Photoetching machine in-situ multichannel imaging quality detection apparatus and photoetching machine in-situ multichannel imaging quality detection method

A technology for imaging quality and detection devices, applied in the field of lithography machines, can solve the problems of limited detector pixels, reduced number of effective detection pixels, and difficulty in increasing the number of parallel detection channels, so as to increase the number of parallel detection channels and reduce data The effect of increasing the amount of computation and detection speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The present invention will be further described below in conjunction with the embodiments and accompanying drawings, but the protection scope of the present invention should not be limited by this embodiment.

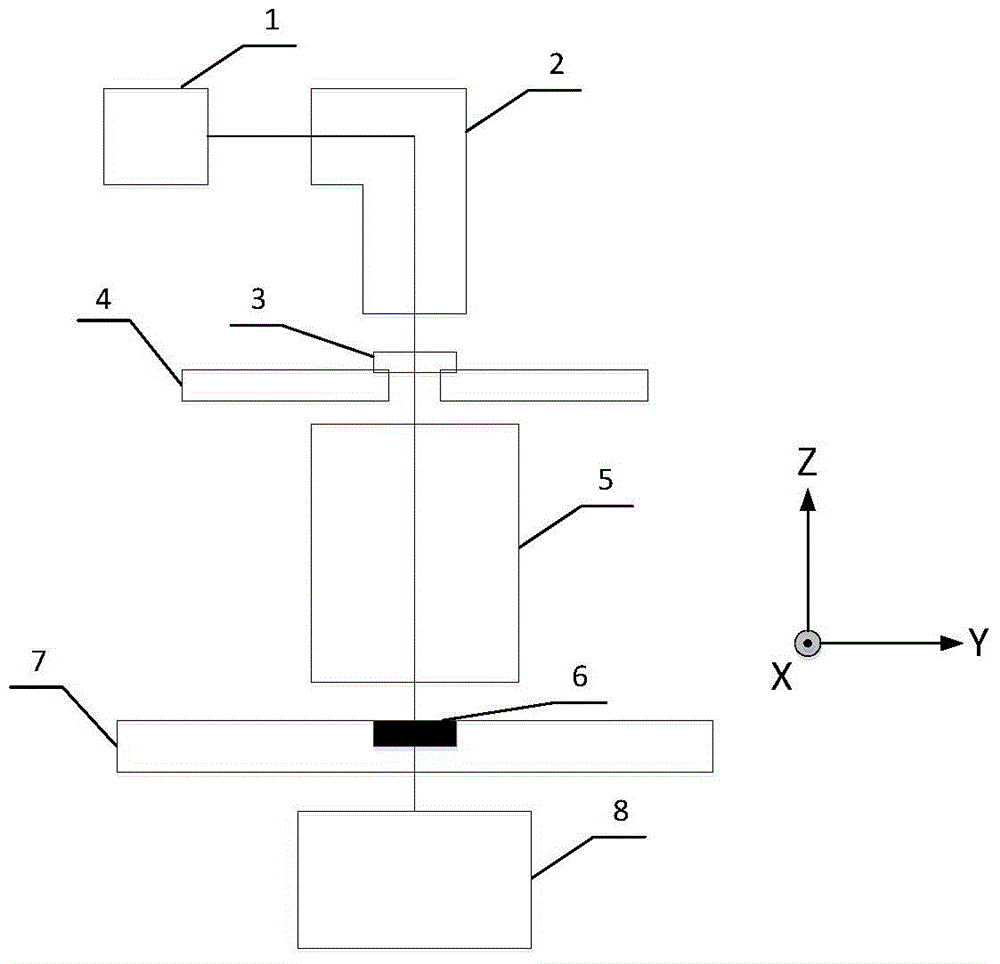

