Method for aligning exposure patterns on two sides of PCB (printed circuit board)

A PCB board and exposure pattern technology, which is applied in the field of realizing the alignment of exposure patterns on both sides of the PCB board, can solve the problems that the position change of the circuit board cannot be measured, and the position of the exposure pattern has no way to correspond one-to-one, so as to improve the accuracy and eliminate the alignment The influence of precision and the effect of simplifying the process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

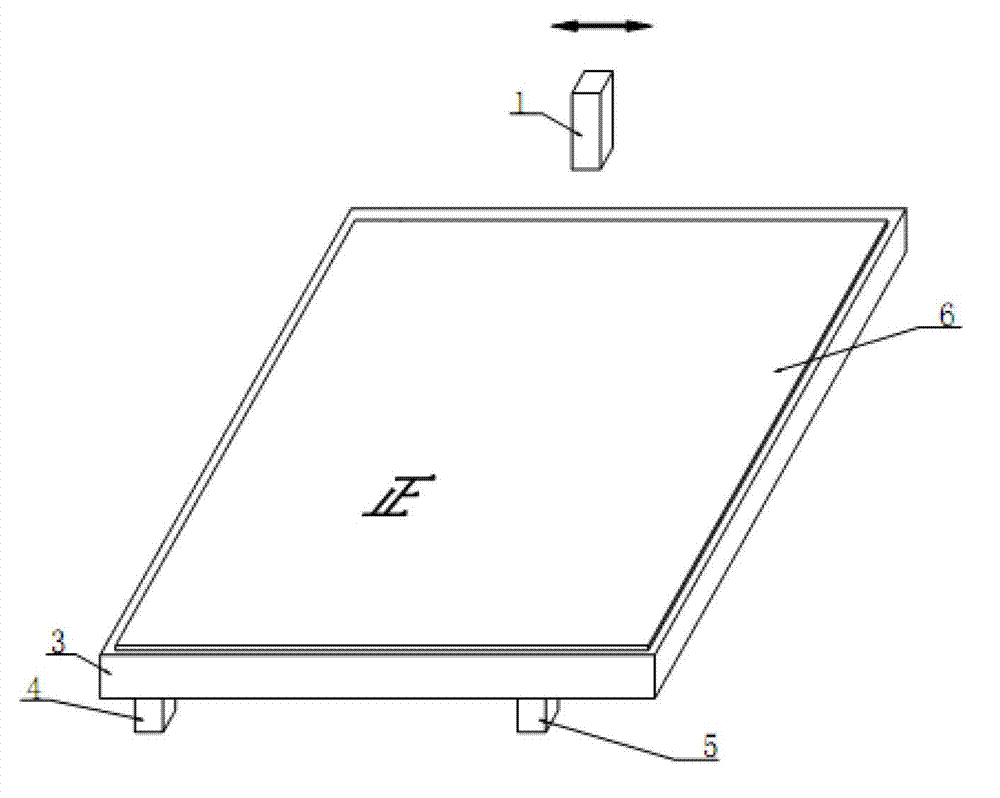

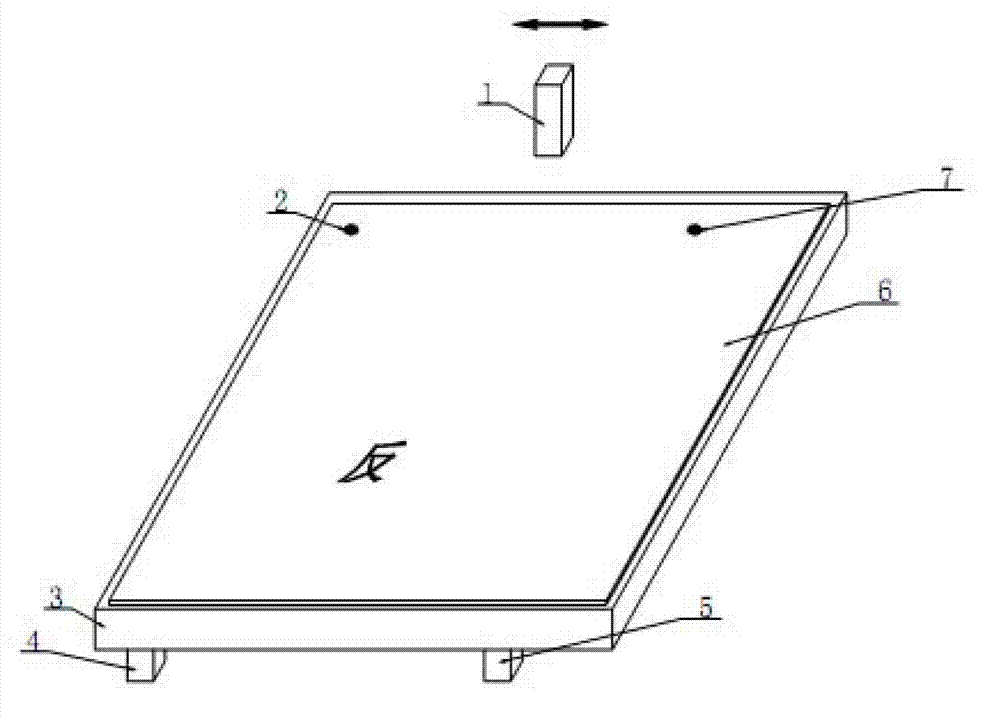

[0020] Such as figure 2 As shown, in the laser imaging system, the alignment method for realizing the alignment of exposure patterns on both sides of the circuit board is characterized in that a PCB board 6 