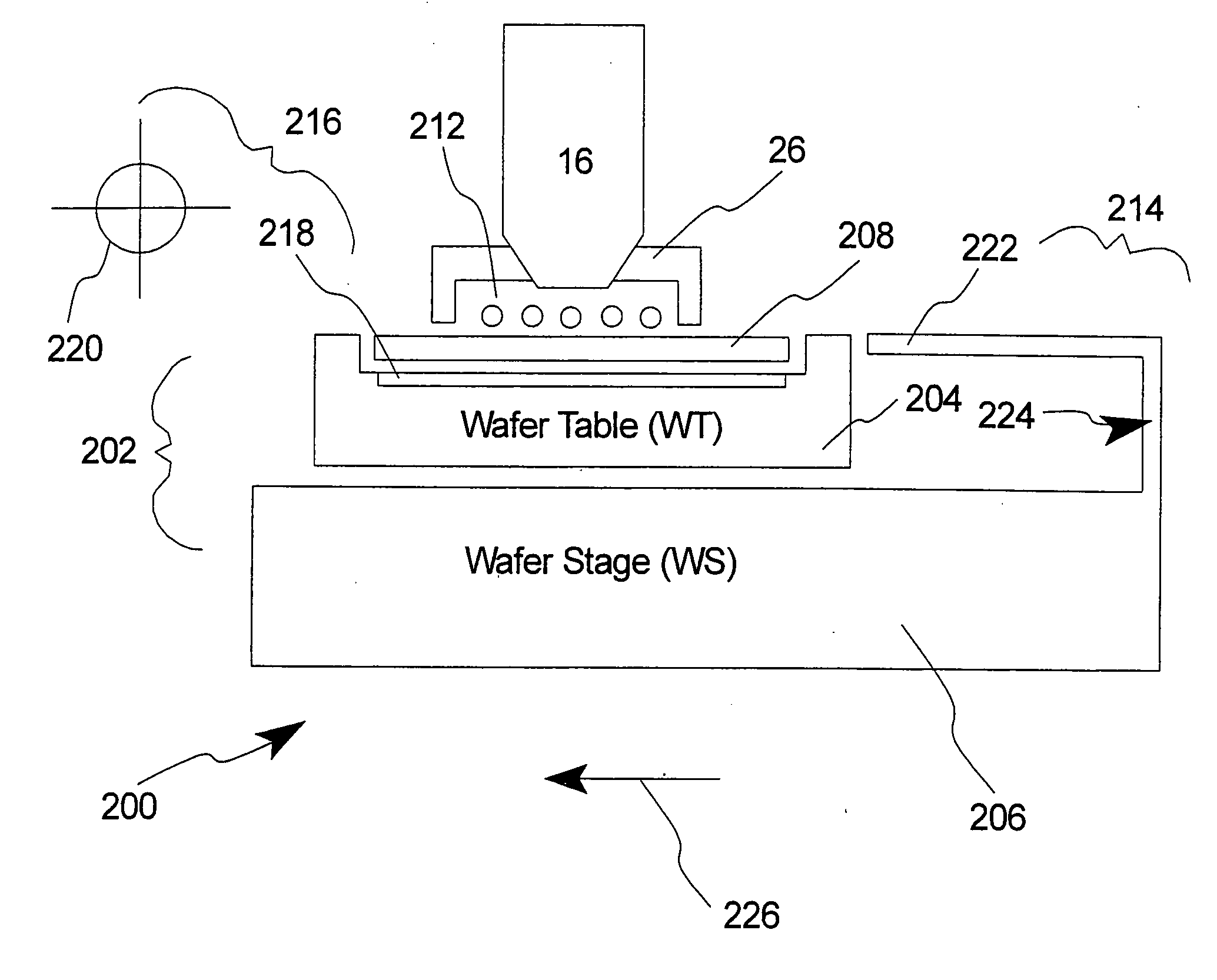

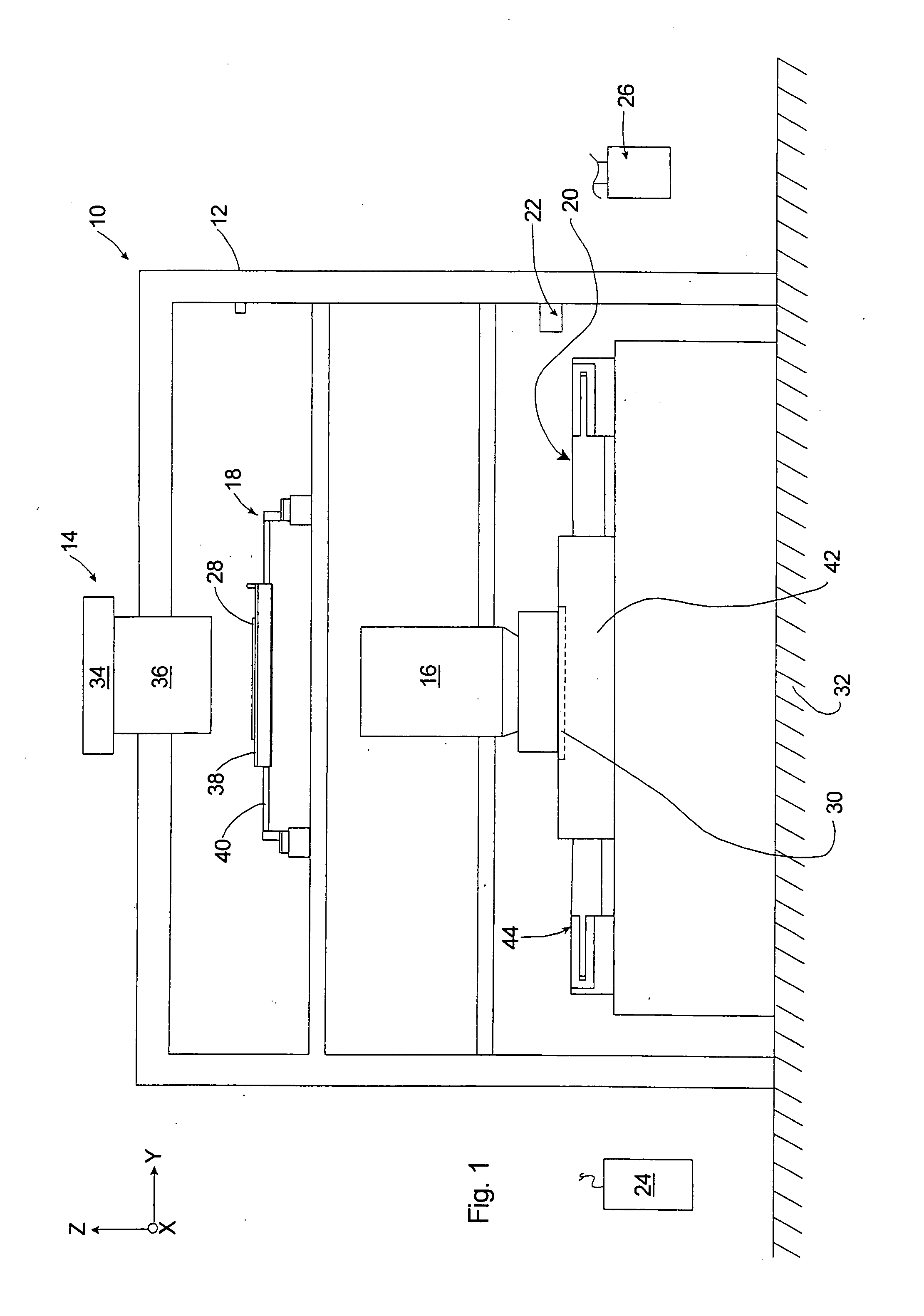

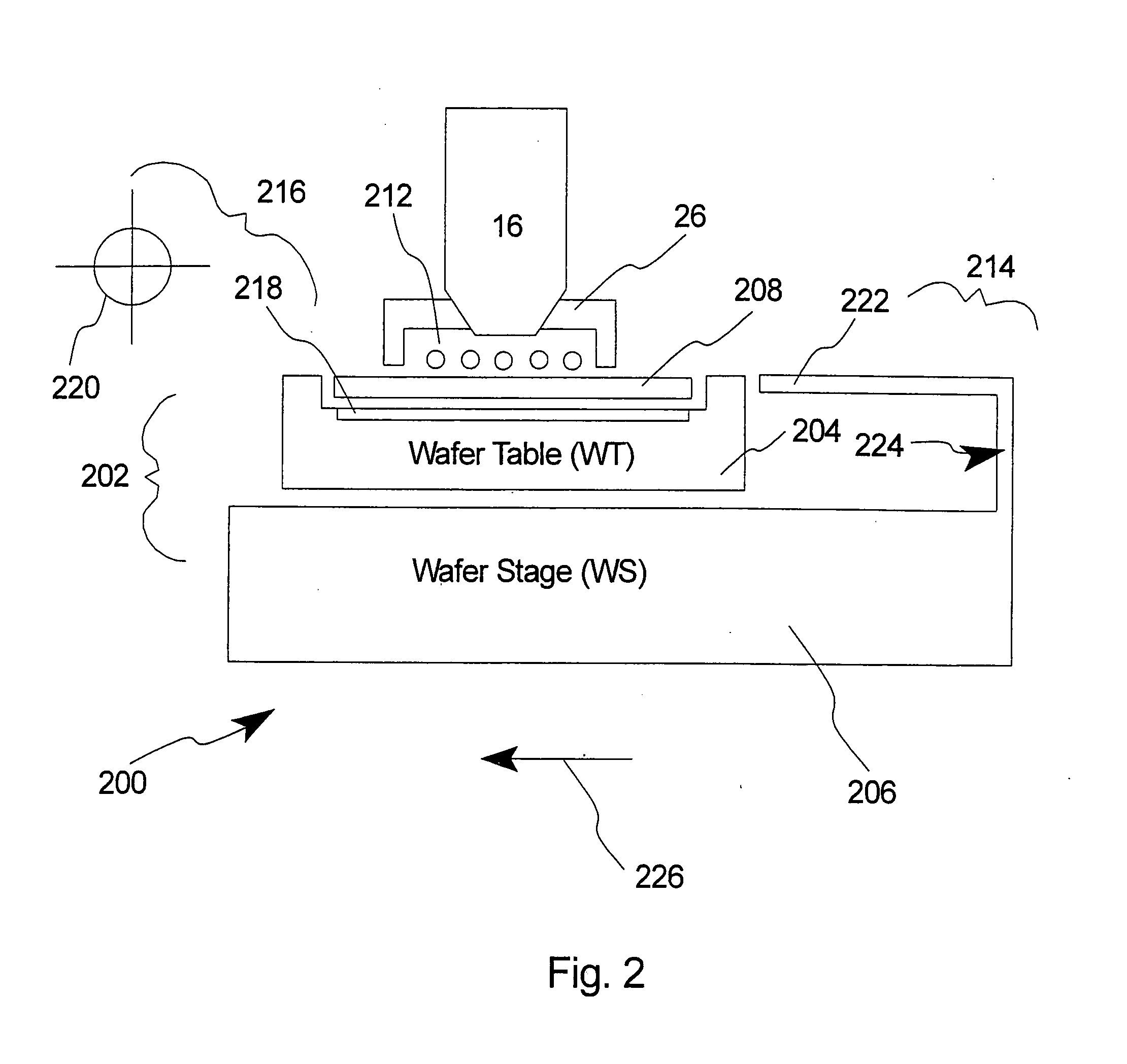

Apparatus and method for maintaining immersion fluid in the gap under the projection lens during wafer exchange in an immersion lithography machine

InactiveUS20070195300A1Semiconductor/solid-state device manufacturingPhotomechanical exposure apparatusEnvironmental systemsLithographic artist

An apparatus and method maintain immersion fluid in the gap adjacent to the projection lens during the exchange of a work piece in a lithography machine. The apparatus and method include an optical assembly that projects an image onto a work piece and a stage assembly including a work piece table that supports the work piece adjacent to the optical assembly. An environmental system is provided to supply and remove an immersion fluid from the gap between the optical assembly and the work piece on the stage assembly. After exposure of the work piece is complete, an exchange system removes the work piece and replaces it with a second work piece. An immersion fluid containment system maintains the immersion liquid in the gap during removal of the first work piece and replacement with the second work piece.

Owner:NIKON CORP

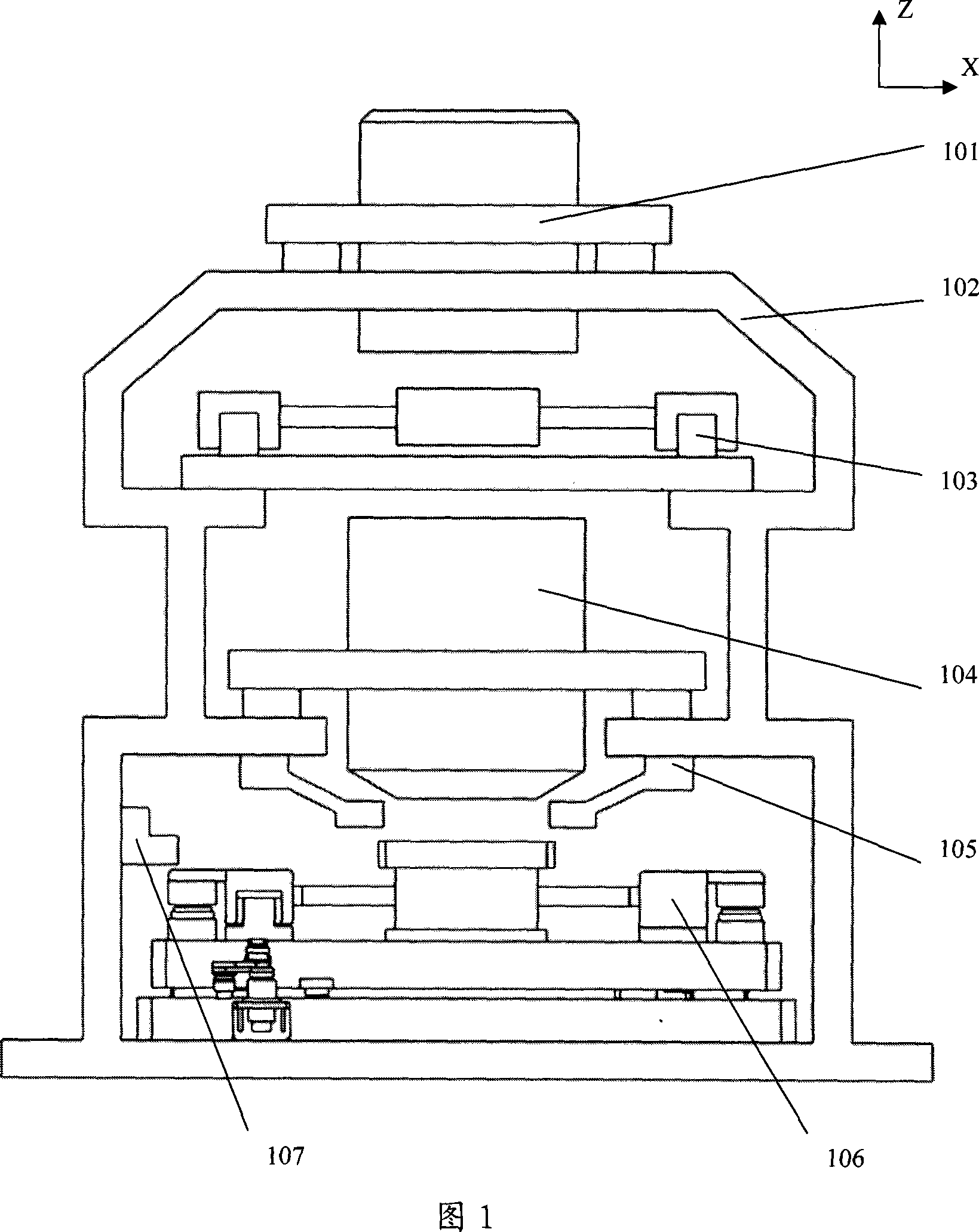

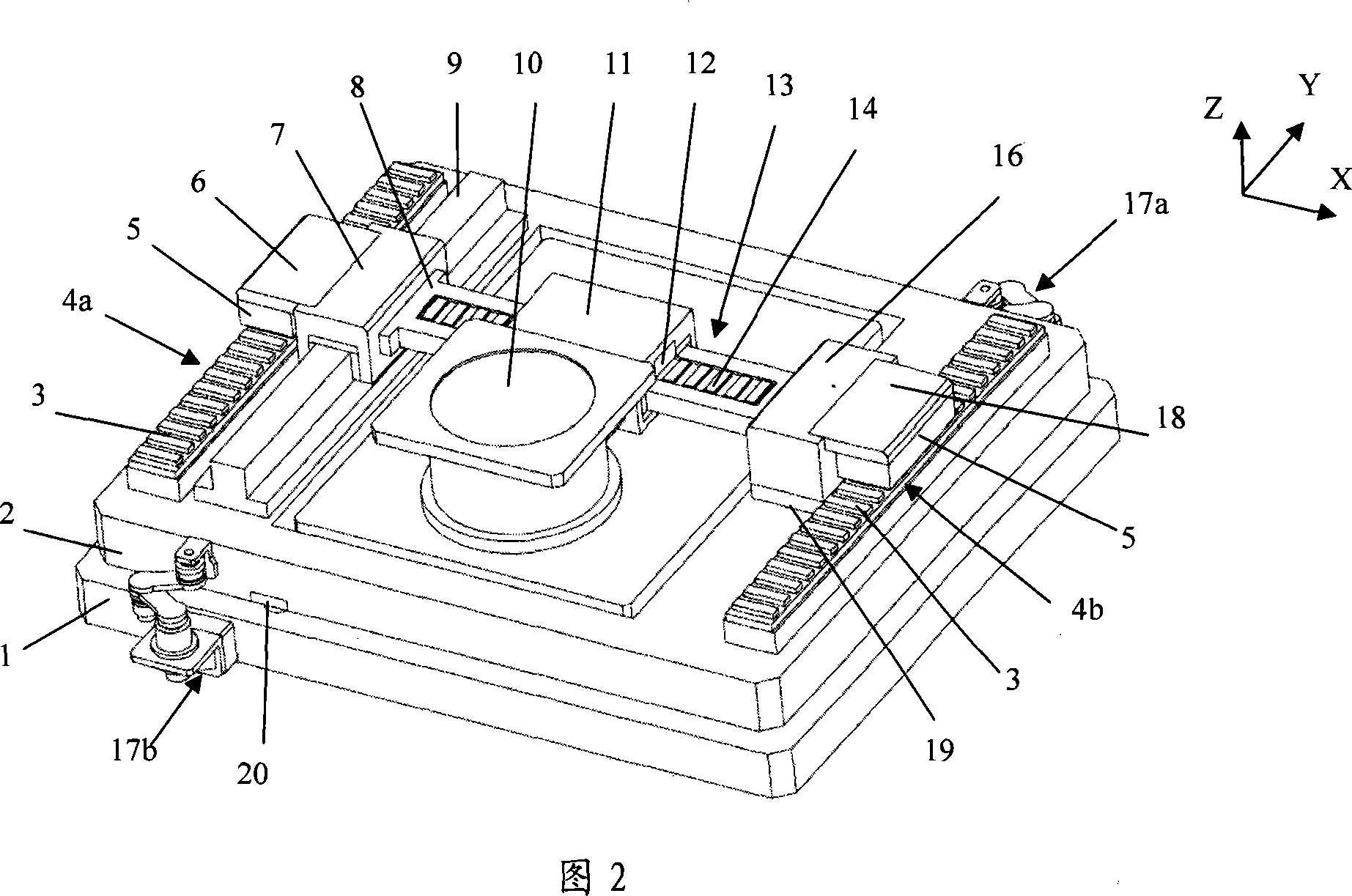

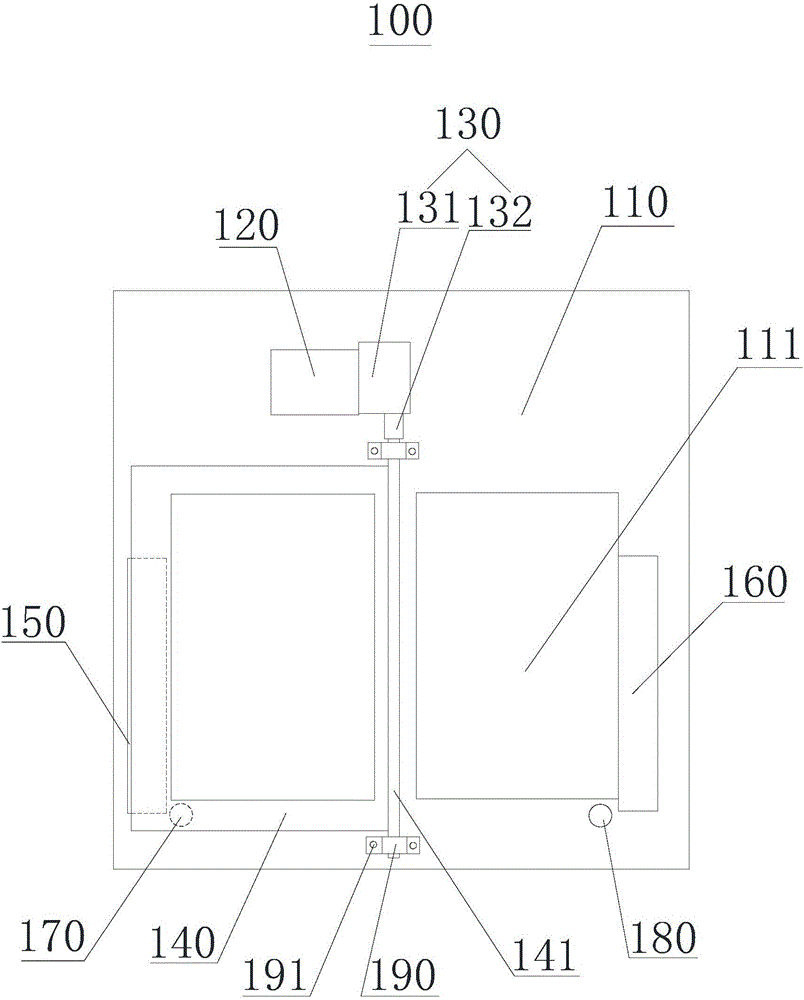

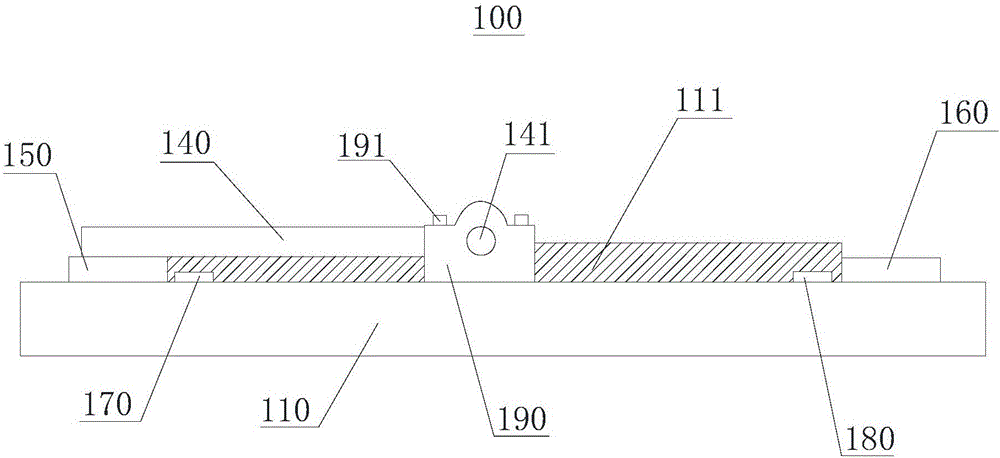

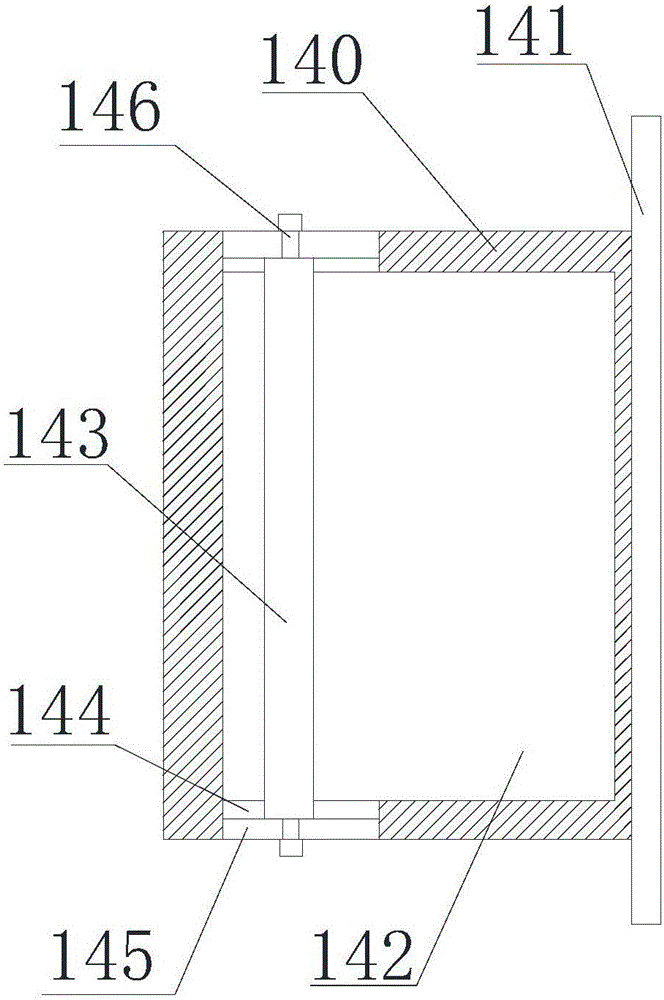

System for balancing and positioning work table of photoetching device

ActiveCN101075096AHigh positioning accuracyReduce reaction forcePhotomechanical exposure apparatusMicrolithography exposure apparatusData controlControl system

A balance-positioning system of work-piece table on photo-etching machine is prepared as setting long stroke module on balance mass unit to drive exposure table to move along X and Y directions, arranging balance mass unit on base frame to balance reverse-acting force and reverse-acting torque, setting balance mass drift-proof unit between base frame and master balance mass to compensate drift of balance mass unit along X and Y as well as Rz directions, using control system to control position compensation of long stroke module and master balance mass according to feedback data of measurement unit.

Owner:SHANGHAI MICRO ELECTRONICS EQUIP (GRP) CO LTD

Method for aligning exposure patterns on two sides of PCB (printed circuit board)

InactiveCN102890428ASimple processHigh precisionPhotomechanical exposure apparatusMicrolithography exposure apparatusEngineeringCcd camera

The invention discloses an alignment method for aligning exposure patterns on two sides of a PCB (printed circuit board). The PCB is placed on a work piece table, a CCD (charge coupled device) camera is arranged on the PCB, and a marking device is arranged below the PCB; and when the front side of the PCB is exposed, the marking device can generate alignment marks on the reverse side of the PCB, and after the PCB is turned over, the CCD camera can capture the alignment marks on the reverse side for alignment, so that the exposure patterns on the two sides of the PCB can be aligned. According to the invention, the alignment of the exposure patterns on the two sides of the PCB can be implemented, the procedure is simple and the alignment accuracy is high.

