Large stroke pricision working platform device and drive method

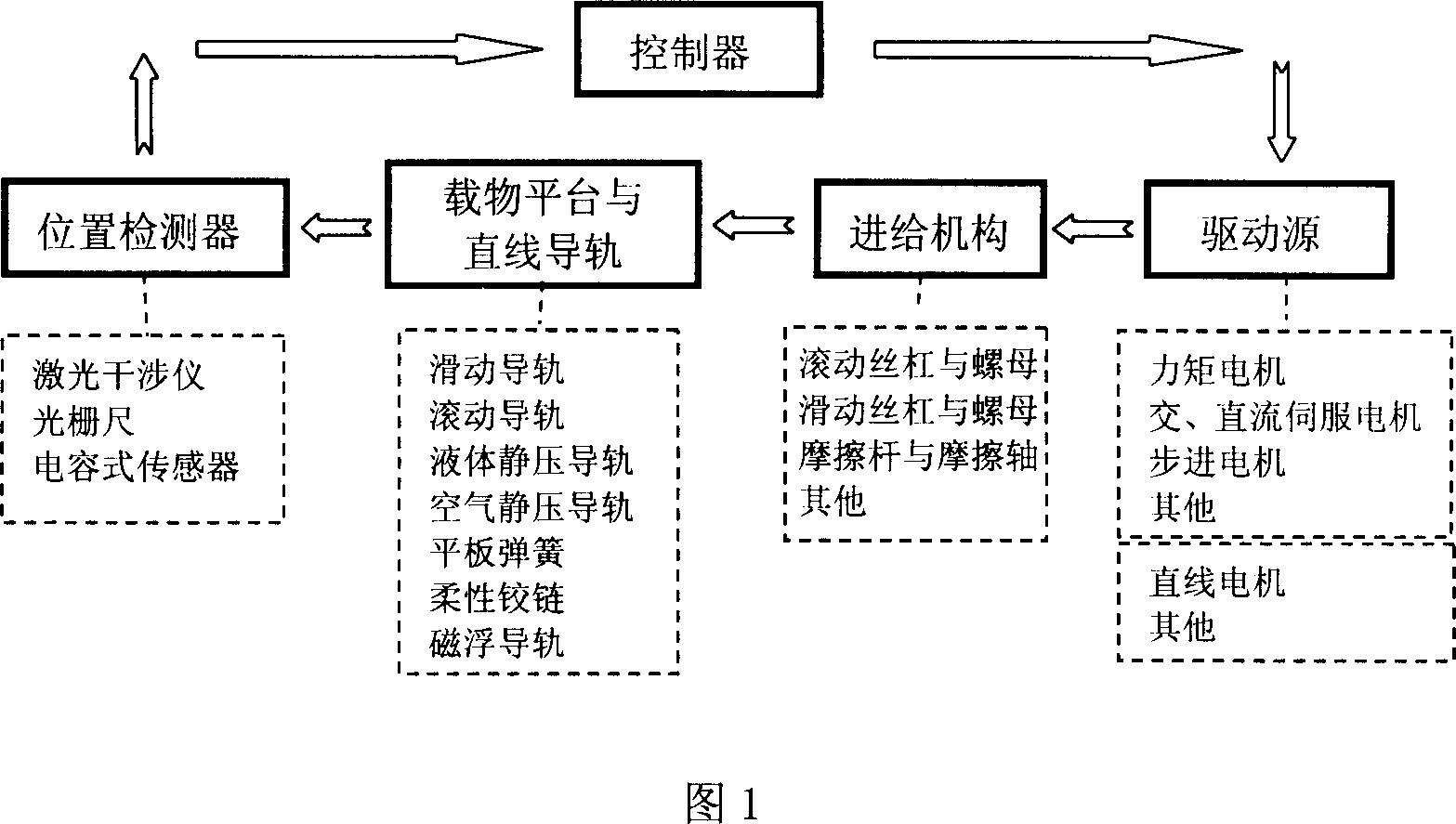

A workpiece table and large stroke technology, which is applied to the parts of the instrument, the instrument, the shell, etc., can solve the problems of difficult control and complicated devices, and achieve the effects of fast power transmission, fast response and high rigidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

