Equipment for customizing individualized contact lenses

A technology for contact lenses and equipment, applied in optomechanical equipment, glasses/goggles, microlithography exposure equipment, etc., can solve problems such as inability to solve spherical projection exposure, difficult processing methods to meet requirements, etc., and achieves simple structure and low cost. , reliable quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

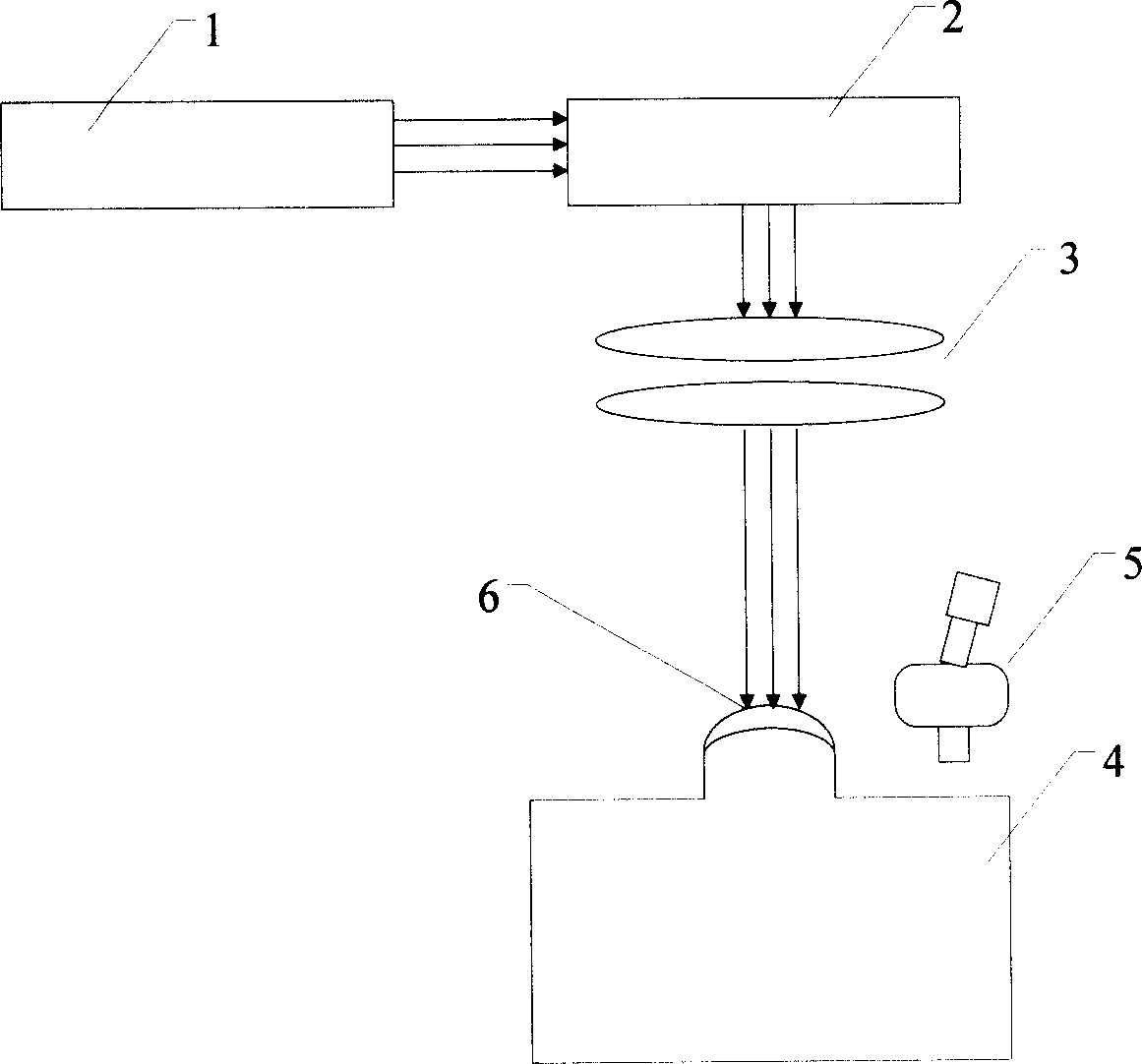

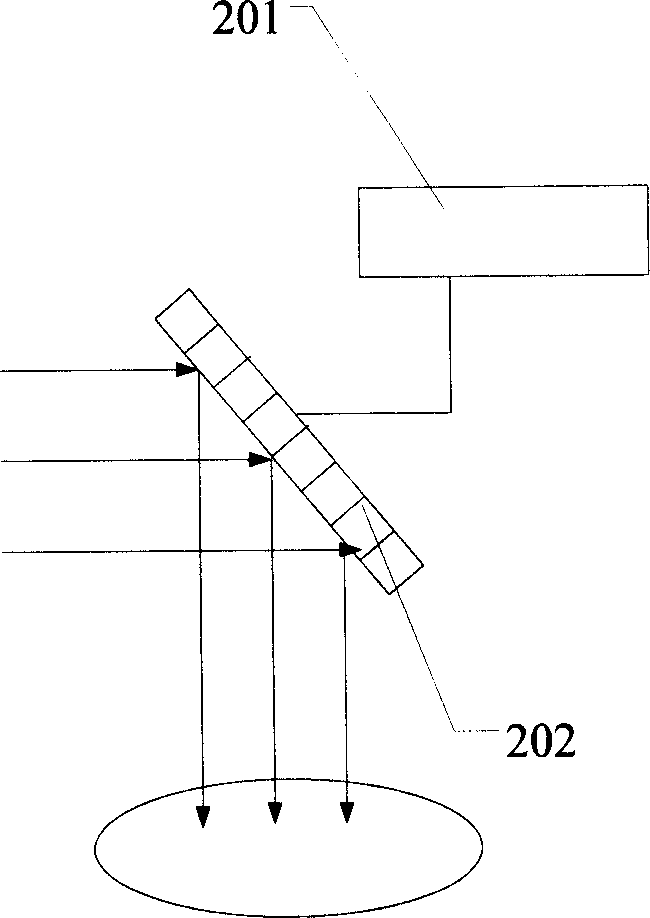

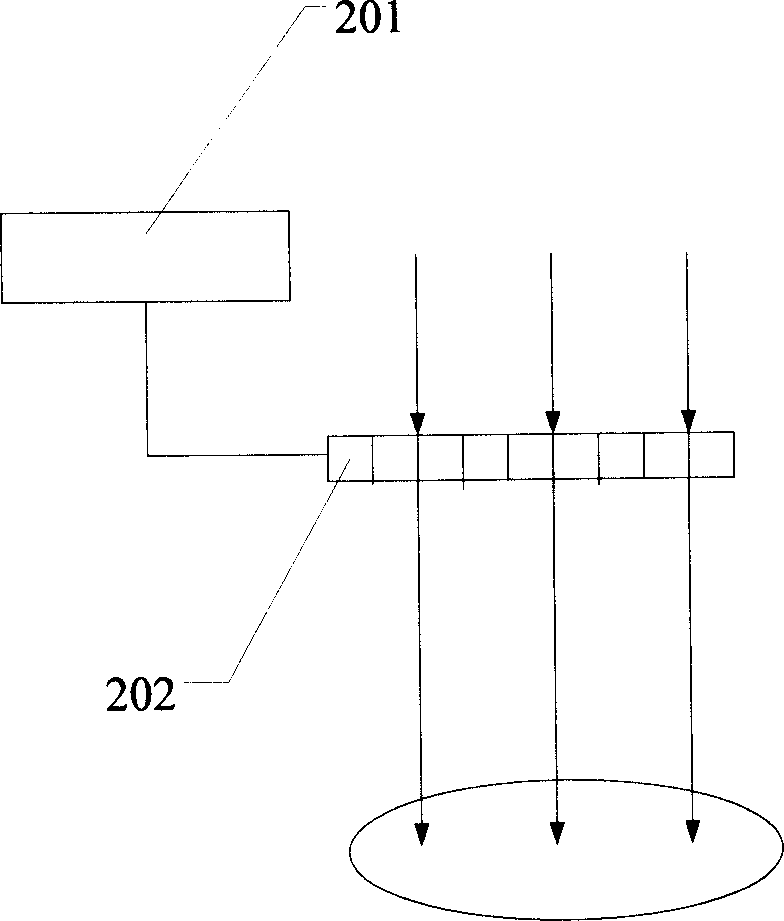

[0015] Such as figure 1 As shown, the present invention is composed of a uniform illumination system 1, a grayscale image production system 2, a projection optical system 3, a workpiece table system 4 and an alignment system 5. The uniform illumination system 1 generates uniform parallel illumination light, and the light beam passes through the gray High-resolution image production system 2, according to the results of human aberration inspection, the gray-scale image generator is controlled by the computer to generate gray-scale images, and then through the projection optical system 3, the gray-scale images are scaled and corrected after the curvature of the image field, Imaging to the image plane with a given radius of curvature—fixed on the workpiece stage 4, adjusted to the correct position by the alignment system 5 and on the surface of the sample coated with photoresist, so that the photoresist on the sample is pressed against The grayscale exposure of the grayscale patt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com