Chip packaging test production line performance control method based on Q-learning reinforcement learning

A technology of chip packaging and reinforcement learning, applied in program control, comprehensive factory control, comprehensive factory control, etc., can solve problems such as control strategy conflicts, incomplete consideration of variability factors, untimely response, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

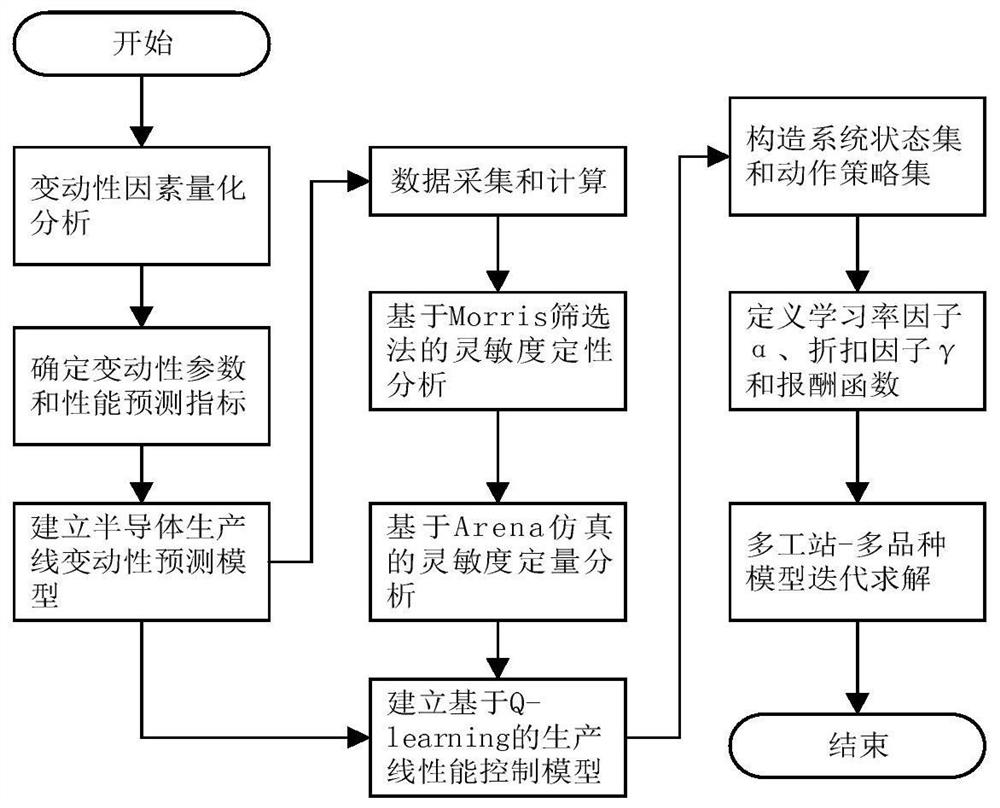

[0086] Below in conjunction with accompanying drawing and embodiment the present invention is described in further detail, present embodiment is implemented under the premise of technical solution of the present invention, has provided detailed embodiment and concrete operation process ( figure 1 ), but the protection scope of the present invention is not limited to the following examples.

[0087] The embodiment can be mainly divided into the following steps:

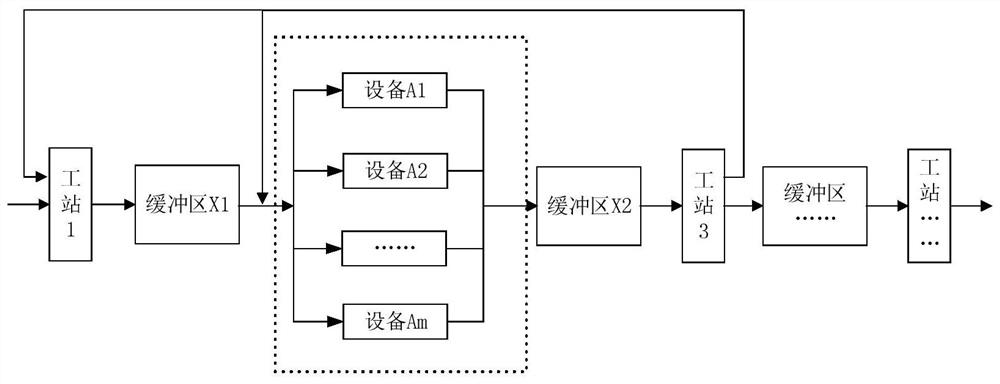

[0088] Step 1: Semiconductor chip packaging and testing production line model abstraction: Taking the chip packaging and testing production line as the research object, assuming that there is a buffer zone of limited size between workstations, and the queuing rule is first-come-first-served, it is abstracted as a model that includes reentry (rework) Multi-station serial-parallel queuing production line model ( figure 2 ).

[0089] Step 2:

[0090] Step 2.1: Calculation of variability.

[0091] Calculate the arriv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com