Gap detection device based on super-resolution lithography

A detection device and super-resolution technology, applied in measuring devices, optical devices, instruments, etc., can solve problems such as mask damage, and achieve the effect of ensuring the quality of photolithographic patterns

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be described in further detail below in conjunction with the accompanying drawings.

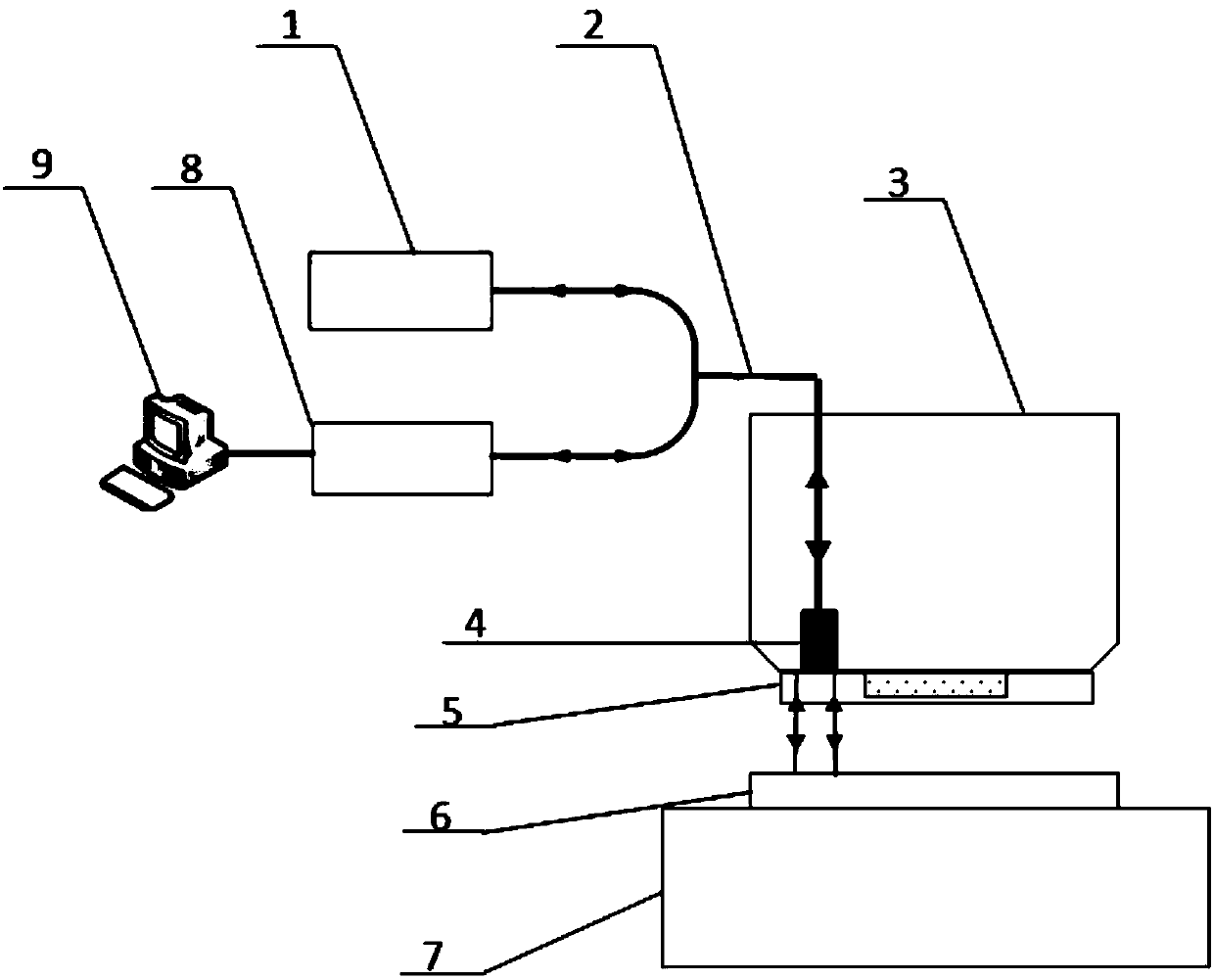

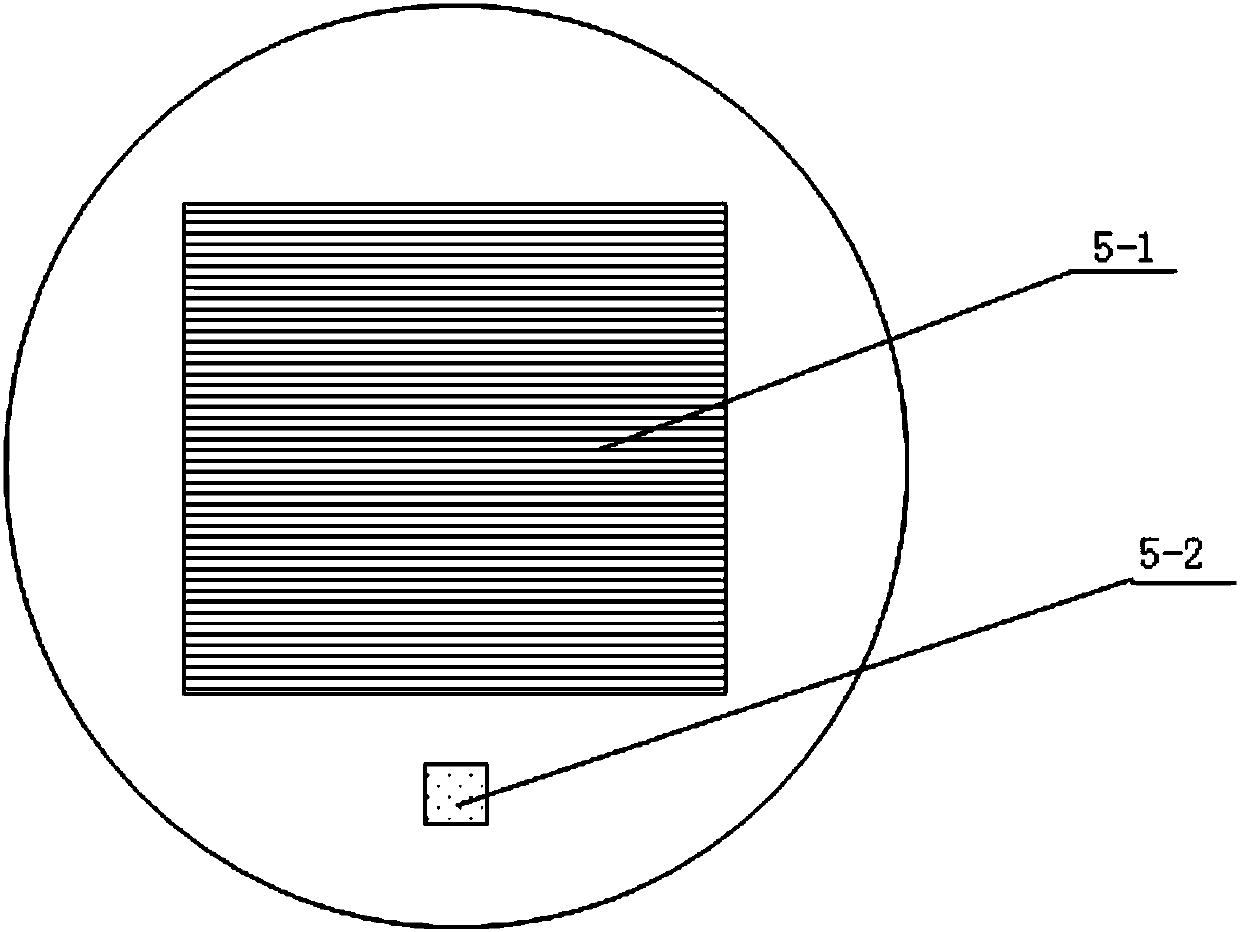

[0015] figure 1 It is a schematic diagram of a gap detection device for super-resolution lithography, which includes a white light source 1, a Y-shaped optical fiber 2, an objective lens frame 3, an optical fiber collimator mirror 4, a mask 5, a substrate 6, a nanometer workpiece table 7, a spectrometer 8 and PC9. Wherein the optical fiber collimator 4 and the mask 5 are clamped by the objective lens frame 3; the non-pattern area of the mask 5 has a semi-transparent window, and the semi-transparent window is plated with a chromium layer, and the substrate 6 is plated with a silver layer. The light output from the white light source 1 is introduced into the optical fiber collimator 4 by the Y-shaped optical fiber 2, and the incident light is split in the semi-transparent and semi-reflective window under the mask 5, and a bunch of light is reflected back to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com