Automatic mold loading manipulator

A manipulator and mold loading technology, which is applied to manipulators, program-controlled manipulators, workshop equipment, etc., can solve problems such as low precision, low efficiency, time-consuming and labor-intensive, and achieve the effects of saving manpower, realizing information production, and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

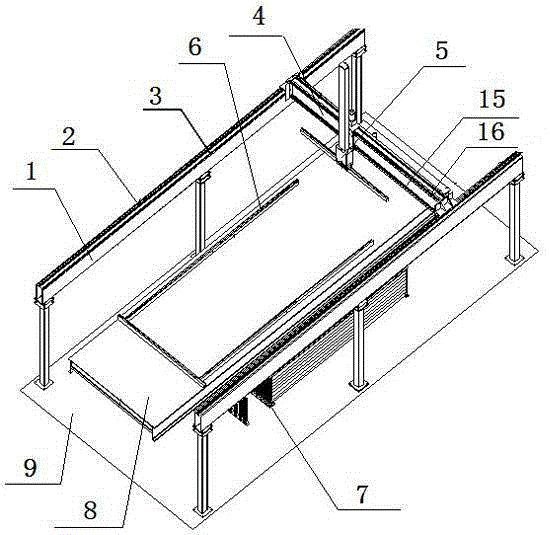

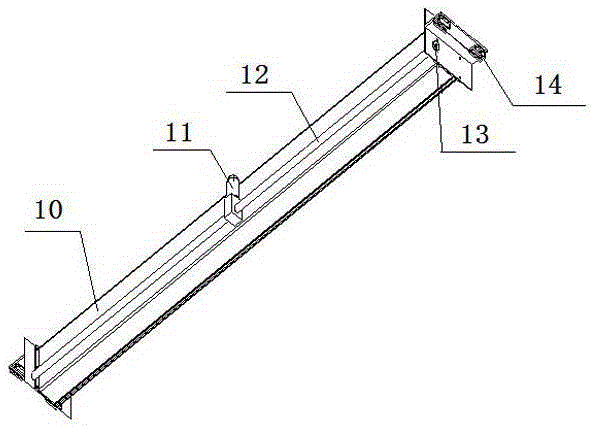

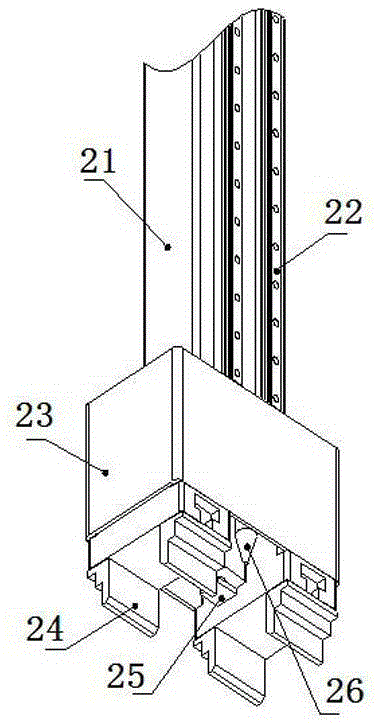

[0023] see figure 1 — Figure 4 , the automatic mold loading manipulator of the present invention includes an X-axis truss 1, a Y-axis girder 4 and a manipulator 5; the X-axis truss 1 has left and right guide longitudinal beams and support columns, and the upper ends of the support columns are connected and fixed to the guide longitudinal beams , the lower end of the supporting column is fixed on the ground, and the longitudinal linear guide rail and the longitudinal rack are installed on the guide longitudinal beam; The horizontal driving mechanism and the longitudinal driving mechanism are installed on the top, the slider is set on the longitudinal linear guide rail of the guiding longitudinal beam, the longitudinal driving mechanism is connected to the gear at the end of the transmission beam through the transmission rod, the gear meshes with the longitudinal rack on the guiding longitudinal beam, and the horizontal driving The mechanism is connected to drive the transvers...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com