Alignment system and alignment method for photolithographic device

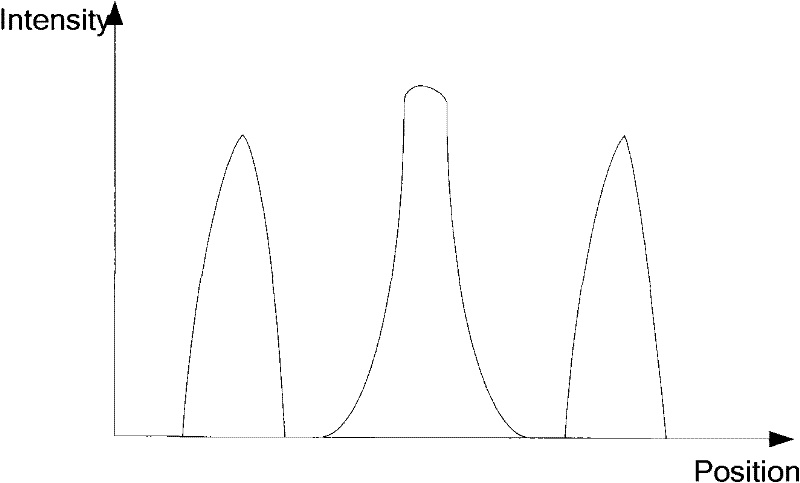

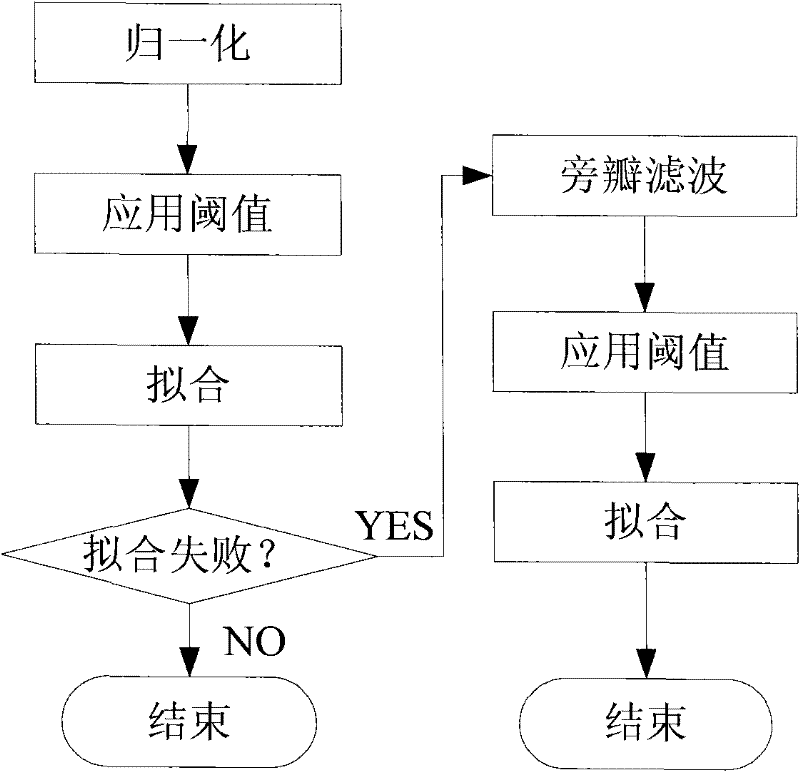

An alignment system and lithography technology, applied in photolithography exposure devices, microlithography exposure equipment, optics, etc., can solve problems such as low contrast of scanning signals, reduced fitting efficiency, and complex subsequent signal processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] In order to better understand the technical content of the present invention, specific embodiments are given together with the attached drawings for description as follows.

[0032] Figure 4 Shown is a schematic structural view of an alignment system for a lithographic apparatus according to an embodiment of the present invention. The alignment system for a lithography apparatus provided by the present invention is used to realize the alignment between a workpiece stage and a mask or between a workpiece stage and a mask stage. Such as Figure 4 As shown, an alignment system 1 for a lithography apparatus includes a light source module 10 , an illumination module 11 , a mask 12 , a mask table 13 , an objective lens module 14 , a detection module 15 and a workpiece table 16 .

[0033] In this embodiment, the light source module 10 may be a DUV light source or a UV light source, which is not limited in the present invention. In addition to being used for exposure, the l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com