Zero-position sensor

A zero-position sensor and device technology, applied in instruments, measuring devices, optical devices, etc., can solve the problems of deviation in the displacement measurement of the laser interferometer, affecting the accurate measurement of the laser interferometer, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] Below in conjunction with accompanying drawing, the present invention is described in further detail:

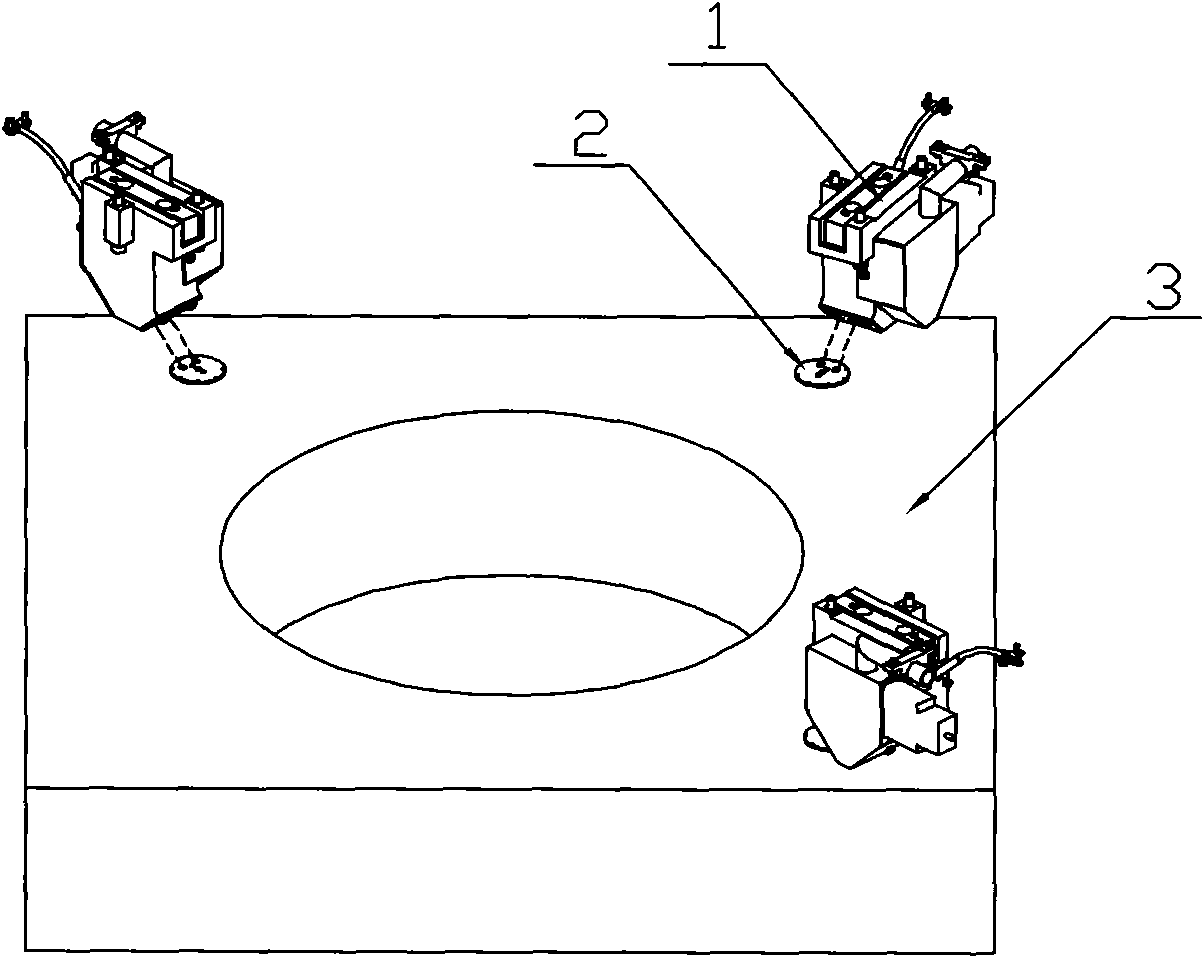

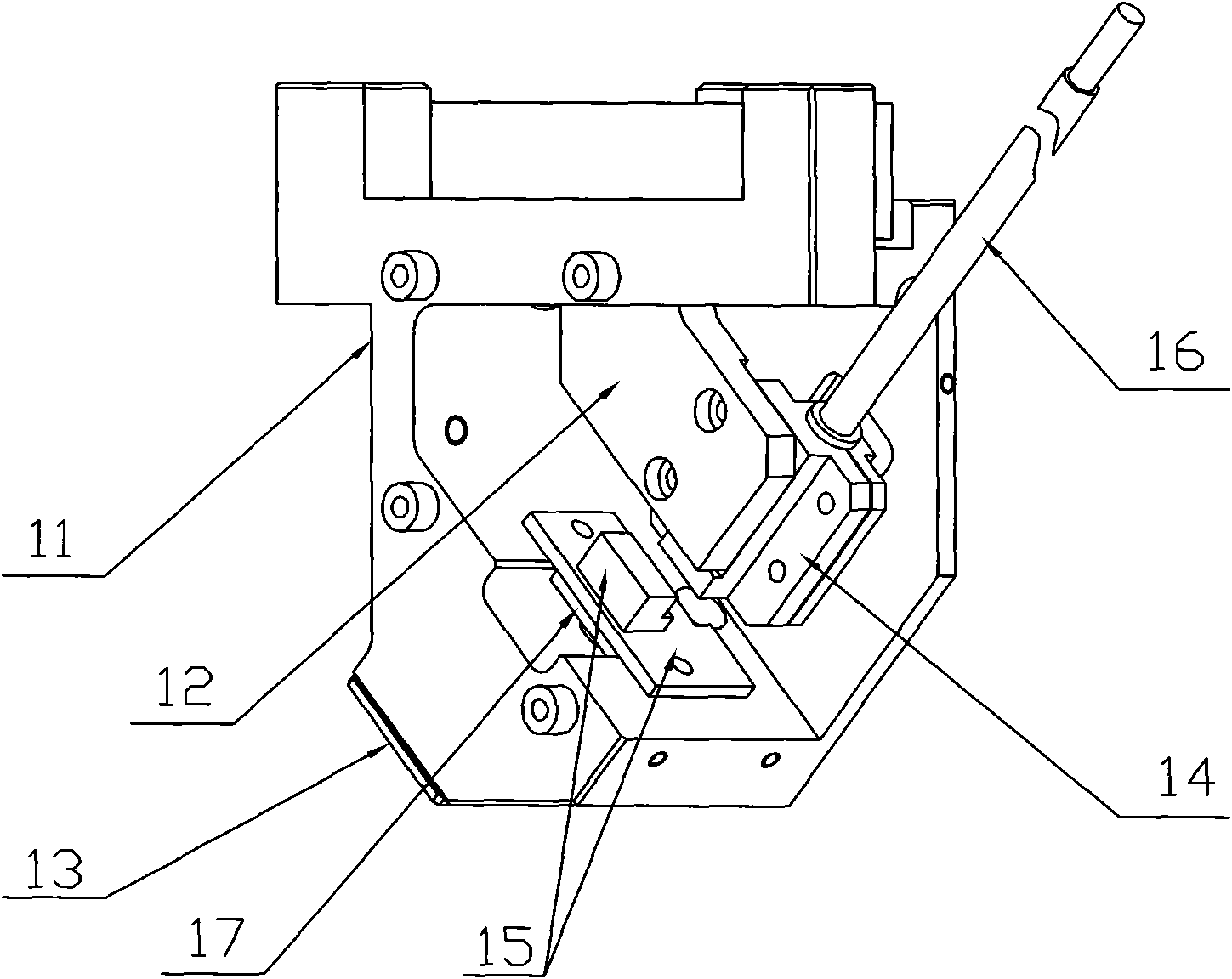

[0030] Such as Figure 1-11 As shown, the zero sensor of the present invention includes a host module 1, and the host module 1 includes a base 11, and the base 11 is provided with a laser collimating mirror 16 and a spot position detection device 17; the spot position The detection device 17 receives the parallel light beam reflected by the reflection module 2 installed on the workpiece table 3; the reflection module 2 parallel reflects the laser beam emitted by the laser collimator 16, and the spot position detection device 17 is electrically connected to A printed circuit board 15 that converts the sensed optical signal into an electrical signal.