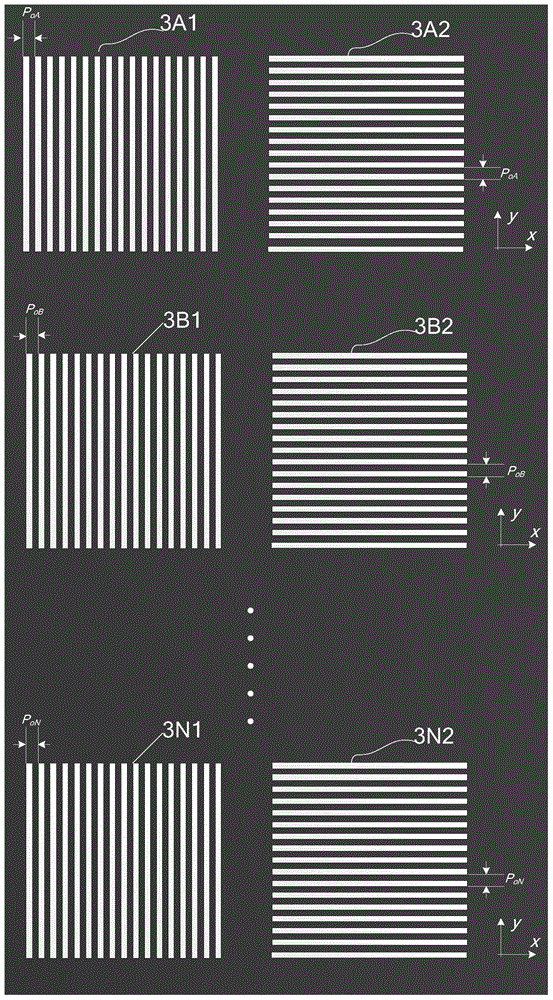

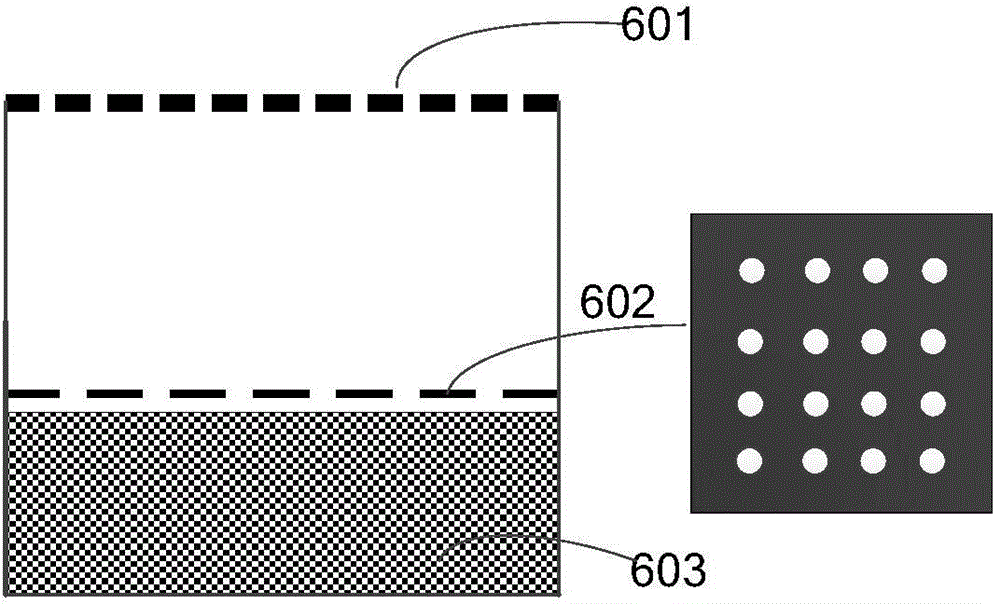

[0043] figure 1 It is a structural diagram of an in-situ multi-channel imaging quality detection device for a lithography machine of the present invention. The in-situ multi-channel imaging quality detection device of the lithography machine of the present invention includes a light source 1 of the lithography machine, an illumination system 2, a mask table 4, a projection objective lens 5 of the lithography machine, a workpiece table 7, and a mask table 4 The object plane grating plate 3 and the wave aberration sensor 6 placed on the workpiece table 7 and the data processing computer 8 connected with the wave aberration sensor 6; the wavelength of the light source 1 of the present embodiment is 193nm; n=14, the described The object plane grating plate 3 is comp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com