Owner:TIANJIN ADVANTOOLS

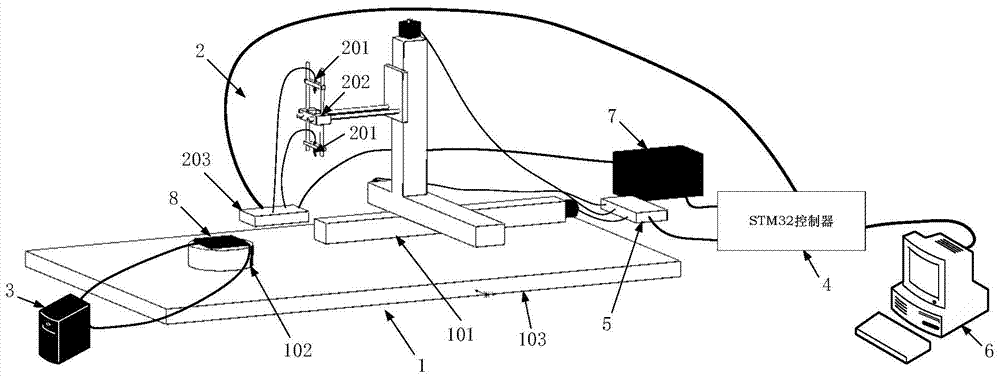

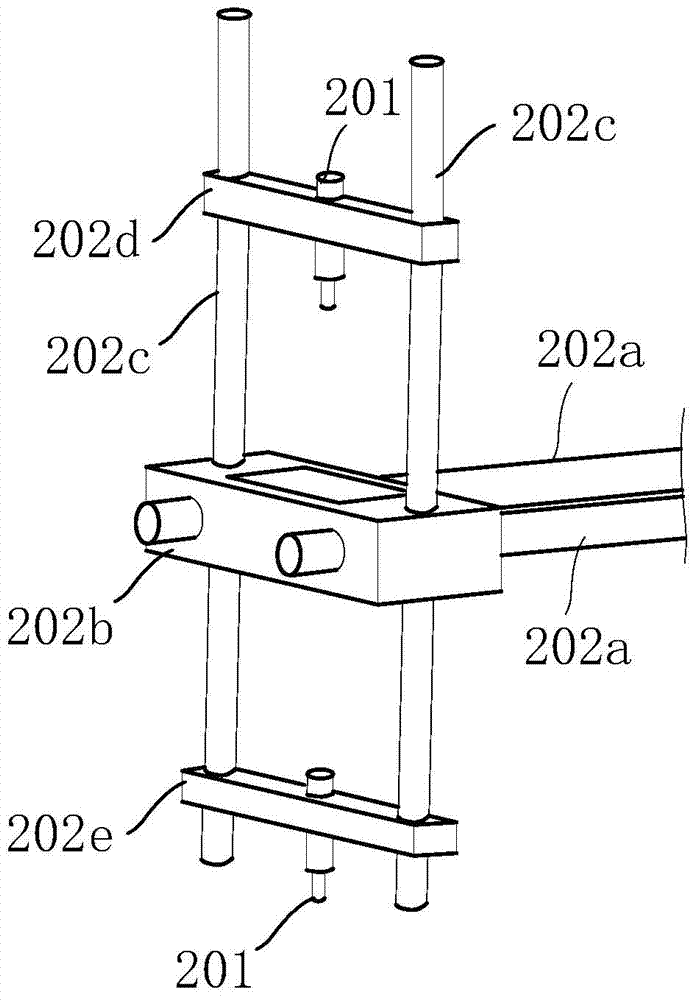

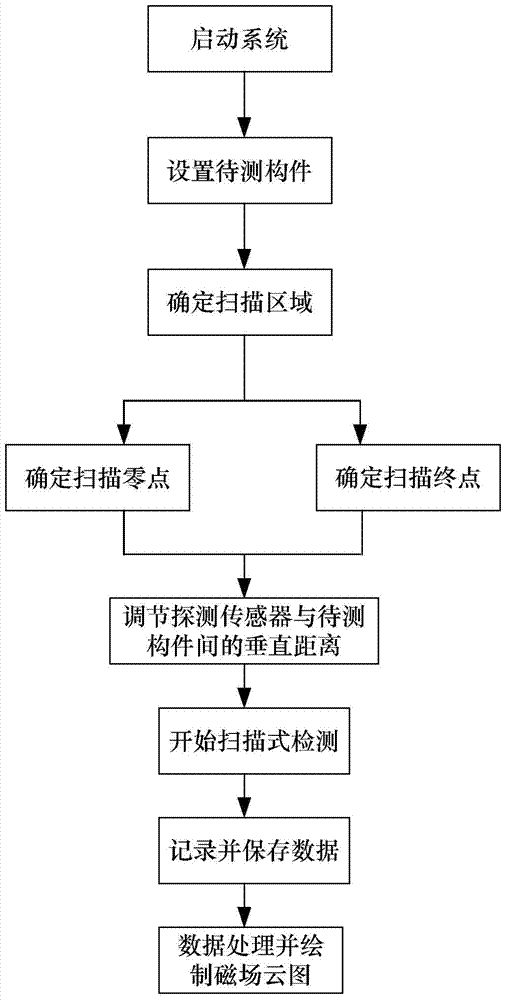

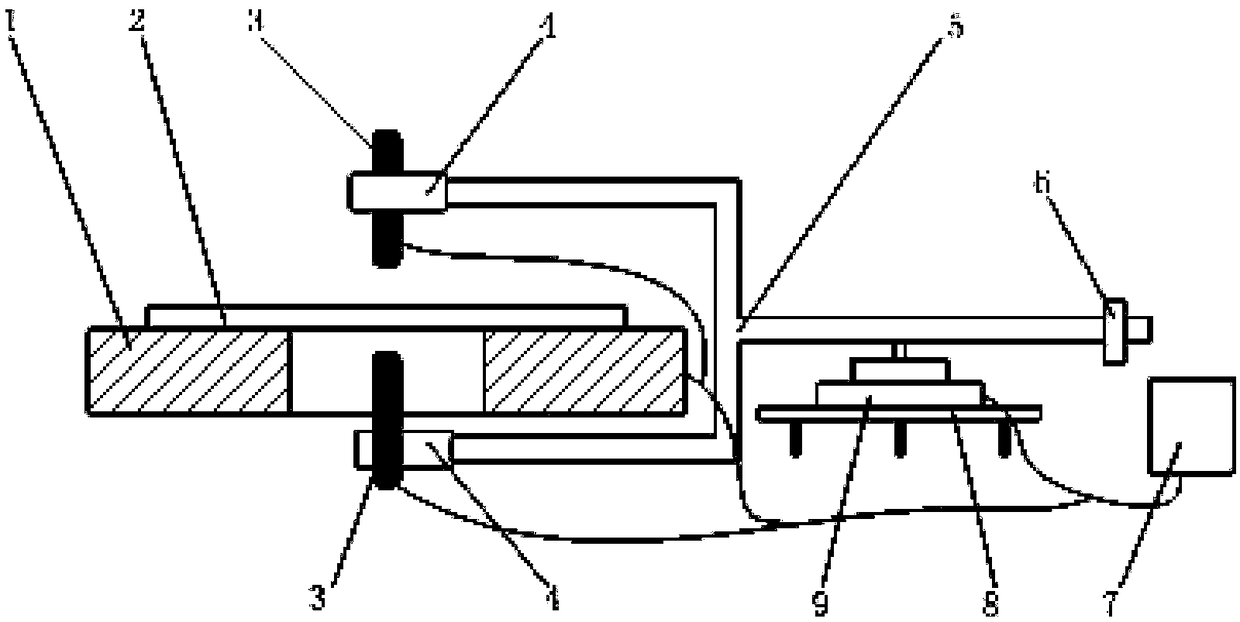

Planar magnetic field scanning and imaging system based on Hall sensor

ActiveCN104730142AEnsure consistencyAccurate plane scanning detectionMaterial magnetic variablesSTM32Electrical conductor

The invention discloses a planar magnetic field scanning and imaging system based on a Hall sensor. The planar magnetic field scanning and imaging system comprises a three-dimensional mechanical displacement platform, a lower computer controller based on STM32, a Hall sensor, a differential amplification circuit module, a data acquisition card, upper computer control and data analyzing and processing software and a constant flow source, wherein a component to be tested is connected with the constant flow source and is arranged on a sample piece table of the three-dimensional mechanical displacement platform; the three-dimensional mechanical displacement platform and the Hall sensor are started, and then the motion parameters of the displacement platform are set according to the size of a sample piece; scanning type acquisition is carried out on the amplitude of the magnetic field on the surface of a measured conductor by the displacement platform which is started, together with the Hall sensor; the magnetic field information acquired by the sensor is sent to an upper computer by the data acquisition card; the scanned image of the magnetic field distribution on the surface of the sample piece to be tested can be displayed by the upper computer. The planar magnetic field scanning and imaging system can be used for scanning and imaging the magnetic field distribution condition of the surface of electrified material, so that the internal structure of the material is further analyzed according to the magnetic field distribution; therefore, the system has a certain practical value for detecting the integrity condition in the material in a nondestructive way.

Owner:BEIHANG UNIV

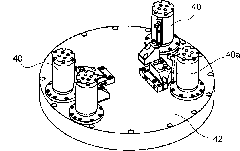

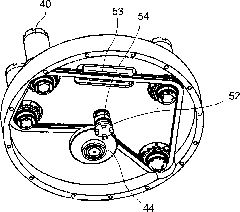

Thickness consistency detection device

The invention discloses a thickness consistency detection device. The device comprises a spectrum confocal displacement sensor, a sensor adjusting unit, a work-piece rotary table, a cantilever rotarytable, a cantilever rotary table adjusting unit, a work-piece table, a cantilever, a weight, and a main controller. The device disclosed by the invention can be used for the thickness consistency measurement and analysis of the large-aperture and high-precision material. The device disclosed by the invention is simple, compact and stable in structure, and the engineering is easy to realize; the movement function is executed by using an air-floating revolving shaft system, the vibration in dynamic measurement is greatly reduced, and the quick and precise measurement can be realized.

Owner:INST OF OPTICS & ELECTRONICS - CHINESE ACAD OF SCI

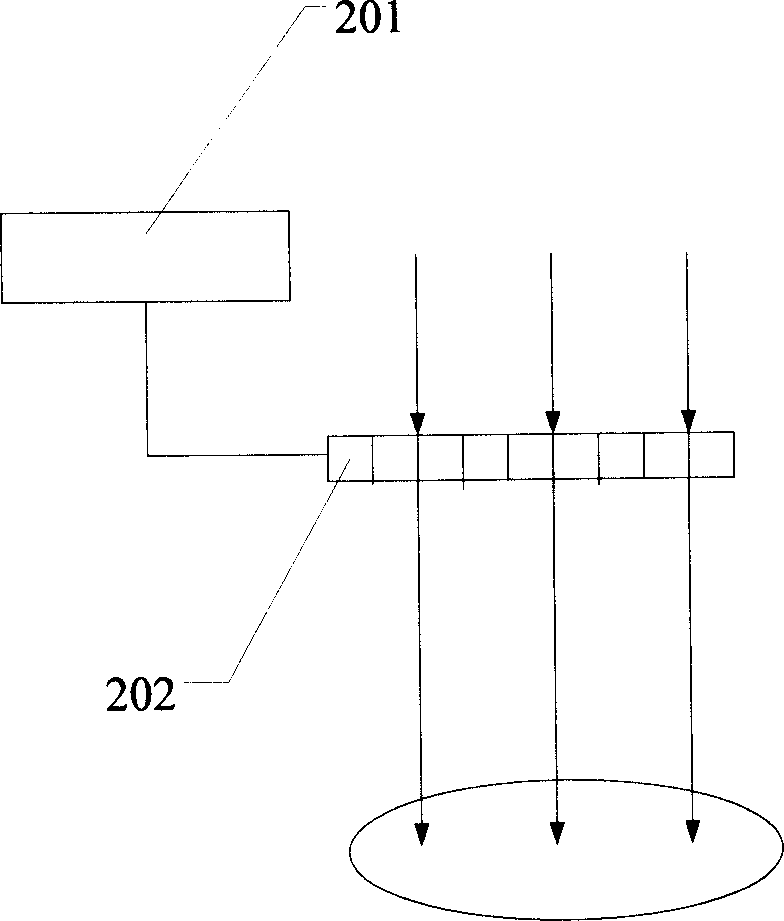

Large stroke pricision working platform device and drive method

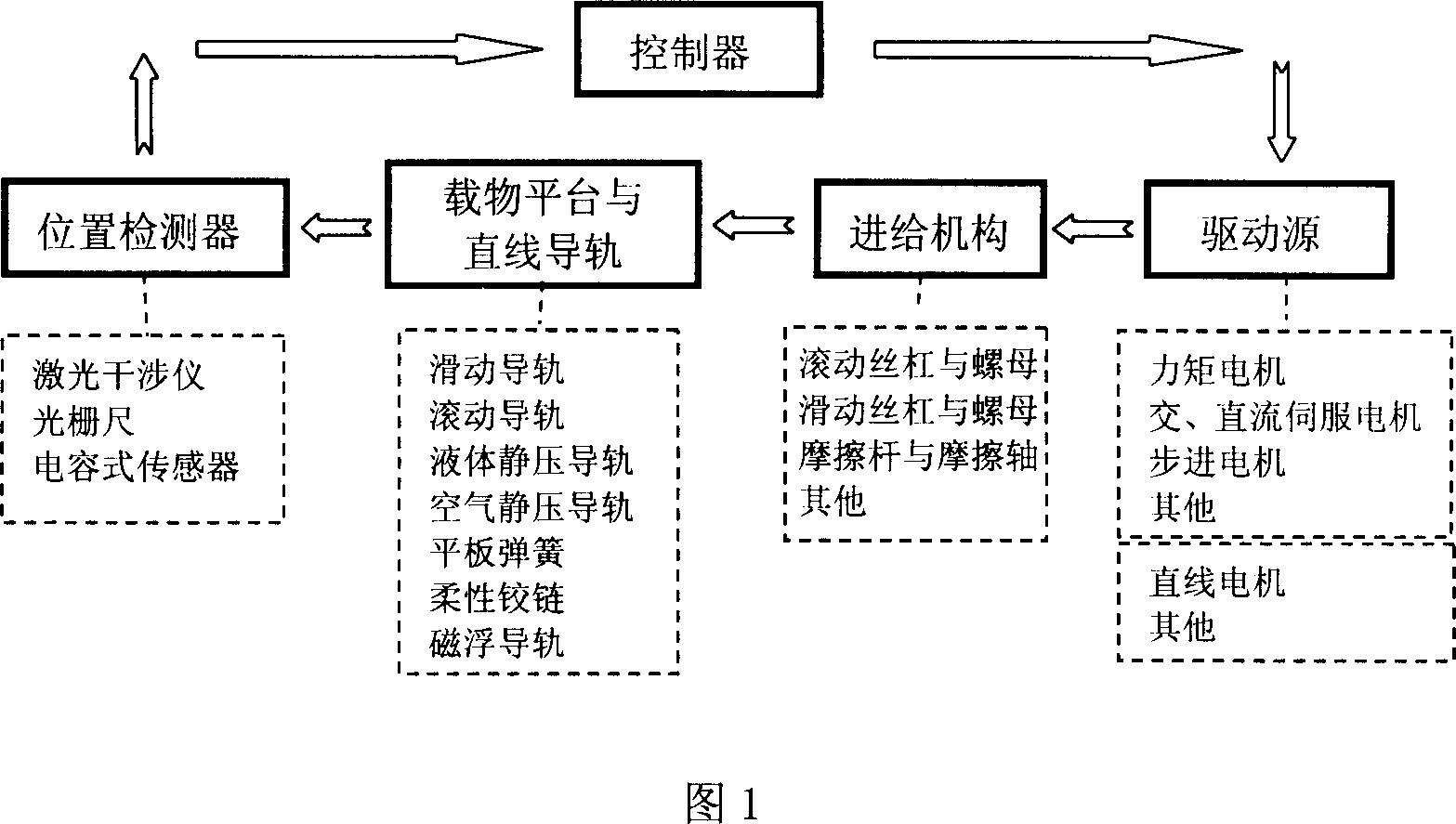

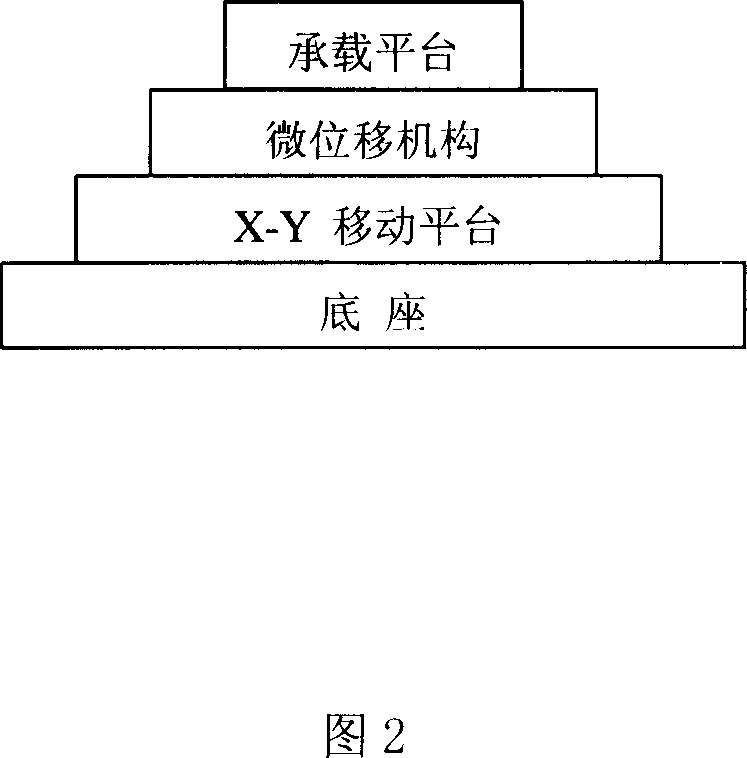

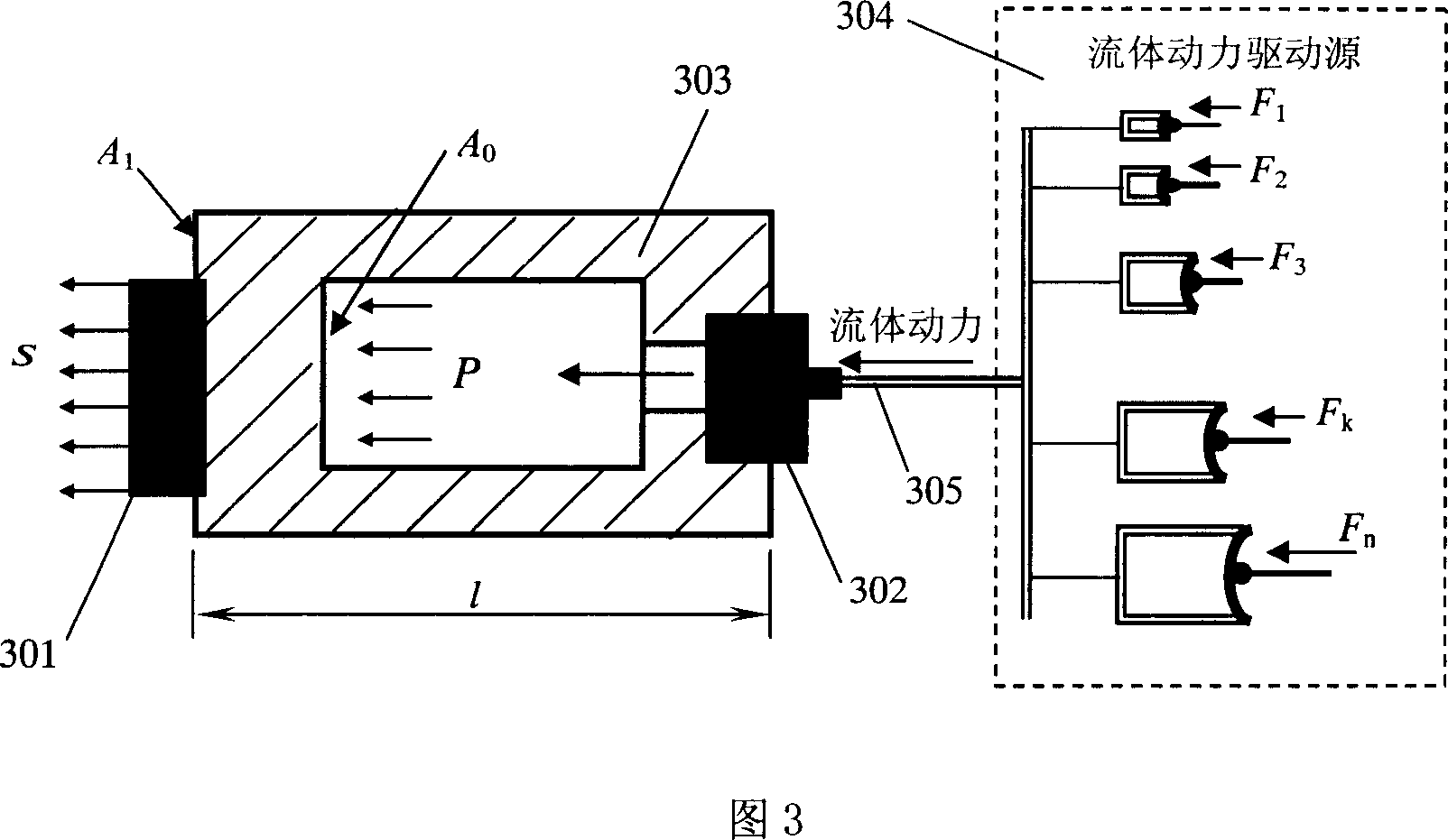

A precise work piece table with large stoke is prepared as connecting fluid-dynamic driving fine mechanism to back of rough moving mechanism through load connection head and rough moving mechanism to load carry platform through said head, using moving guide track of rough moving mechanism and said platform together with fixed guide track to form relative movement pair, fixing position detector and fixed track as well as fine moving mechanism on base, carrying position detector and fixed track as well as fine moving mechanism on base, carrying rough-positioning by rough moving mechanism under control of controller then using fine moving mechanism to carry out fine-positioning till positioning goal is realized.

