Gypsum block integral casting block cutting forming equipment

A technology of integral casting and gypsum blocks, which is applied in the direction of ceramic molding core, ceramic molding mandrel, mold separation device, etc., can solve the problems of increased labor cost, equipment utilization rate, and greatly reduced cost performance of investment, so as to improve production efficiency, The effect of improving efficiency and flexibility and reducing the frequency of cleaning residues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with the accompanying drawings.

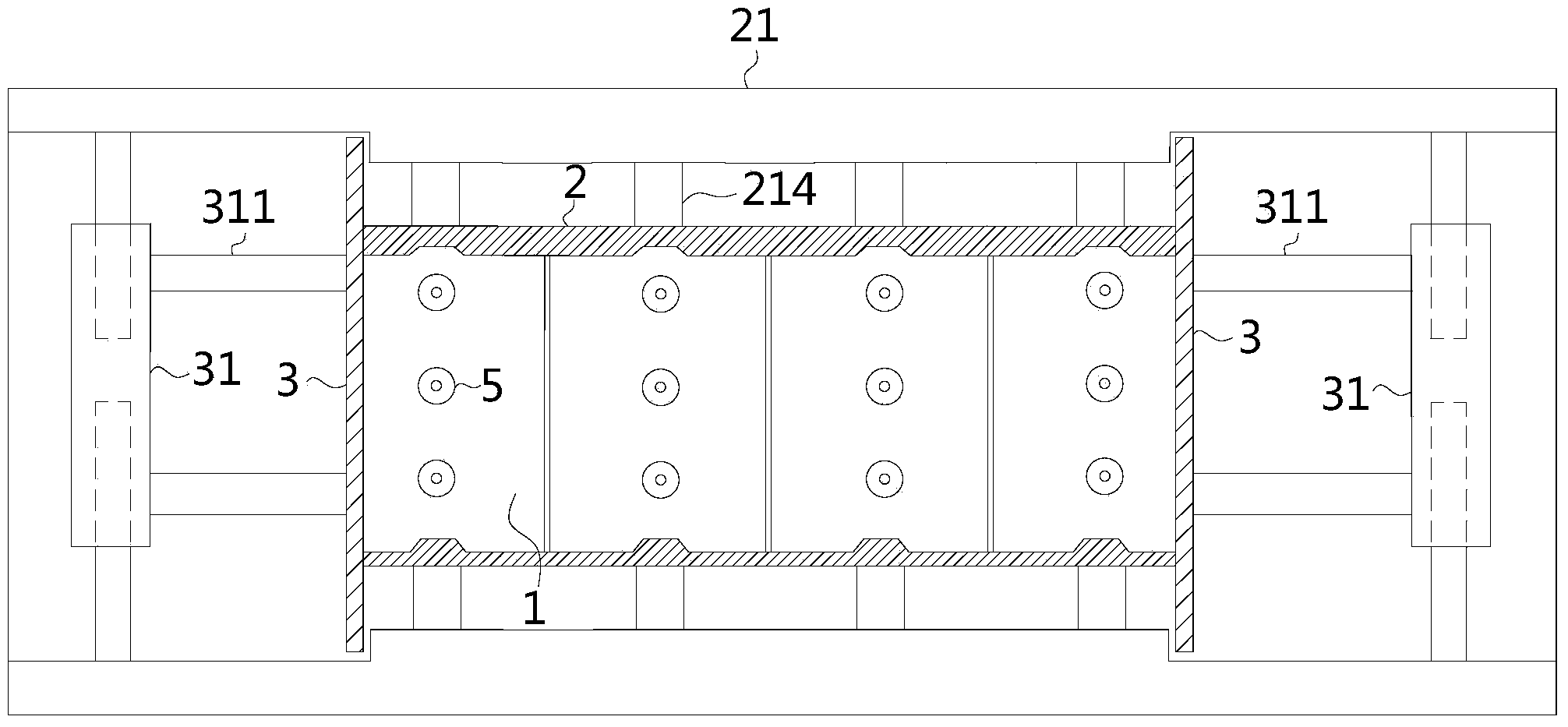

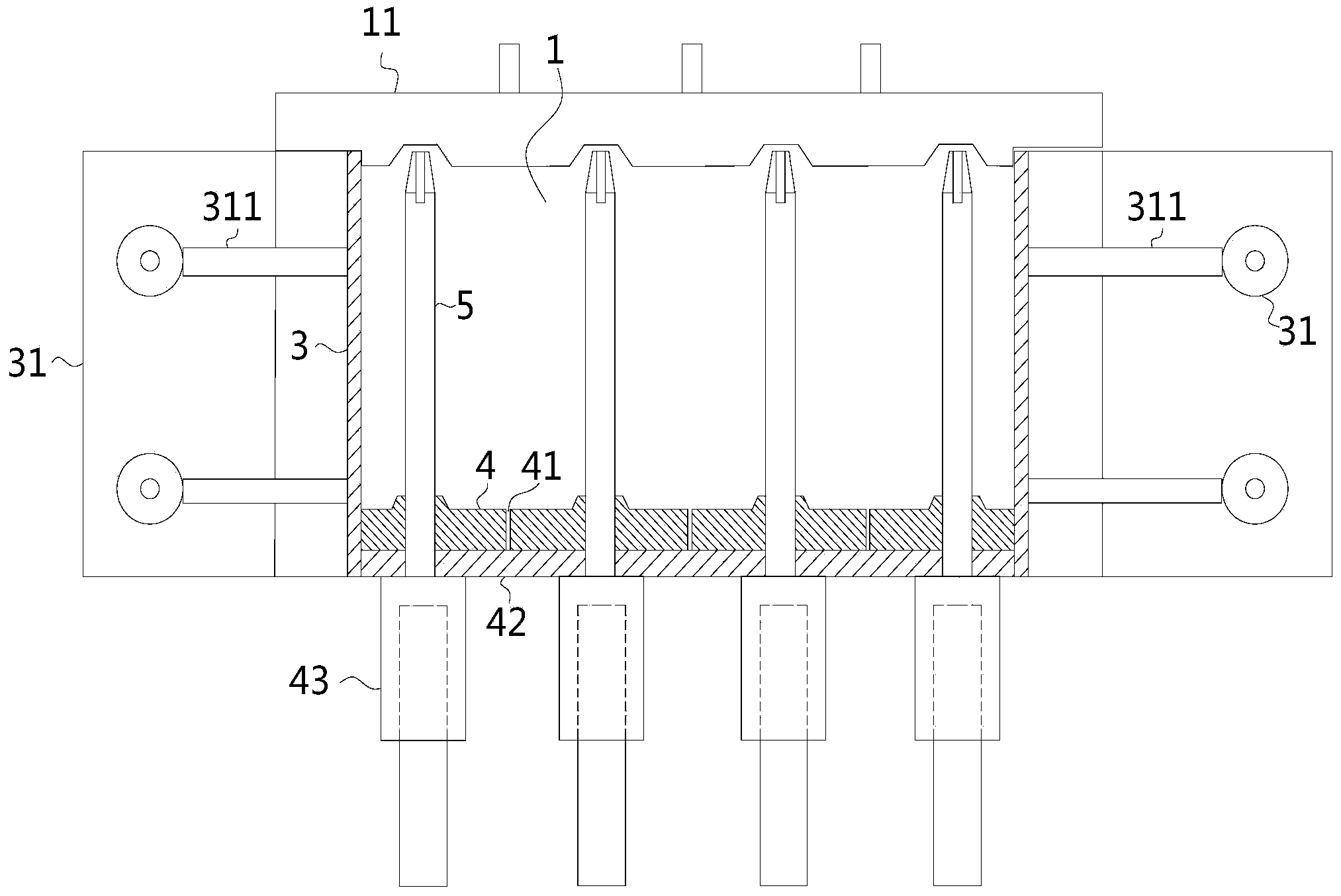

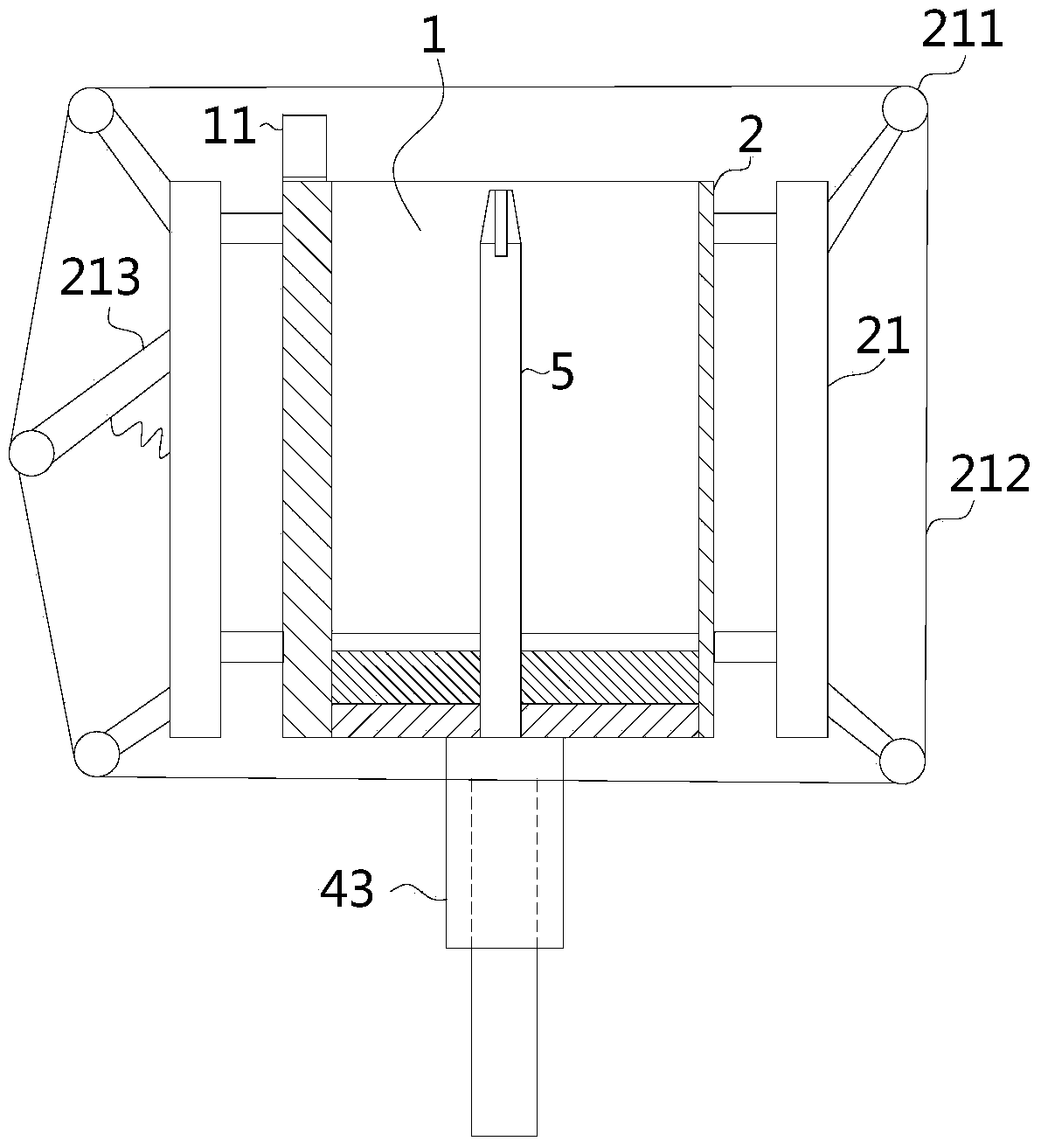

[0027] Such as Figure 1 to Figure 10 The shown gypsum block integral pouring is divided into block molding equipment, including bottom template 4, side baffle 2, end baffle 3 and mandrel 5, and also includes integral cavity 1 and gypsum cutting device 7, the integral type Cavity 1 is surrounded by bottom formwork 4, side baffles 2 and end baffles 3. The mandrel 5 passes through the bottom formwork 4 through the bottom formwork hole on the bottom formwork 4 and the mandrel 5 is arranged in the overall cavity 1 Inside, the integral cavity scraper 11 is slidably arranged above the integral cavity 1; the side baffle 2 is driven by the side baffle driving device 21, and the end baffle 3 is driven by the end baffle driving device 31; the plaster cutting The block device 7 cuts the gypsum block 9 formed in the integral cavity 1 into gypsum blocks 91 .

[0028] In actual pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com