Method for preparing graphene oxide by chemical peeling

A graphene and fossil technology, applied in the field of chemical exfoliation to prepare graphene oxide, can solve problems such as harsh preparation conditions and difficult operation, and achieve the effects of realizing large-scale industrial production, improving production efficiency and high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

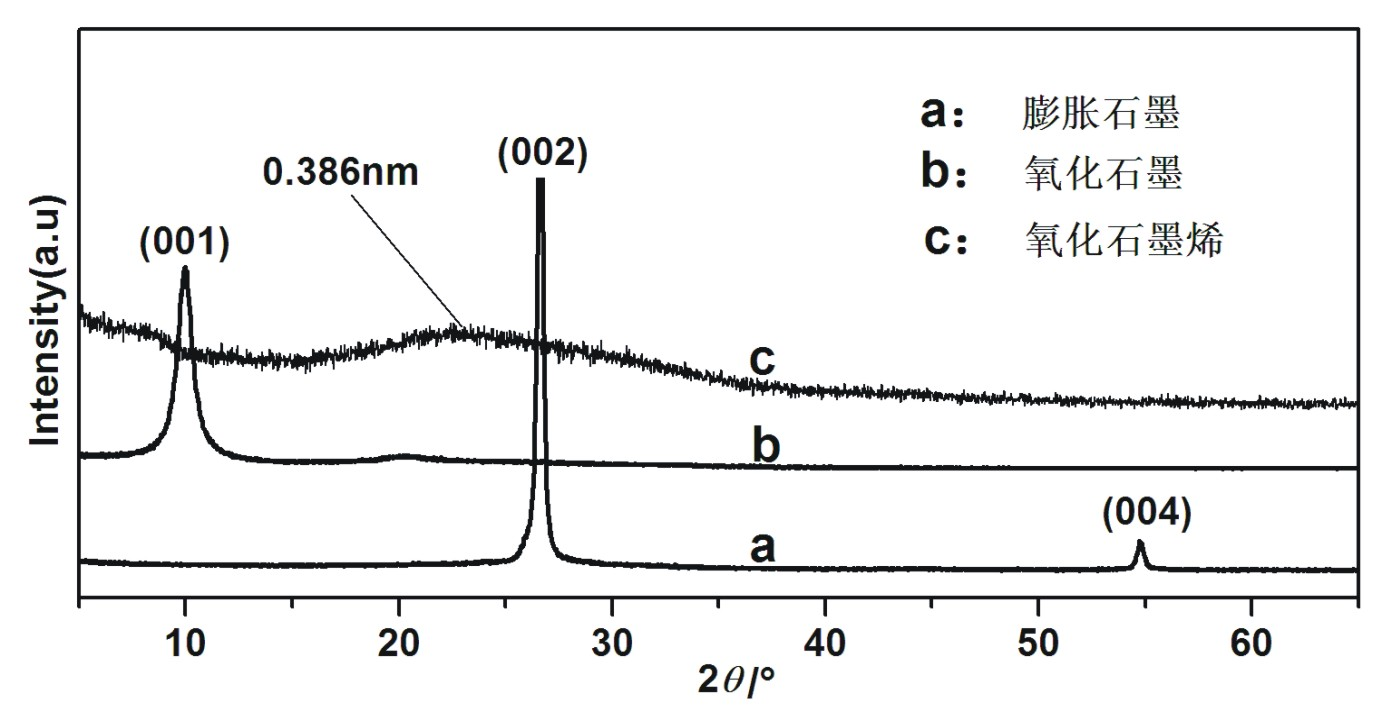

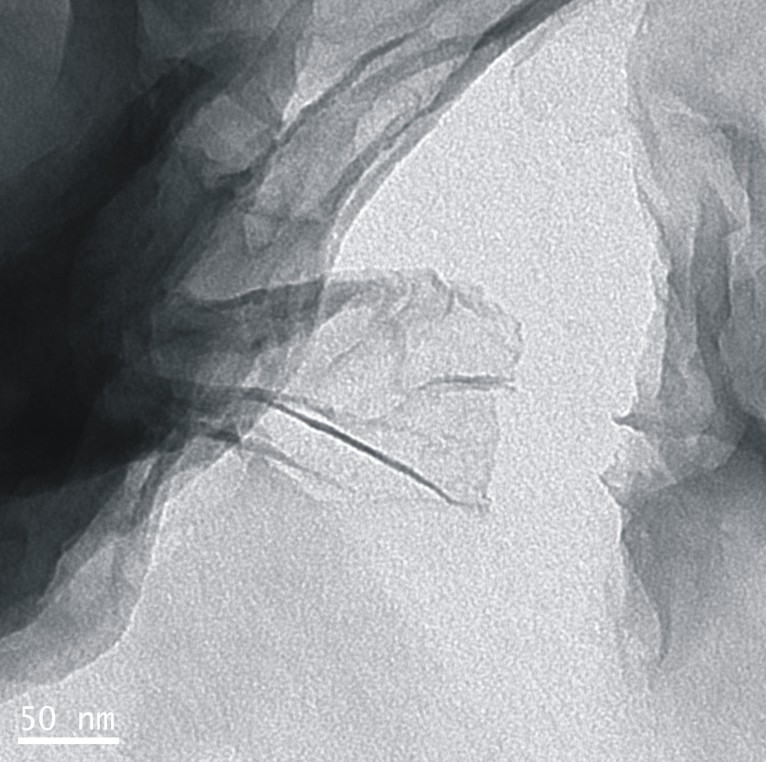

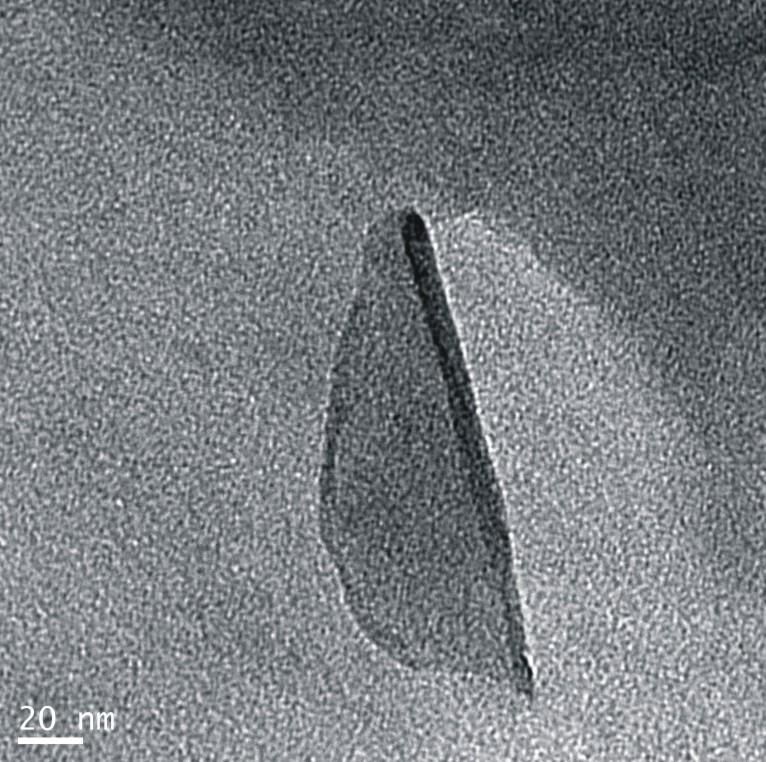

Image

Examples

Embodiment 1

[0028] (1) Preparation of graphite oxide

[0029] Take 0.1g of expanded graphite and 10mL of concentrated sulfuric acid and mix evenly in an ice-water bath, then slowly add 0.6g of potassium permanganate, and then react in a water bath at 30°C for 0.25h, then add 40mL of distilled water to react for 0.5h, and then Add 5mL of 30wt% hydrogen peroxide, stir for 0.5h, and centrifuge with 5wt% hydrochloric acid solution until it no longer contains SO 4 2- Ions (with 5wt%Ba(NO 3 ) 2 solution detection), and then washed with distilled water until neutral, that is, a dark red viscous graphite oxide filter cake was obtained; the filter cake was washed down with absolute ethanol, dried in an oven at 50°C, and black graphite oxide was obtained;

[0030] (2) Preparation of graphene oxide

[0031] Add 0.02g of graphite oxide into 15mL of ethylene glycol solution, disperse at 40kHz ultrasonic frequency for 0.5h, then centrifuge at 3000rpm for 20min, pour out the upper suspended solution...

Embodiment 2

[0033] (1) Preparation of graphite oxide