Owner:许宏

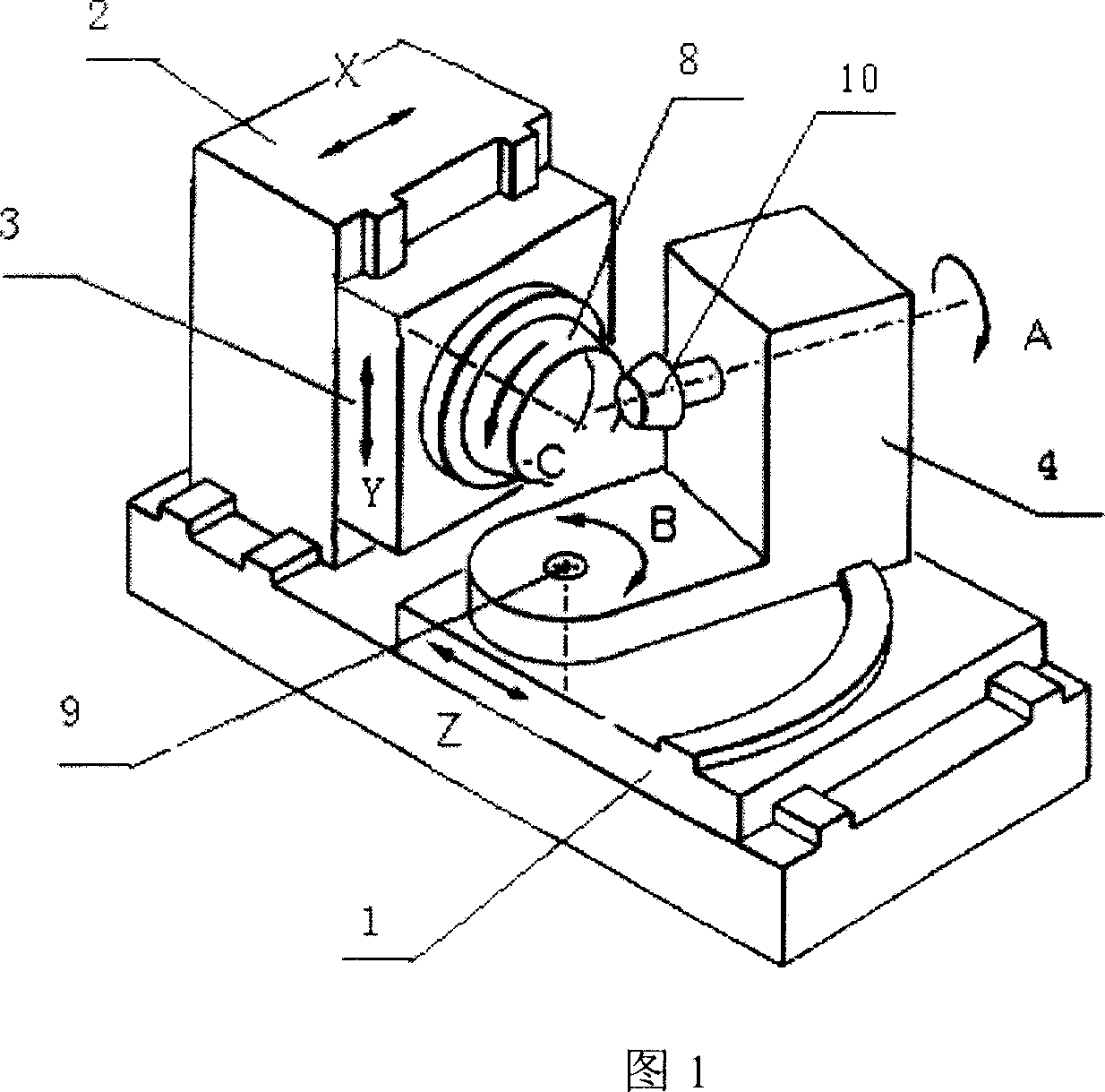

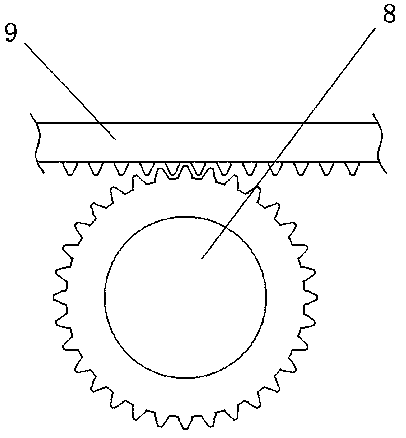

Large mode number helical awl gear cutting machine

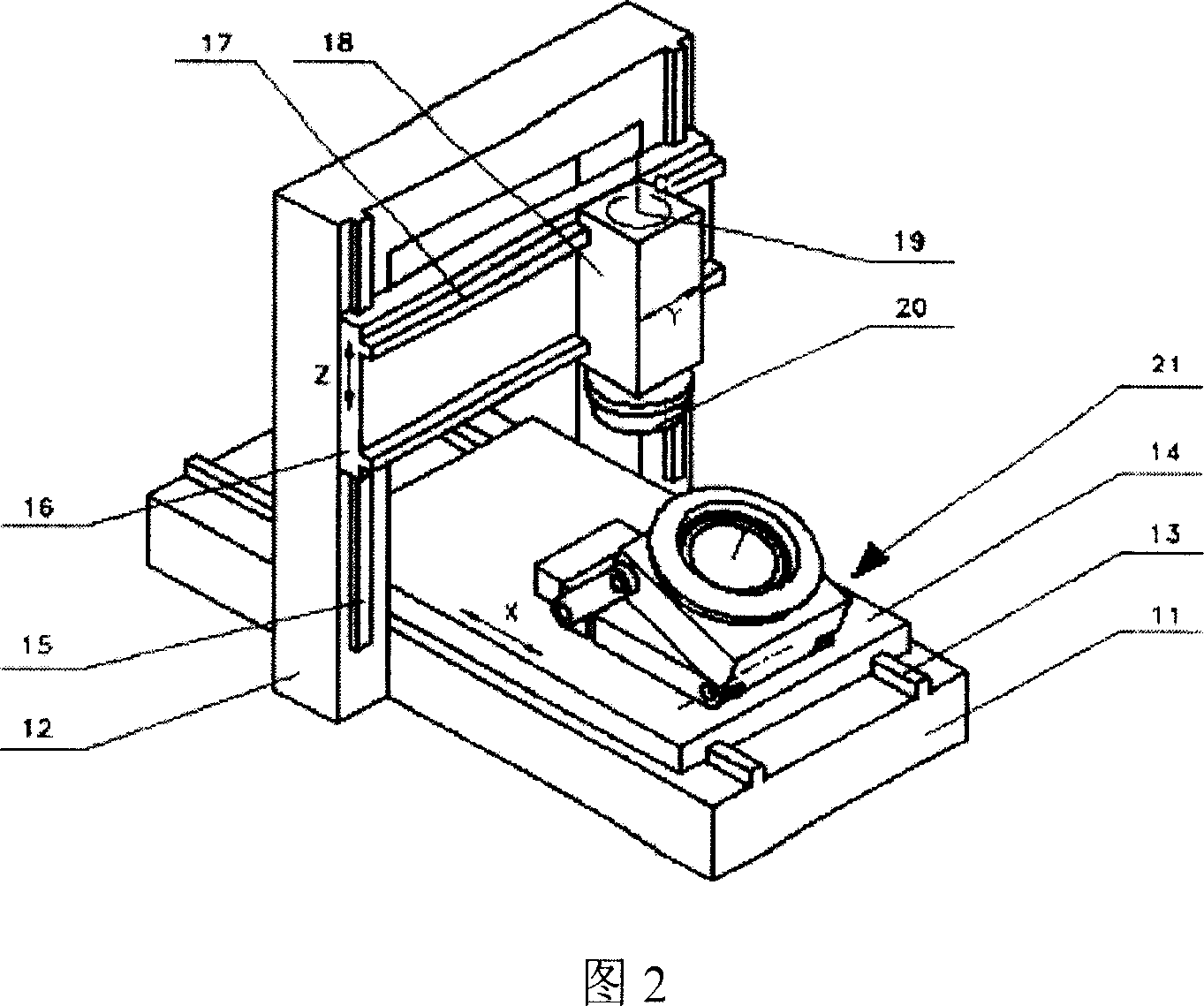

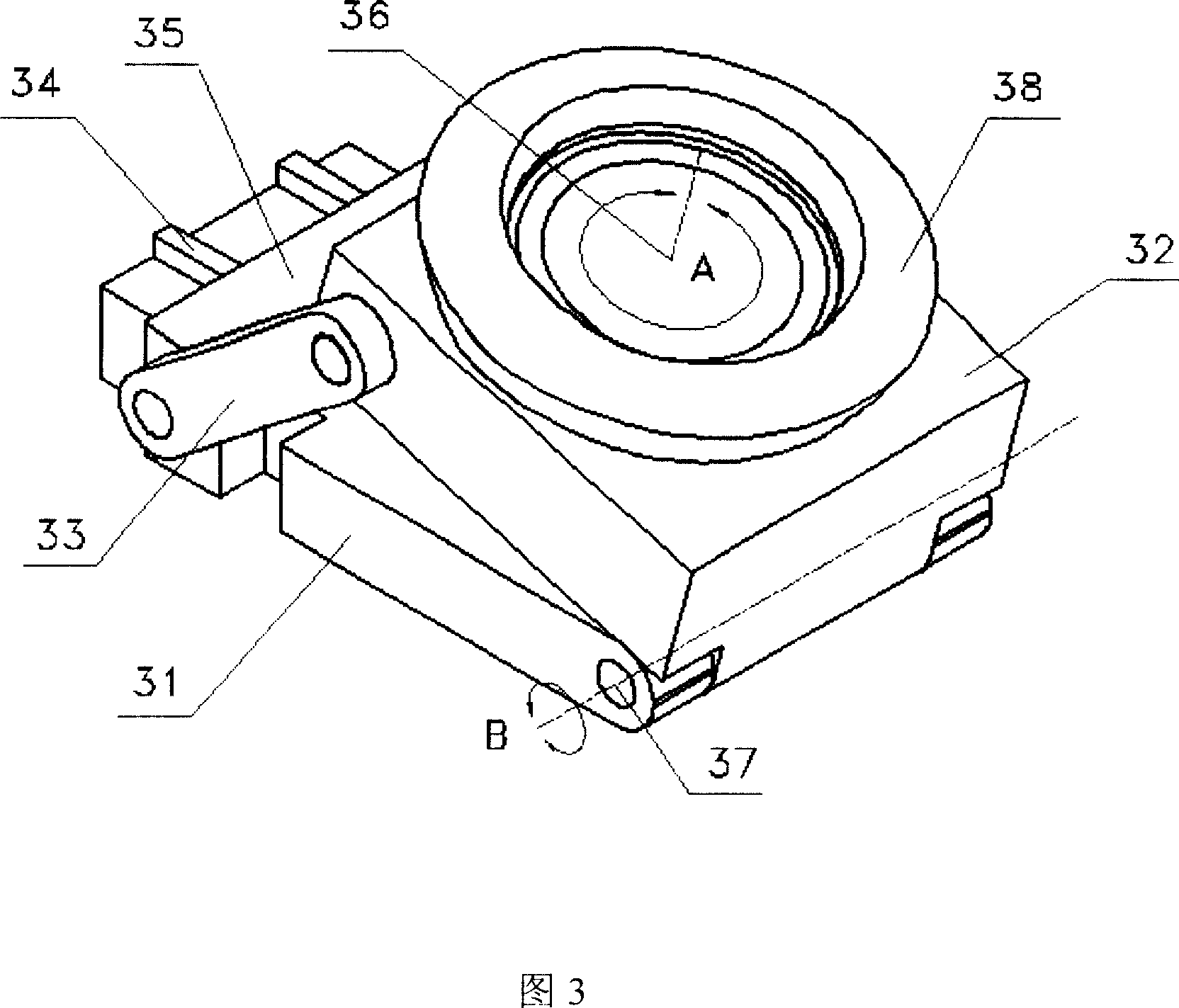

InactiveCN1923419ASimple structureEasy to manufactureGear-cutting machinesGear teethEngineeringGear cutting

The invention relates to a large-module screw taper gear processing lathe. Wherein, said lathe has X straight track and relative X sliding table; the crane has Z straight track 15 and relative beam; said beam has Y straight track and relative blade box; the blade box has rotational blade main axle mounted with blade; the X sliding table is mounted with work piece table mounted with screw taper gear; said table can be disc one or axle one. The invention has simple structure, high stability and high reliability.

Owner:HUNAN ZDCY (ZHONGDA CHUANG YUAN) CNC EQUIP CO LTD

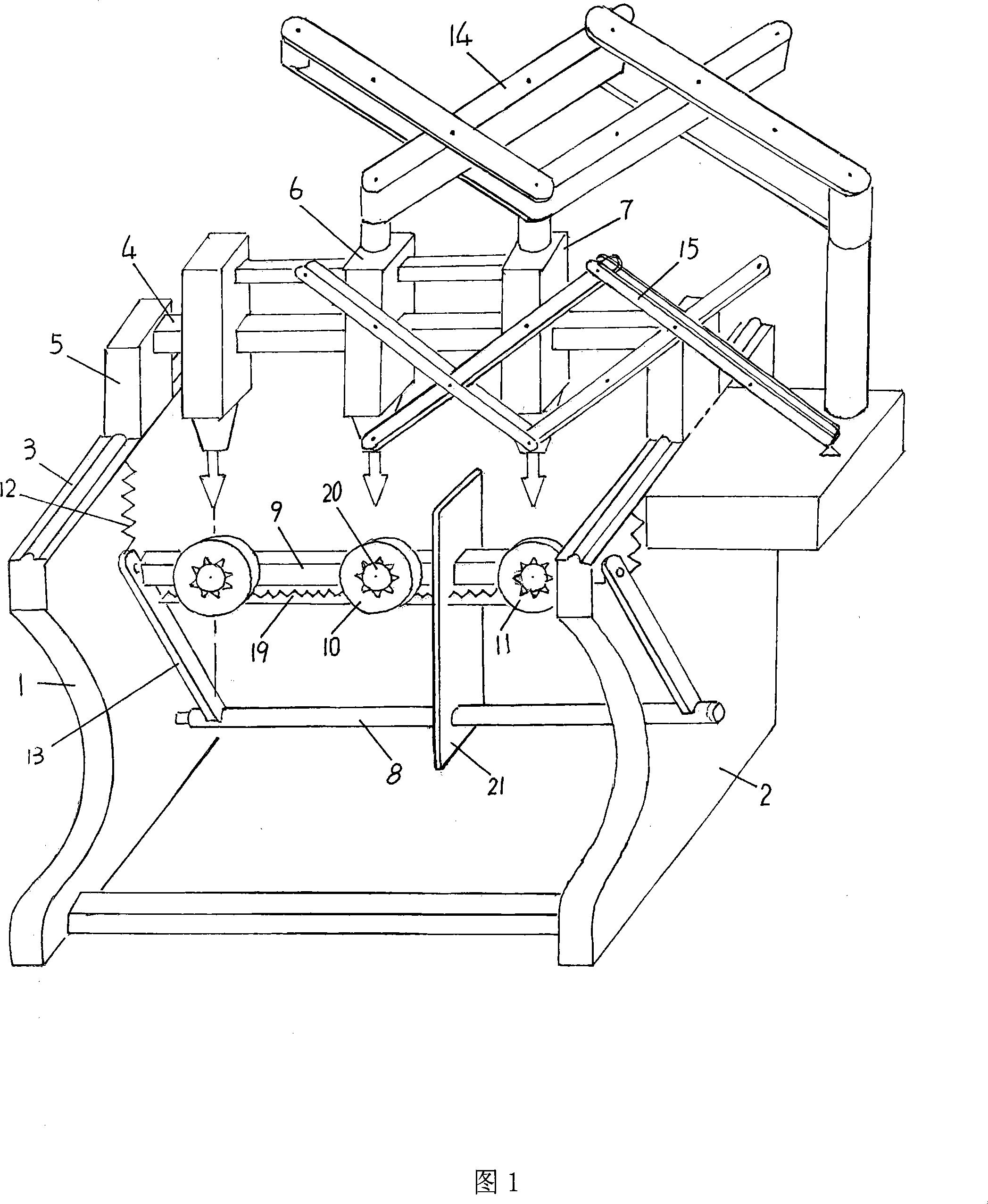

Burr removing machine tool

InactiveCN101108466AThe processing method is simple and practicalSave human effortEdge grinding machinesWire wheelProcess efficiency

The invention belongs to a removing furr machine tool technology field, which solves the problem in the existing technology that the removing furr machine tool is not suitable for the removing burr of refined component. The removing burr machine tool comprises a removing furr tool, a work piece table and a drive device, which is characterized by the furr removing tool steel wire wheel, the steel wire wheel is connected with a drive device by a steel wire wheel axle, the steel wire wheel axle is arranged on a motherboard, the bottom of the motherboard is connected with a hydraulic pressure oil cylinder, the work piece table is an automatic work piece table. The beneficial effects are as follows: the process method is simple and practical, which can save a great deal of work labor; the operation is simple and convenient, adopts PC control, the operation only need the upper and the lower work piece, start the switch; the process efficiency is high, the using time of proceeding one end surface is about 10 to 20 seconds; the cost is low, a steel wire wheel can process 5000 to 10000 work piece; the investment is little, the machine tool has simple structure, the investment of producing a set of machine tool is about 40 thousand Yuan.

Owner:SHANXI DATONG GEAR GROUP

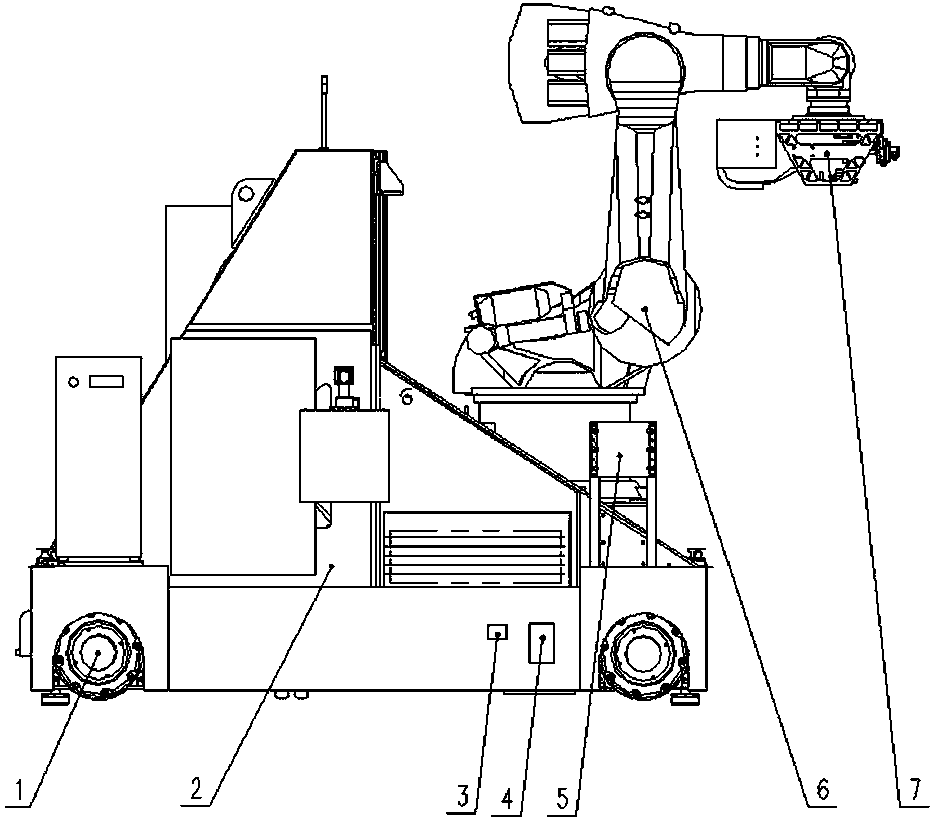

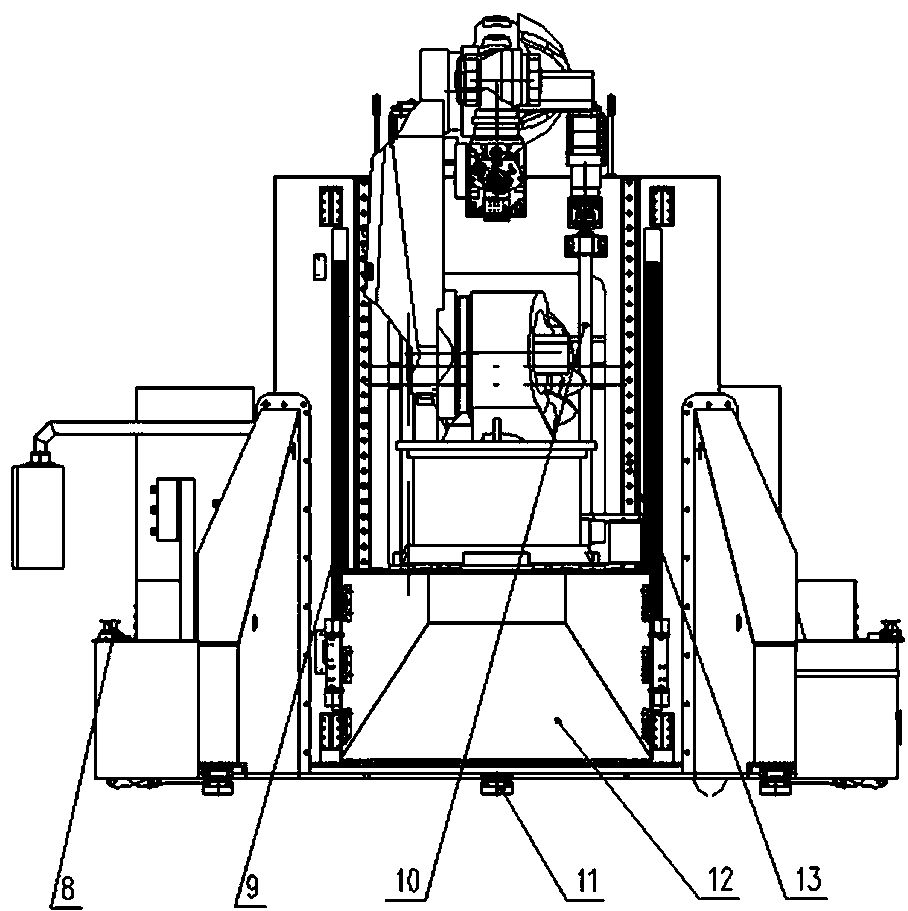

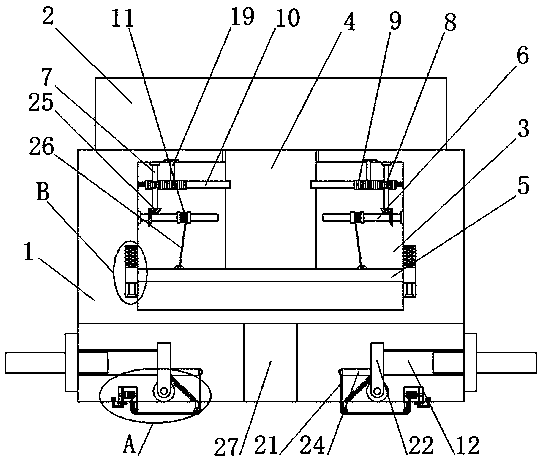

Hole making system for intelligent AGV lifting robot

InactiveCN108247598AGuaranteed accuracyGuaranteed precision movementProgramme-controlled manipulatorLaser transmitterGrating

The invention provides a hole making system for an intelligent AGV lifting robot. The hole making system comprises mecanum wheel assemblies, a vehicle body, a laser emitter, a positioning camera, a test piece table, a six-axis robot, an end effector, a laser scanner, a grating ruler, a lifting driving device, self-adaptive supporting legs, a lifting platform and a linear guide rail. According to the hole making system, the mecanum wheel assemblies are driven by a servo motor and a storage battery, so that omni-directional movement is realized, and meanwhile, an external power source is not required to be connected; the laser emitter and the positioning camera are used for positioning and measuring, so that accurate positioning and position deviation feedback are realized; in the hole making process, the three self-adaptive supporting legs are used for forming a triangular stable support for the vehicle body so that the robot can overcome the influence caused by uneven ground plane, andhole making precision is guaranteed; accurate lifting of the six-axis robot is completed by the lifting mechanism and a grating ruler measuring control system, so that the working space of the robotis greatly expanded; and The hole making system has the advantages that the assembling quality and efficiency of an aircraft can be greatly improved, and meanwhile, assembling cost of the aircraft isreduced.

Owner:大连四达高技术发展有限公司

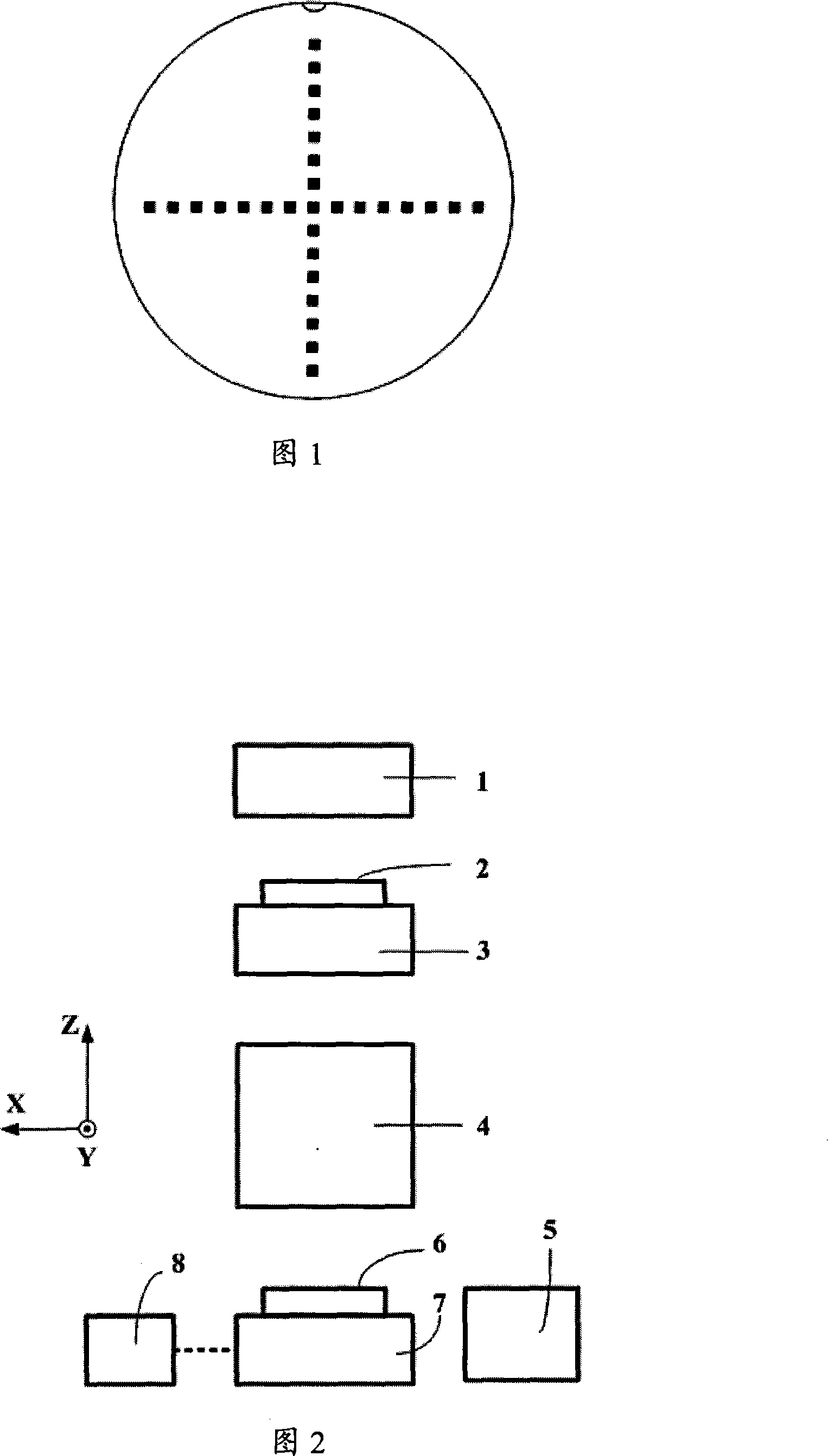

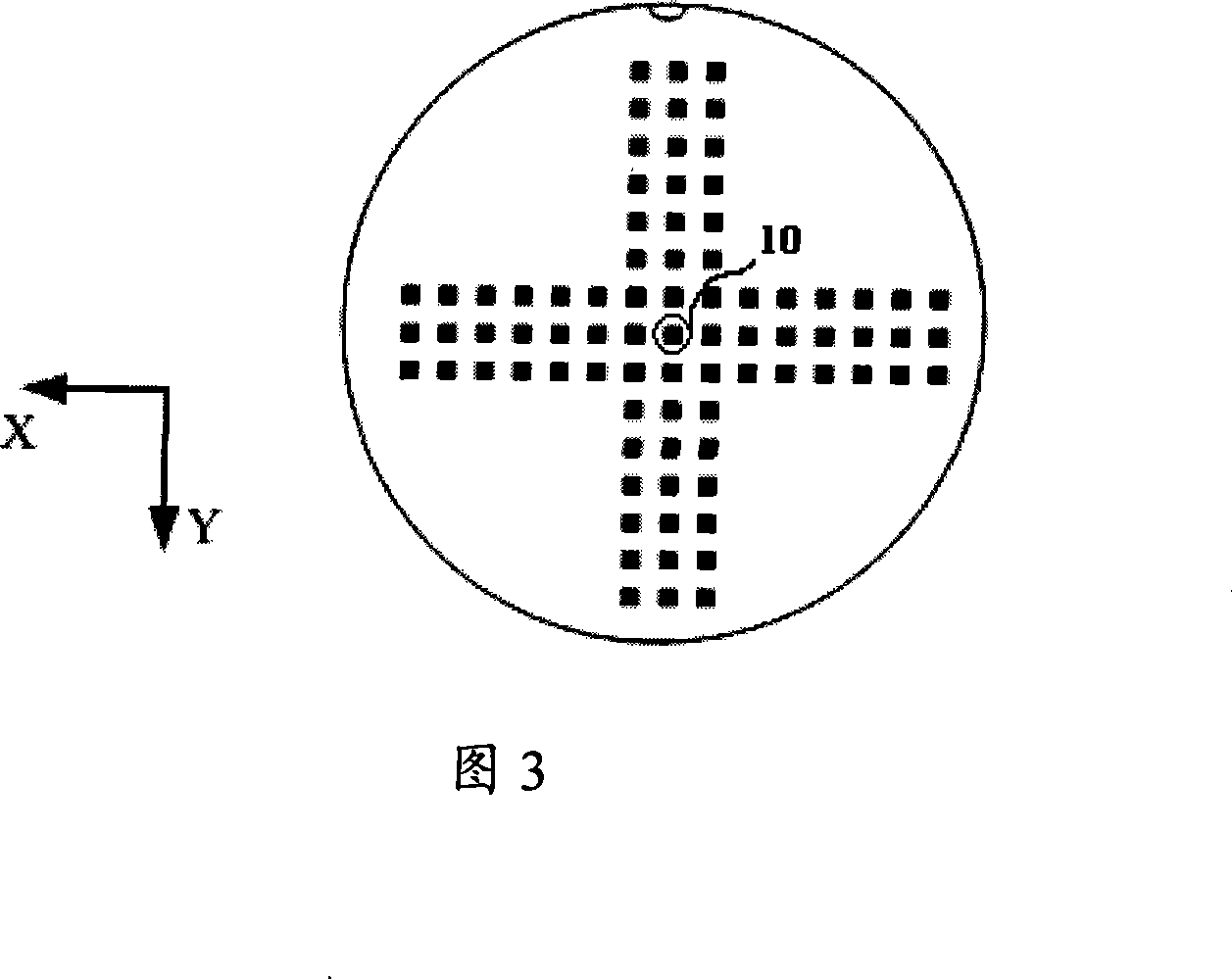

Method for measuring Cube-Prism non-orthogonality angle and scale factor correct value

ActiveCN101216680ASimple label designLabel design is convenientPhotomechanical exposure apparatusMicrolithography exposure apparatusPrismAbsolute measurement

A method for measuring corrected values of non-rothogonality angles and scaling factors of a square mirror comprises the following steps: placing and exposing a marking image (A) on a mask onto a gummed blank silicon wafer via a photoetching system according to a designated graph, and taking off the wafer when exposure is completed; putting up the wafer after rotating the silicon wafer by a certain angle, placing and exposing a marking image (B) on the mask onto the silicon wafer according to the same graph, wherein compared to the first layer, the exposure marking position is deviant; developing again when the exposure is completed; putting up the wafer again without rotating the silicon wafer, and reading all the marking positions after aligning the marks on the silicon wafer via an off-axis alignment system of a photographic machine; and calculating the non-rothogonality angles and the scaling factors of a coordinate system of a working piece table according to the measured marking positions. The measurement method is an absolute measurement method, and can be applied in different photoetching systems.