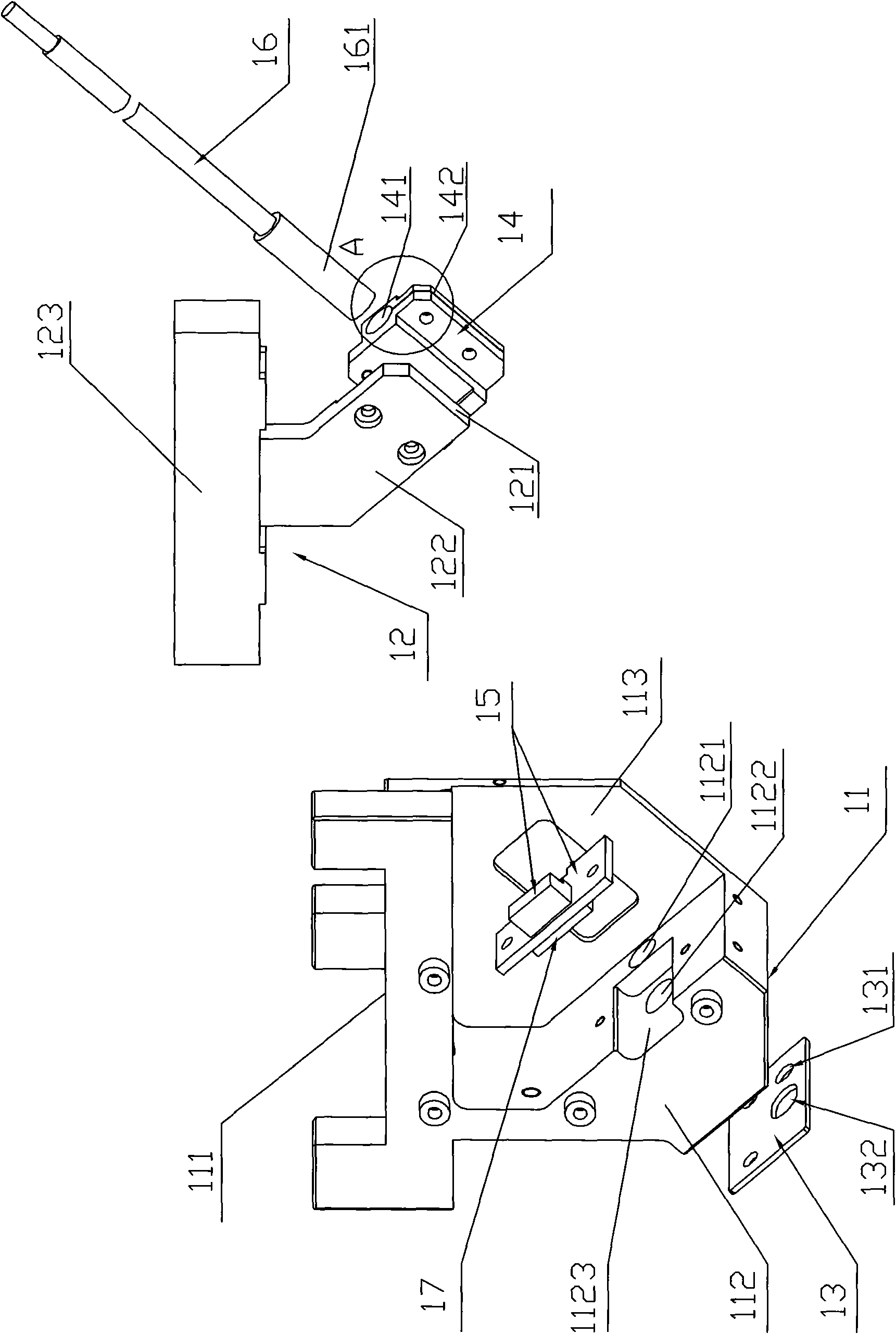

[0031] Such as figure 2 , image 3 , Figure 5 , Image 6 , Figure 7 , Figure 8 As shown, the base 11 of the host module 1 includes a bottom plate 111 and a sloping plate 112, the bottom plate 111 is provided wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com