Method for synthesizing graphene oxide by ultrasonic assistance Hummers method

An ultrasonic-assisted, synthetic oxidation technology, applied in the field of ultrasonic-assisted Hummers method to prepare graphene oxide with large interlayer spacing, can solve the problems of introducing impurities, complicated operation process, etc., and achieve the effect of improving intercalation efficiency and oxidation degree.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

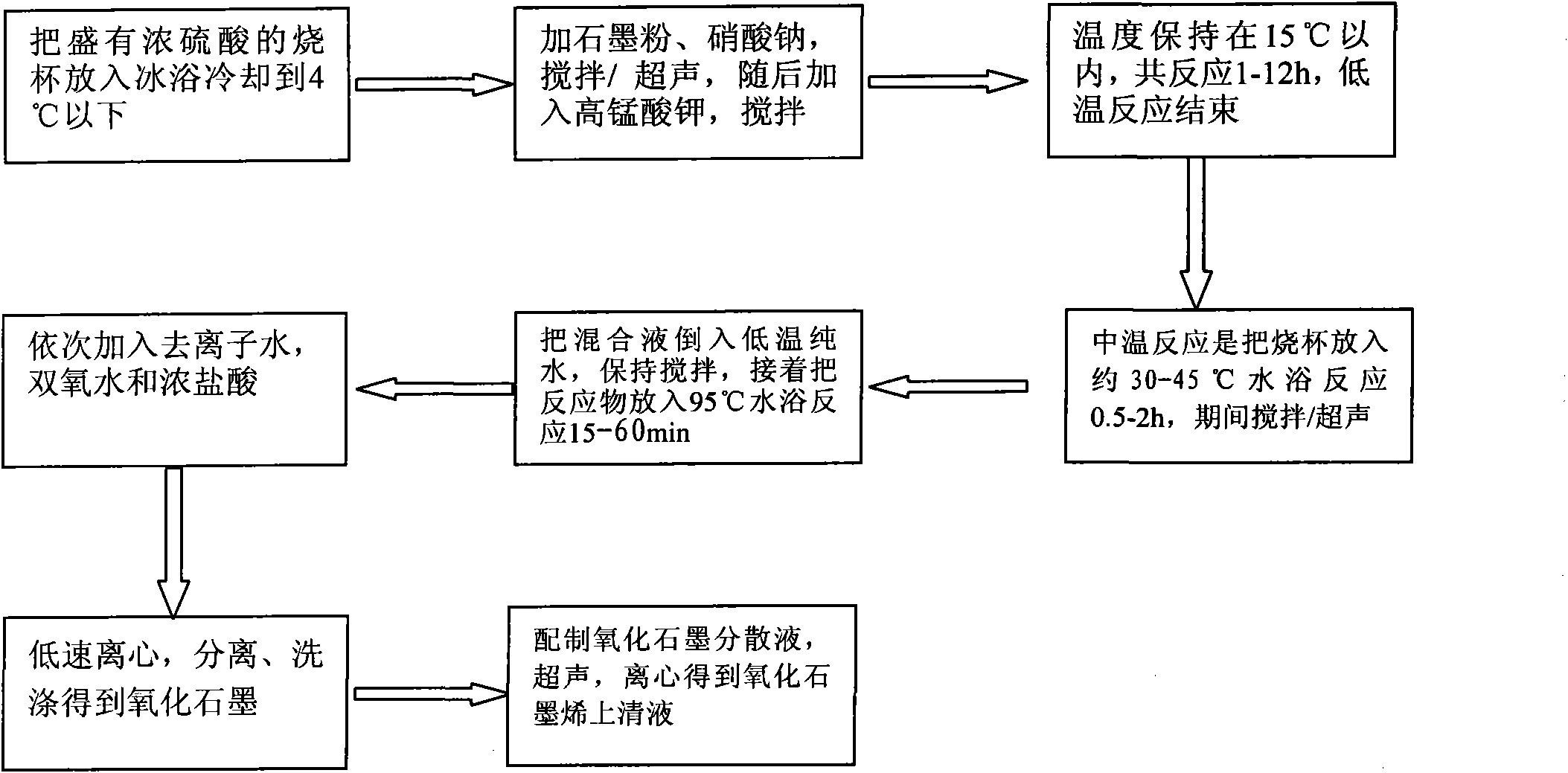

Method used

Image

Examples

Embodiment 1

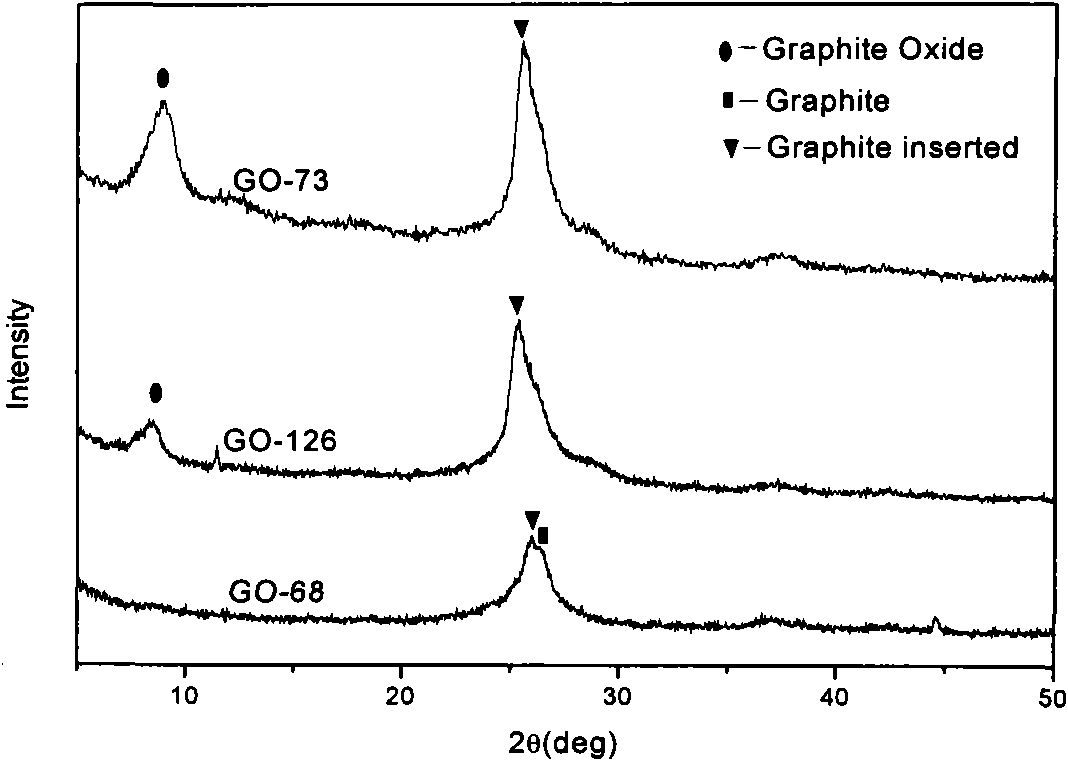

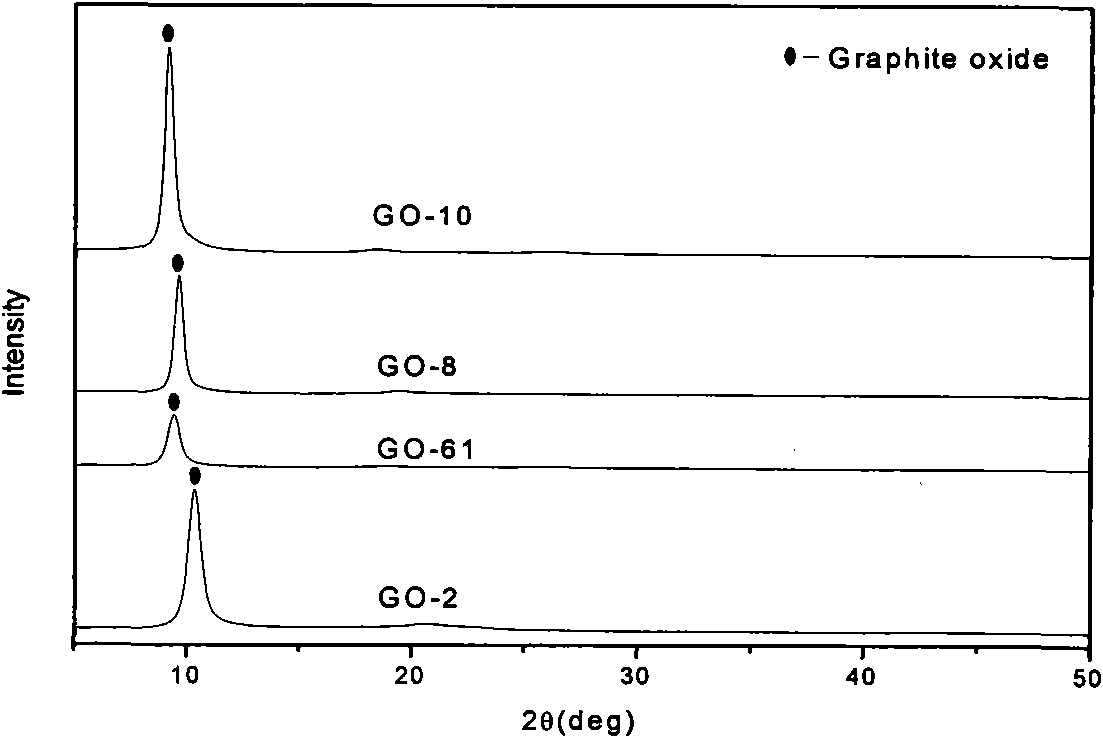

[0026] Low-temperature ultrasonic-assisted synthesis of graphene oxide by the Hummers method: Measure 23ml of sulfuric acid with a volume fraction of 98% and pour it into a beaker, put the beaker in an ice bath and cool it below 4°C, weigh 1g of graphite powder and 0.5g of sodium nitrate into the beaker, Turn on the ultrasound, slowly add 3g of potassium permanganate after 1 hour, turn off the ultrasound and start stirring, control the temperature not to exceed 10°C, and the reaction time at low temperature is 2h; move the beaker to a water bath at 38°C, react for 0.5h, and keep stirring