Owner:SHANGHAI MICRO ELECTRONICS EQUIP (GRP) CO LTD

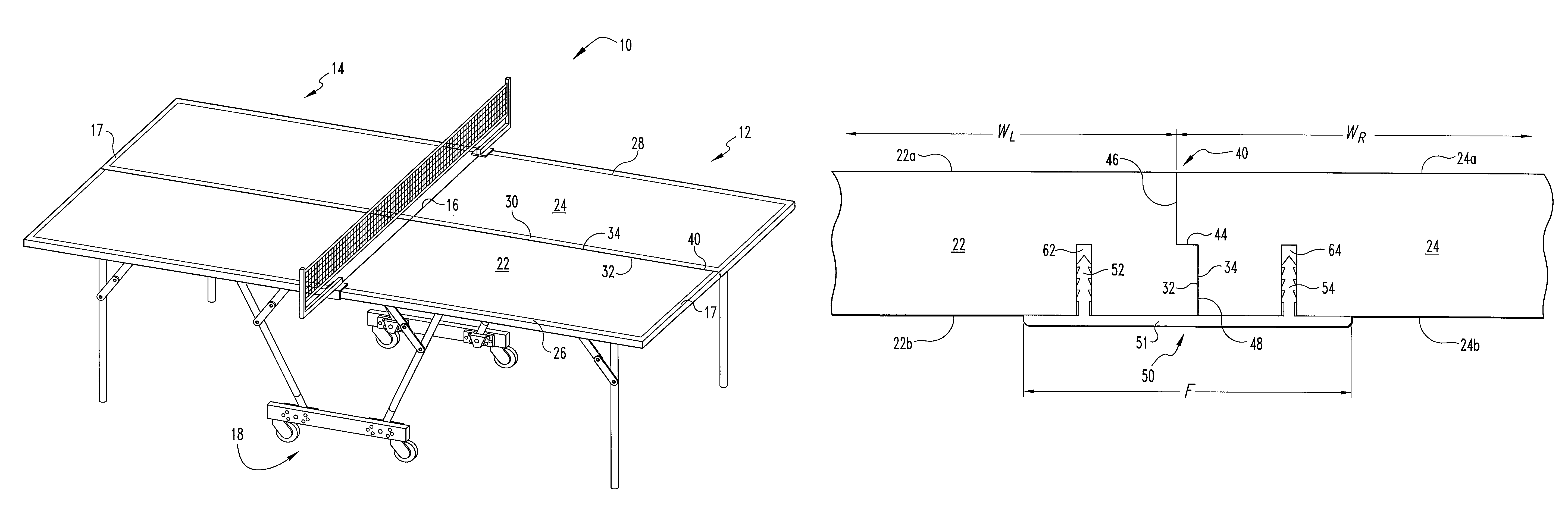

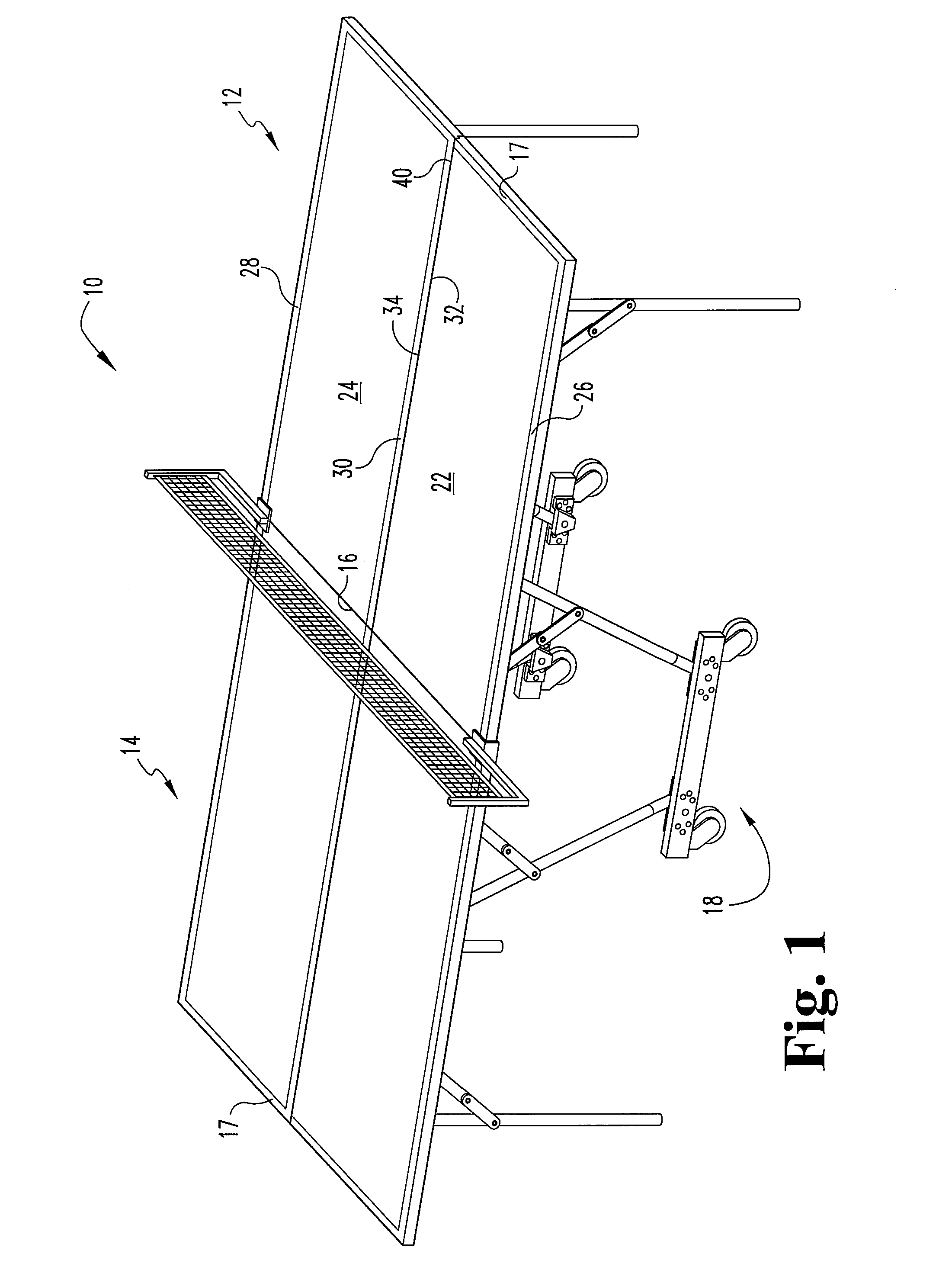

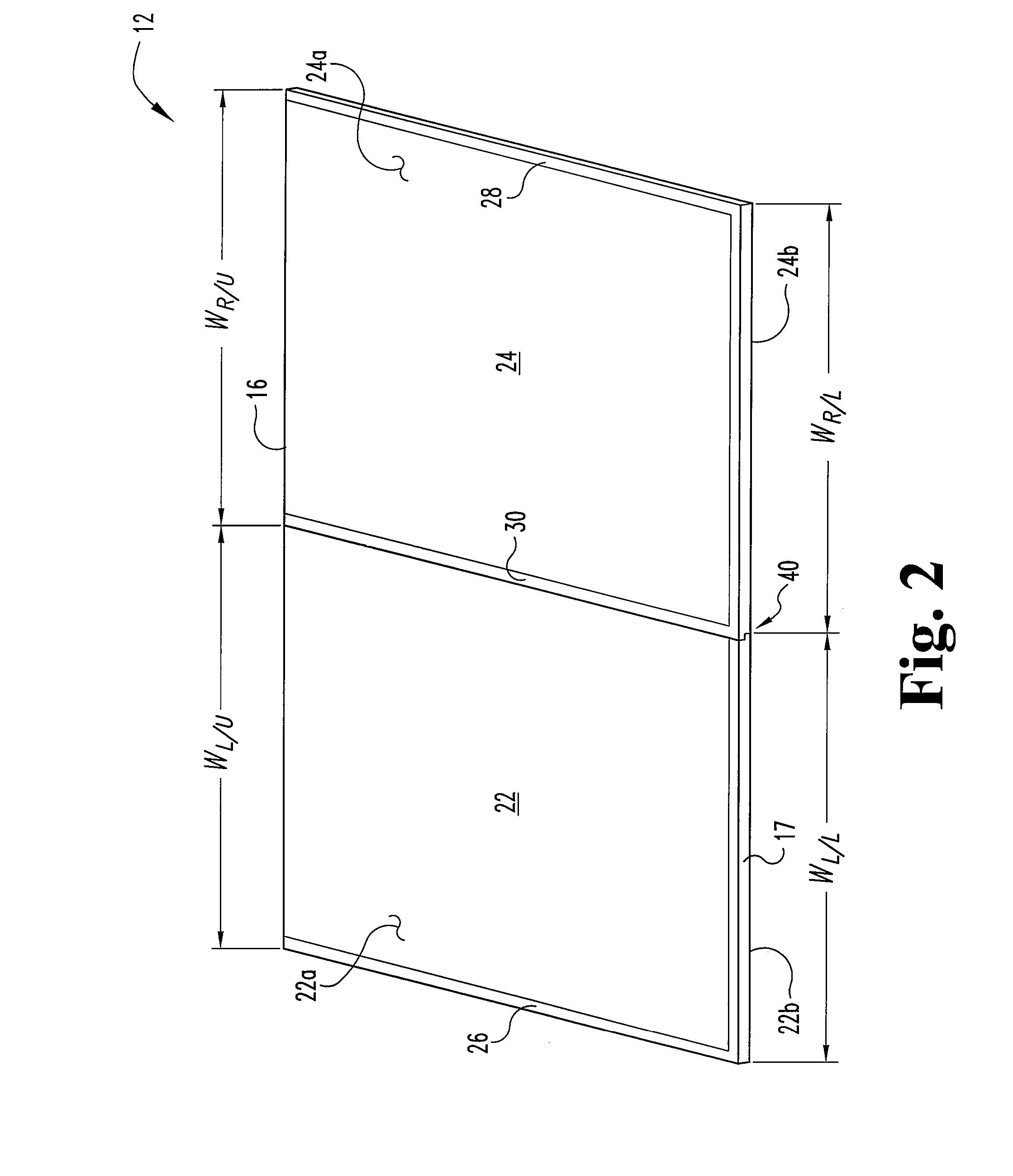

Four piece table tennis table having a stabilized joint

A multi-section table tennis table half comprises first and second table sections which abut to form a first table half. Each of the sections includes an upper surface for playing table tennis, an opposite lower surface an inner edge. The inner edges of the first and second sections abut to form a first table half joint. The vertical cross-section of the joint may be stepped, with each of the inner edges being stepped and thereby including a horizontal section positioned between two vertical sections. The table half may further include a fastener spanning the abutment between the sections to secure the connection of the sections.

Owner:INDIAN IND INC

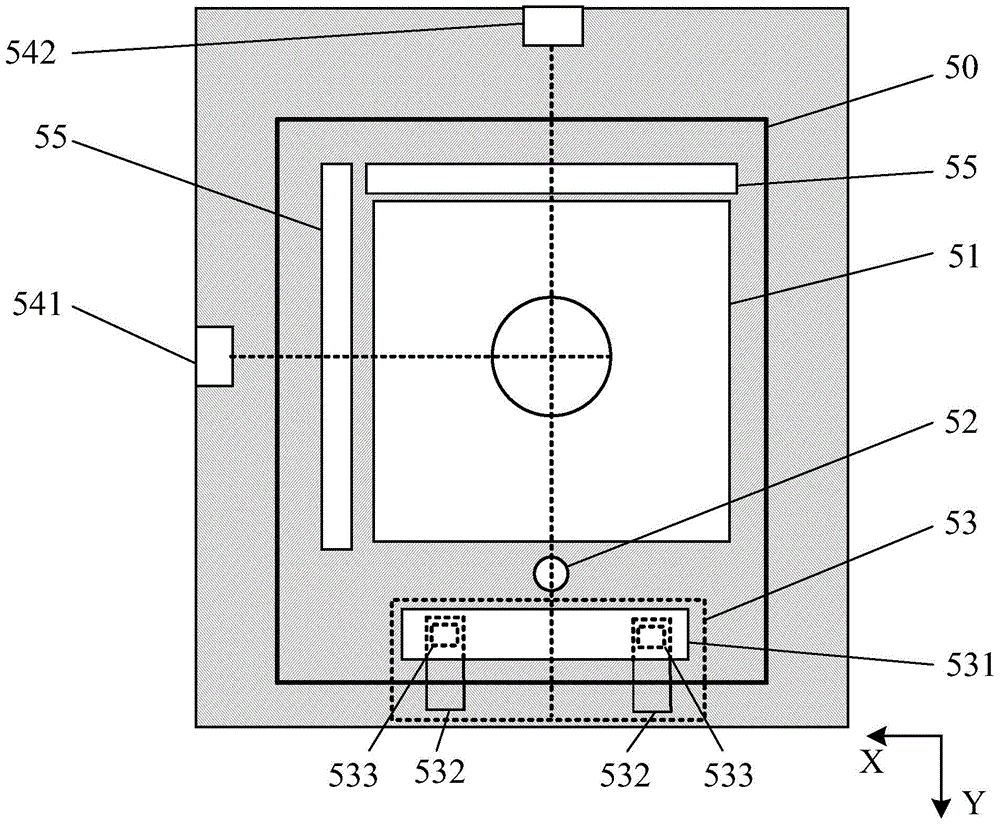

Projection exposure apparatus

ActiveCN104793465AReduce exposureReduce process complexityPhotomechanical exposure apparatusMicrolithography exposure apparatusLight spotMeasurement point

The present invention discloses a projection exposure apparatus, which comprises an illumination system, a mask table for bearing a mask, a projection object lens and a work-piece table for bearing a substrate, wherein the illumination system generates an illumination light beam to irradiate the mask, and the projection object lens projects the pattern on the mask onto the substrate surface. The projection exposure apparatus is characterized by further comprising a focusing leveling device, wherein the focusing leveling device generates a plurality of measurement points in the visual field of the projection object lens, and each measurement point comprises at least three measurement sub-light spots. According to the present invention, with the projection exposure apparatus, the production efficiency of the exposure equipment can be substantially improved, and the equipment use cost can be reduced; the screen with the large size can be obtained through the single exposure so as to reduce the complex process and the increased manufacturing cost caused by the splitting exposure; and the synchronous scanning technology, the image sensor technology and the exposure process focal plane real-time control technology are utilized to substantially increase the projection exposure apparatus overlay precision and the imaging quality and meet the low-cost and high-yield production requirements.

Owner:SHANGHAI MICRO ELECTRONICS EQUIP (GRP) CO LTD

Calibration device and calibration method for photoelectric detector

ActiveCN102890423AReduce pollutionImprove accuracy and precisionPhotomechanical exposure apparatusMicrolithography exposure apparatusBeam splitterPhotovoltaic detectors

The invention discloses a calibration device and a calibration method for a photoelectric detector. The calibration device comprises a beam splitter prism, an absolute detector and a processing unit; the beam splitter prism is arranged above the photoelectric detector; the photoelectric detector is arranged on a work-piece table; a lighting light is divided by the beam splitter prism into a first measuring light and a second measuring light; the absolute detector is arranged at one side of the beam splitter prism; the second measuring light comes into the absolute detector; the first measuring light comes into the photoelectric detector; the processing unit is used for calculating the light intensity of the second measuring light measured by the absolute detector and the light intensity of the first measuring light measured by the photoelectric detector, building a relation between the photoelectric detector and the absolute detector, and calibrating gain and offset of the photoelectric detector. The calibration device and the calibration method are simple to operate; environmental pollution of a human factor on inside of a photoetching machine is reduced; the test accuracy is improved; and the light measured by the absolute detector and the light measured by the calibration detector are the same light, so that the situation of transmittance change caused by volatility of a light source is avoided, thereby improving the measurement accuracy.

Owner:SHANGHAI MICRO ELECTRONICS EQUIP (GRP) CO LTD

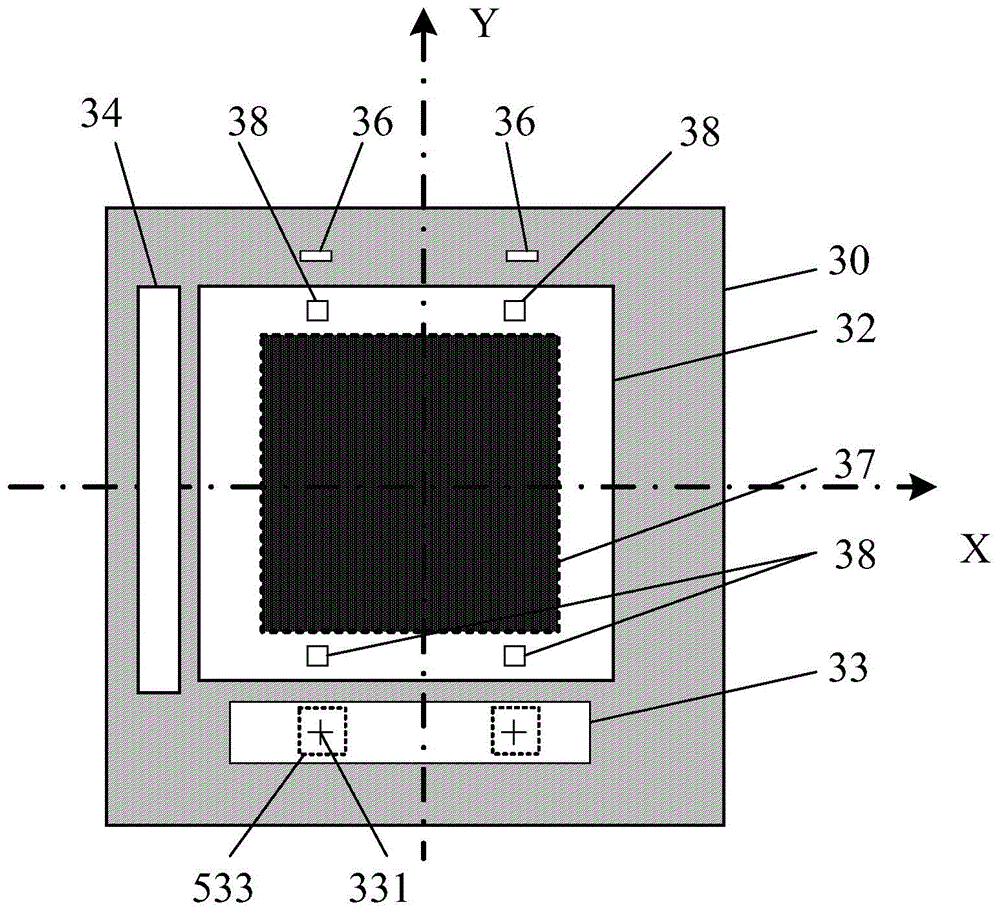

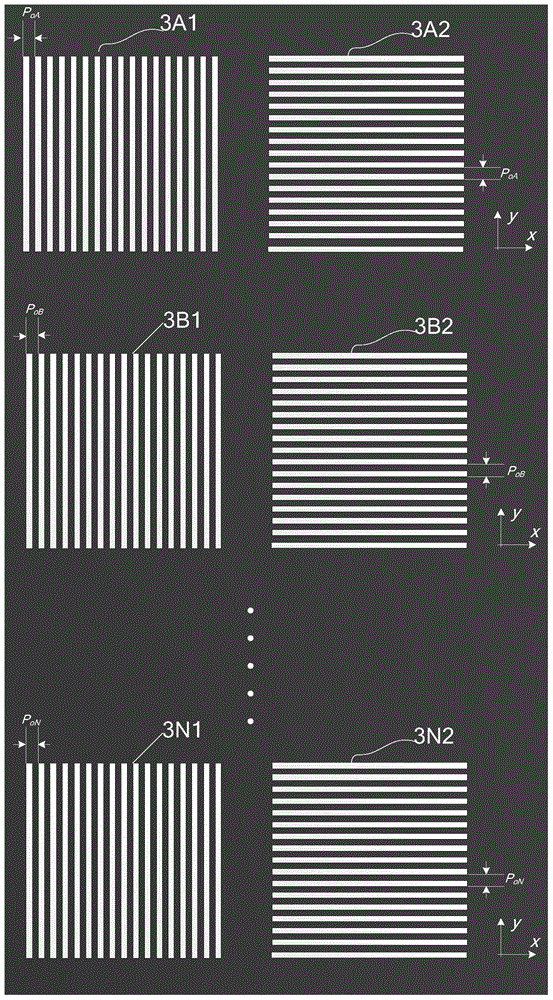

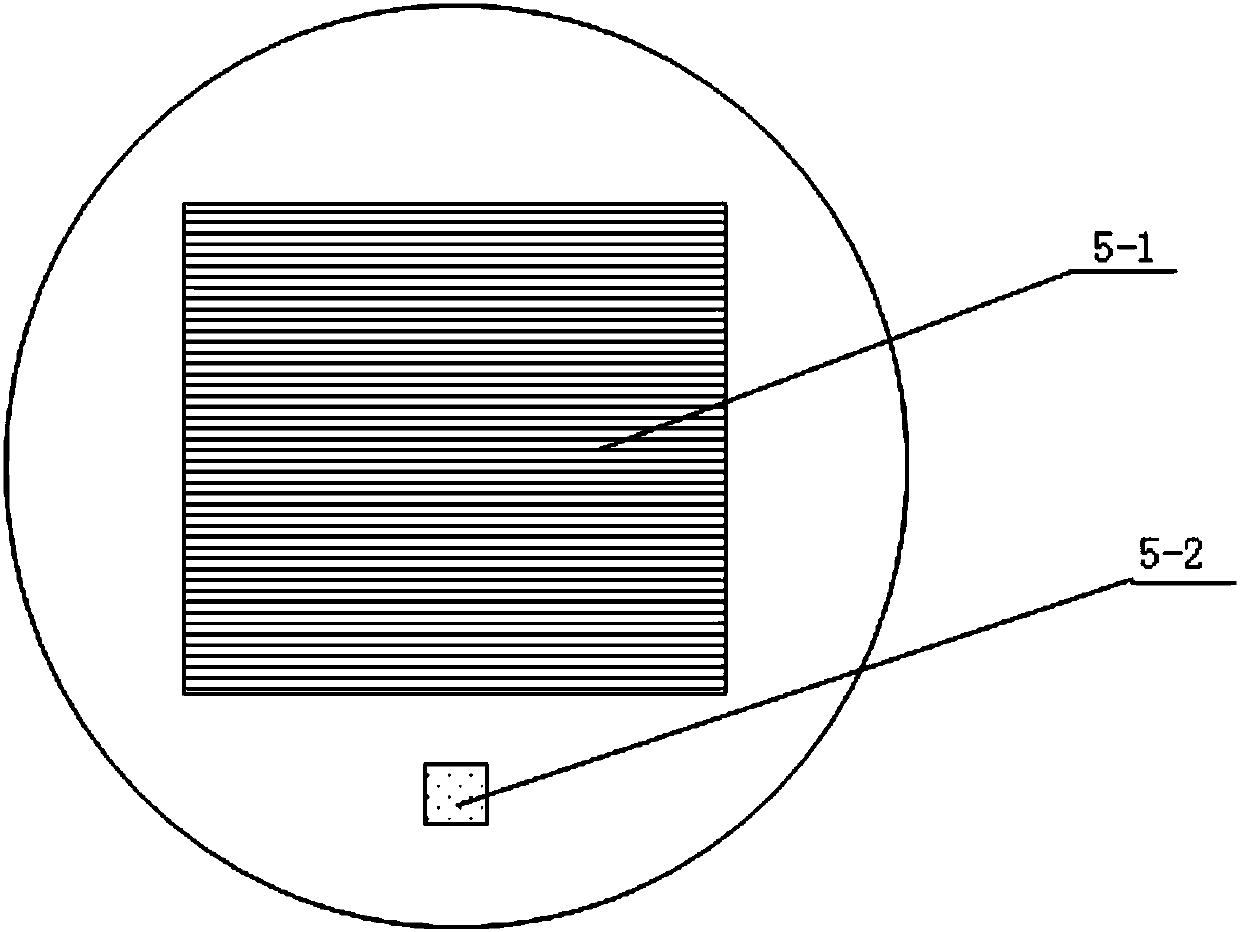

Alignment system and alignment method for photolithographic device

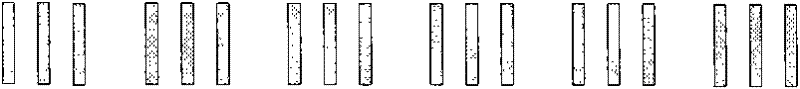

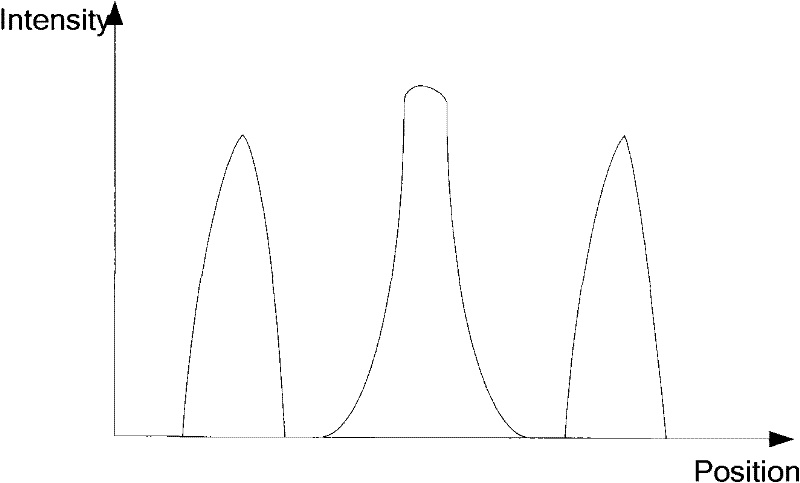

InactiveCN102207695APhotomechanical exposure apparatusMicrolithography exposure apparatusSignal-to-noise ratio (imaging)Grating

The invention provides an alignment system and an alignment method for a photolithographic device, which are used for implementing alignment of a work piece table and a mask or of the work piece table and a mask table. The alignment system for the photolithographic device comprises a light source module, an objective lens module, a detection module, an alignment mark and a reference mark. The alignment mark is arranged at the mask or the mask table, and comprises a first square mark for coarse alignment and a first grating mark for fine alignment. The reference mark is arranged at the work piece table, and comprises a second square mark for coarse alignment and a second grating mark for fine alignment. The alignment mark in the alignment system has extremely high contrast ratio in a small scanning range, so that the signal-to-noise ratio of scanning signals is greatly improved, post treatment on the scanning signals is simplified and efficiency is improved.

