System for balancing and positioning work table of photoetching device

A technology of positioning system and workpiece table, which is applied in the direction of microlithography exposure equipment, photoplate making process exposure device, etc., can solve the problem that it is difficult to match the rotating motor, etc., and achieve the effect of reducing difficulty, reducing reaction force and improving positioning accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The preferred embodiments of the present invention will be described below in conjunction with the accompanying drawings, so that the purpose, specific structural features and advantages of the present invention can be further understood.

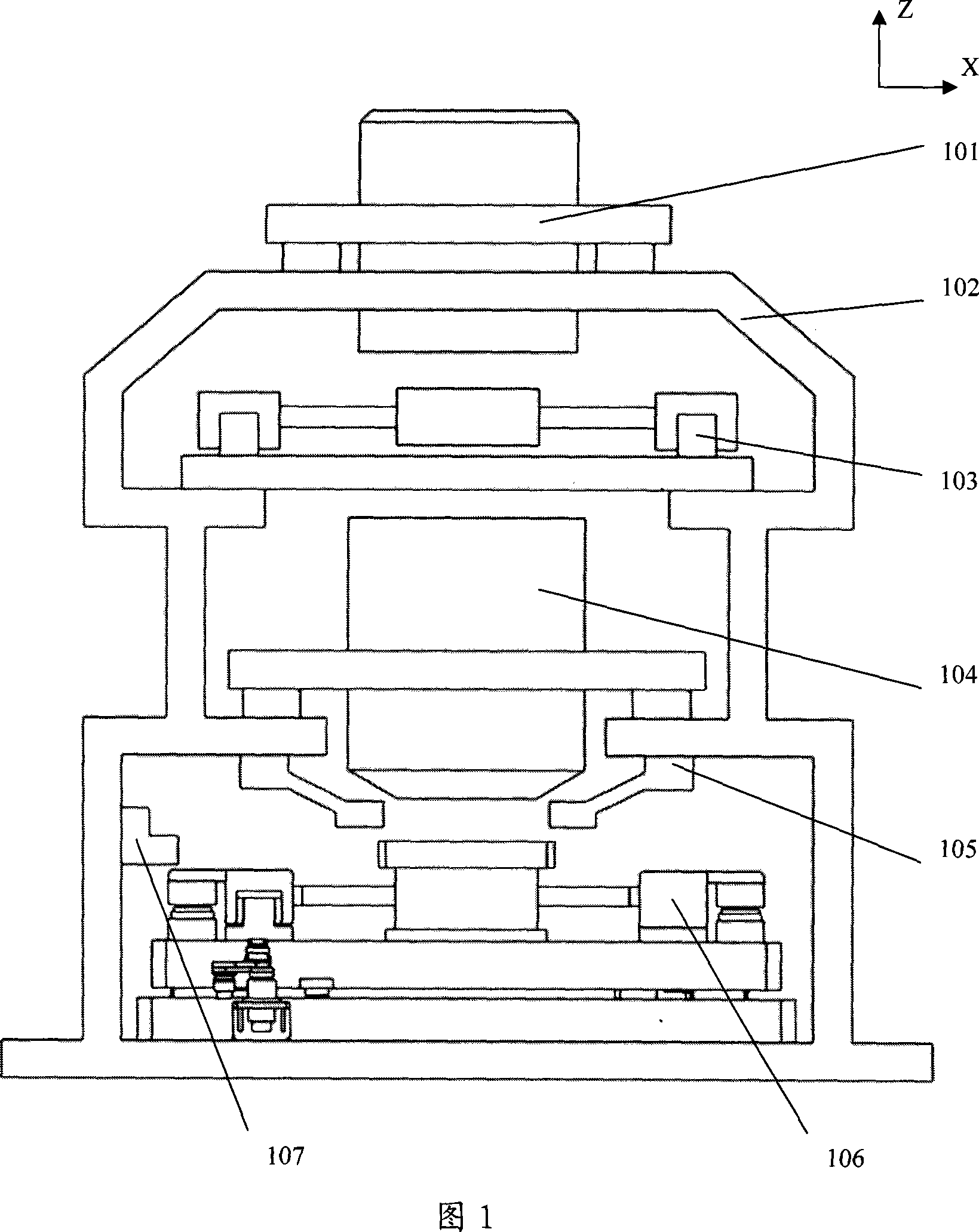

[0032] Fig. 1 is a 2D view of the exposure unit of a lithography machine. It can be seen from the figure that the exposure unit of the lithography machine mainly includes a whole machine frame 102, an illumination system 101, a mask table system 103, an objective lens system 104, a focusing Leveling system 105, workpiece platform system 106, workpiece platform laser interferometer 107, etc. Wherein the workpiece table system 106 is exactly the workpiece table balance positioning system that we will explain in this invention.

