Energy-saving method and device for product aging test

A technology of product testing and aging testing, which is applied in the direction of measuring devices, power supply testing, measuring electricity, etc., can solve the problems of high power consumption, power consumption, huge energy, etc., and achieve the effect of saving energy and improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

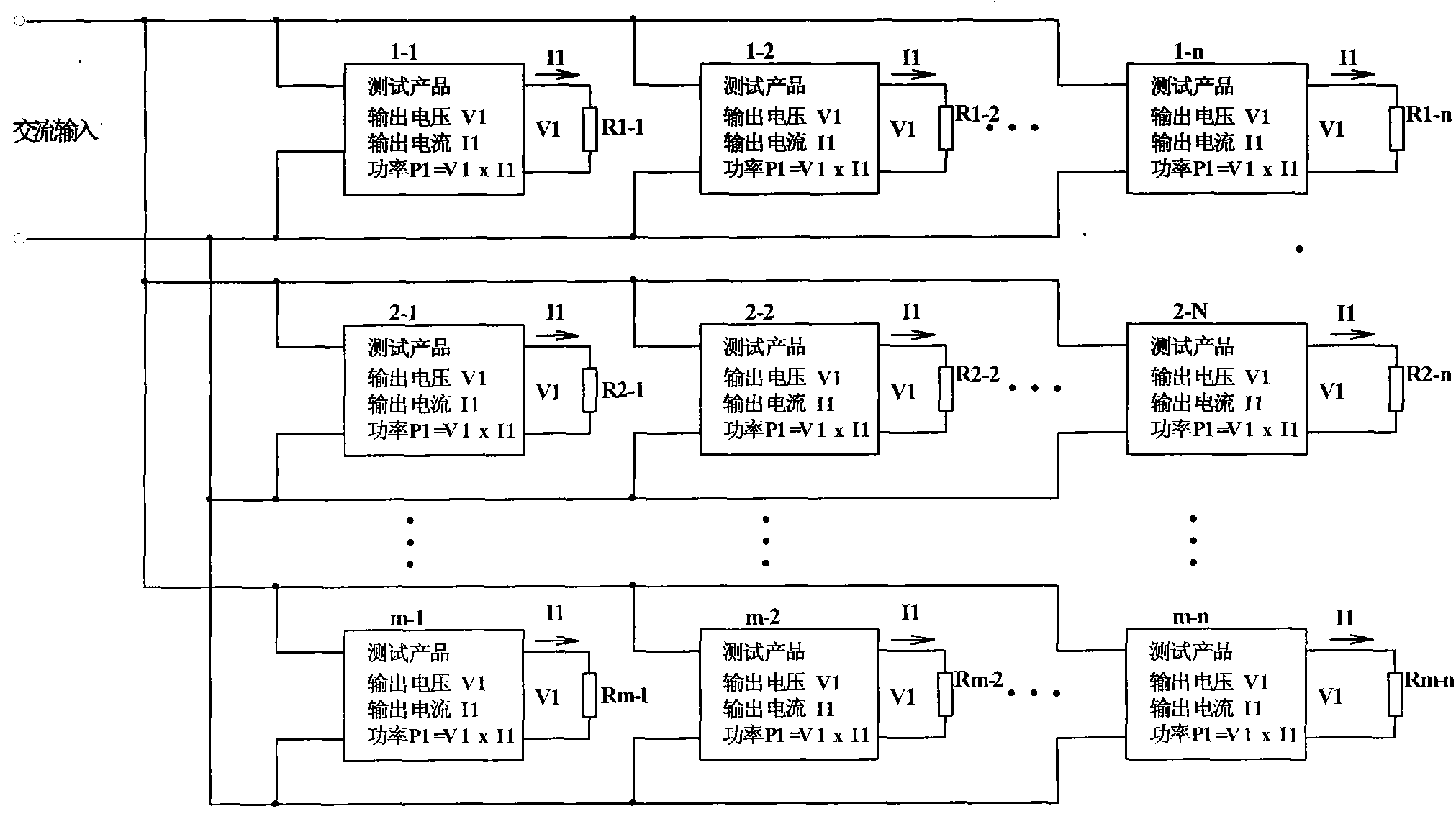

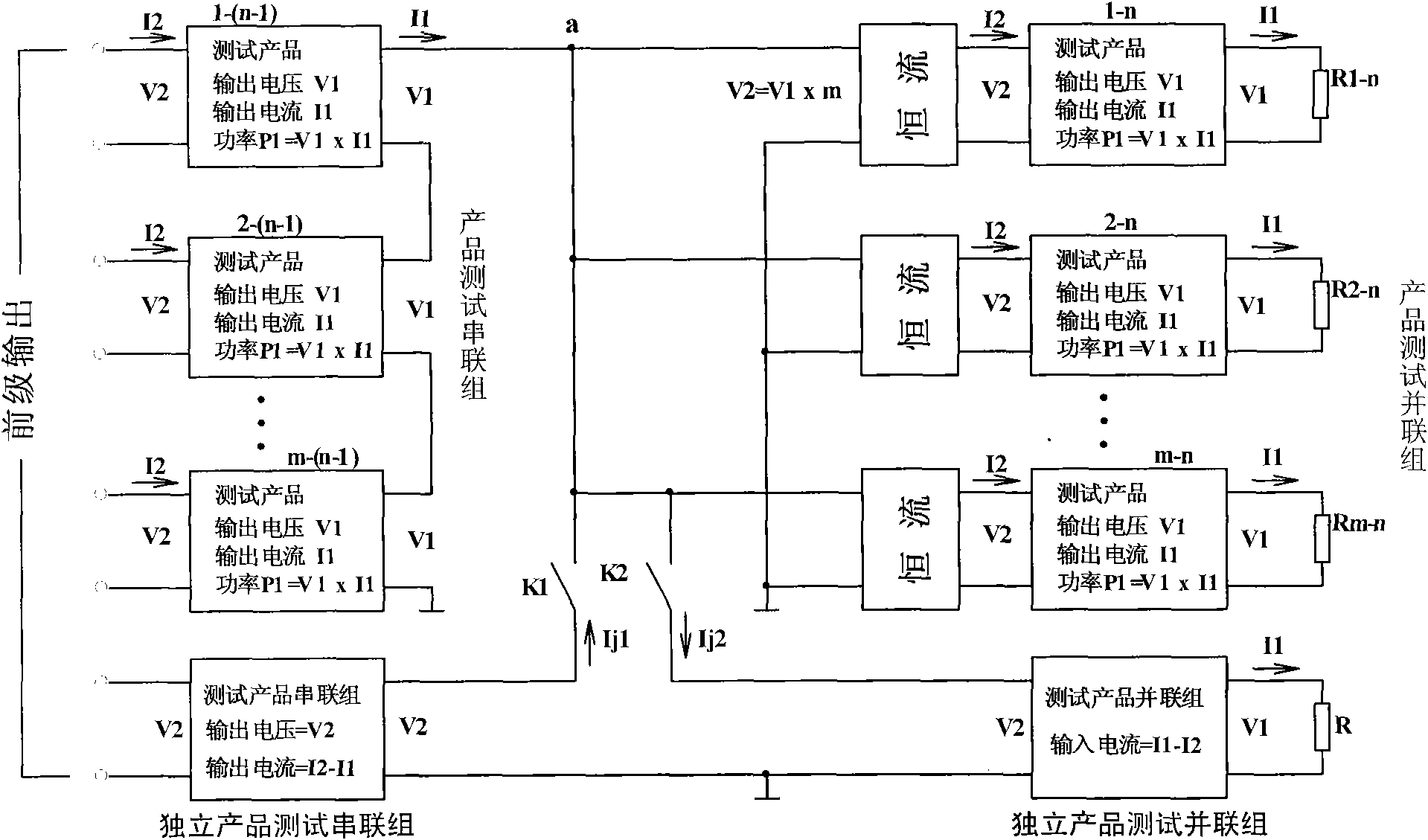

[0032] A product aging test energy-saving method of the present invention, figure 2 The connection diagram of the last two stages is shown. The electrical connection and control principle of the middle stages are the same as those of

[0033] 1) Prepare a plurality of test units 1-1 to m-1 of the same testable product, and connect the output terminals of each test unit in series as the series output terminal a to obtain a group of product test series groups;

[0034] 2) Repeat step 1) multiple times to obtain n-1 groups of product test series groups;

[0035] 3) The electrical connection of the n-1 group product test series group is similar, that is, the input end of each test unit in the latter group is connected to the series output terminal a of the previous group, and each test unit of the rear stage is used as the front stage. load;

[0036] 4) Connect the input terminals of each test unit in the first group to the power supply to provide input voltage V2 and input cur...

