Method for preparing fluorescent graphene quantum dots by solvothermal method

A graphene quantum dot, solvothermal technology, applied in chemical instruments and methods, luminescent materials, etc., can solve the problems of low yield, high cost, and complicated preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

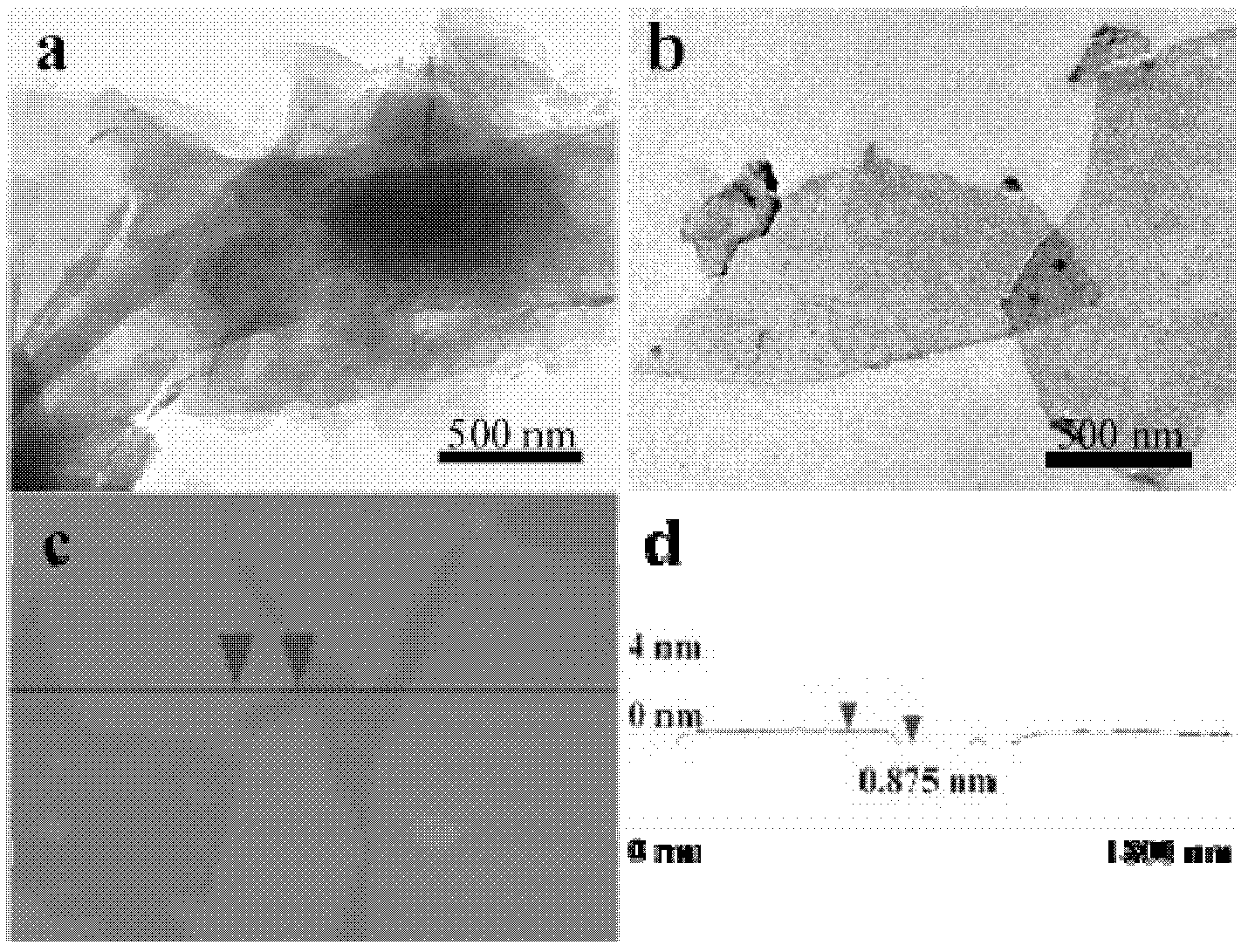

[0033] 1: Preparation of graphene oxide

[0034] 8 grams of graphite powder (Aldrich, figure 1a) join in the concentrated sulfuric acid of 30 milliliters mass fractions 98% (500 milliliters there-necked bottles) that dissolves 10 gram potassium persulfate, 10 gram phosphorus pentoxides of 80 ℃ (500 milliliters there-necked bottles); Place cooling after mechanical stirring 6 hours, use a large amount of Dilute (slowly) with deionized water, filter, and wash until neutral; then the product is dried at room temperature to obtain pre-oxidized graphite powder. The pre-oxidized graphite powder is added to 184 milliliters of mass fraction 98% concentrated sulfuric acid (500 milliliters there-necked bottle) of 0 ℃, carry out mechanical stirring (350 revolutions per minute); Add 4 grams of sodium nitrate again, then slowly add 24 grams Potassium permanganate in fine powder form, the speed is slow to ensure that the temperature of the system does not exceed 5°C; after stirring at low t...

