A kind of preparation method of graphene material

A technology of graphene and graphene film, which is applied in the direction of nanotechnology, can solve the problems of difficulty in controlling the thickness of graphene oxide and ensuring sufficient expansion of graphite oxide, and achieve the effect of effective utilization, high yield and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

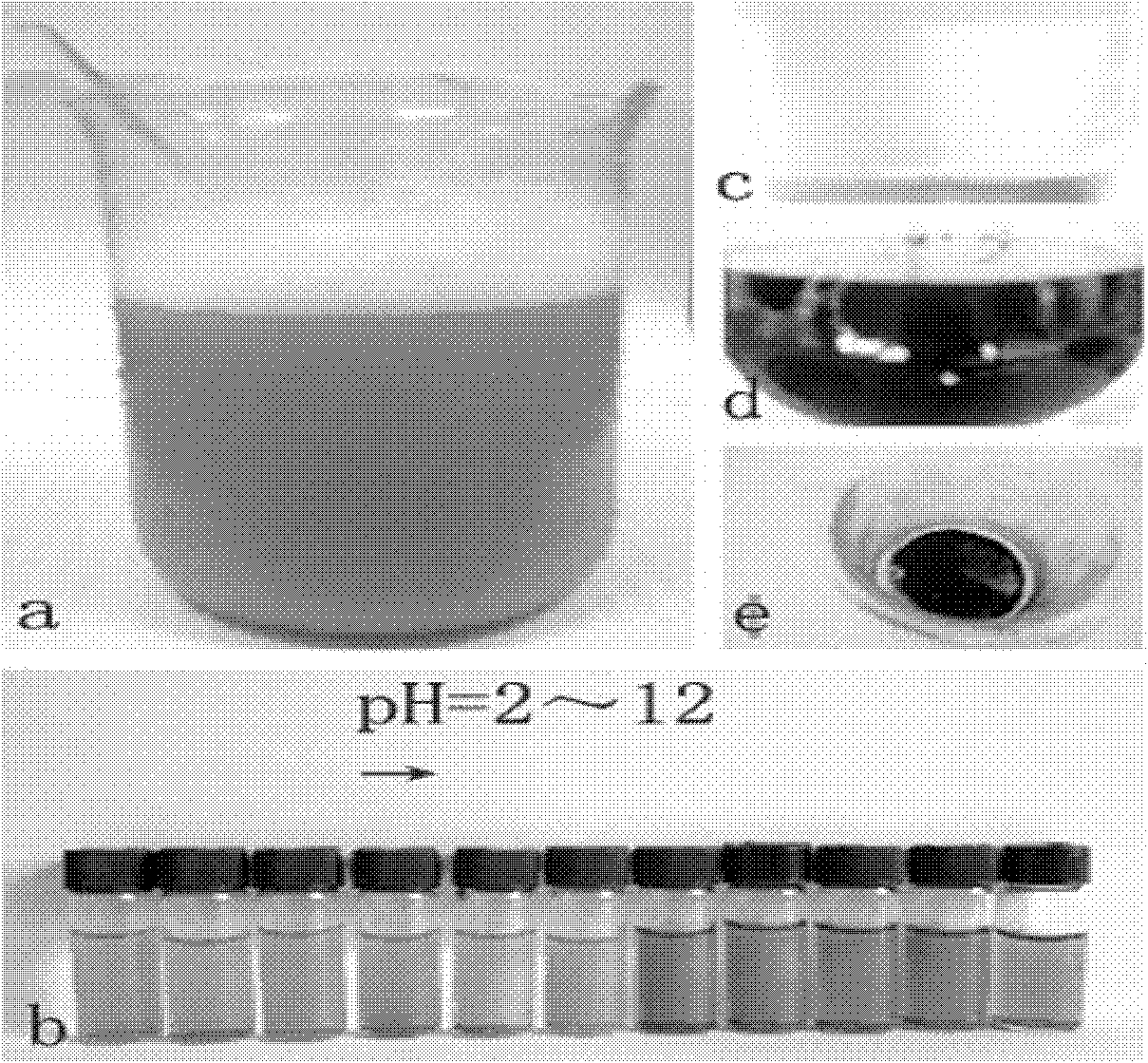

Image

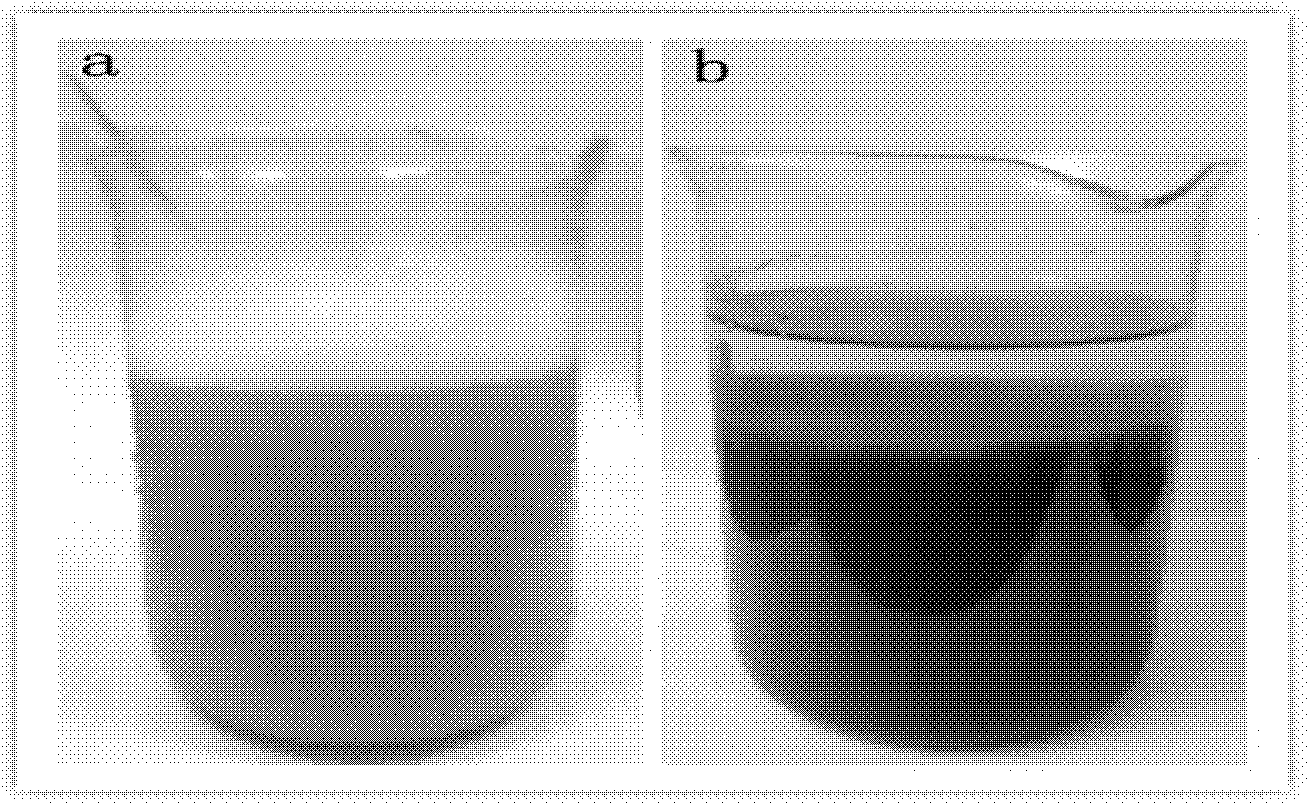

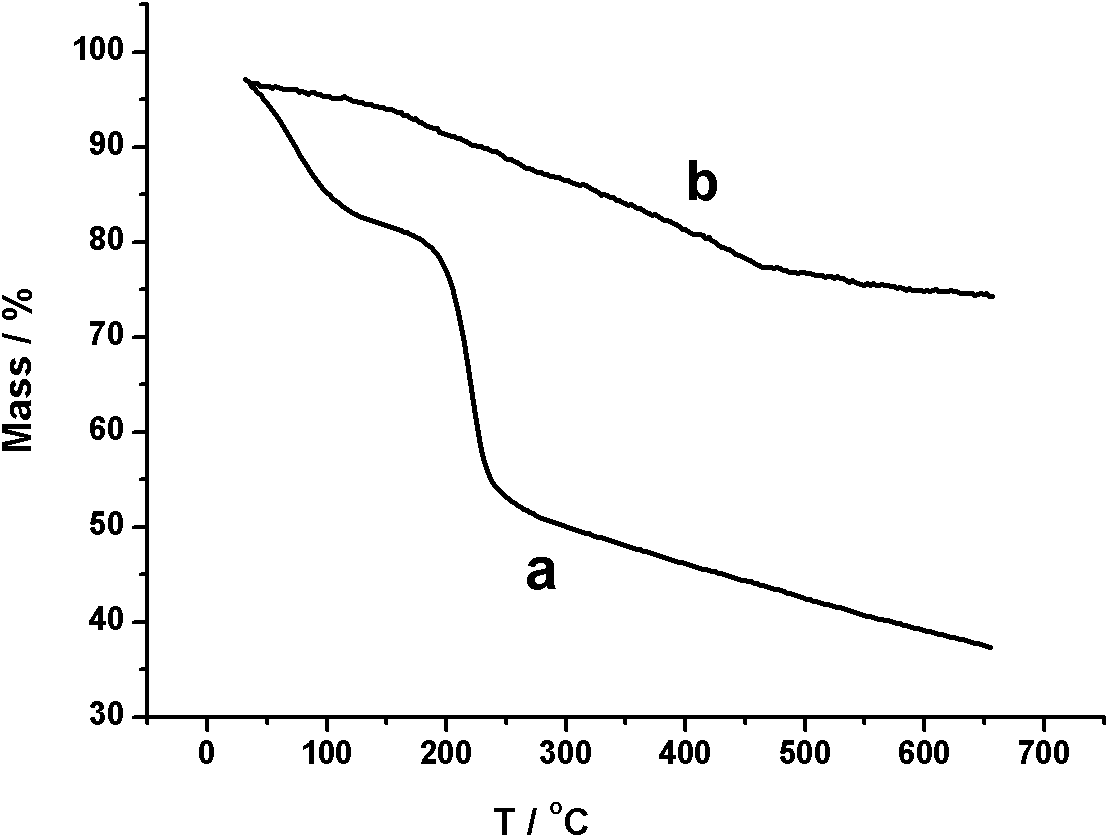

Examples

Embodiment 1

[0042] The preparation method described in this embodiment comprises the following steps:

[0043] 1. Add 2g of graphite flakes to a beaker that has been dried and washed. Under ice bath conditions, add 100ml of 98% concentrated sulfuric acid. Stir thoroughly to mix the graphite and concentrated sulfuric acid evenly. Then add 1.5g of sodium nitrate solid and stir for 30min. , fully dissolved. Then slowly add 6 g of potassium permanganate solid in batches (0.5 g each time, the interval between each time is 10 min), control the temperature of the reaction system not to exceed 20 ° C, and react for 6 h. Afterwards, the ice bath was removed, and the reaction was heated in a water bath to raise the temperature to 35° C., and the reaction was carried out for 24 hours. Then add 9g of potassium permanganate, (0.5g each time, each interval is 10min), and react for 4h.

[0044] 2. Subsequently, 100ml of 98% concentrated sulfuric acid was added to react for 24 hours to obtain a reddish...

Embodiment 2-10

[0048] Operating steps are with embodiment 1, condition control and graphite oxide colloid product result are listed in the following table:

[0049]

[0050] *The obtained graphite oxide colloid is the same as embodiment 1, and is easy to convert into other graphene materials.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com