Embodiment 2

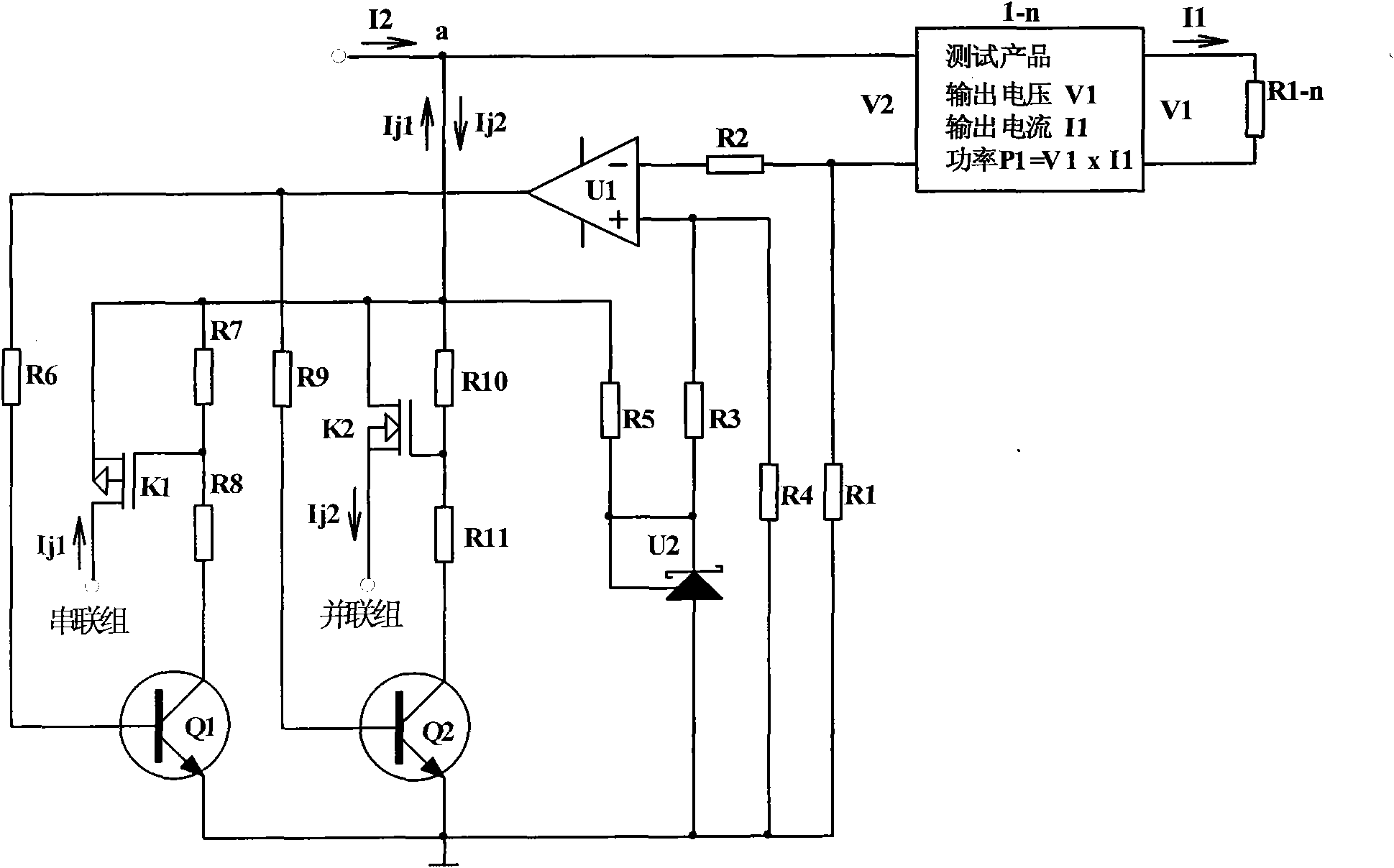

[0056] Such as Figure 4 As shown, when two PNP transistors Q1 and Q2 are used, their emitters are sequentially connected to the series output terminal a of the product test series group through resistors R9, R8, R13 and R12, the collector is grounded, and the compensation current on-off switch K1 uses N Type MOS tube, its drain and source are respectively connected to the series output terminal a of the product test series group and the independent product test series group, the shunt switch K2 uses a P-type MOS tube, and its drain and source are respectively connected to the independent product test The parallel group and the series output terminal a of the product test series group, the gates of the two switches are respectively connected to the series output terminals of the product test series group through resistors R8 and R12.

Embodiment 3

[0058] Such as Figure 5 As shown, when both the compensation current on-off switch K1 and the shunt on-off switch K2 use N-type MOS tubes, the drain and source of K1 are respectively connected to the series output terminal a of the independent product test series group and the product test series group, and the drain of K2 The pole and the source are respectively connected to the series output terminal a of the independent product test parallel group and the product test series group. The gates of the two switches are respectively connected to the series output terminal of the product test series group through resistors R8 and R11. The emitter of the transistor Q1 passes through the resistors in turn R9, R8 and the collector of transistor Q2 are respectively connected to the series output terminal a of the product test series group through R12 and R11, the emitter of Q2 is grounded, the collector of Q1 is grounded and connected to the base through resistor R7.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com