Embodiment 2

[0040] 1: The preparation of graphene oxide is as described in Example 1.

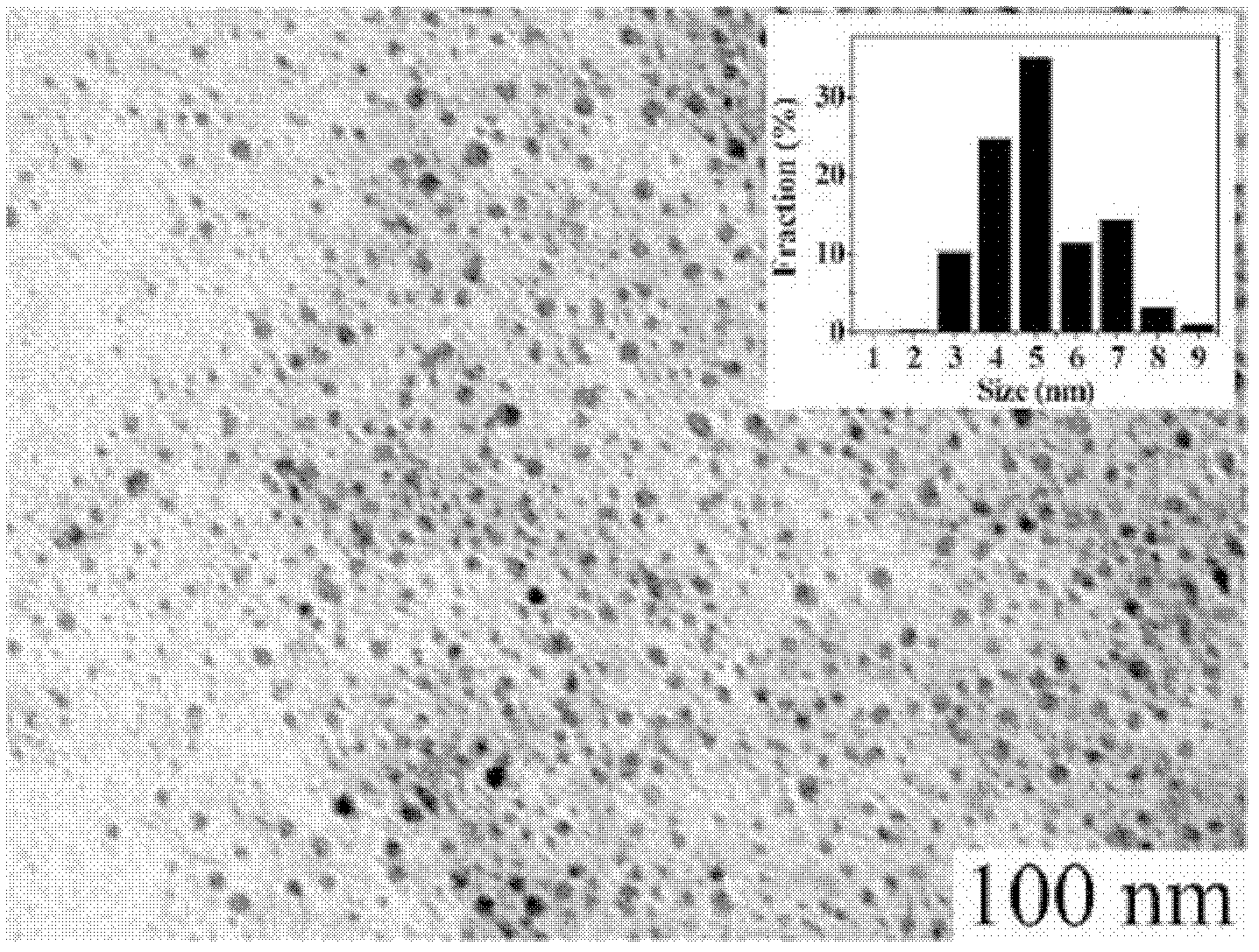

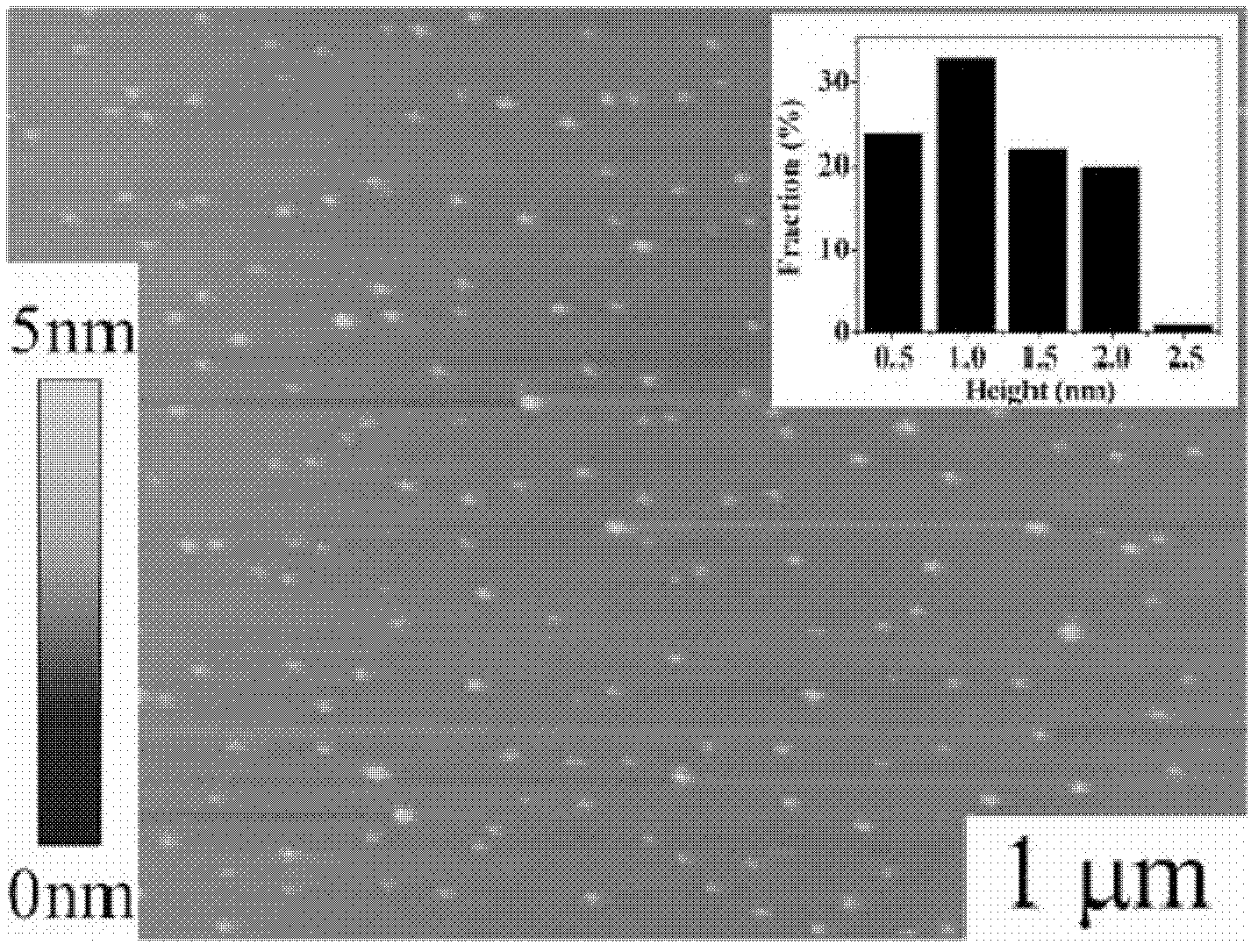

[0041] 2: Preparation of green fluorescent graphene quantum dots

[0042] 100 milligrams of graphene oxide powders were dispersed into 10 milliliters of N,N-dimethylformamide (DMF), then the dispersion was ultrasonically (120W, 100kHz) after 30 minutes, transferred to a polytetrafluoroethylene reactor, The reaction was carried out at 200 degrees Celsius for 10 hours; after the reaction, the supernatant was taken, dried by rotary evaporation, and graphene quantum dots with strong green fluorescence properties were obtained, with a mass of 1.6 grams.

[0043] 3: Preparation of fluorescent graphene quantum dots with controllable oxidation degree

[0044] The dried graphene quantum dots were subjected to two-step gradient column chromatography (the stationary phase was silica gel). The first phase developer is a 2:1 mixture of dichloromethane and methanol, and the second phase developer is deionized wate...

Embodiment 3

[0046] 1: The preparation of graphene oxide is as described in Example 1.

[0047] 2: Preparation of green fluorescent graphene quantum dots

[0048] 270 milligrams of graphene oxide powders were dispersed into 10 milliliters of N,N-dimethylformamide (DMF), and then the dispersion was ultrasonically (120W, 100kHz) after 30 minutes, transferred to a polytetrafluoroethylene reactor, The reaction was carried out at 200 degrees Celsius for 10 hours; after the reaction, the supernatant was taken, dried by rotary evaporation, and graphene quantum dots with strong green fluorescence properties were obtained, with a mass of 7.32 grams.

[0049] 3: Preparation of fluorescent graphene quantum dots with controllable oxidation degree

[0050] The dried graphene quantum dots were subjected to two-step gradient column chromatography (the stationary phase was silica gel). The first phase developer is a 2:1 mixture of dichloromethane and methanol, and the second phase developer is deionized...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

| Average height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com