Owner:SHANGHAI MICRO ELECTRONICS EQUIP (GRP) CO LTD +1

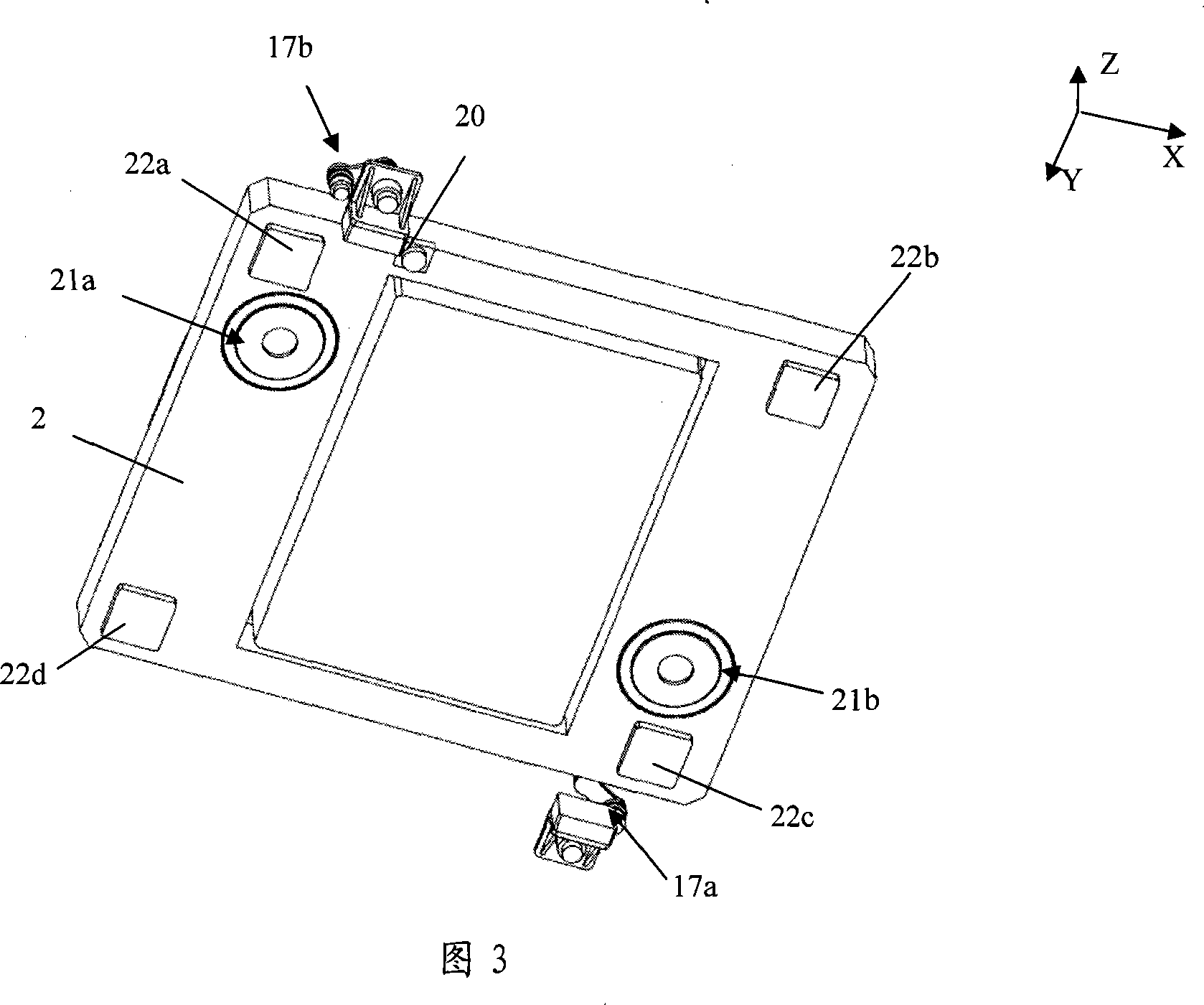

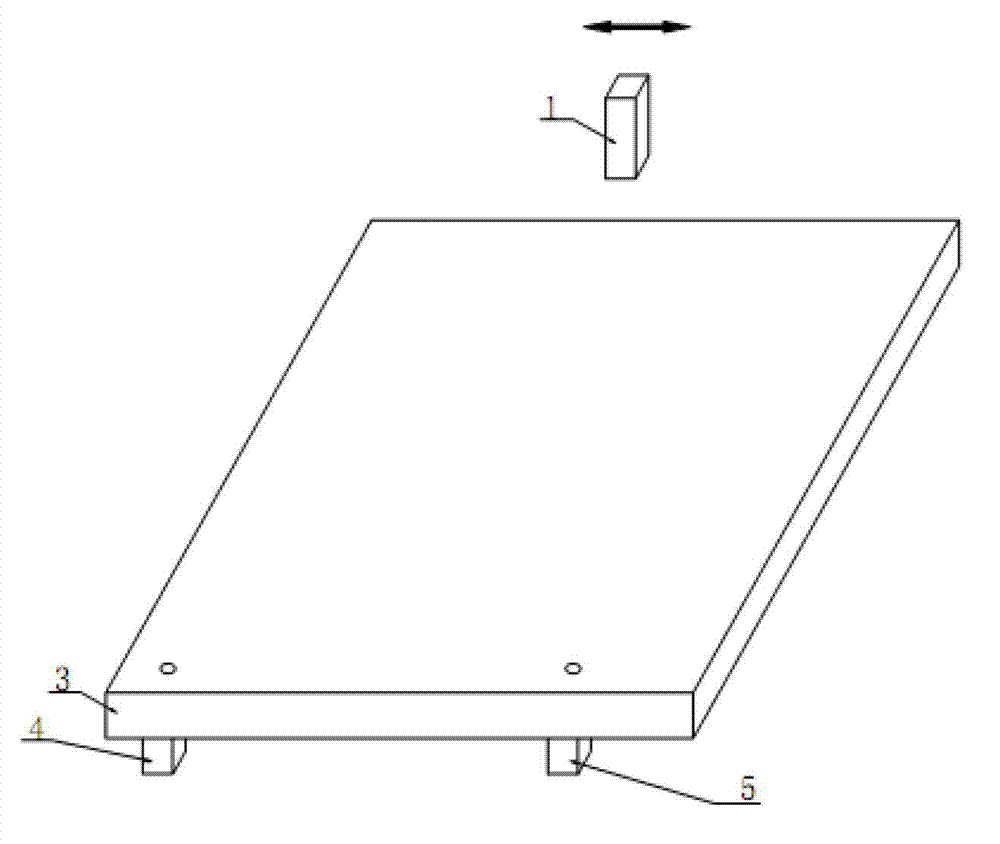

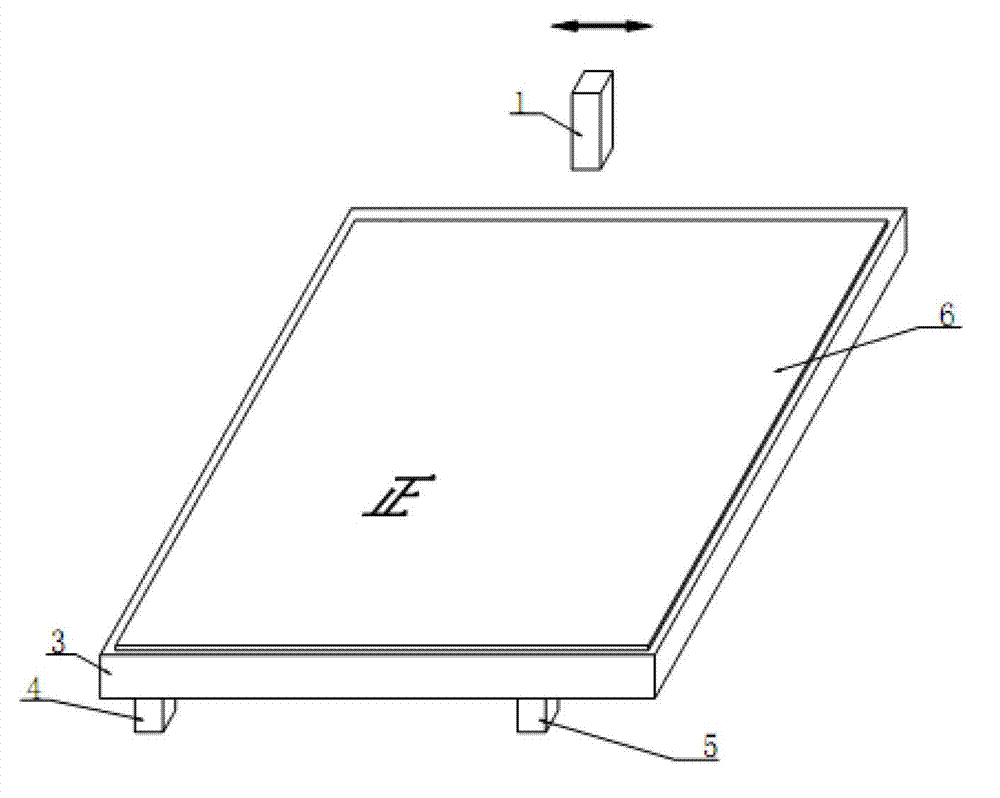

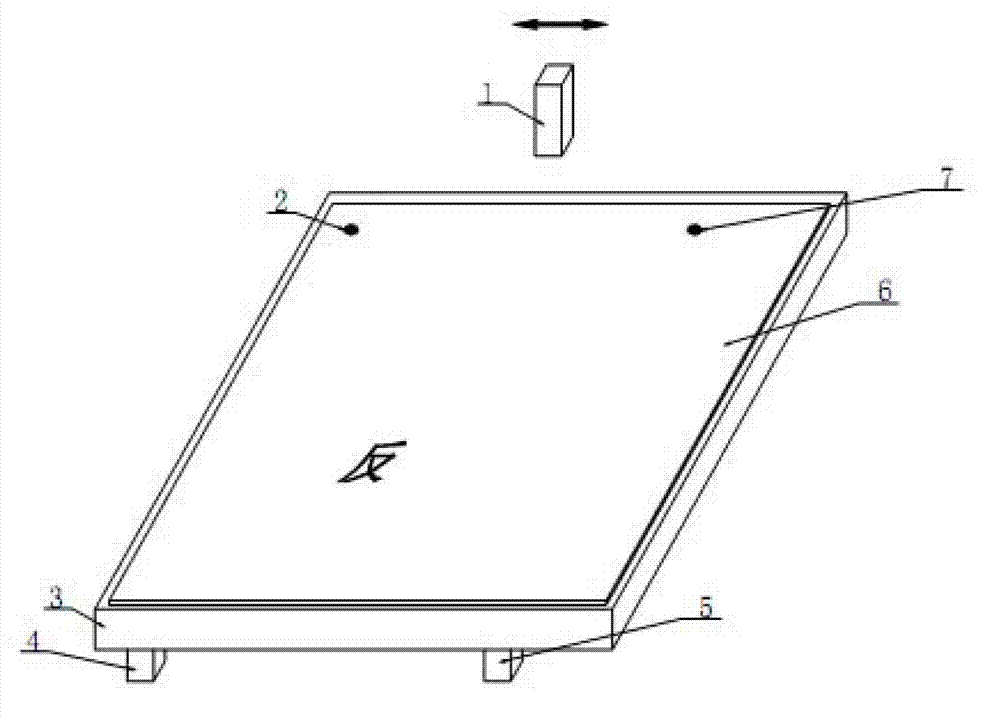

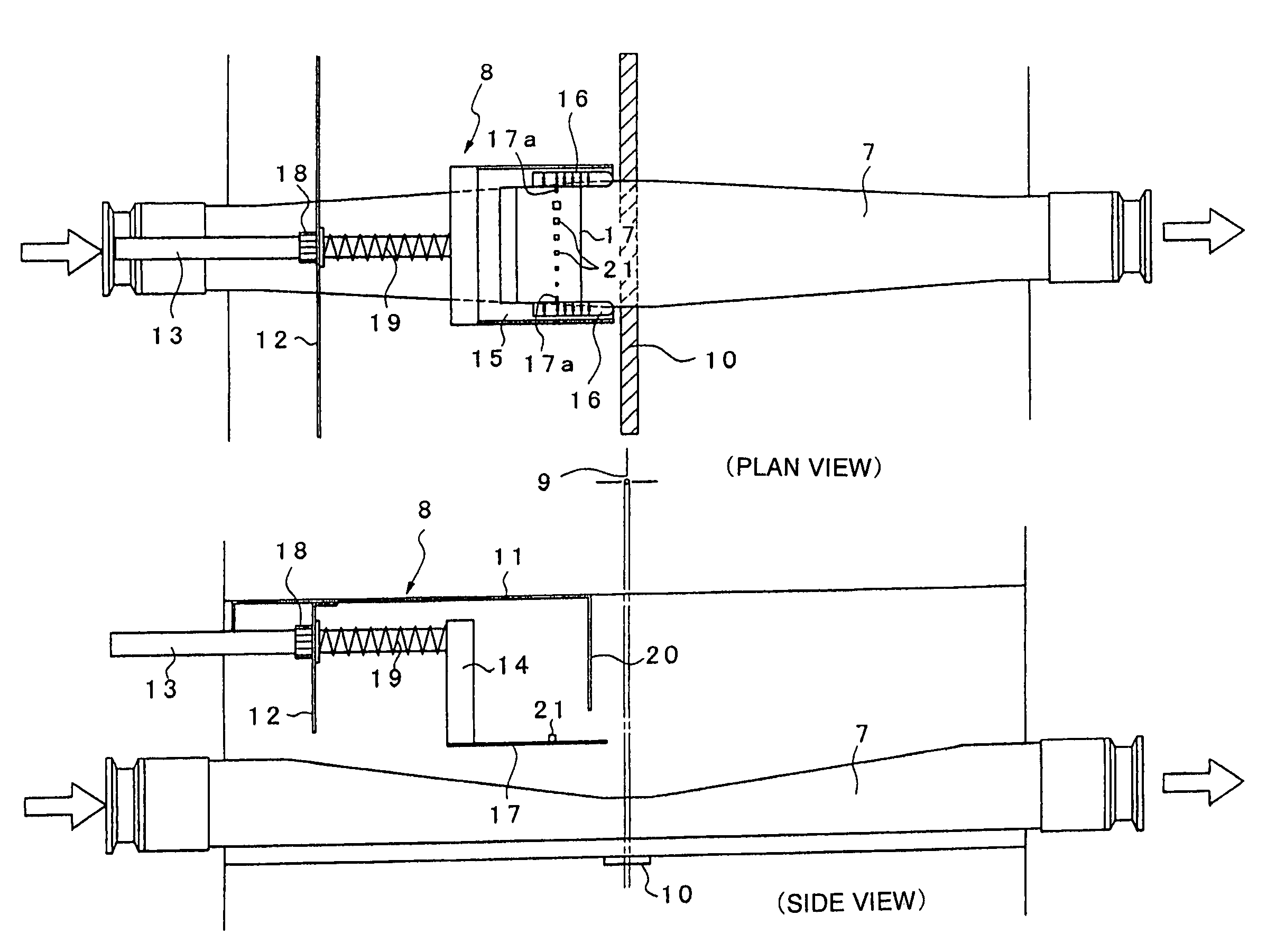

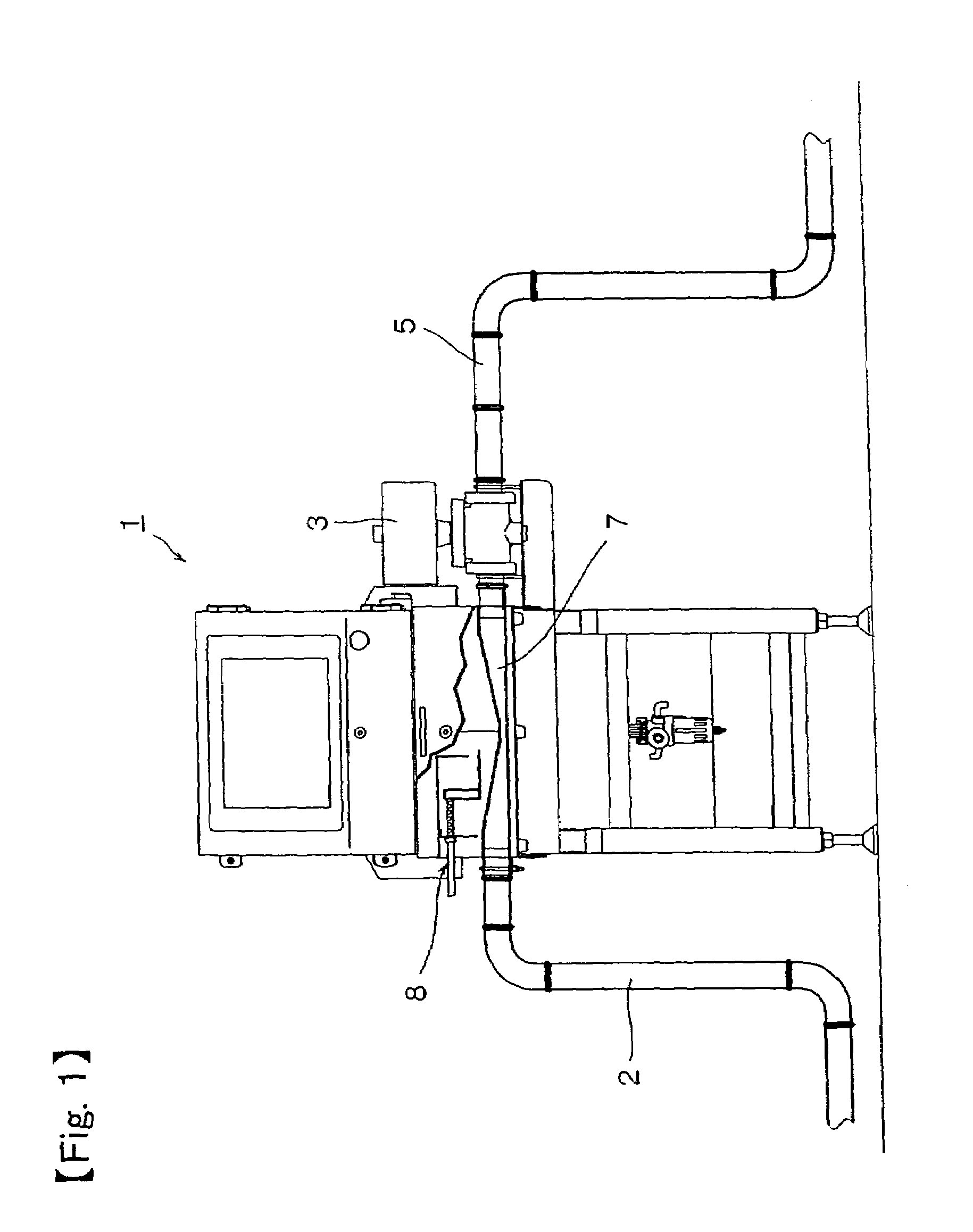

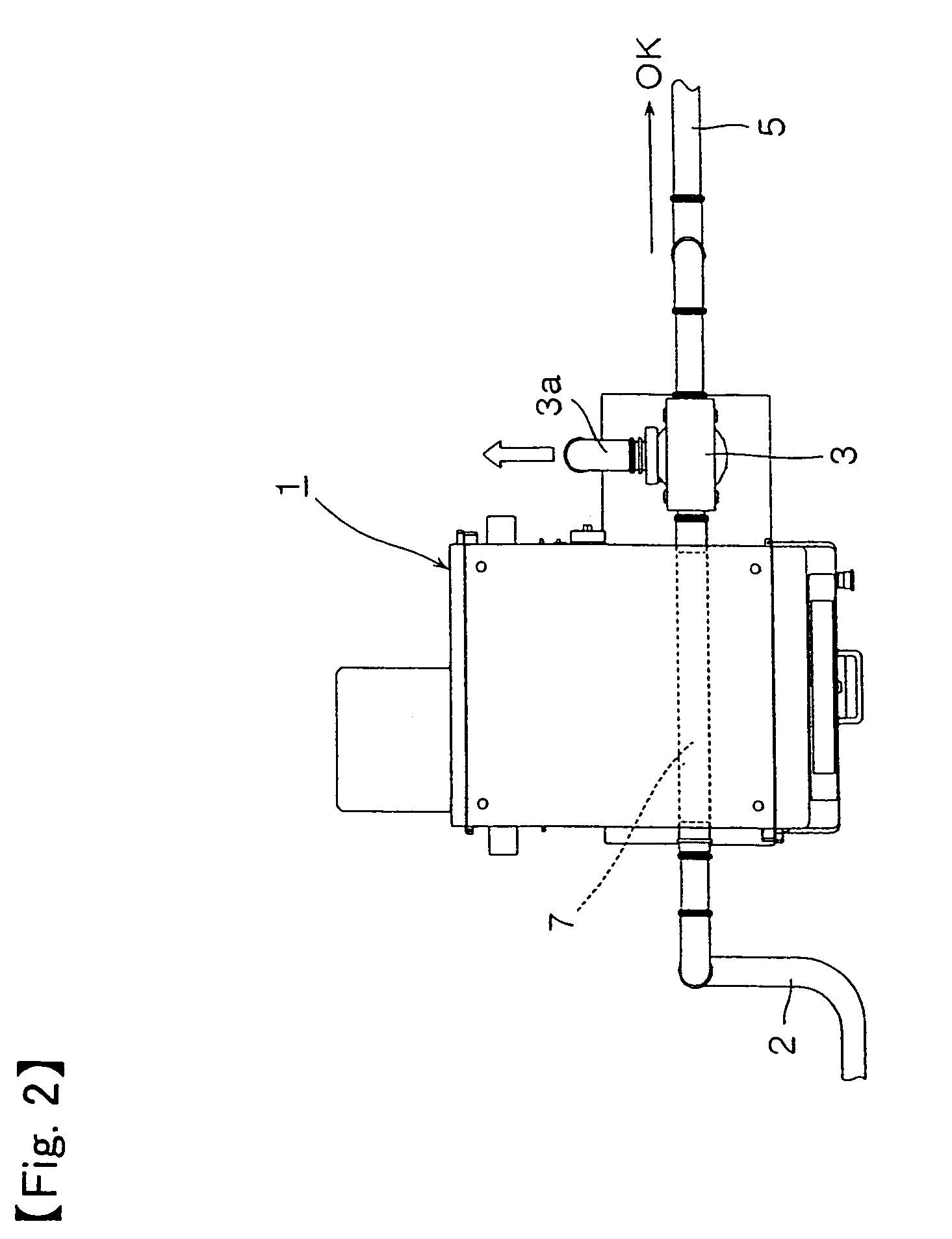

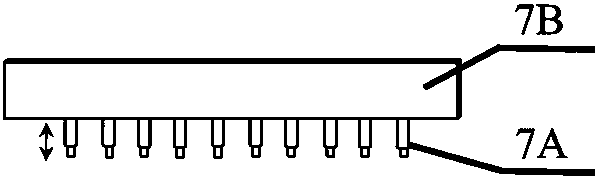

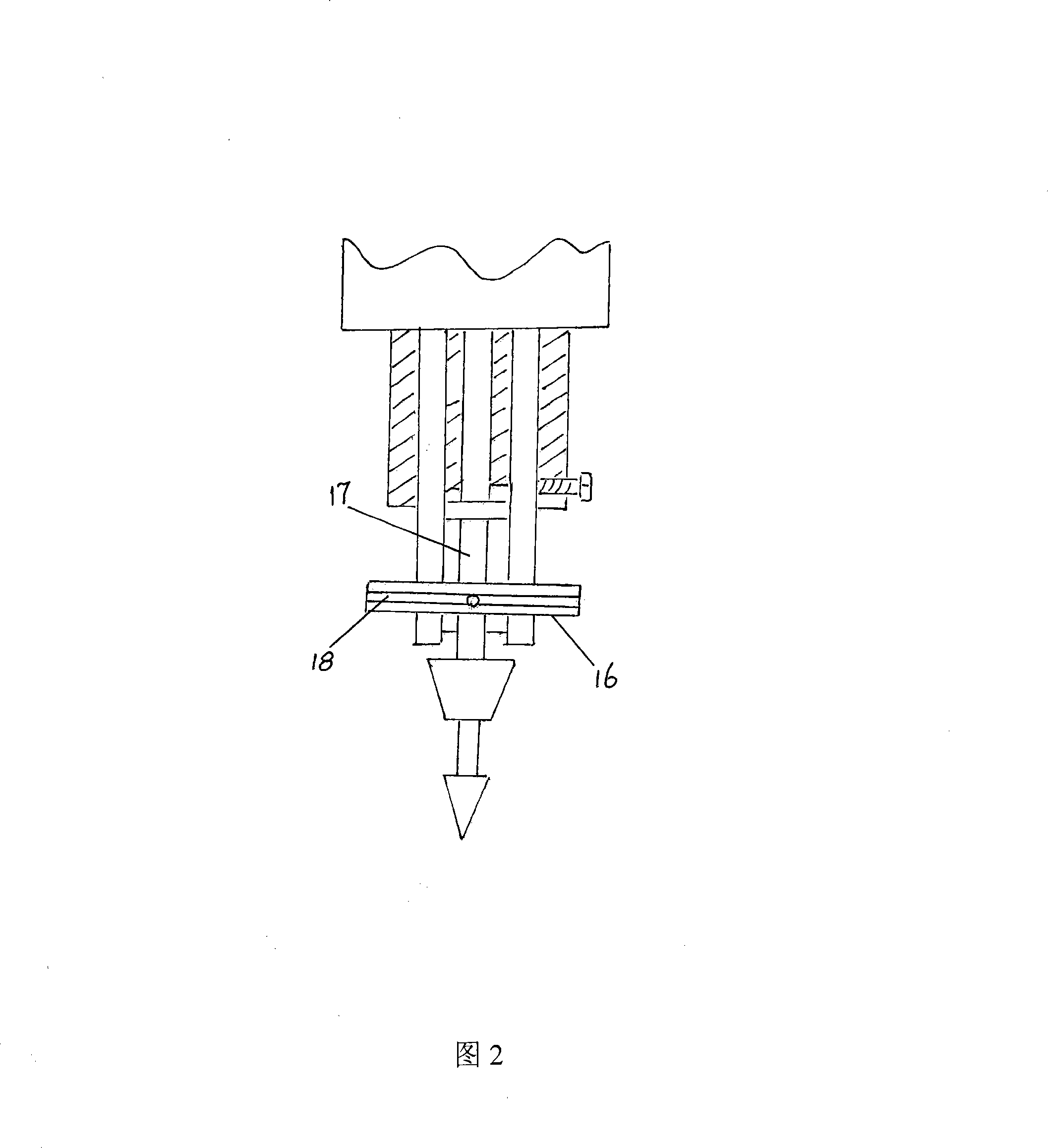

X-ray detection device for foreign matter

ActiveUS7561663B2Easy to checkEasy to mergeVolume/mass flow measurementPatient positioning for diagnosticsForeign matterSoft x ray

An X-ray detection device for detecting whether or not foreign matter is mixed in on the basis of the transmission amount of X-rays that have penetrated an examination subject article by applying X-rays, at a predetermined detection position to an examination subject article being conveyed in a pipe (7), wherein a test-piece table (17) capable of passing by the detection position at substantially the same speed as that of the examination subject article is installed in the vicinity of the pipe (7), with a test-piece (21) placed thereon. X-ray detection sensitivity can be detected without mixing the test-piece in the actual examination subject article.

