Hydraulic piece table position fast changing device

A technology for hydraulic parts and positioning columns, which is applied in the field of quick-change devices for hydraulic parts, can solve problems such as waste of resources, high-pressure oil injection, injury to test personnel, etc., and achieve the effects of strong practicability, prevention of oil leakage, and reasonable structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

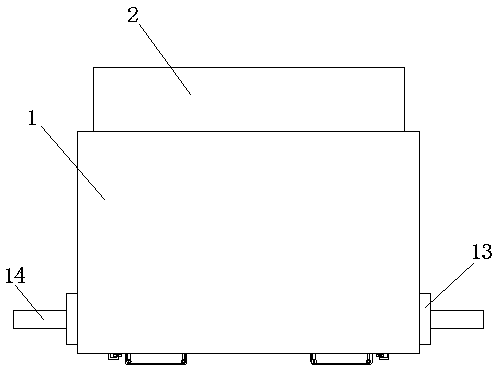

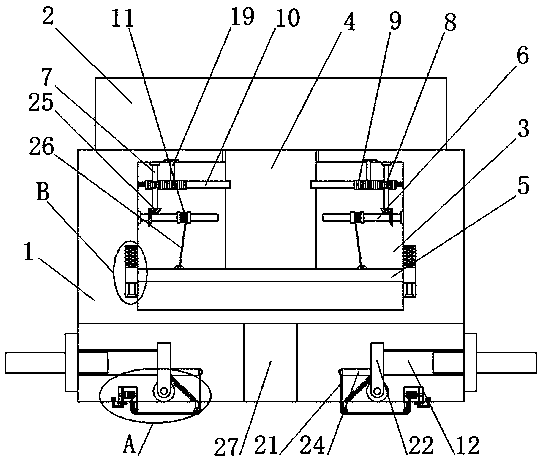

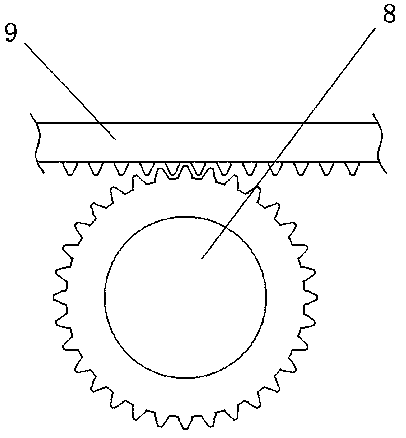

[0024] refer to Figure 1-5 In this embodiment, a quick-change device for hydraulic parts is proposed, including a connecting valve 1 and a hydraulic part main body 2. A cavity 3 is provided on the connecting valve 1, and a positioning column 4 is fixedly connected to the bottom of the hydraulic part main body 2. The bottom of the positioning column 4 runs through the top of the connecting valve 1 and extends into the cavity 3. A sliding plate 5 is slidably connected in the cavity 3. The bottom of the positioning column 4 is in contact with the top of the sliding plate 5. Both sides of the cavity 3 Two first rotating rods 6 are rotatably connected on the inner wall, and a second rotating rod 7 is connected to the first rotating rod 6. The fixed sleeve on the second rotating rod 7 is provided with a gear 8, and two tooth racks 9 are slidably connected to each other on the top inner wall of the cavity 3, the gear 8 is meshed with the tooth rack 9, and the sides of the two tooth ...

Embodiment 2

[0033] refer to Figure 1-5 In this embodiment, a quick-change device for hydraulic parts is proposed, which includes a connecting valve 1 and a main body 2 of the hydraulic part. The bottom of the column 4 runs through the top of the connecting valve 1 and extends into the cavity 3. A sliding plate 5 is slidably connected in the cavity 3. The bottom of the positioning column 4 is in contact with the top of the sliding plate 5. The inner walls on both sides of the cavity 3 There are two first rotating rods 6 connected to each other in rotation, and a second rotating rod 7 is connected to the first rotating rod 6. The tops of the two second rotating rods 7 are connected to the top inner wall of the cavity 3 in rotation. The rotating rod 7 is fixedly sleeved with a gear 8, and the top inner wall of the cavity 3 is slidably connected with two racks 9, the gear 8 is meshed with the rack 9, and the sides of the two racks 9 are welded to each other. Bayonet 10, both sides of positi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com