during the reaction at medium temperature ; Slowly add the resulting mixed solution into 100ml of 0°C deionized water, then place the above mixed solution in a 95°C water bath for 30 minutes, keep moderate mechanical stirring during this period; add 60ml of deionized water to stop the reaction after high temperature reaction, and add volume 15ml of hydrogen peroxide with a fraction of 20% was u...

Embodiment 2

[0028] Low-temperature ultrasonic-assisted synthesis of graphene oxide by Hummers method: Measure 23ml of concentrated sulfuric acid with a volume fraction of 98% and pour it into a beaker, put the beaker in an ice bath and cool it below 4°C, weigh 1g of graphite powder and 0.5g of sodium nitrate into the beaker , turn on the ultrasound, slowly add 3g of potassium permanganate after 3 hours, turn off the ultrasound and start stirring, control the temperature not to exceed 10°C, and the reaction time at low temperature is 6h; move the beaker to a water bath at 38°C, the reaction time is 2h, during the middle temperature reaction Stir continuously; slowly add the obtained mixture into 100ml of 0°C deionized water, then place the above mixture in a 95°C water bath for 1 hour, and keep moderate mechanical stirring during the period; add 60ml of deionized water after high temperature reaction to stop the reaction 15ml of hydrogen peroxide with a volume fraction of 20% was added to r...

Embodiment 3

[0030] Medium-temperature ultrasound-assisted Hummers method to synthesize graphene oxide: Measure 23ml of concentrated sulfuric acid with a volume fraction of 98% and pour it into a beaker, put the beaker in an ice bath and cool it below 4°C, weigh 1g of graphite powder and 0.5g of sodium nitrate into the beaker After 1 hour, slowly add 3g of potassium permanganate, control the temperature not to exceed 10°C, react for 2 hours, and keep stirring at low temperature; move the beaker to a 38°C water bath, react for 0.5h, and keep ultrasonic oscillation during the middle temperature; mix the obtained Slowly add 100ml of deionized water at 0°C, and then place the above mixed solution in a water bath at 95°C for 30 minutes while maintaining moderate mechanical stirring; 15ml of hydrogen peroxide was used to remove metal oxides, and after 15min of reaction, 40ml of hydrochloric acid with a volume fraction of 10% was added. Low-speed centrifugal washing to remove excess acid and by-p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com