Calibration device and calibration method for photoelectric detector

A technology of photodetectors and calibration devices, which is applied in photometry using electric radiation detectors, photolithography exposure devices, micro-lithography exposure equipment, etc., can solve inaccurate calibration results, large environmental pollution of lithography systems, Inconvenient operation and other problems, to achieve the effect of convenient and accurate calibration, improve test accuracy, and improve measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

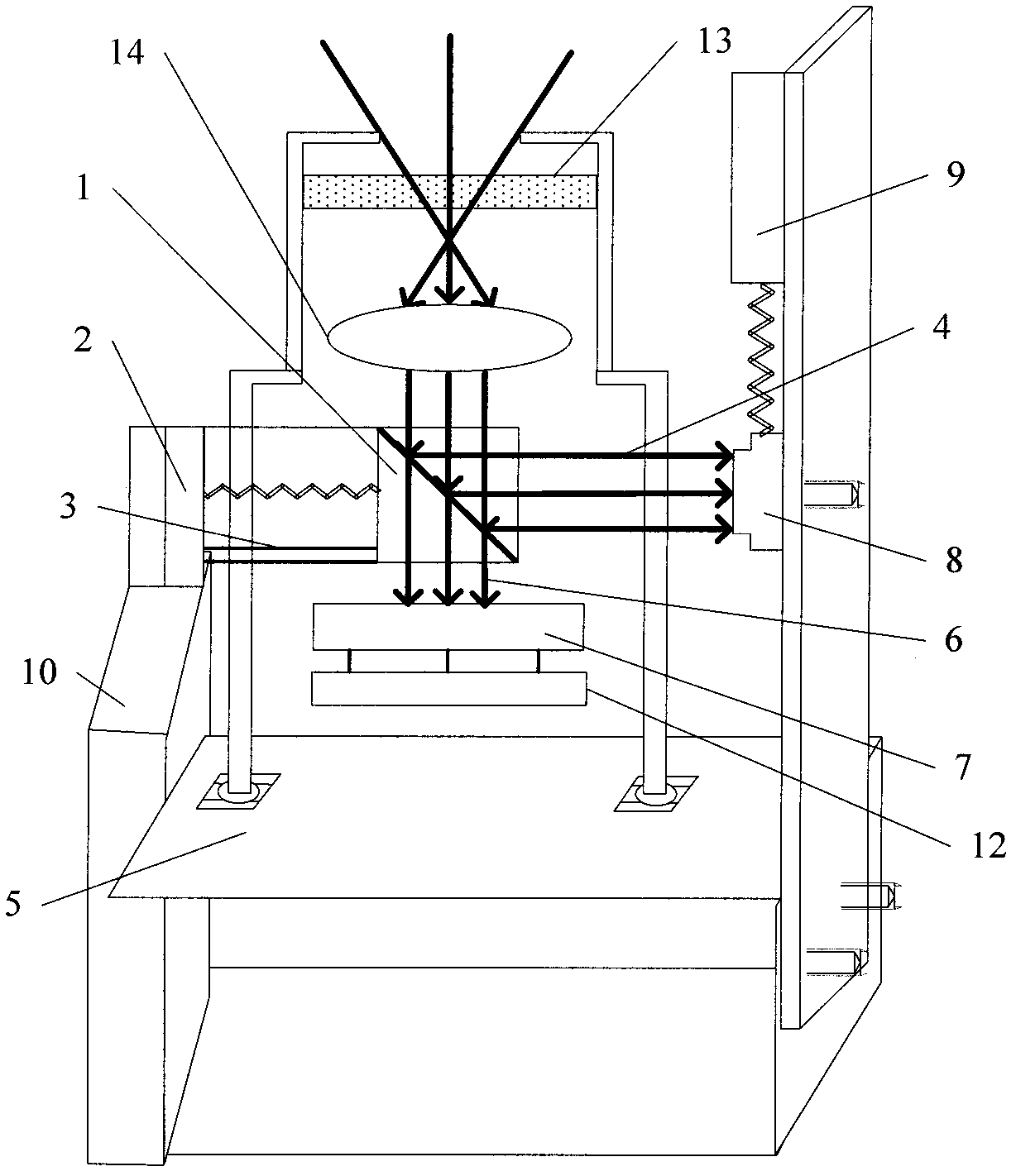

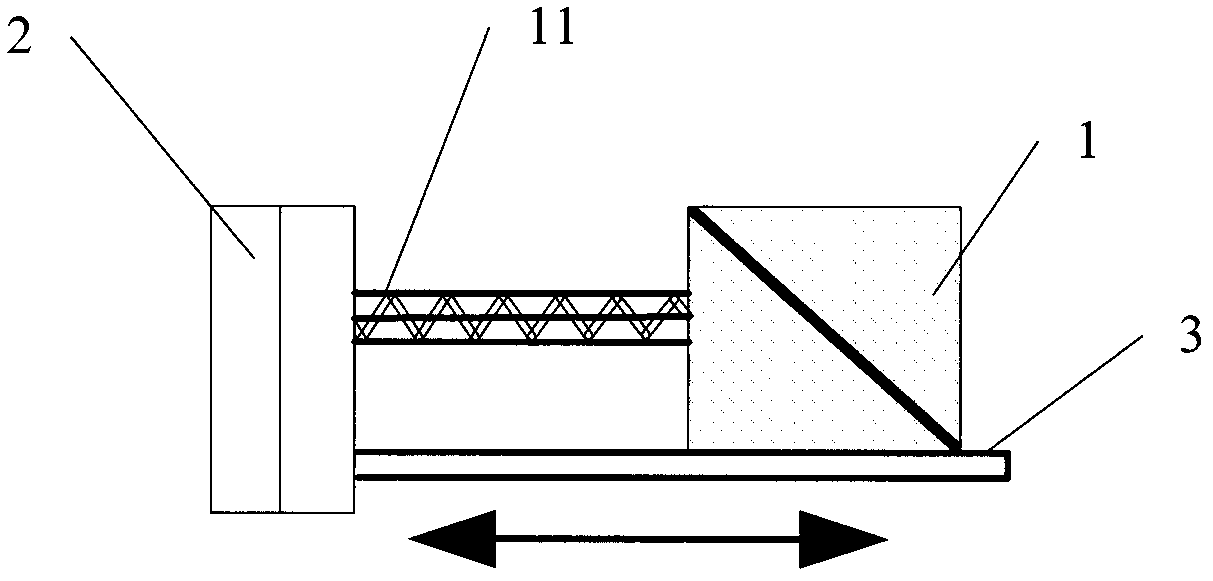

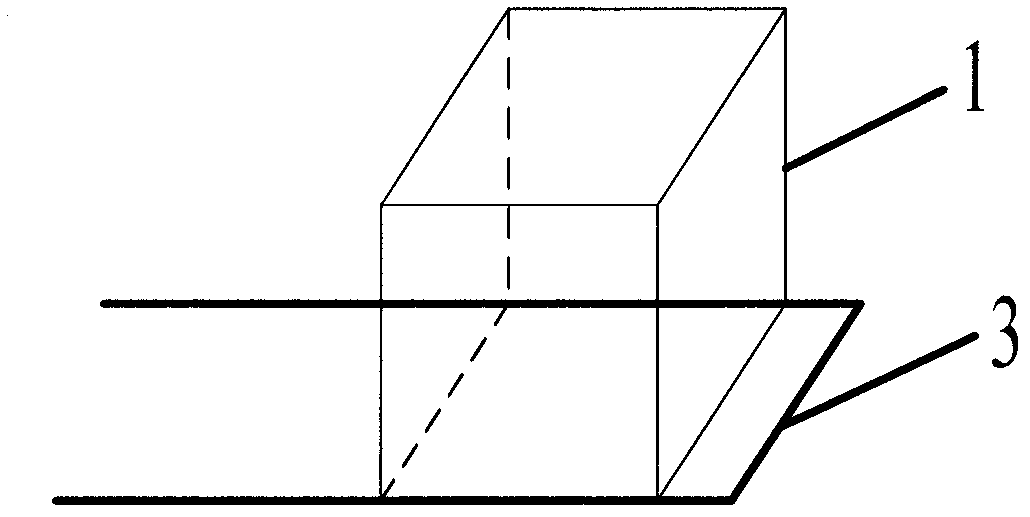

[0042] refer to figure 1 As shown, the photodetector calibration device of the present invention includes a spectroscopic prism 1 and an absolute detector 8, and its calibrated object photodetector 7 is placed on the workpiece table 8 to monitor the actual light intensity of the lighting system, and the output of the lighting system The illuminating light is projected onto the dichroic prism 1, and the dichroic prism 1 reflects and transmits the received light intensity, preferably 50% of the light intensity is reflected and 50% of the light intensity is transmitted; the transmitted light 6 is received by the photodetector 7, And the reflected light 4 is received and sampled by the absolute detector 5 placed on the right. It is also possible to change the setting of the dichroic prism so that the transmitted light is received by the absolute ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com