Owner:ANRITSU CORP

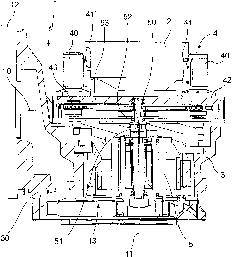

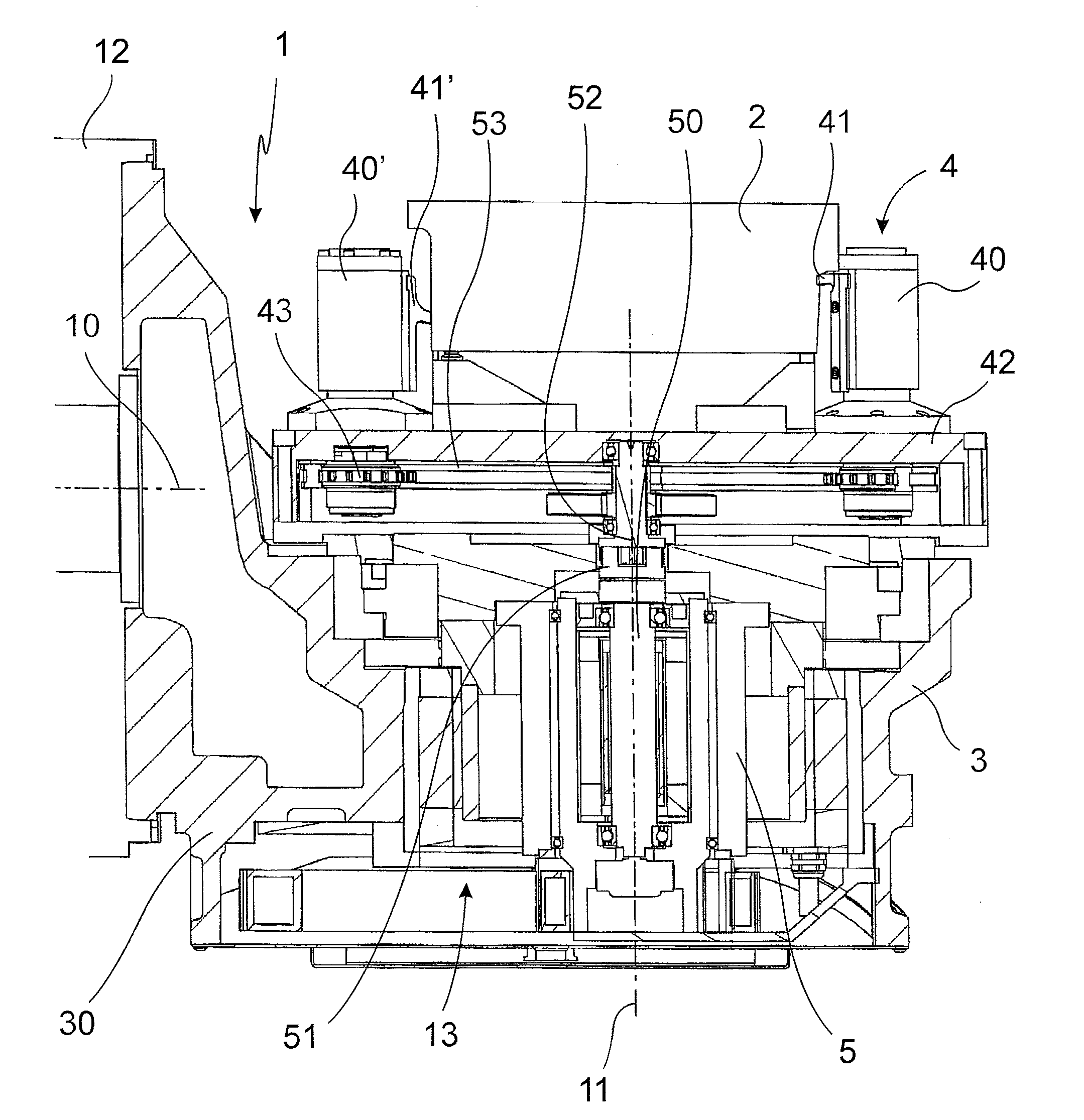

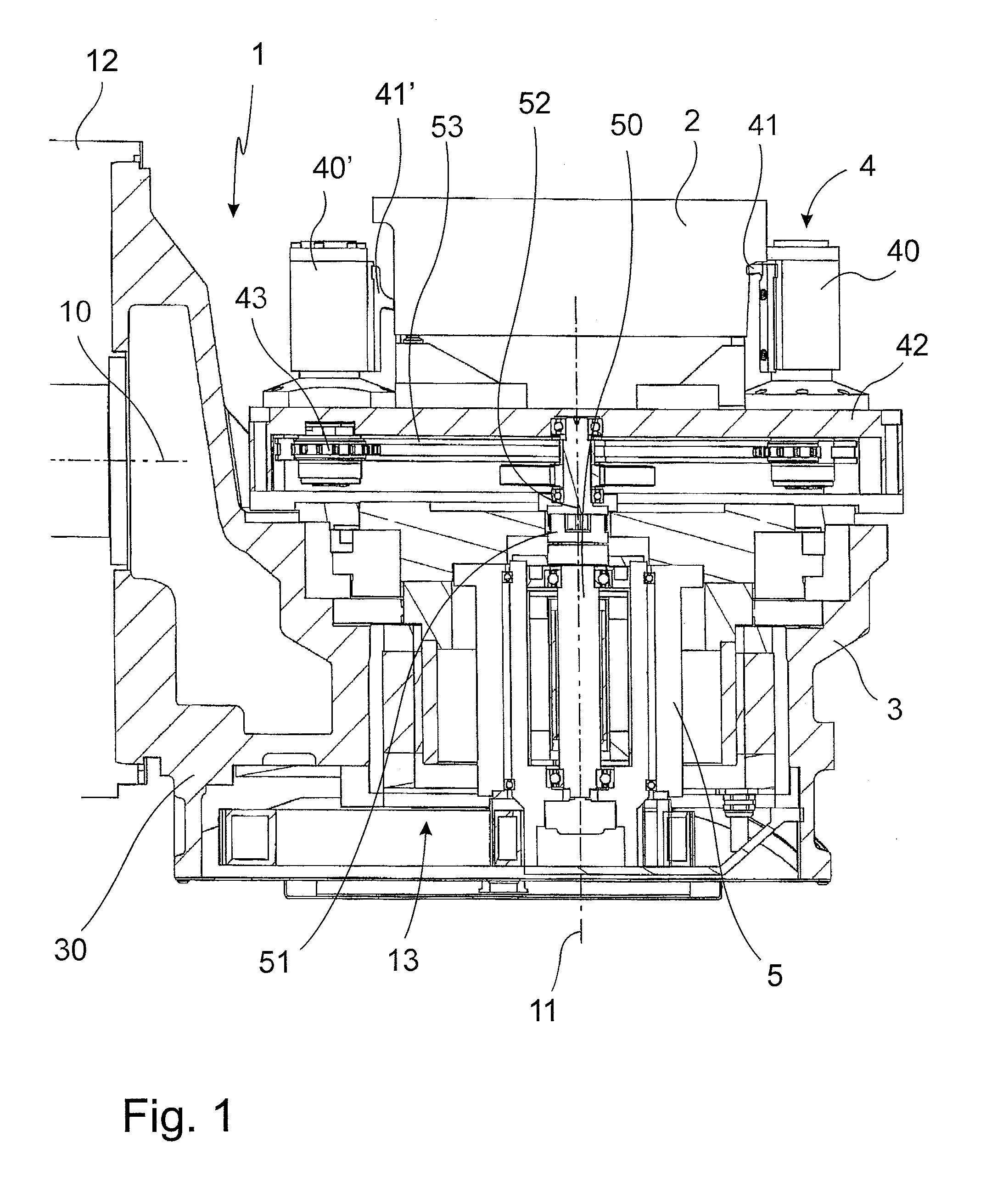

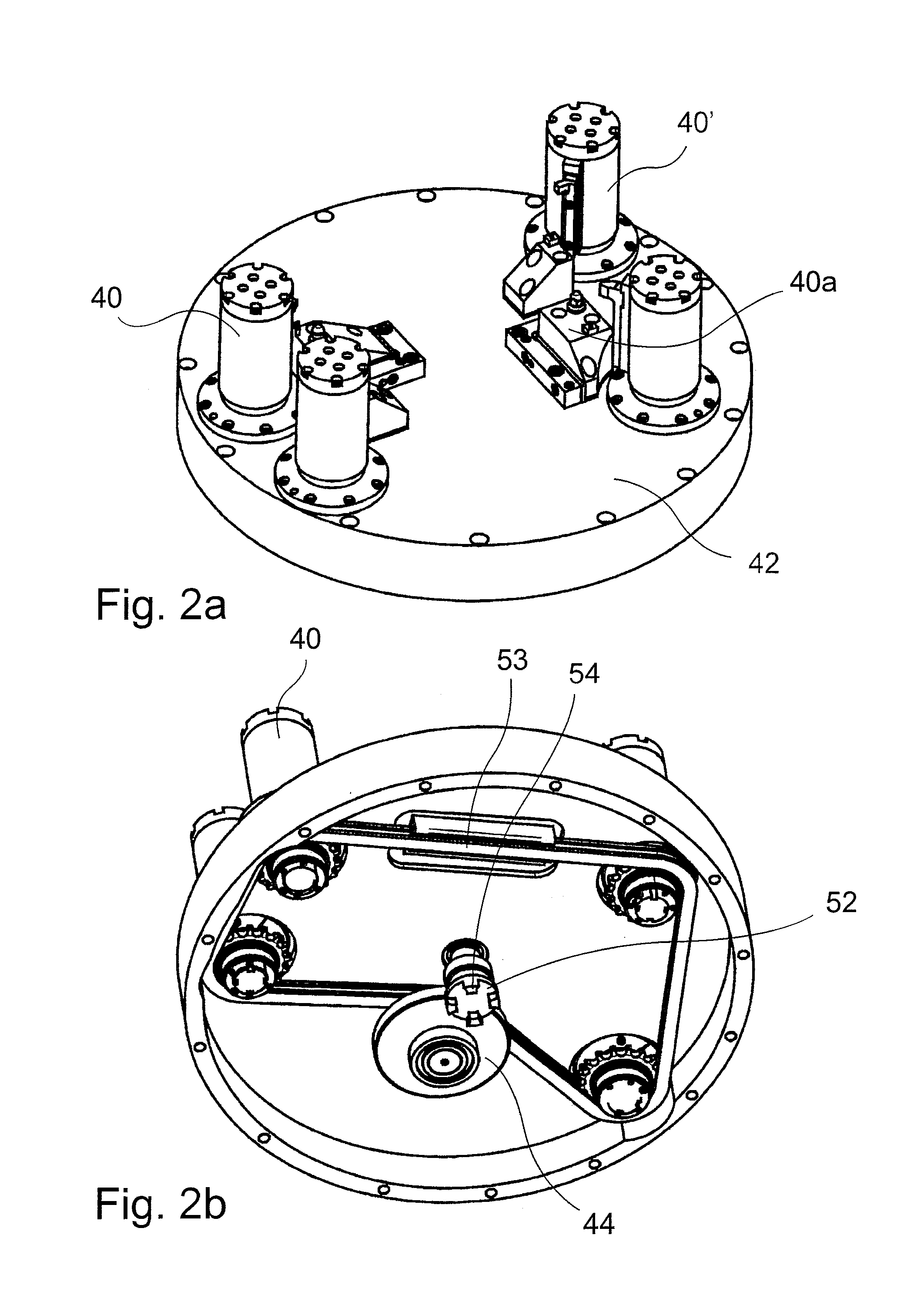

Machining unit

The invention refers to a machine tool for machining one or more work pieces, wherein the work piece is held indirectly or directly by a clamping device in the machine tool on or at a non-rotary work piece table or a work piece table rotating around at least one axis. The invention is characterized in that the clamping device comprises at least one clamping element interacting indirectly or directly with the work piece, and an electric motor is provided for generating the clamping power that is in active connection with the clamping element.

Owner:GROB WERKE & K G

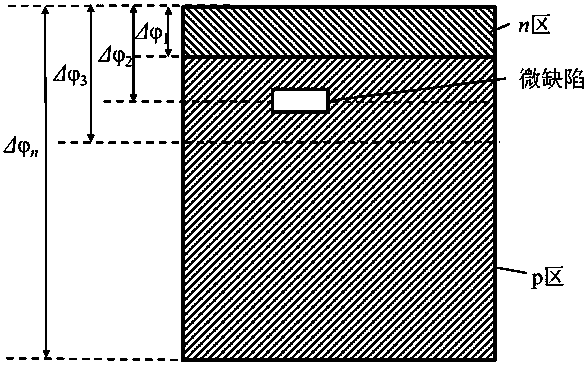

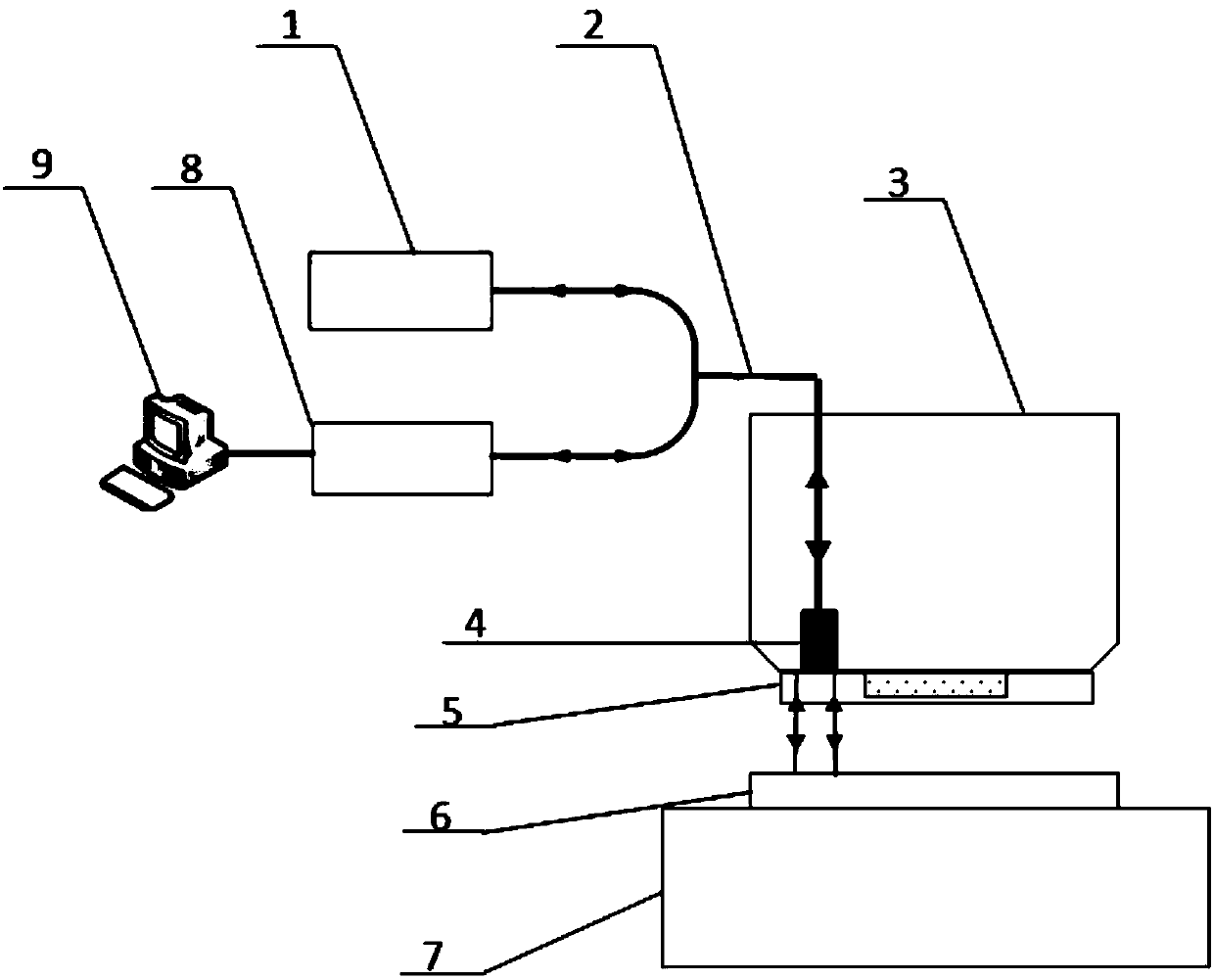

System and method for performing lock-phase thermography chromatography characterization on microdefects of solar cell

InactiveCN108445012AInhibition of lateral diffusionLarge detection areaOptically investigating flaws/contaminationElectrical batteryData acquisition

The invention discloses a system and a method for performing lock-phase thermography chromatography characterization on microdefects of solar cells. The system comprises a short-wave infrared camera,a medium-wave infrared camera, a data acquisition card, a computer, a three-dimensional mobile station, a metal sample piece table, a sample piece clamping device and a direct current (DC) power supply, wherein the computer is used for controlling the data acquisition card to control the DC power supply to be triggered and carrying out amplitude modulation change on sample pieces, and simultaneously controls the data acquisition card to control the short-wave infrared camera and the medium-wave infrared camera to synchronously trigger the acquisition of an image sequence; images acquired by the short-wave infrared camera are transmitted to the computer, so that the lateral distribution and positioning of the defects of the sample pieces can be obtained; images acquired by the medium-wave infrared camera are transmitted to the computer, so that an amplitude figure and a phase diagram at the frequency can be obtained; amplitude figures and phase diagrams at different frequencies are obtained by changing the frequency; the deep chromatography results of the sample pieces can be obtained by using lock-phase thermography chromatography software. The method provided by the invention is anew rapid, large-area, visual and accurate infrared heat wave nondestructive testing method.

Owner:HARBIN INST OF TECH

Machine tool

InactiveUS20110215511A1Increase pressureEasy to retouchWork clamping meansFeeding apparatusEngineeringMachine tool

The invention refers to a machine tool for machining one or more work pieces, wherein the work piece is held indirectly or directly by a clamping device in the machine tool on or at a non-rotary work piece table or a work piece table rotating around at least one axis.The invention is characterized in that the clamping device comprises at least one clamping element interacting indirectly or directly with the work piece, and an electric motor is provided for generating the clamping power that is in active connection with the clamping element.

