Multifunctional circular carving duplicator

A multi-functional, replicating machine technology, applied in the field of engraving machines, can solve the problems of low efficiency, inability to reproduce carved pieces, inability to make deep engravings, hollow engravings and internal engravings, etc. The effect of efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

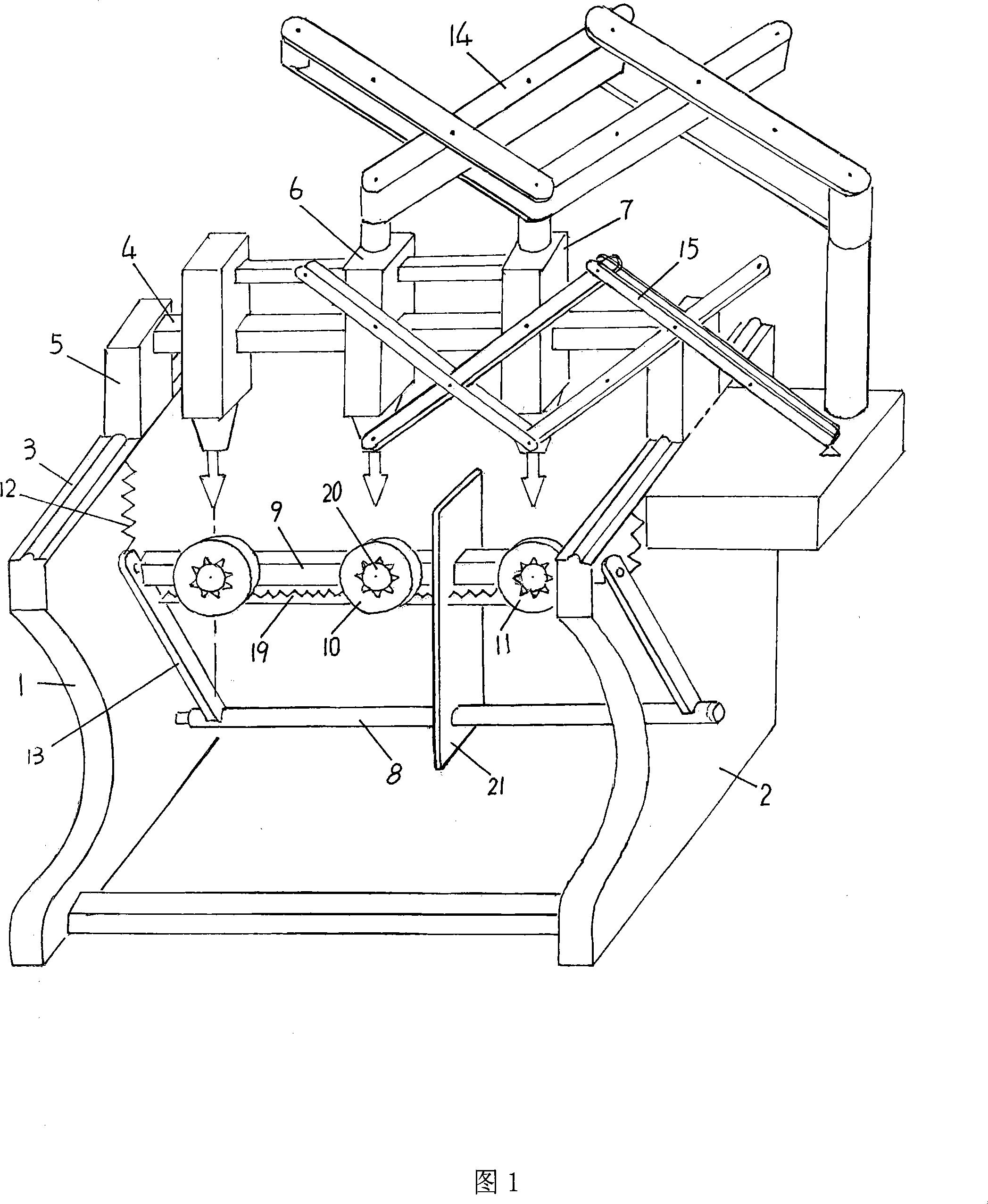

[0023] Referring to Fig. 1, present embodiment is made of body, machine head, engraved piece stand and put like mechanism, wherein:

[0024] The body has a left side frame 1 and a right side frame 2 that are upright and parallel to each other, and the top surfaces of the left side frame 1 and the right side frame 2 are a pair of parallel longitudinal slideways 3 along the Y direction;

[0025] The machine head has a machine head beam 4 along the X direction, and the two ends of the machine head beam 4 are slidably matched with the longitudinal slideway 3 along the Y direction with a slider 5, so that the machine head beam 4 can move in the Y direction; at least There are two working heads 6 and one prototype head 7 connected in series on the head beam 4, and slidingly fit with the head beam 4 along the X direction;

[0026] Carving piece stand, has and is positioned at below the machine head, is the turning bar 9 that is horizontally arranged, and each carving piece seat is re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com