Automatic overturning mechanism

A technology of automatic turning and rotating shaft, applied in metal processing machinery parts, clamping, supporting and other directions, can solve the problems of unstable start and stop, inaccurate positioning, etc., and achieve the effect of simple structure, accurate and reliable positioning, and low cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described in further detail below through specific implementation examples and in conjunction with the accompanying drawings.

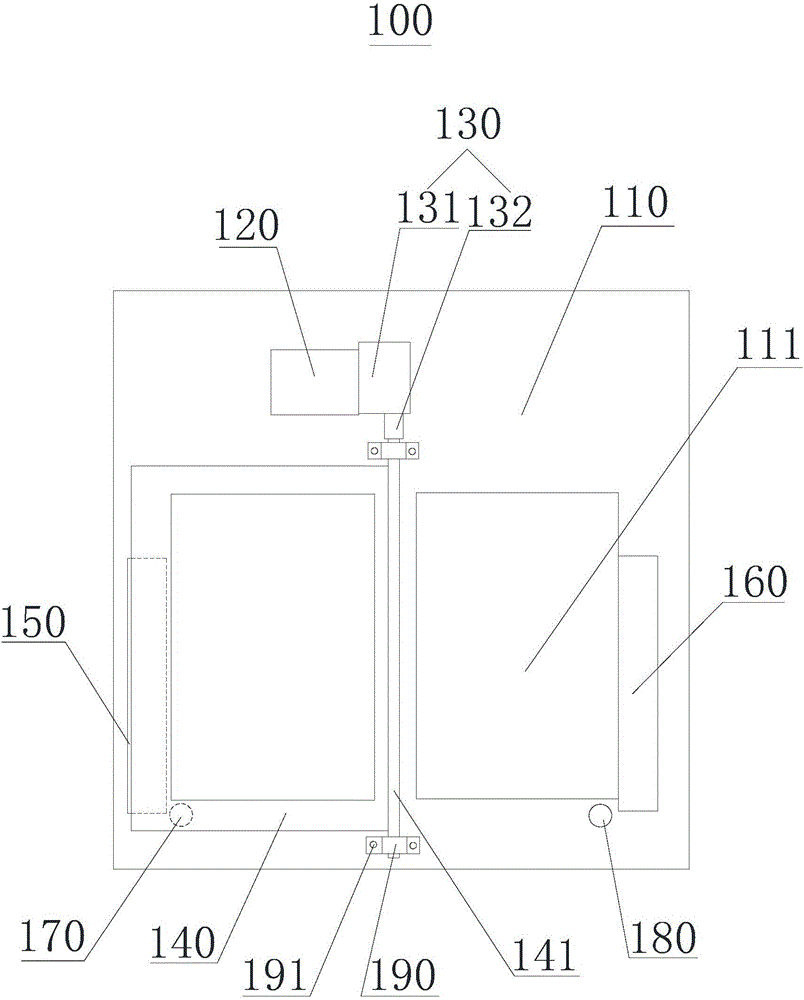

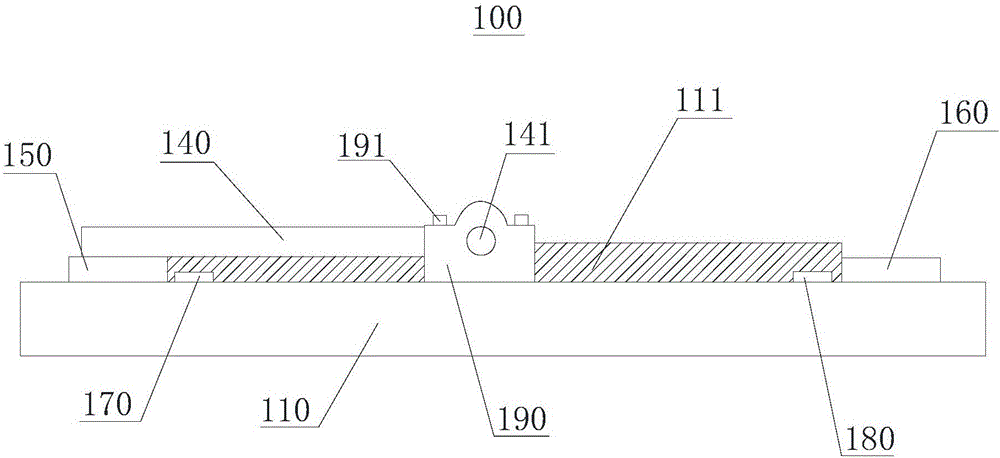

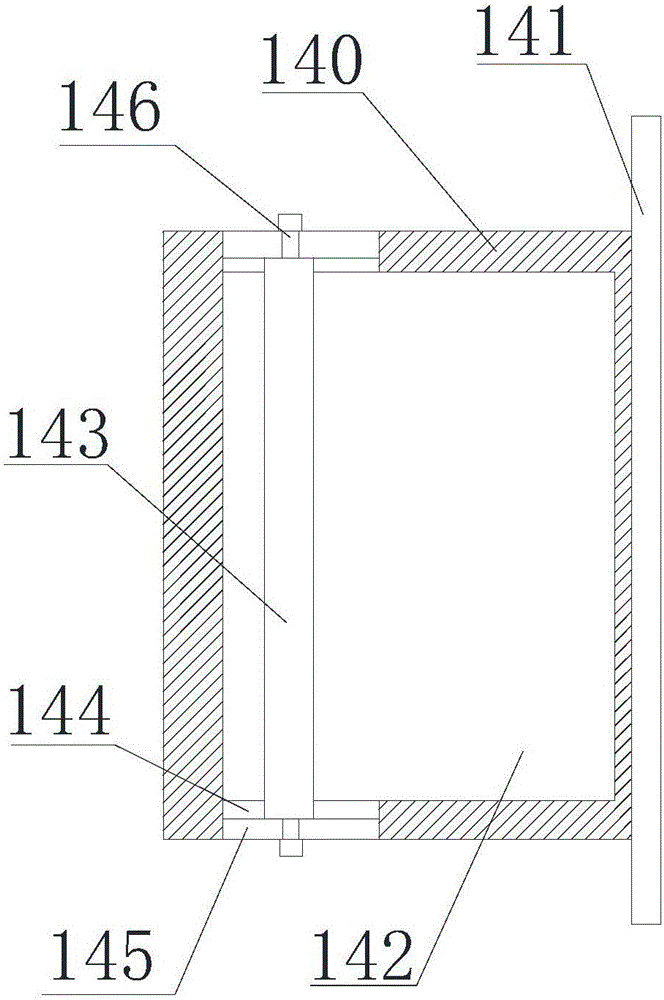

[0022] See attached figure 1 , An automatic turning mechanism 100 provided by an embodiment of the present invention includes a workpiece table 110 , a motor 120 , a worm gear reduction device 130 , a metal workpiece fixture 140 , a first electromagnet 150 , and a second electromagnet 160 .

[0023] The workpiece platform 110 is the supporting structure of the entire automatic turning mechanism 100 , and the rotating operation of the metal workpiece fixture 140 and subsequent processing operations on the workpiece are all performed on the workpiece platform 110 . In this embodiment, the workpiece table 110 is in the shape of a cuboid, and the table surface of the workpiece table 110 is relatively smooth, so as to facilitate processing operations. Of course, in other embodiments, the workpiece table 110 can also be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com