Test bed for visual measurement system of test piece high temperature deformation machine

A technology of machine vision measurement and high-temperature deformation, which is applied in the direction of measuring devices, instruments, and optical devices, etc., can solve the problem of difficulty in meeting the application diversity of machine vision detection and measurement technology, difficulty in effectively carrying out teaching and scientific research work, and lack of experimental research instruments or means, etc., to achieve the effect of friendly interface, satisfying application diversity, and intuitive layout

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be further described below in conjunction with embodiments and drawings. The examples are only used to further illustrate the present invention in detail, and do not limit the protection scope of the claims of this application.

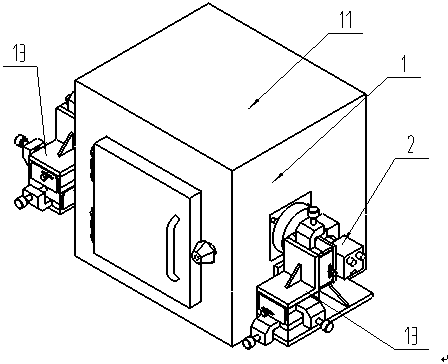

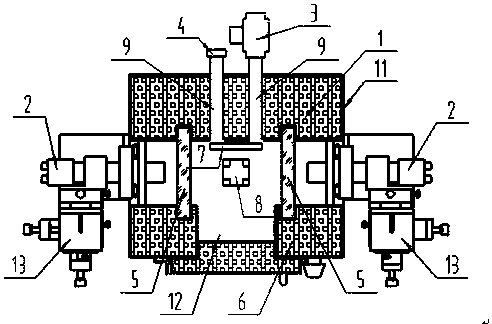

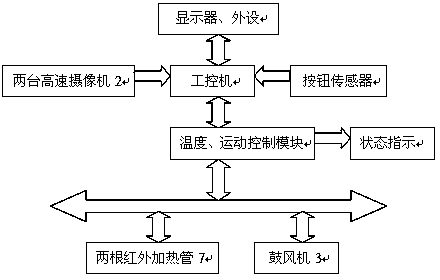

[0013] The experimental platform of the machine vision measurement system for the high temperature deformation of the specimen designed by the present invention (referred to as the experimental platform, see Figure 1-3 ), which is characterized in that the experimental bench includes three parts: a heating furnace part, a visual inspection part and a control system. The heating furnace part includes a heating furnace 1, a heating furnace shell 11, a heating furnace inner cavity 12, a blower 3, two air ducts 9, two air duct covers 4, two quartz glass windows 5, heat preservation materials 6, two Infrared heating tube 7 and a sample table 8; the heating furnace shell 1 is a hexahedron, and the inner and outer walls of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com