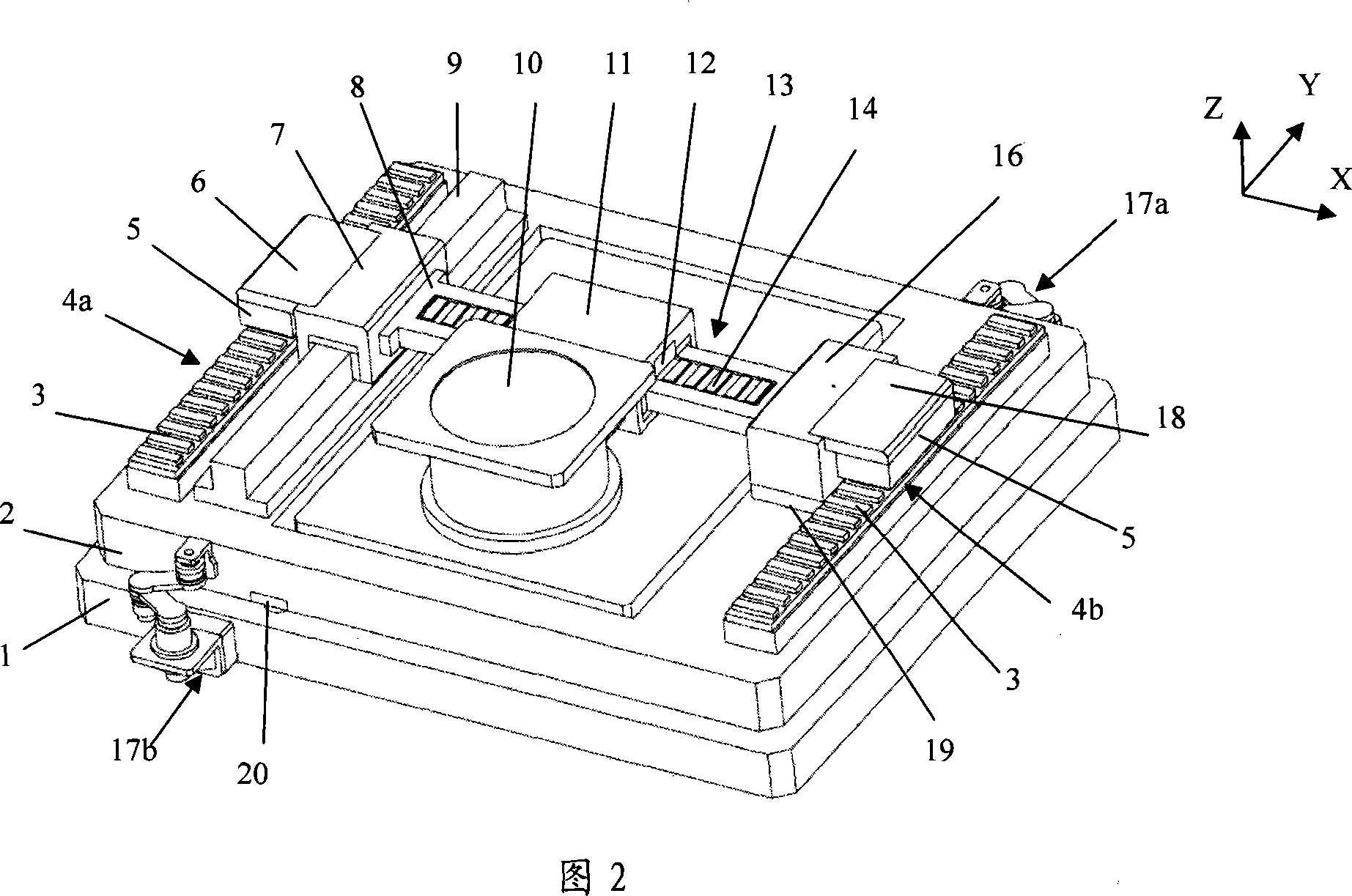

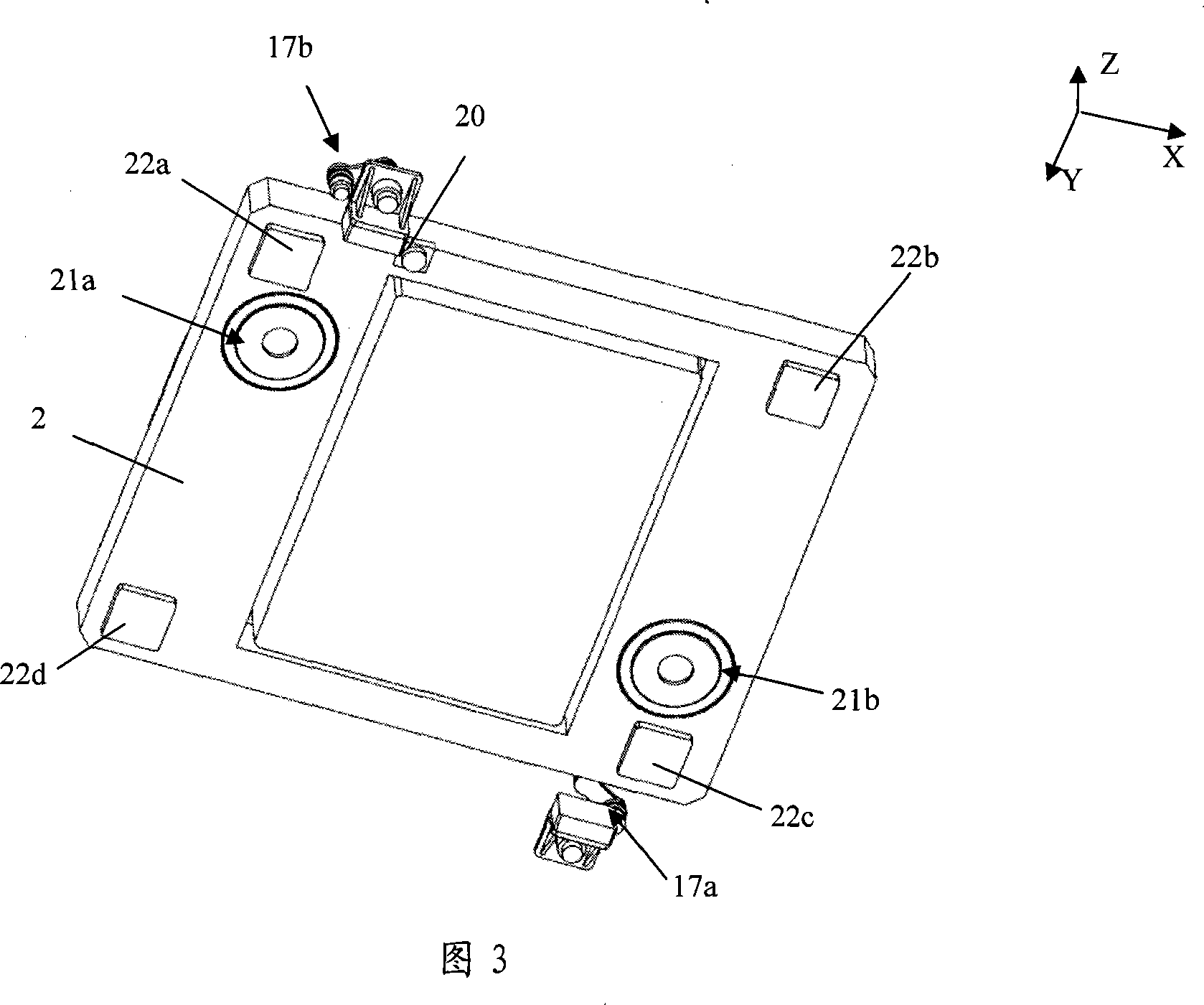

[0033] Please refer to Figures 2 and 3, the workpiece platform balance positioning system mainly includes a basic frame 1, a long-stroke module, an exposure platform 10, a balance mass system, a balance mass an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com