[0034] Take 0.5g of expanded graphite and 60mL of concentrated sulfuric acid and mix evenly in an ice-water bath, then slowly add 12g of potassium permanganate, react in a water bath at 35°C for 1 hour, then add 200mL of distilled water for 2 hours, then add 15mL of 30wt% hydrogen peroxide, stirred for 1h, then centrifuged and washed with 5wt% hydrochloric acid solution until it no longer contains SO 4 2- Ions (with 5wt%Ba(NO 3 ) 2 solution detection), and then washed with distilled water until neutral, and a dark red viscous graphite oxide filter cake was obtained. Rinse down the filter cake with absolute ethanol and dry it in an oven at 70°C to obtain black graphite oxide;

[0035] (2) Preparation of graphene oxide

[0036] Add 0.05g of graphite oxide to 50mL of N,N-dimethylformamide solution, disperse at 50kHz ultrasonic frequency for 3h, then centrifuge at 5000rpm for 60min, and pour off the upper suspension solution , place...

Embodiment 3

[0040] (1) Preparation of graphite oxide

[0041] Take 0.2g of expanded graphite and mix evenly with 10mL of concentrated sulfuric acid, then slowly add 10mL of concentrated nitric acid, and keep stirring. Next, 5 g of potassium permanganate was slowly added, and reacted in a water bath at 38° C. for 2 h. Then add 100mL of distilled water to react for 1h, then add 5mL of 30wt% hydrogen peroxide, stir for 2h, and centrifuge with 5wt% hydrochloric acid solution until it no longer contains SO 4 2- Ions (with 5wt%Ba(NO 3 ) 2 solution detection), and then washed with distilled water until neutral, and a dark red viscous graphite oxide filter cake was obtained. Rinse down the filter cake with absolute ethanol and dry it in an oven at 65°C to obtain black graphite oxide;

[0042] (2) Preparation of graphene oxide

[0043] Take 0.08g of graphite oxide and add it to 60mL of ethanol solution, disperse it at an ultrasonic frequency of 40kHz for 4h, then centrifuge at a speed of 400...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com