Owner:GROB WERKE & K G

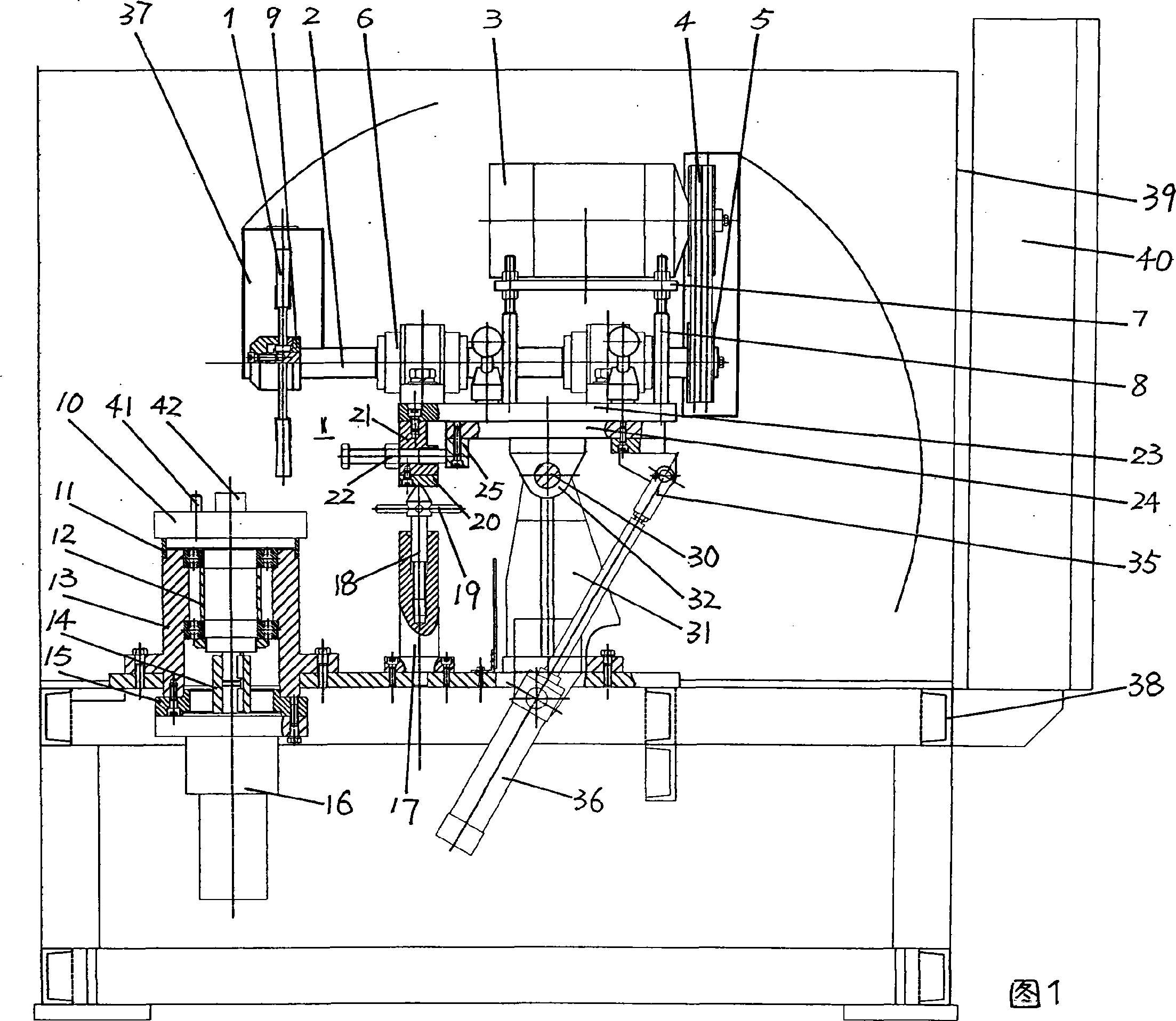

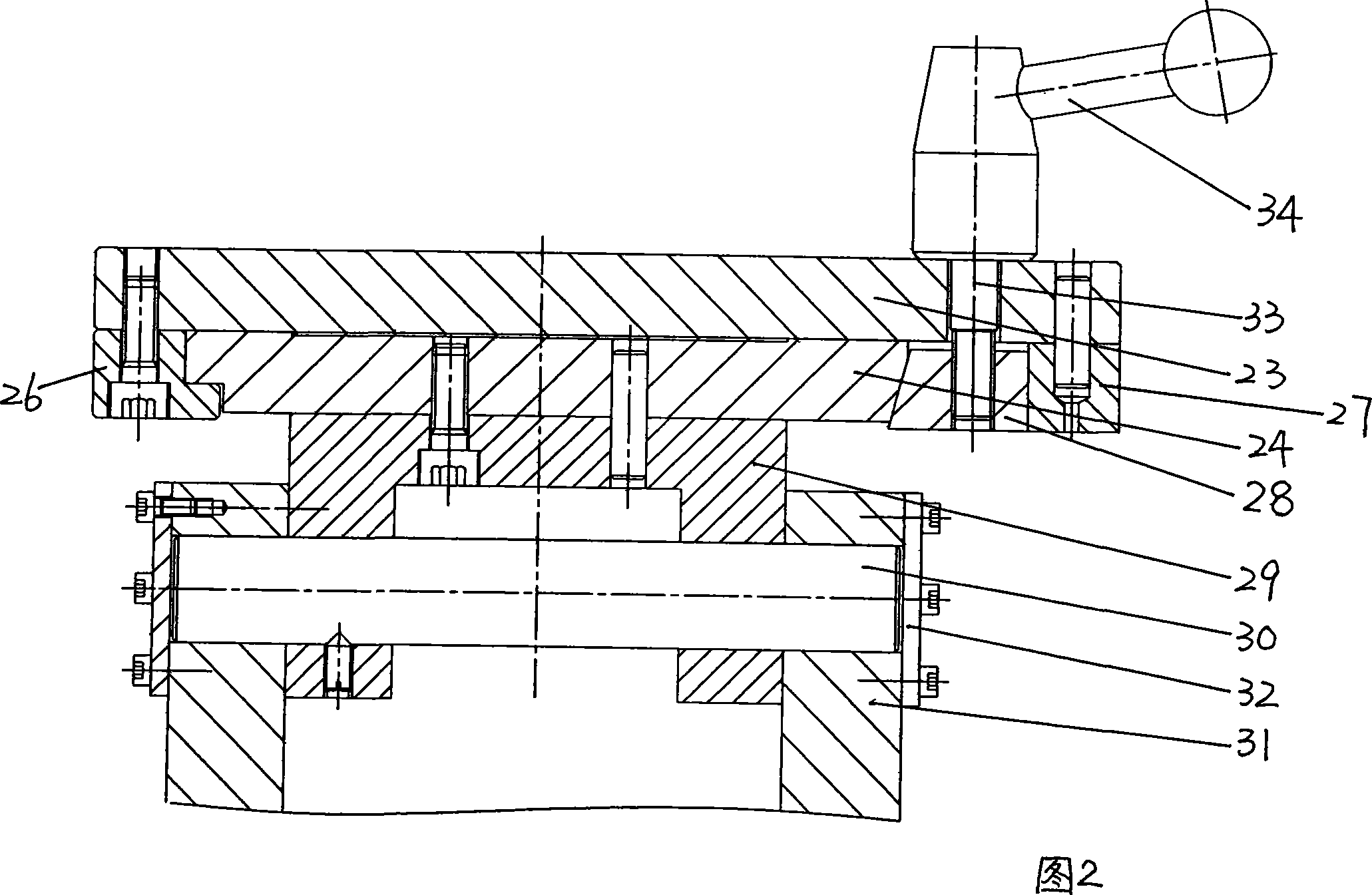

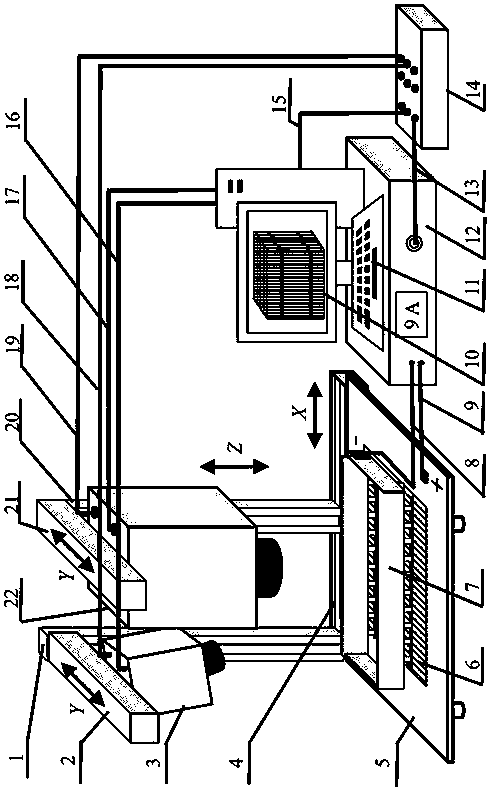

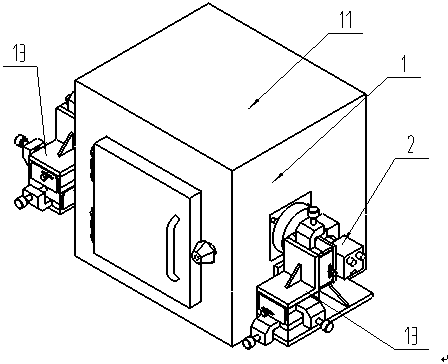

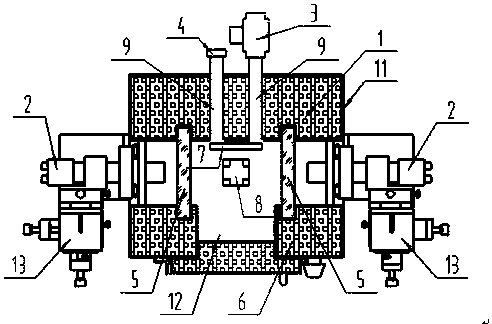

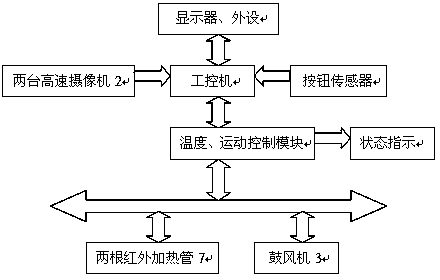

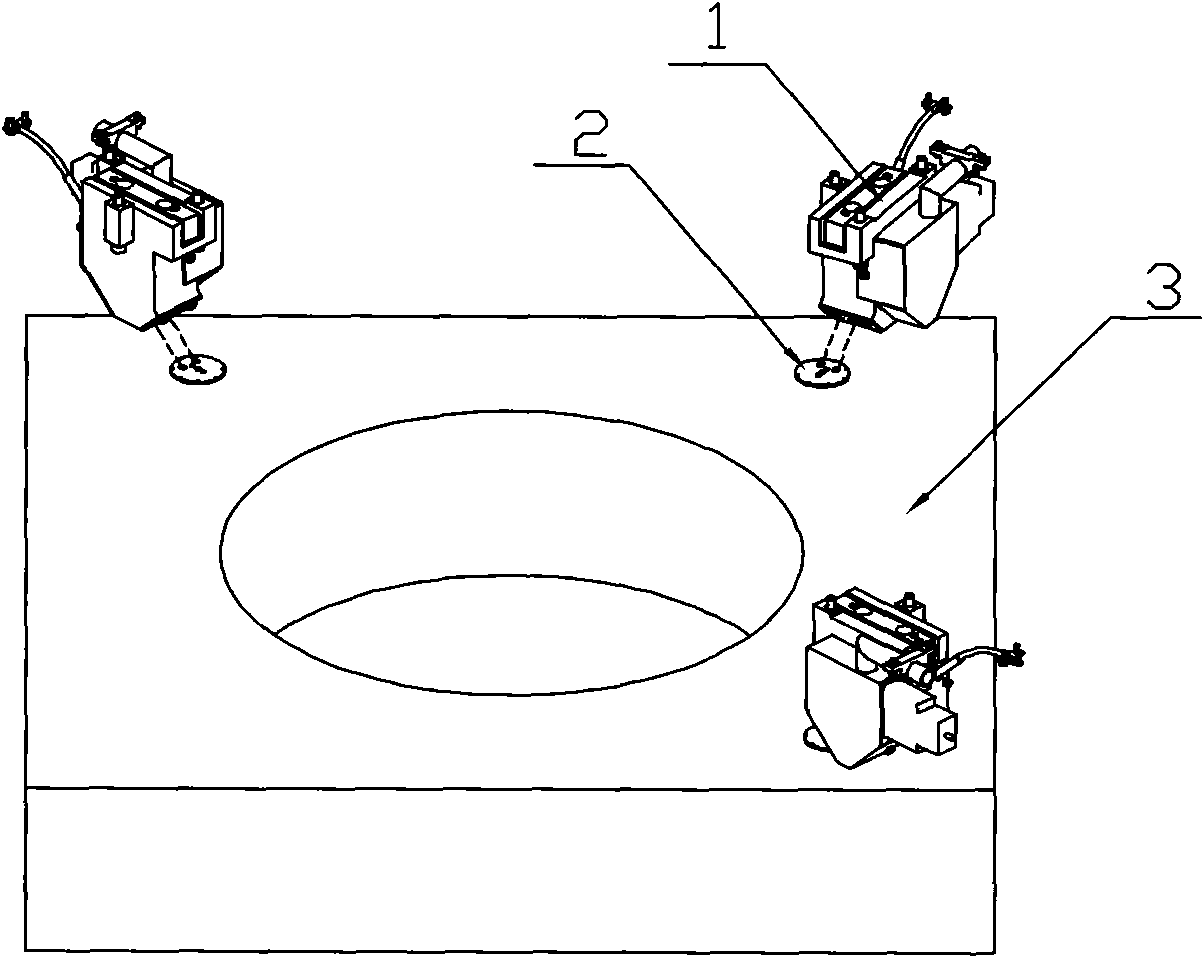

Test bed for visual measurement system of test piece high temperature deformation machine

ActiveCN103594017AEase of workMeet application diversityUsing optical meansEducational modelsClosed loopEngineering

The invention discloses a test bed for a visual measurement system of a test piece high temperature deformation machine. The test bed is characterized by being composed of a heating furnace part, a visual detecting part and a control system. The heating furnace part comprises a heating furnace, a heating furnace shell, a heating furnace inner cavity, a blower, two air ducts, two air duct covers, two quartz glass windows, two infrared heating tubes, an insulation material and a test piece table. The visual detecting part comprises two high speed cameras, two sets of video camera combination type supports, an industrial control computer and software. The control system part comprises a closed-loop control system and a visual detecting system of the visual detecting part, wherein the closed-loop control system has a control adjusting effect on the temperature in the heating furnace. The test bed is based on the machine visual measurement technology, micro-deformation of the test piece under the condition of high temperature can be measured, teaching demonstration on the machine visual measurement technology which is currently in typical application can be conducted, and the test bed can be used as an open type multifunctional test platform for correlative technique research and development.

Owner:HEBEI UNIV OF TECH

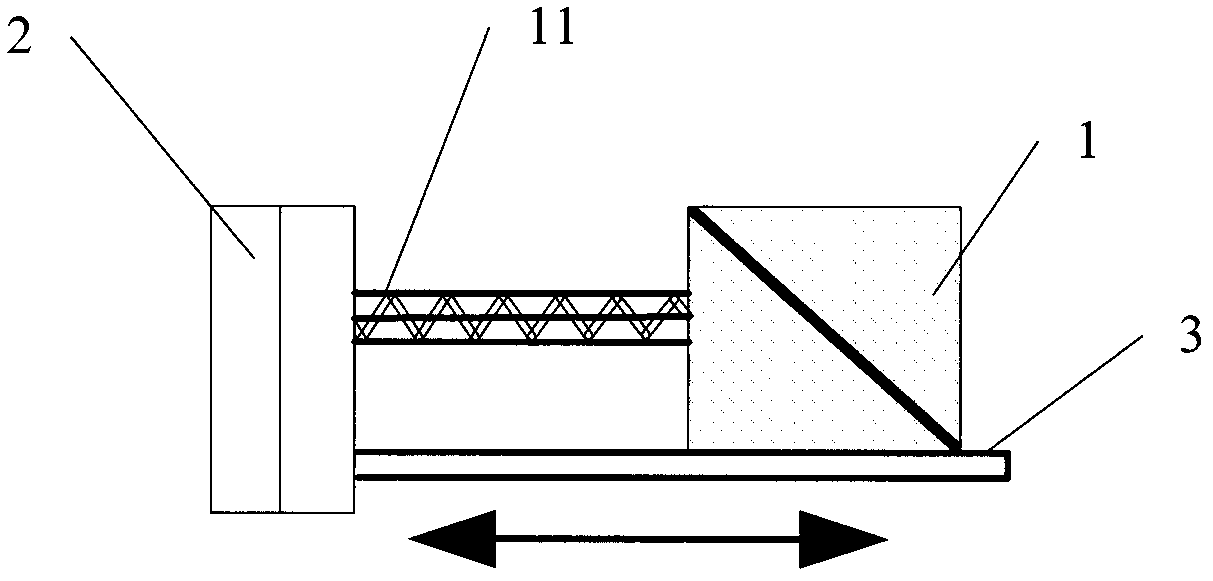

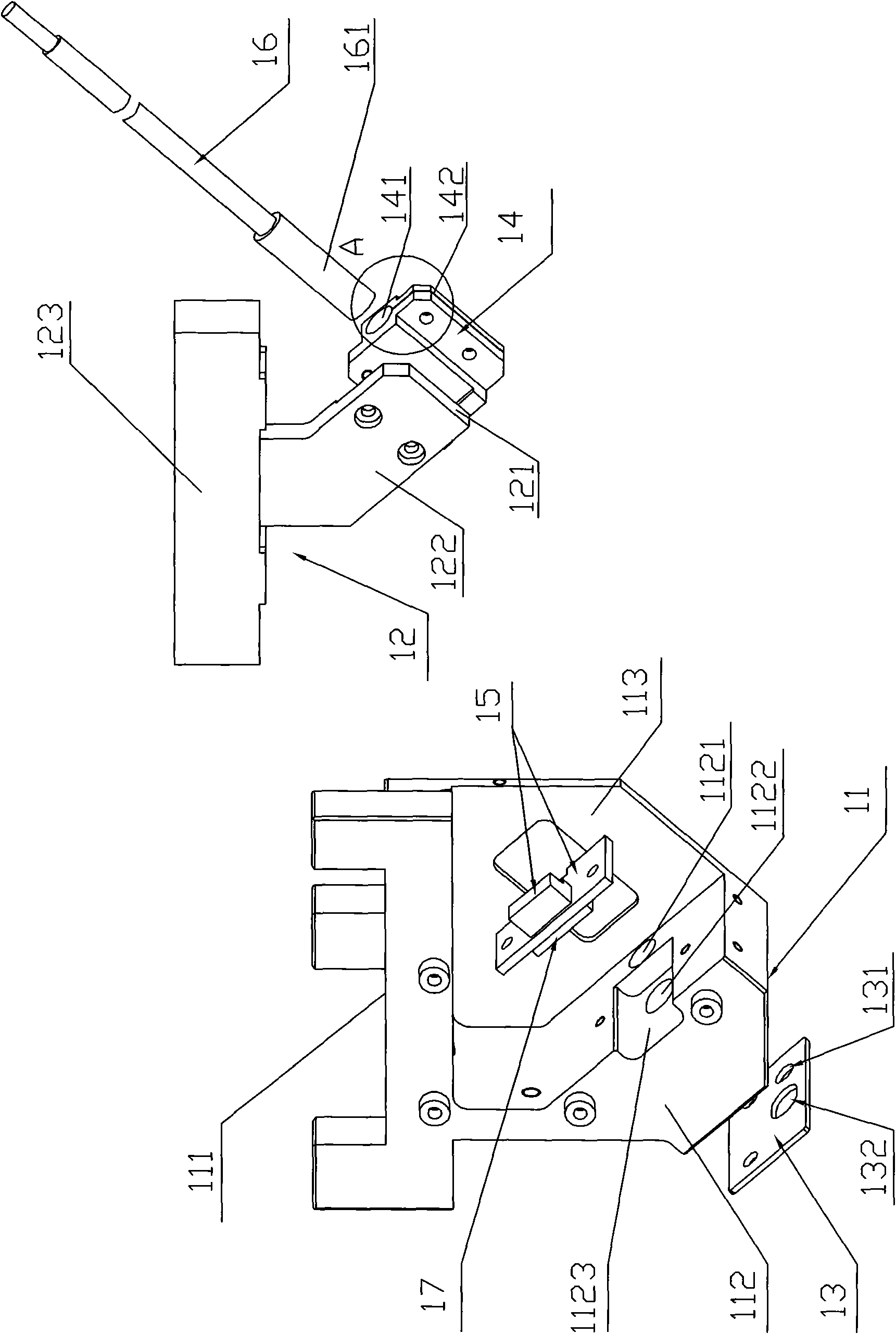

Zero-position sensor

ActiveCN102455169APrecise initial position reference pointReduce measurement errorUsing optical meansPhotomechanical exposure apparatusLight spotOptoelectronics

The invention discloses a zero-position sensor, which comprises a host module (1). The host module (1) comprises a base (11). A laser collimating mirror (16) and a light spot position detecting device (17) are arranged on the base (11). The light spot position detecting device (17) is used for receiving parallel beam reflected by a reflective module (2) installed on a work-piece table (3). The reflective module (2) is used for reflecting laser beam emitted by the laser collimating mirror (16) in parallel. The light spot position detecting device (17) is electrically connected with a printed circuit board (15) for converting an inducted optical signal into an electrical signal. The zero-position sensor disclosed by the invention is applied to a position measurement system and has the advantage of being high in measurement precision.

Owner:SHANGHAI MICRO ELECTRONICS EQUIP (GRP) CO LTD

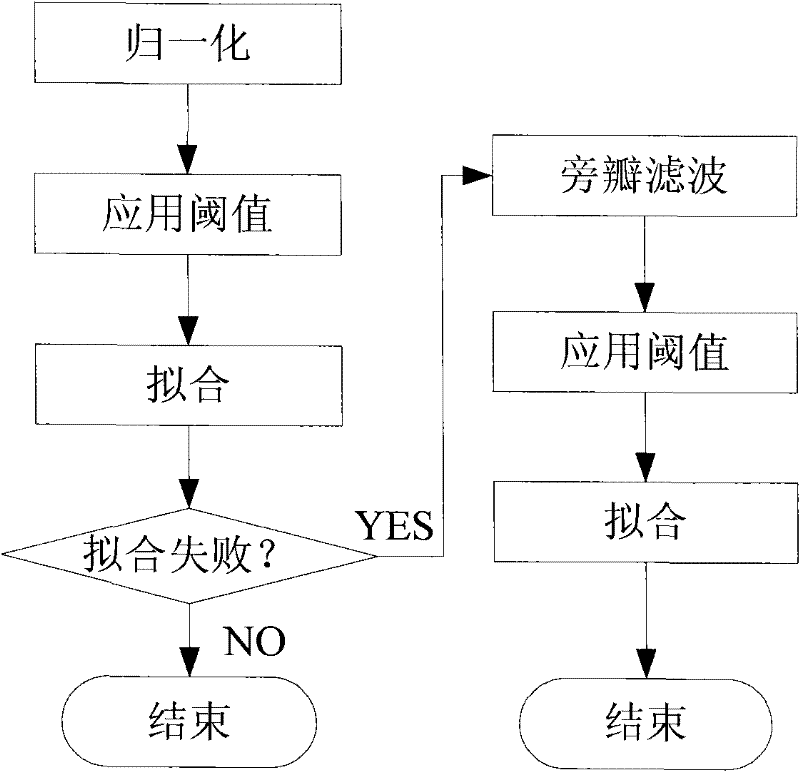

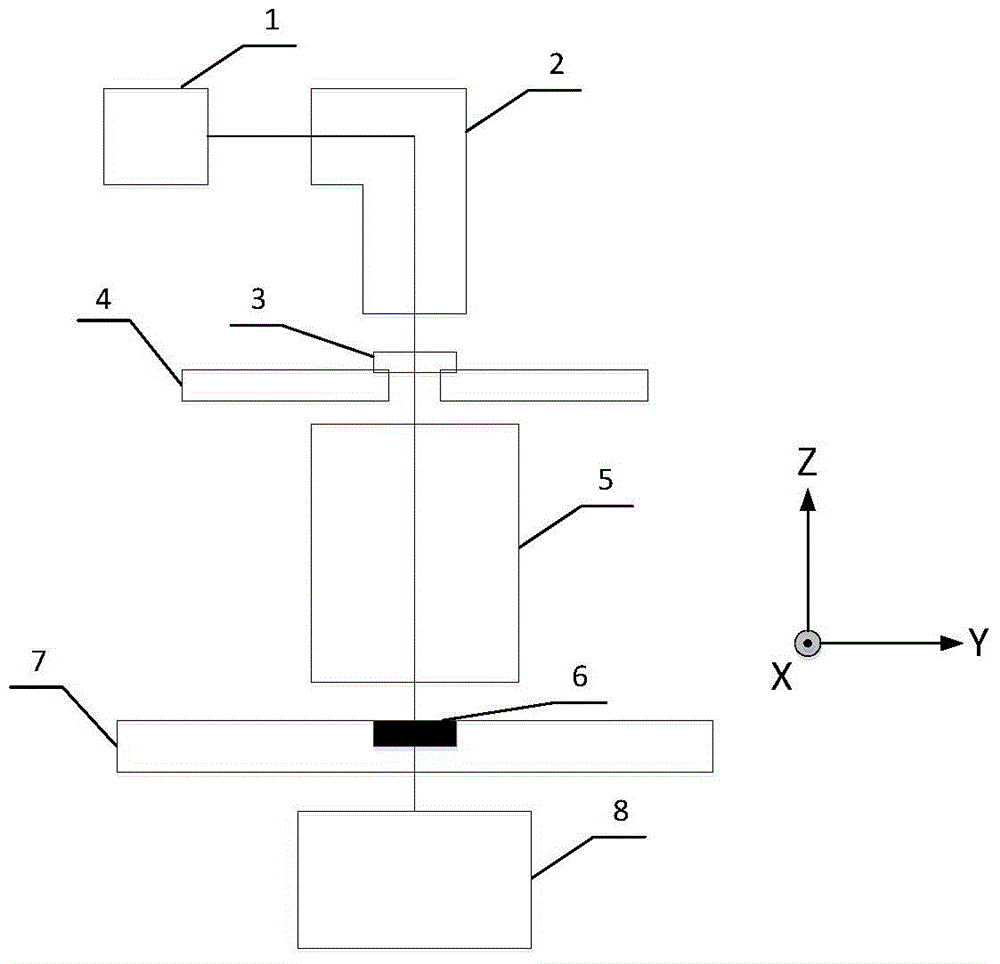

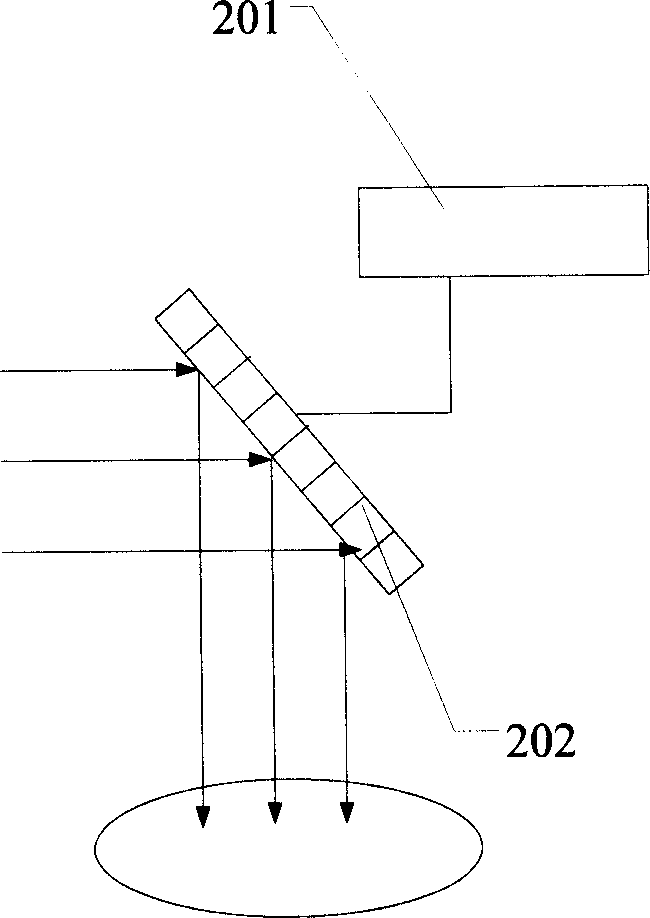

Photoetching machine in-situ multichannel imaging quality detection apparatus and photoetching machine in-situ multichannel imaging quality detection method

ActiveCN106324996AReduce the number of pixelsImprove spatial resolutionPhotomechanical exposure apparatusMicrolithography exposure apparatusImaging qualityLighting system

The invention relates to a photoetching machine in-situ multichannel imaging quality detection apparatus and a photoetching machine in-situ multichannel imaging quality detection method, wherein the photoetching machine in-situ multichannel imaging quality detection apparatus comprises a photoetching machine light source, an illumination system, a mask table, a projection object lens, a work-piece table and a computer, and further comprises an object surface grating plate and a wavefront aberration sensor. According to the present invention, the photoetching machine imaging qualities such as the wavefront aberration, the distortion and the field curvature are detected by using the photoetching machine in-situ multichannel imaging quality detection apparatus so as to improve the parallel channel number and the detection speed of the imaging quality detection.

Owner:SHANGHAI INST OF OPTICS & FINE MECHANICS CHINESE ACAD OF SCI

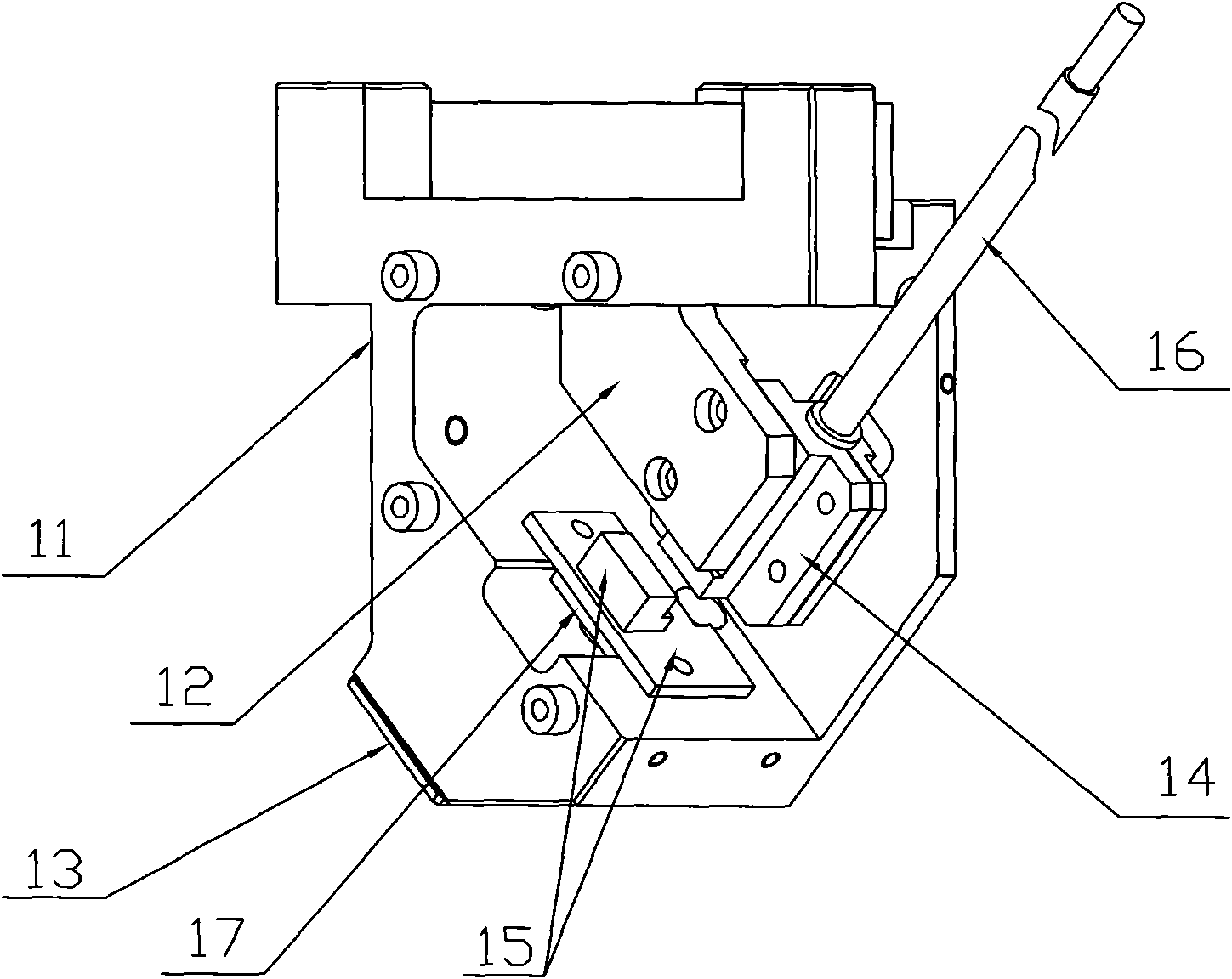

Automatic overturning mechanism

ActiveCN105817943ASimple structureSmooth startMeasurement/indication equipmentsMetal working apparatusMetal workingMagnet

The invention relates to the field of mechanical processing and specifically provides an automatic overturning mechanism. The mechanism comprises a work piece table, a motor, a worm gear speed reduction device, a metal work piece clamp, a first electric magnet and a second electric magnet, wherein the metal work piece clamp is in a rotatable connection with the table surface of the work piece table; the first electric magnet and the second electric magnet are disposed on the table face of the work piece table; the first electric magnet and the second electric magnet are located on two sides of a rotatable joint between the metal work piece clamp and the table face respectively; when the metal work piece clamp is rotated to the horizontal direction, the metal work piece clamp can get contacted with the first electric magnet or the second electric magnet; the motor and the worm gear speed reduction device are disposed on the work piece table; the motor is connected to the worm gear speed reduction device; and the worm gear speed reduction device is connected to the metal work piece clamp. The automatic overturning mechanism has the advantages that starting and stopping are smooth and steady; positioning is accurate and reliable; and manufacture cost is low, etc.