is placed on the workpiece table 3, a CCD camera 1 is arranged above the PCB board 6, and a CCD camera 1 is arranged below the workpiece table 3. There are marking device 1 4 and marking device 2 5, and the workpiece table 3 is provided with two through holes for marking device 1 4 and marking device 2 5 to generate specific alignment marks on the PCB board 6;

[0021] Specifically include the following steps:

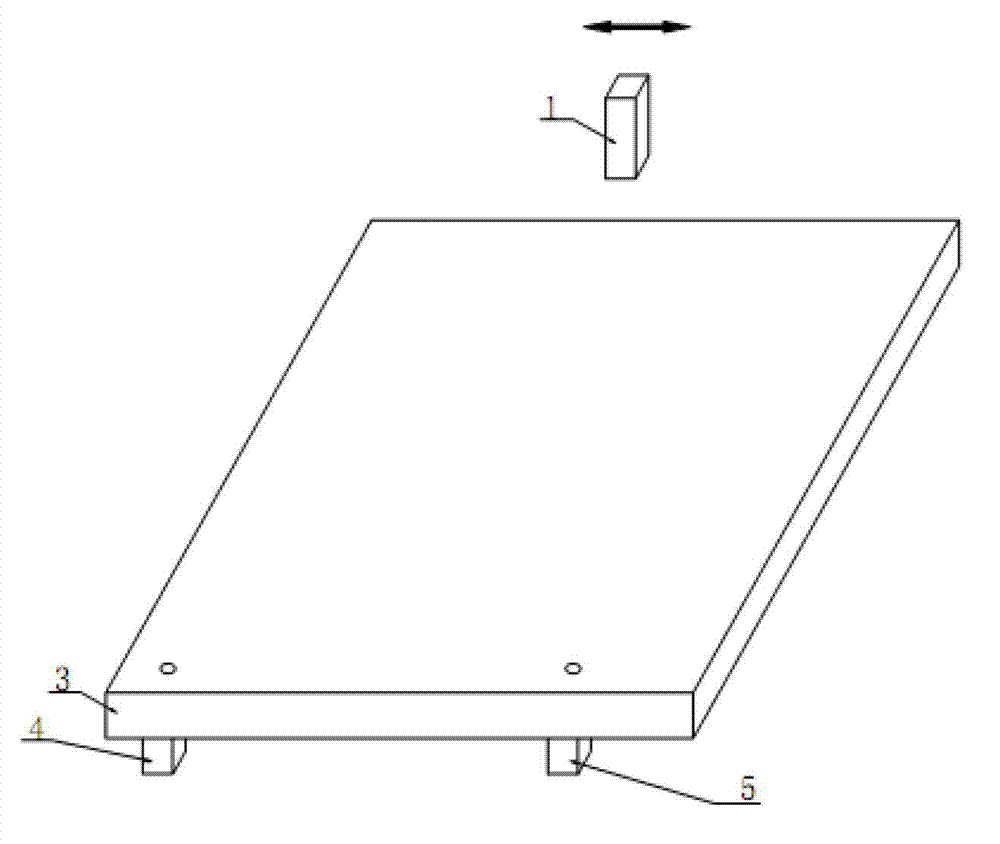

[0022] 1) if figure 1 As shown, use the CCD camera 1 to calibrate the position coordinates of the marking device 1 4 and the marking device 2 5 fixed below the workpiece table 3;

[0023] 2) if figure 2 As shown, the PCB board 6 is placed on the workpiece table 3, while the front side of the PCB board is exposed, the marking device 1 4 generates alignment marks...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com