Machining unit

A technology for processing machines and workpieces, which is applied in the direction of metal processing machine parts, metal processing equipment, manufacturing tools, etc., can solve the problems of high holding force, impossibility, cost, etc., to improve the clamping process, expand the scope of use, and improve clamping The effect of tightening

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0070] Elements that are identical or correspond to one another in the figures are denoted with the same reference numerals and are therefore not described again unless this is intended.

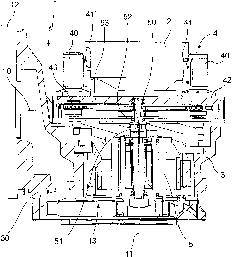

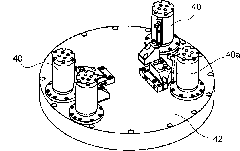

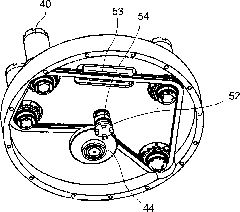

[0071] exist figure 1 The invention is schematically shown in . The processing machine 1 includes on the one hand a workpiece table 3 which holds a workpiece 2 . exist figure 1 A machining tool not shown in the figure is driven by the tool spindle and can be moved in a suitable manner relative to the workpiece 2 , and is formed, for example, as a drill or a milling cutter. The processing machine 1 according to the invention has a plurality of axes. Provision is made for machining to be as flexible as possible, that the workpiece 2 can be positioned relative to the machining tool along three spatial axes. In addition to these longitudinal axes, however, rotational axes are also provided. The first axis of rotation is shown with reference numeral 10 and is called the B-axis. It allows th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com