Thickness consistency detection device

A detection device and a consistent technology, applied in the field of precision measurement, can solve the problems that linear motion mechanism is not easy to move precisely, prone to average error, cannot achieve high precision, etc., and achieves compact structure, reduced surface error, and reduced vibration. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

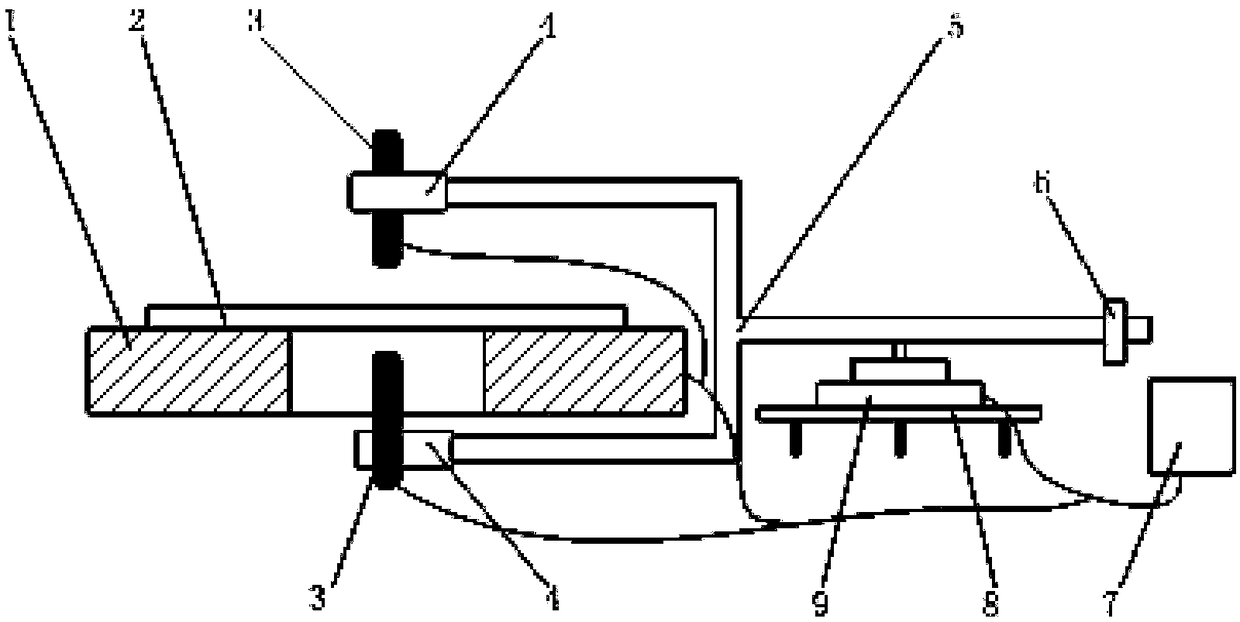

[0025] As shown in Figure 1, it is a schematic diagram of thickness consistency detection, consisting of a workpiece turntable 1, a workpiece table 2, a spectral confocal displacement sensor 3, a sensor adjustment unit 4, a cantilever 5, a counterweight 6, a controller 7, and a cantilever turntable adjustment mechanism 8 , consisting of a cantilever turntable 9;

[0026] Both the workpiece turntable 1 and the cantilever turntable 9 adopt air bearing shafting, which can provide frictionless, low-vibration dynamic motion and good static stability. Servo motors and angle encoders are integrated in the two turntables, which can provide precise rotary motion and Real-time angular displacement signal. The workpiece turntable 1 adopts a hollow structure, which can ensure that when the sample is placed on the workpiece turntable, the upper and lower s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com