Owner:CHONGQING RONGAN MEDICAL APP CO LTD

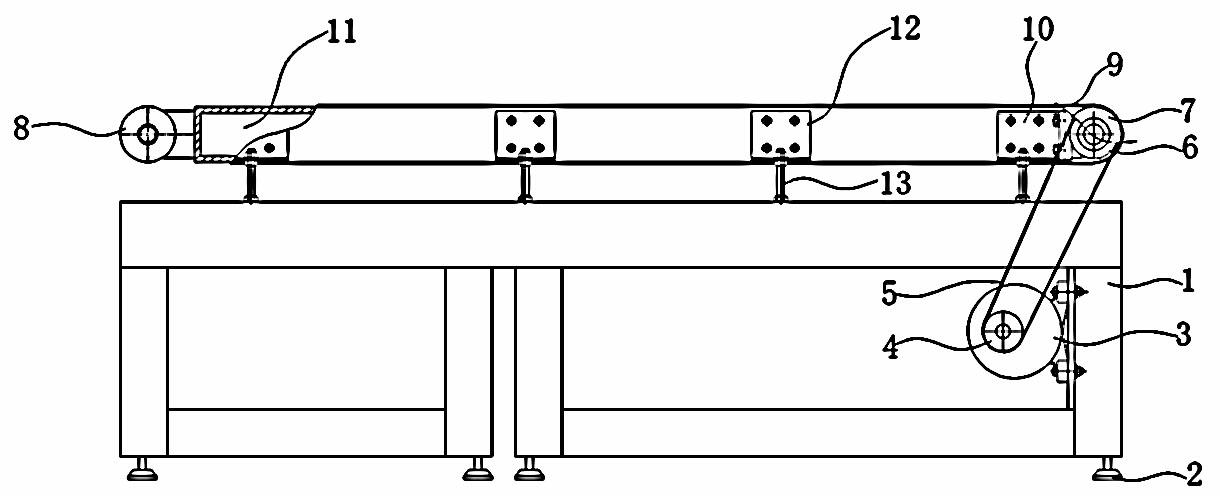

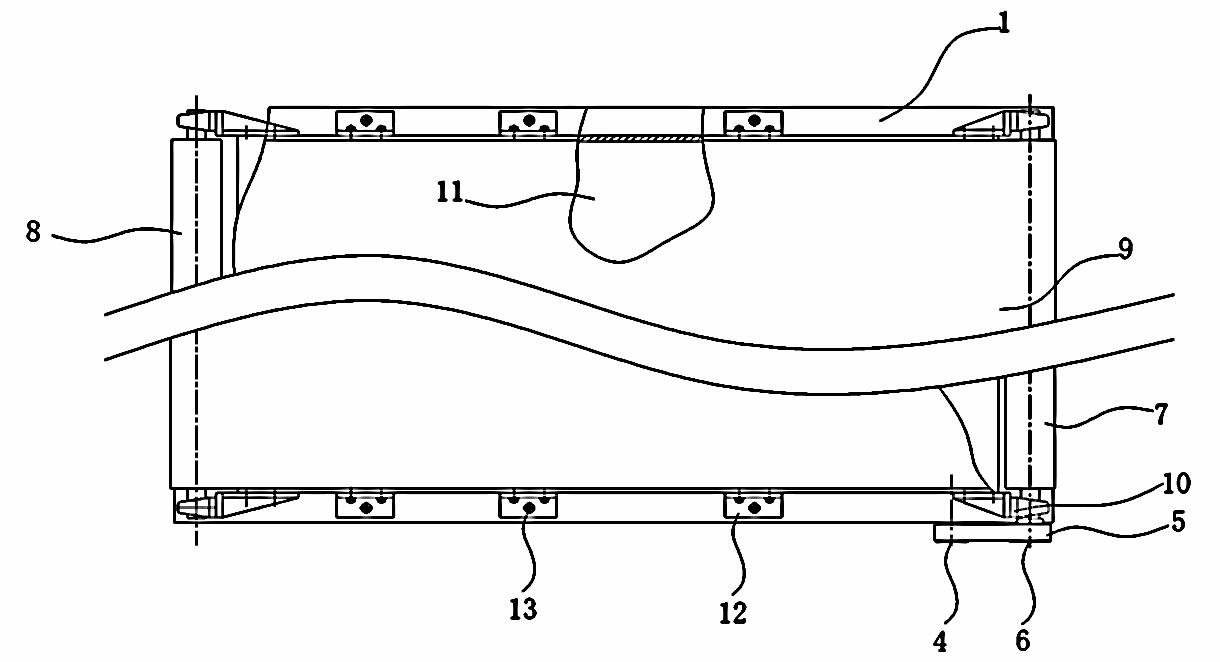

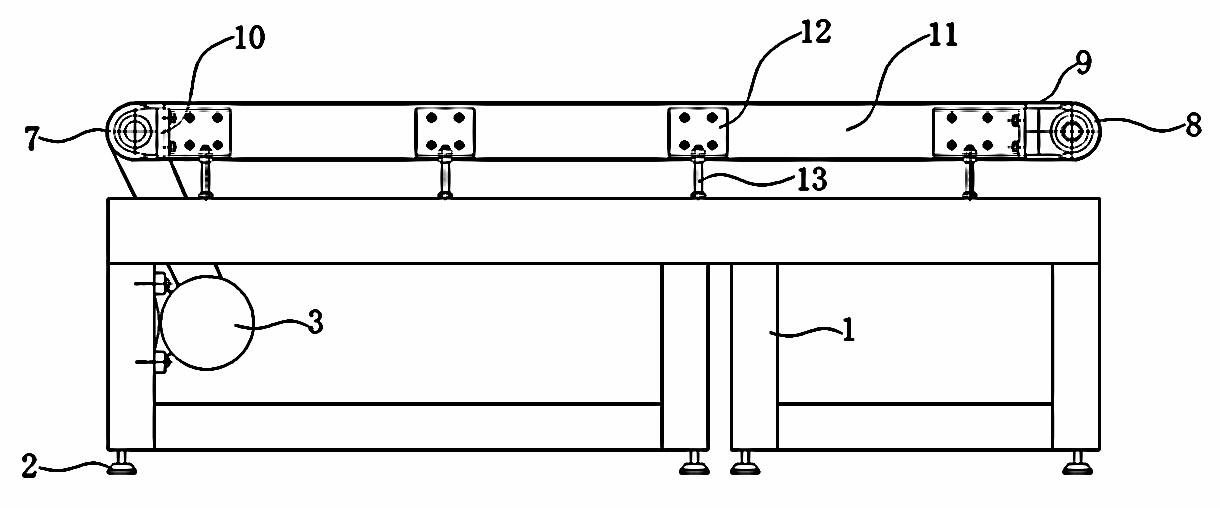

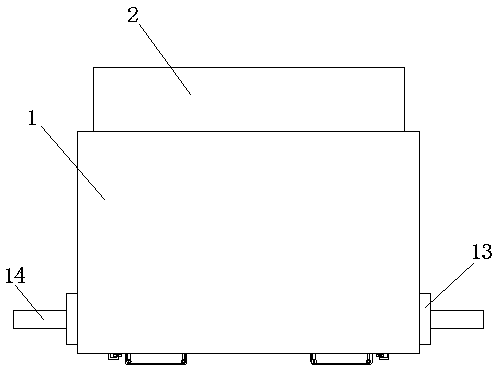

Conveying type glass lower piece table

InactiveCN102310985ALabor savingImprove work efficiencyConveyorsCharge manipulationEngineeringPiece table

The invention relates to a conveying type glass lower piece table, which is characterized in that a rectangular table (11) is arranged on a machine frame (1) of an ordinary glass piece lower piece table, a driving roller (7) and a driven roller (8) are respectively arranged at the front end and the back end of the rectangular table and are connected through a conveying belt (9), the upper side and the lower side of the rectangular table (11) are covered by the conveying belt (9), and a conveying type work table is formed. The conveying type glass lower piece table has the advantages that during the glass piece separation, the glass does not need to be manually pushed to the edge of the lower piece table, the automatic conveyance can be realized only through switching on the conveying belt, in addition, the conveying type glass lower piece table can also be connected with a glass cutting machine to be used, the cut large-piece glass does not need to be manually lifted up to be placed to the lower piece table for piece separation, operators only need to push one end of the glass onto the conveying belt, the labor is greatly saved, and the work efficiency is improved.

Owner:陈邦善

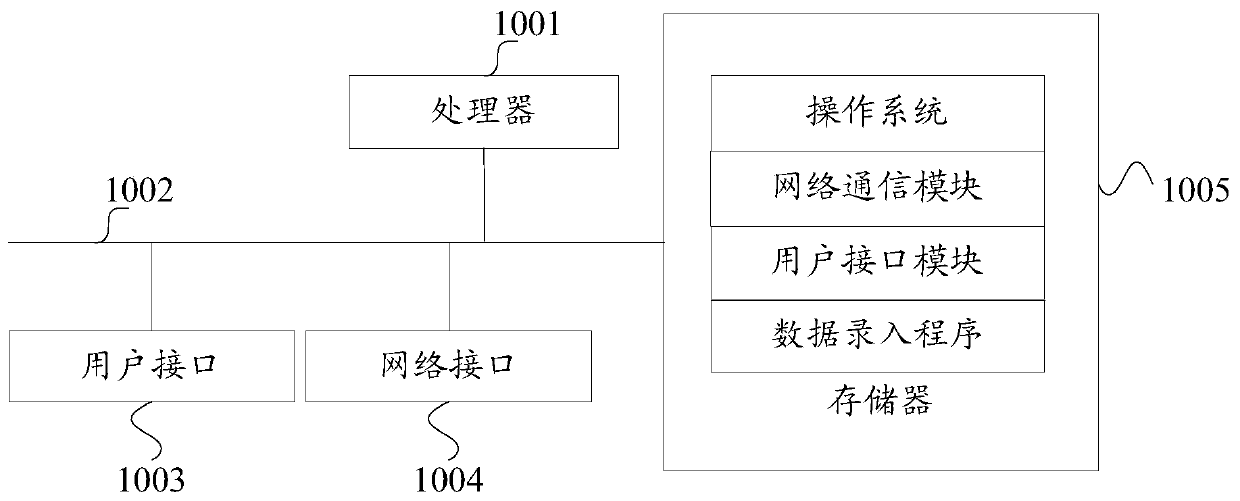

Data input method and device, terminal and computer readable storage medium

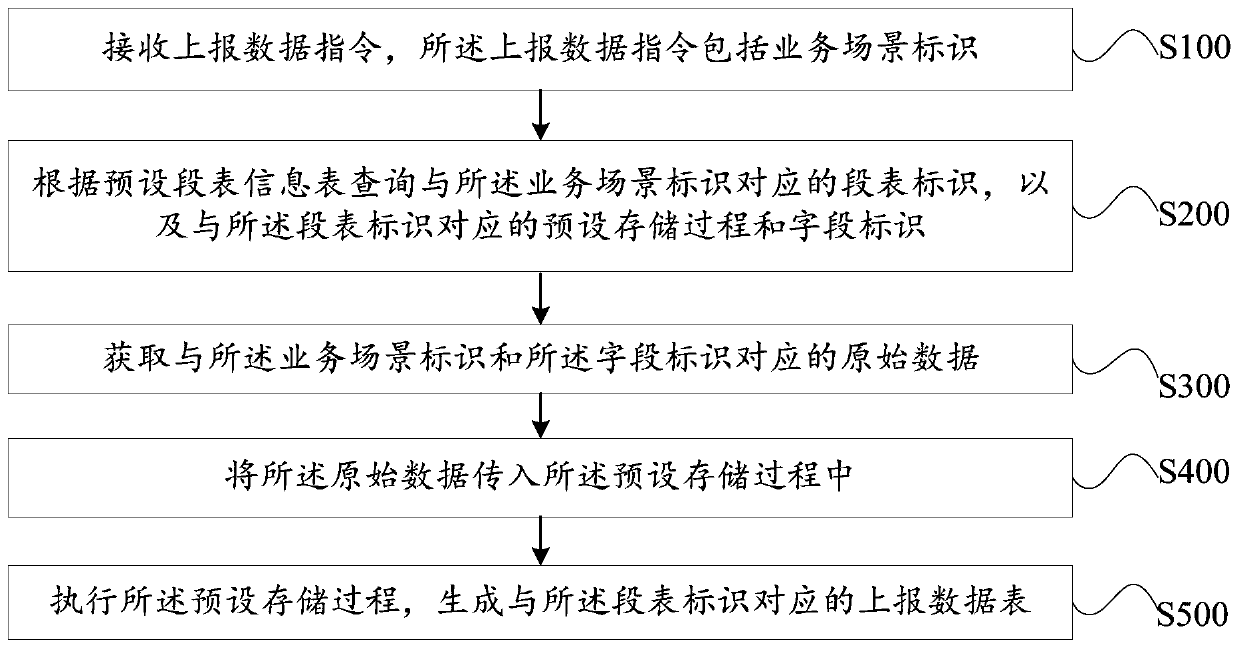

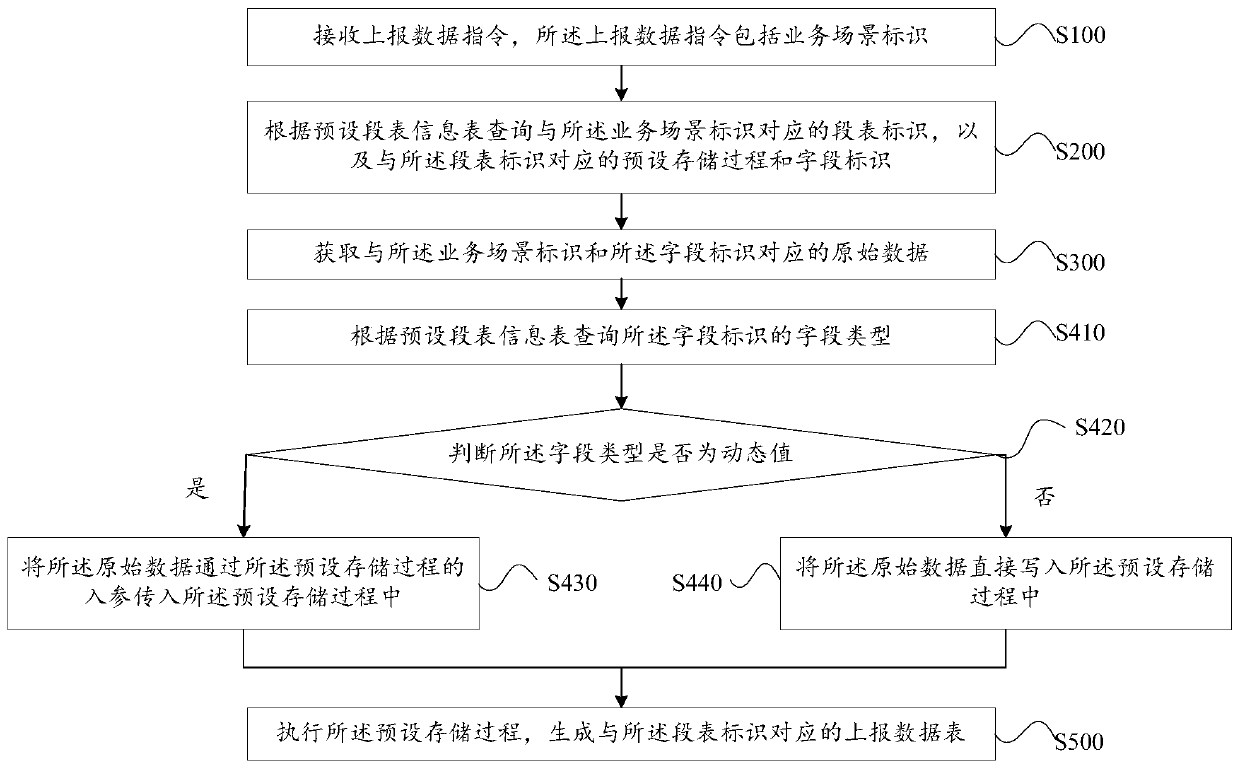

ActiveCN109814856AReduce workloadReduce errorsDigital data information retrievalIntelligent editorsOriginal dataData reporting

The invention discloses a data input method and device, a terminal and a computer readable storage medium, wherein the method comprises the steps of receiving a data reporting instruction which comprises a service scene identifier; querying a segment table identifier corresponding to the service scene identifier and a preset storage process and a field identifier corresponding to the segment tableidentifier according to a preset segment table information table; obtaining original data corresponding to the service scene identifier and the field identifier; transmitting the original data into the preset storage process; and executing the preset storage process, and generating a report data table corresponding to the segment table identifier. According to the present invention, the preset storage process is set for different service scenes, so that the maintenance efficiency of data report generation is improved.

Owner:PING AN TECH (SHENZHEN) CO LTD

Multifunctional circular carving duplicator

The invention relates to a multifunctional round sculpture reproducer, which is characterized in that the reproducer body is provided with vertical and mutually parallel left side frame and right side frame. A pair of parallel longitudinal slipways are arranged on the top surfaces of the left side frame and right side frame along the Y direction; the reproducer head is provided with a reproducer head crossbeam along the X direction, the both ends of the reproducer head crossbeam are matched with the longitudinal slipways in a slipping way along the Y direction, at least two operating reproducer heads and a sample piece reproducer head are connected on the reproducer head crossbeam in series, and are matched with the reproducer head crossbeam in a slipping way along the X direction; the carved piece table frame is provided with rotating rods positioned below the reproducer head and levelly arranged, various carved piece seats are all arranged on the rotating rods, the various carved piece seats are rotating disks sleeved on the rotating axles vertical to the rotating rods, and the longitudinal distance between the rotating rods and the reproducer head can be adjusted relatively; the placement mechanism is provided with a level placement frame and a vertical placement frame. The invention can reproduce, enlarge or reduce the round sculpture works, and can complete the reproduction to internal carving and external carving, intaglio and curvette, shallow-and-deep relief, hollow-out vulture, and three-dimensional sculpture and so on.

Owner:郭福鹏

Hydraulic piece table position fast changing device

ActiveCN110454465APrevent oil spillsAvoid harmFluid-pressure actuator testingFluid-pressure actuator componentsHigh pressurePiece table

The invention belongs to the field of detecting equipment and particularly relates to a hydraulic piece table position fast changing device directing at the problems that an existing hydraulic piece and a connection valve are instable in connection, when a pressure measuring oil pipe is disassembled, high-pressure oil injection can be caused very easily, injuries are caused to test personnel or the test environment is polluted, and meanwhile resource waste is also caused. Now the following scheme is put forwards, the hydraulic piece table position fast changing device comprises a connection valve and a hydraulic piece body; the connection valve is provided with a cavity; and a positioning column is fixedly connected to the bottom of the hydraulic piece body. The hydraulic piece table position fast changing device is reasonable in structure, and due to fast fixing on the hydraulic piece body, the oil leaking problem generated between the connection valve and the hydraulic piece body canbe effectively solved; a first rotating shaft is rotated so that two sealing plates can be used for sealing a through pipe, it can be effectively prevented that when a pressure measuring oil pipe isdisassembled, high pressure oil injection is caused, the test personnel are injured or the test environment is polluted, meanwhile resources are saved, and high practicability is achieved.

Owner:YANTAI ZHONGYU AEROHYDRAULIC

Gap detection device based on super-resolution lithography

ActiveCN108036732ARealize detectionQuality assuranceUsing optical meansPhase differenceOptical pathlength

The invention provides a gap detection device based on super-resolution lithography. The light emitted by a light source is introduced into an optical fiber collimating mirror through a Y-shaped optical fiber, and is divided at a semi-transparent and semi-reflective window of a mask. One beam of light is reflected back into the optical fiber collimating mirror, and the other beam of light is transmitted by the semi-transparent and semi-reflective window of the mask, reflected by the surface of a substrate and received by the optical fiber collimating mirror through the semi-transparent and semi-reflective window of the mask. At the moment, a phase difference is generated due to the different optical paths of the two beams of light. The phase difference is detected through a spectrometer, and the phase difference corresponding to different wavelength is analyzed in a principal computer. Thus, the measurement of the absolute gap between the mask and the substrate is realized. The absolute value of the optical path difference between the substrate and the mask can be obtained, and further, the phase difference caused by the optical path difference between the substrate and the mask can be obtained, and the absolute gap between the mask and the substrate can be obtained. The gap is eliminated by controlling a nano work piece table, and gap exposure is realized. Therefore, a super-resolution lithography device is effectively protected, and the quality of lithography graphics is ensured.

Owner:INST OF OPTICS & ELECTRONICS - CHINESE ACAD OF SCI

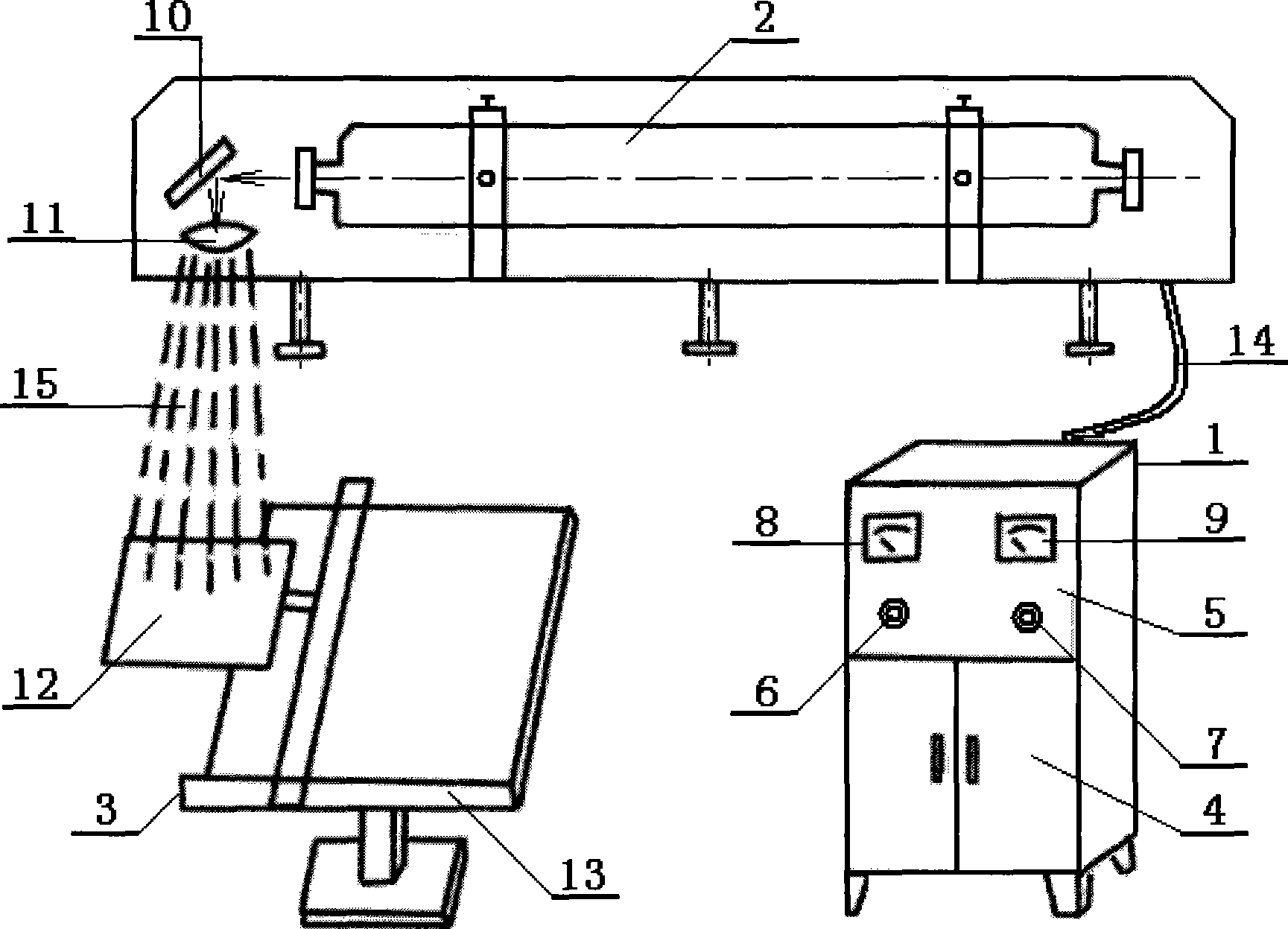

Processing method for enhancing solar cell working stability and apparatus thereof

InactiveCN101483206AImprove job stabilityReduce output powerFinal product manufactureSemiconductor/solid-state device manufacturingLight energyEngineering

The invention relates to a processing method for improving a solar cell work stability and a device thereof comprising: irradiating a solar cell or a solar cell film by using a laser with a spectral wave length of 10. 06 micron so as to make an internal crystal phase arrangement of the solar cell or the solar cell film to tend to consistent, usefully improving and stabilizing the light energy absorption efficiency, the electric energy conversion efficiency and the output power of the solar cell, implementing the improvement of the attenuation of the output power and improving the work stability and prolonging the effective work life interval. The device comprises an operation control box, a CO2 laser generator and a work piece irradiation table. The operation control box and the CO2 laser generator are interconnected by conductors. The CO2 laser generator and the work piece irradiation table are interconnected by a light path. The solar cell or the solar cell film is arranged on the work piece table for irradiation. The output power attenuation of the solar cell made after the processing is less than 5, the effective work life interval is at least prolonged to 40 years so as to satisfy any special use demands.

Owner:上海雷洛森能源科技有限公司

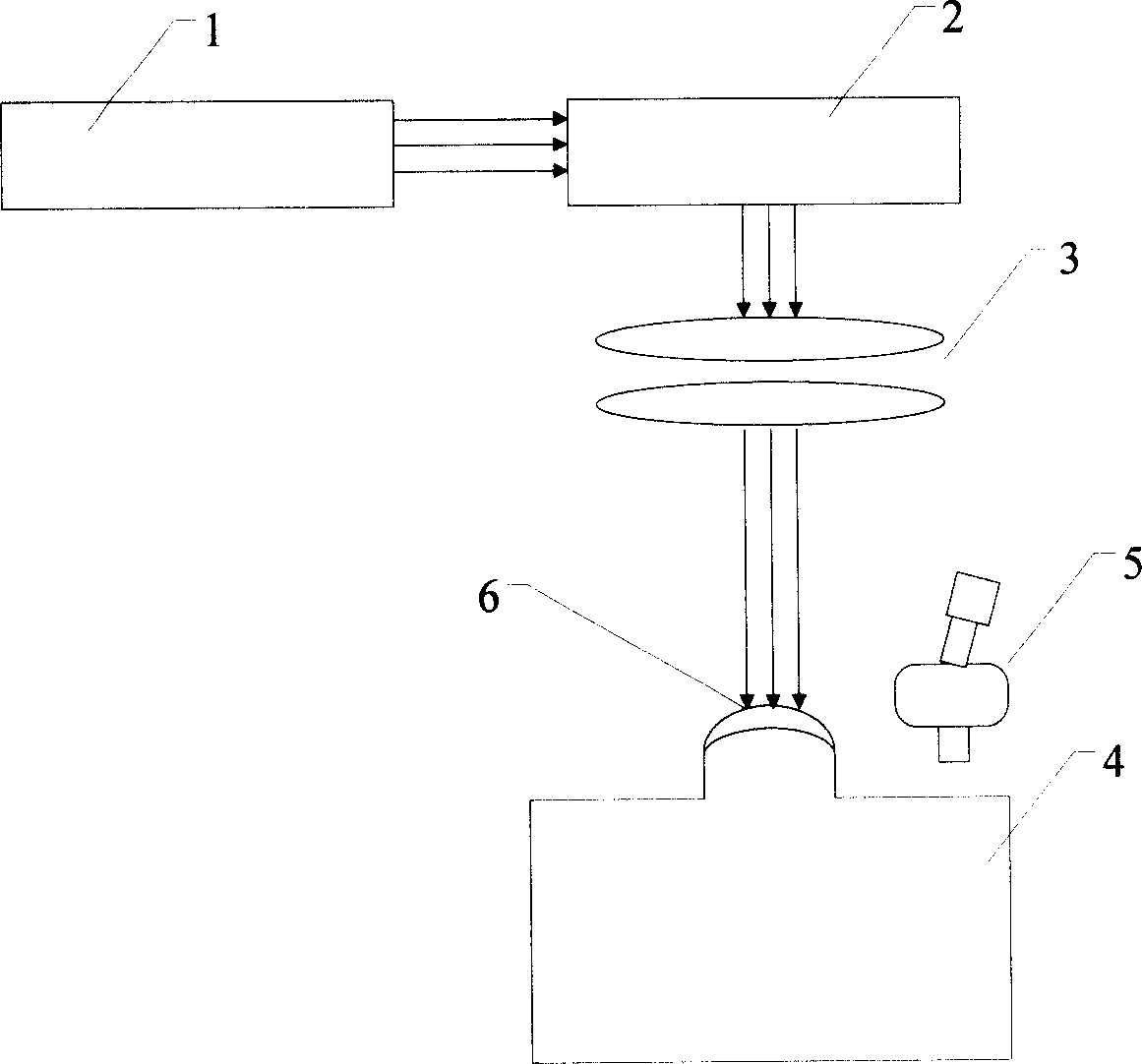

Equipment for customizing individualized contact lenses

InactiveCN1916768AQuality improvementLow costOptical articlesPhotomechanical exposure apparatusPersonalizationResist

A device used to prepare personalized contact lenses is prepared as using uniform lightening system to generate parallel lightening light, passing said light through grey image generating system and using computer to control said generating system to generate grey image, using projection system to image grey image on image work piece table, using aligning system to regulate said table to correct position for exposing photo resist on sample according to grey grade, developing and etching exposed sample to obtain component with continuous relief structures on spherical surface then using said component to prepare personalized contact lenses.

Owner:INST OF OPTICS & ELECTRONICS - CHINESE ACAD OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com