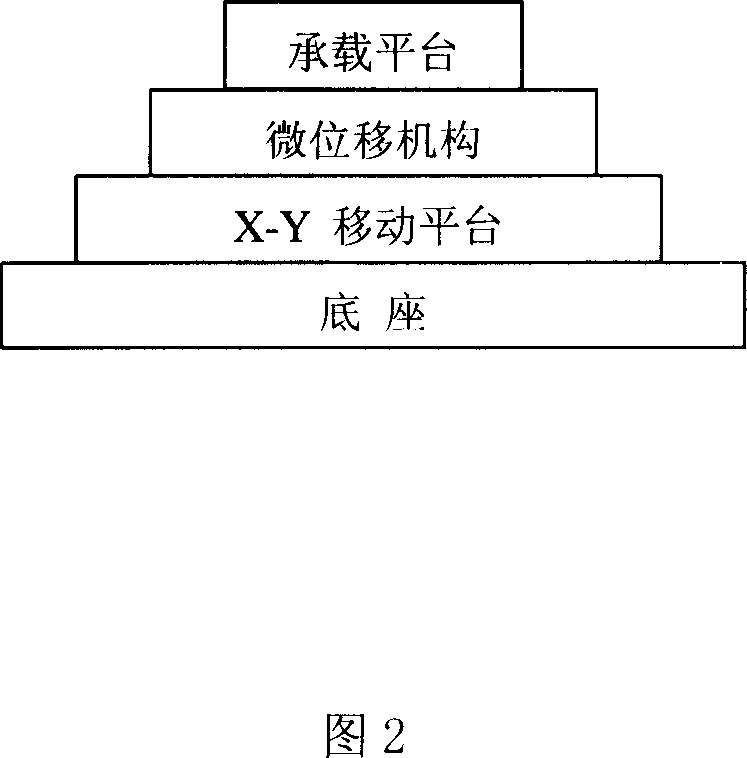

Method used

Image

Examples

Embodiment Construction

[0064] The key of the present invention is the fine motion mechanism driven by the fluid power drive source. After this part of the problem is solved, the entire workpiece table can truly achieve high-precision positioning, high-speed motion, high-rigidity positioning and high-rigidity motion.

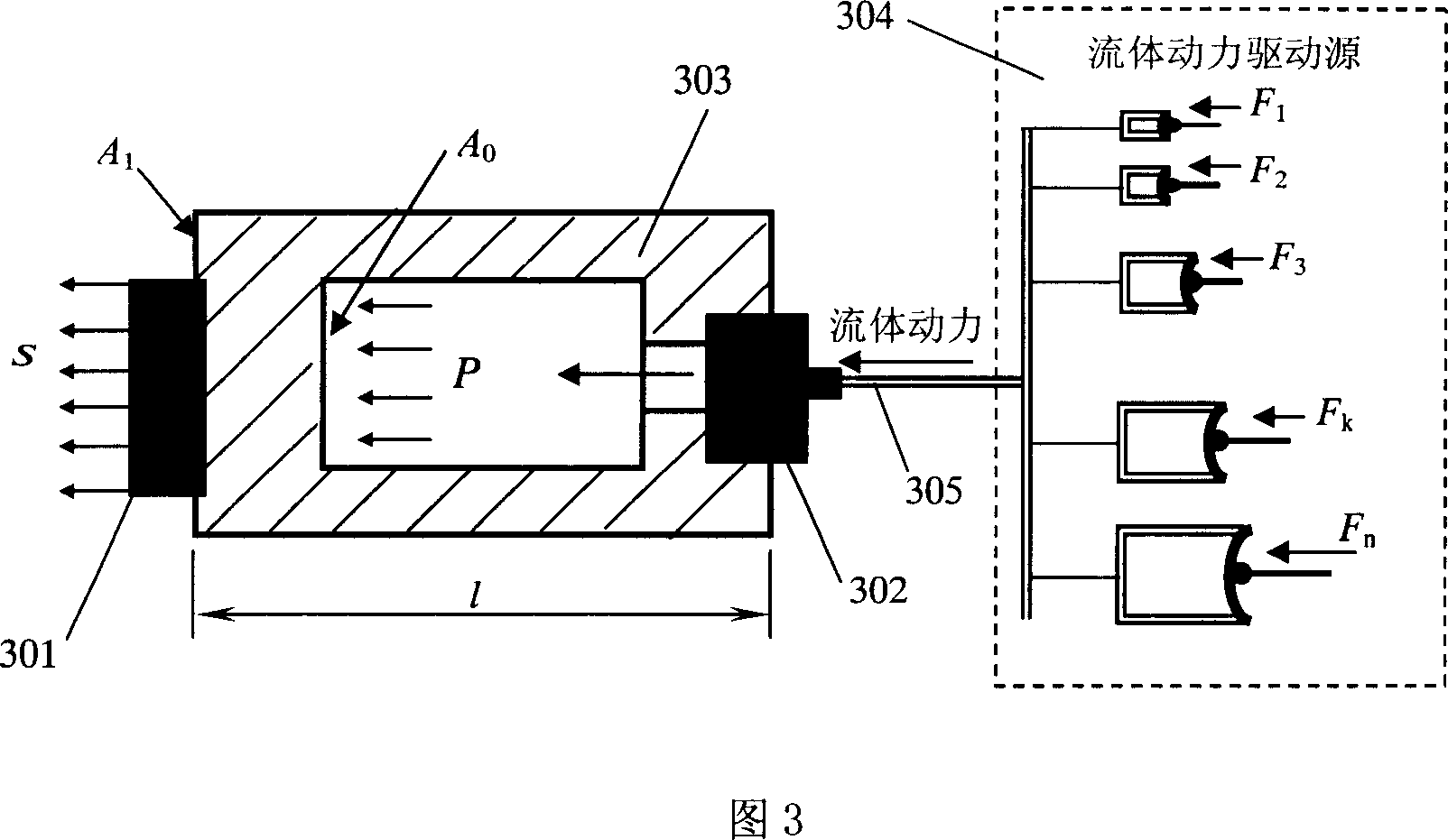

[0065]The structural principle of the fluid power driver referred to in the present invention is shown in Figure 3, and its structure is designed as an internal hollow pressure deformation body 303, and the fluid power of the fluid power drive source 304 is transmitted to the pressure deformation body through the pipeline 305 and the fluid connection head 302 Inside the pressure deformation chamber of 303, under the action of internal pressure, the wall of the pressure deformation body produces a small deformation of expansion and elongation. small displacement. Similarly, when the internal pressure of the pressure deformation chamber decreases, the outer end of the pressure deformatio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com